Patents

Literature

64results about How to "Reduce motor cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

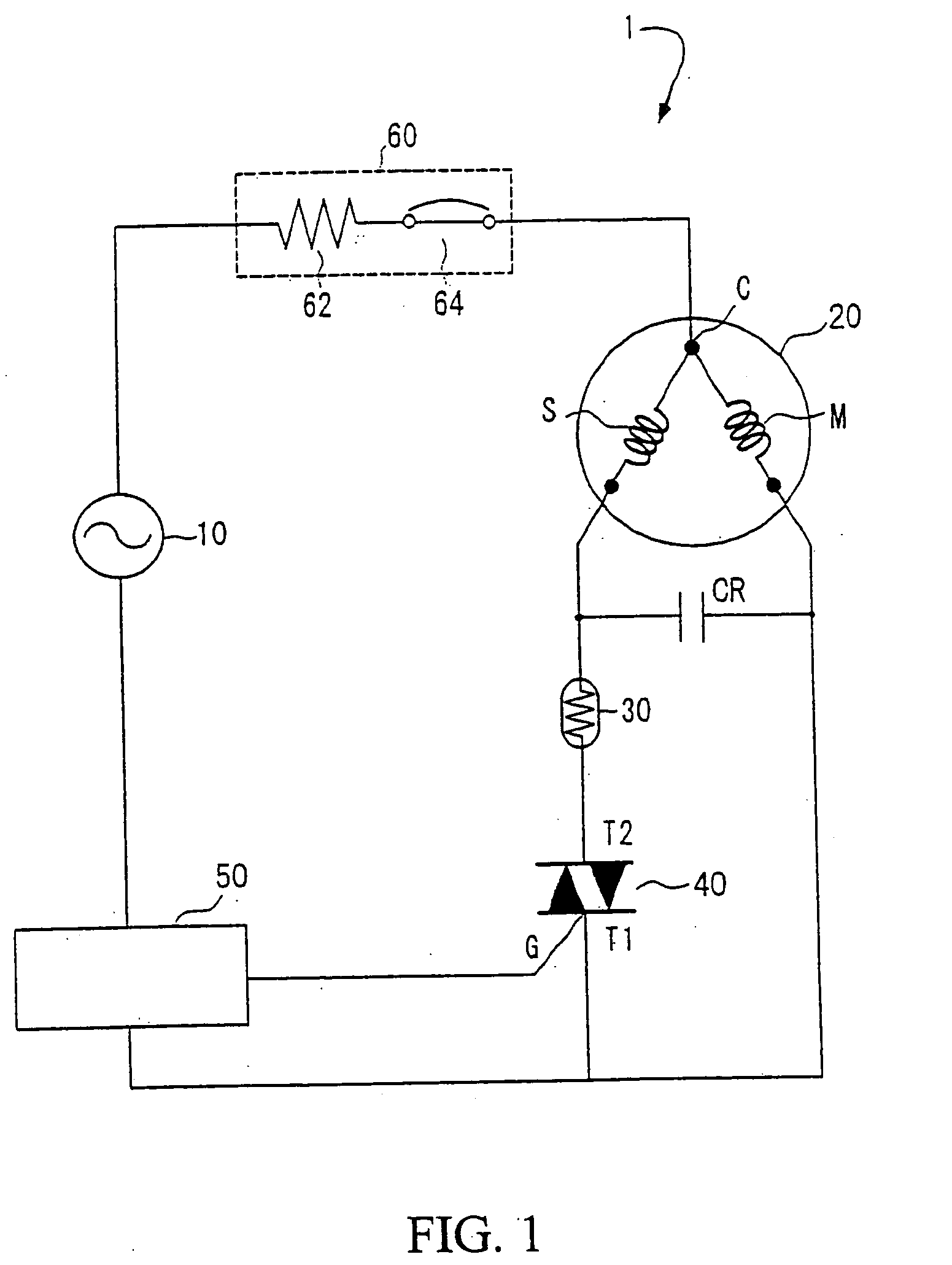

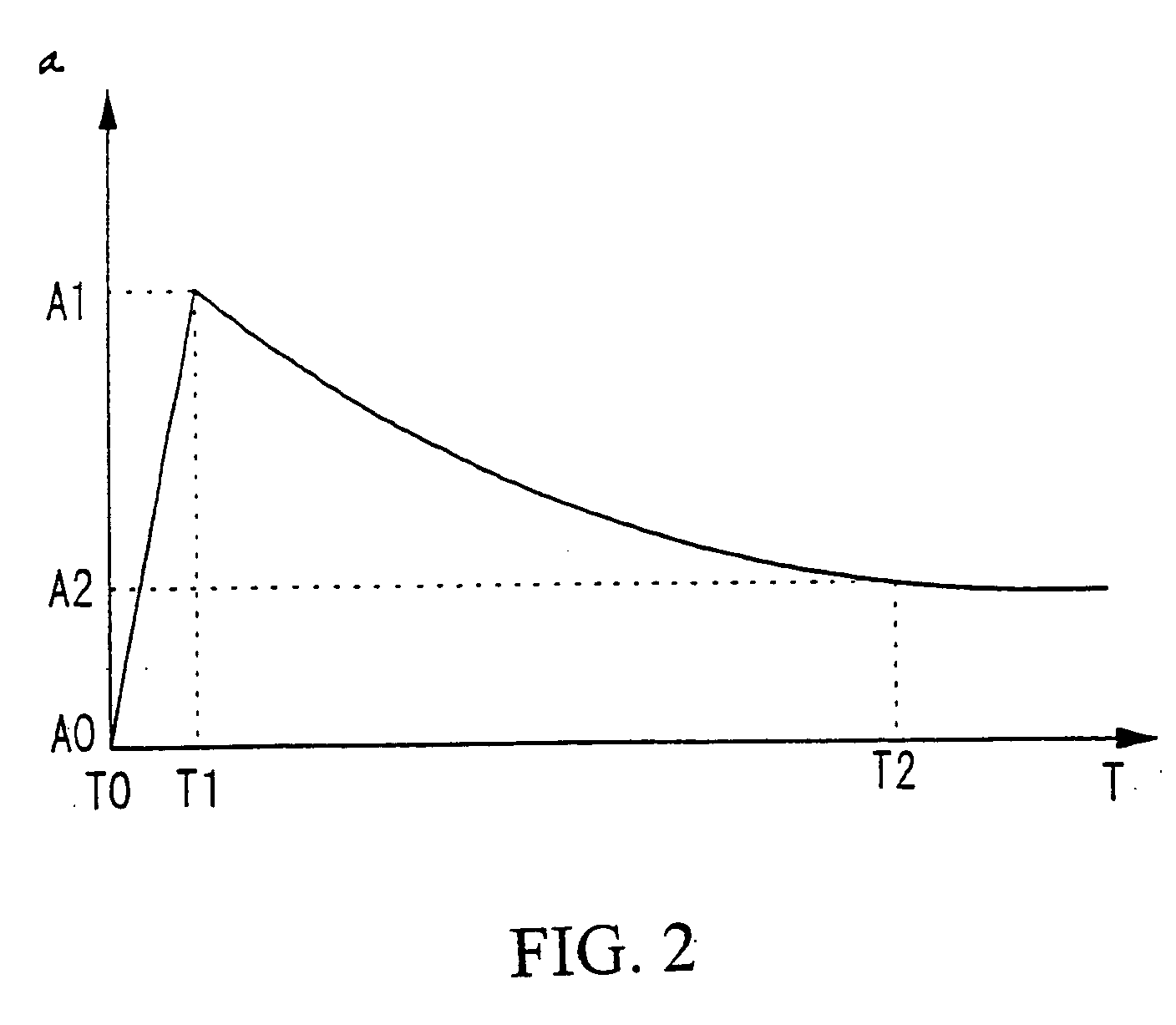

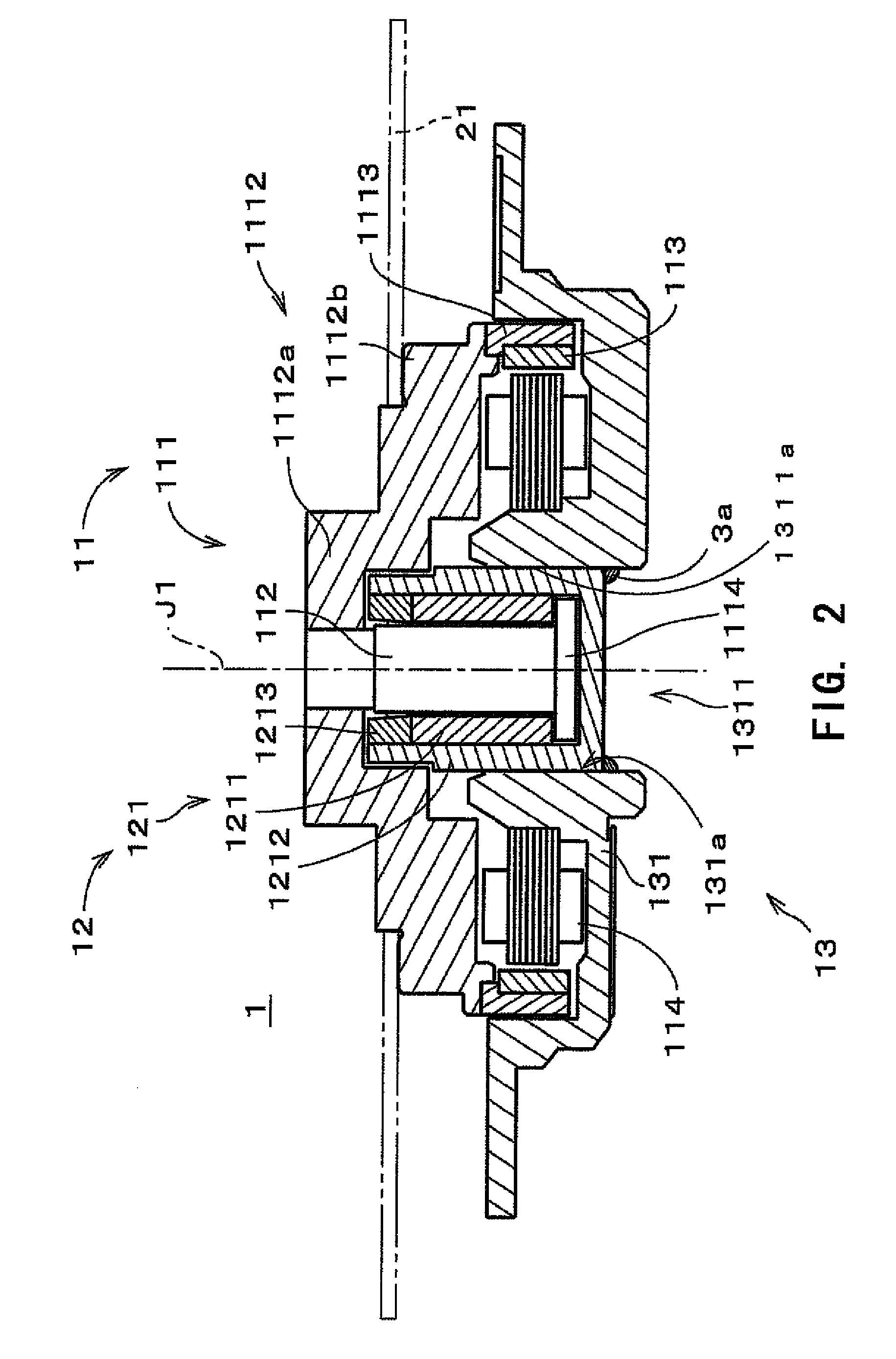

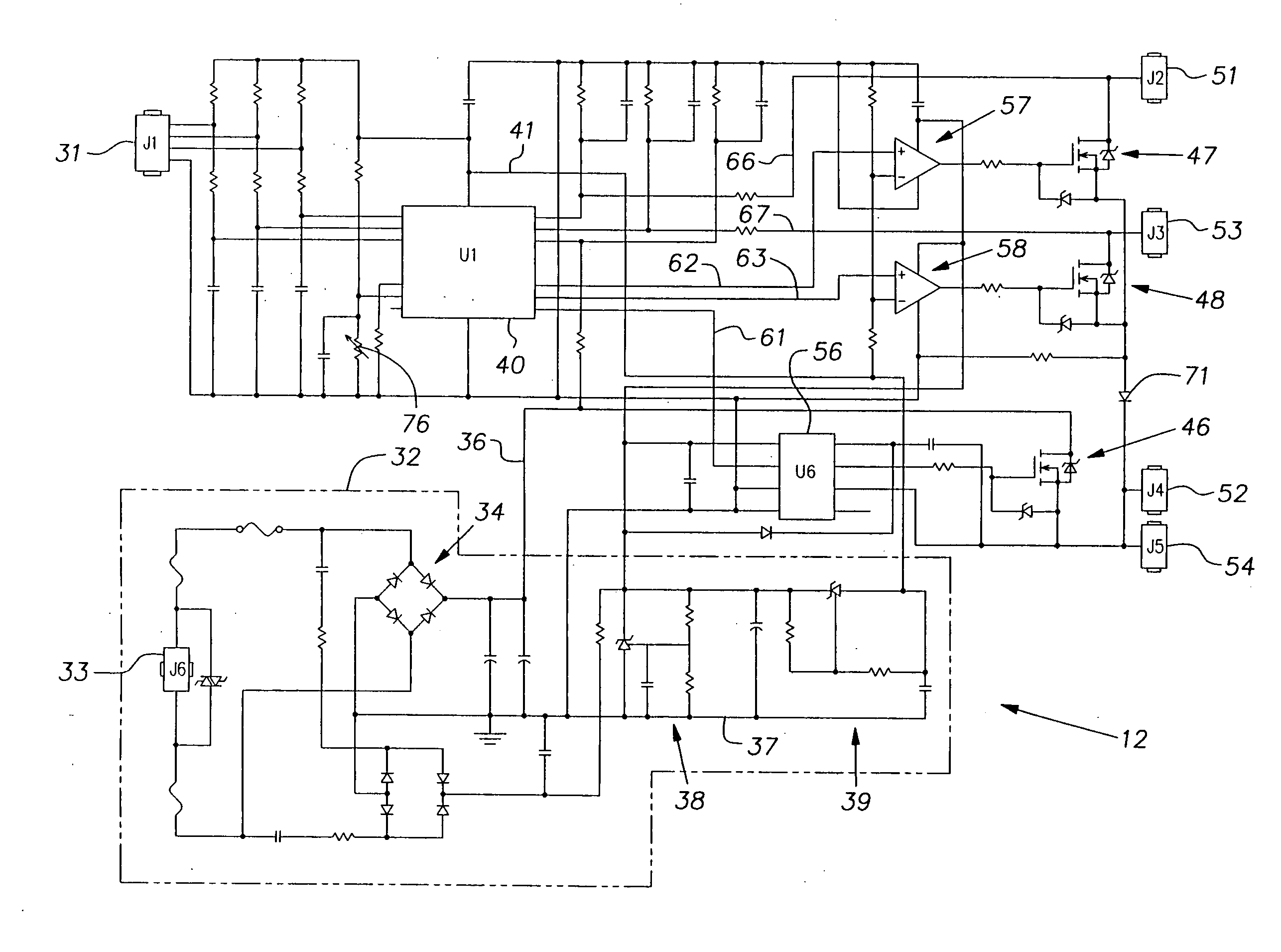

Motor starter device having reduced power consumption

ActiveUS7061204B2Reduce power consumptionPower-saving affectSingle-phase induction motor startersSynchronous motors startersDIACEngineering

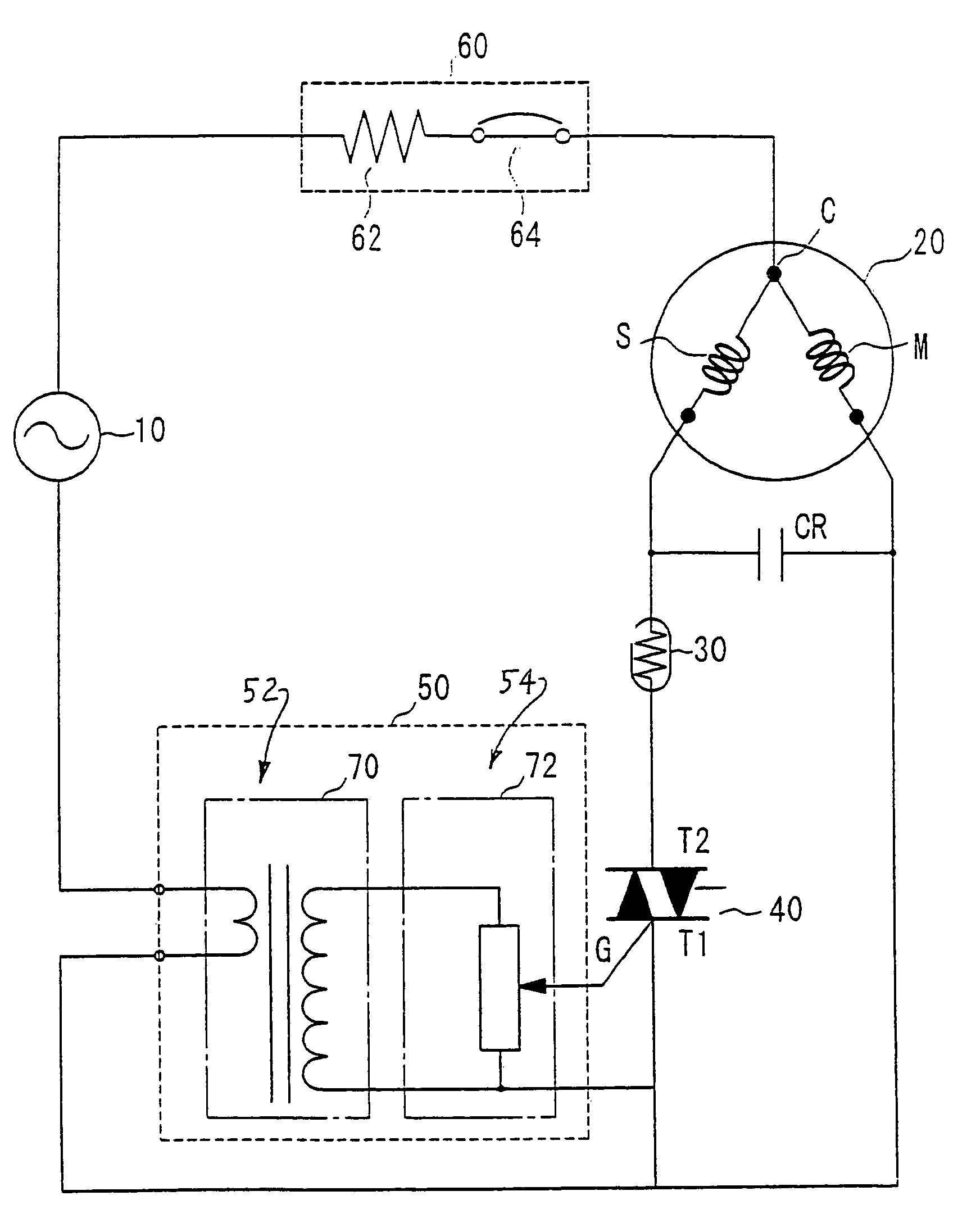

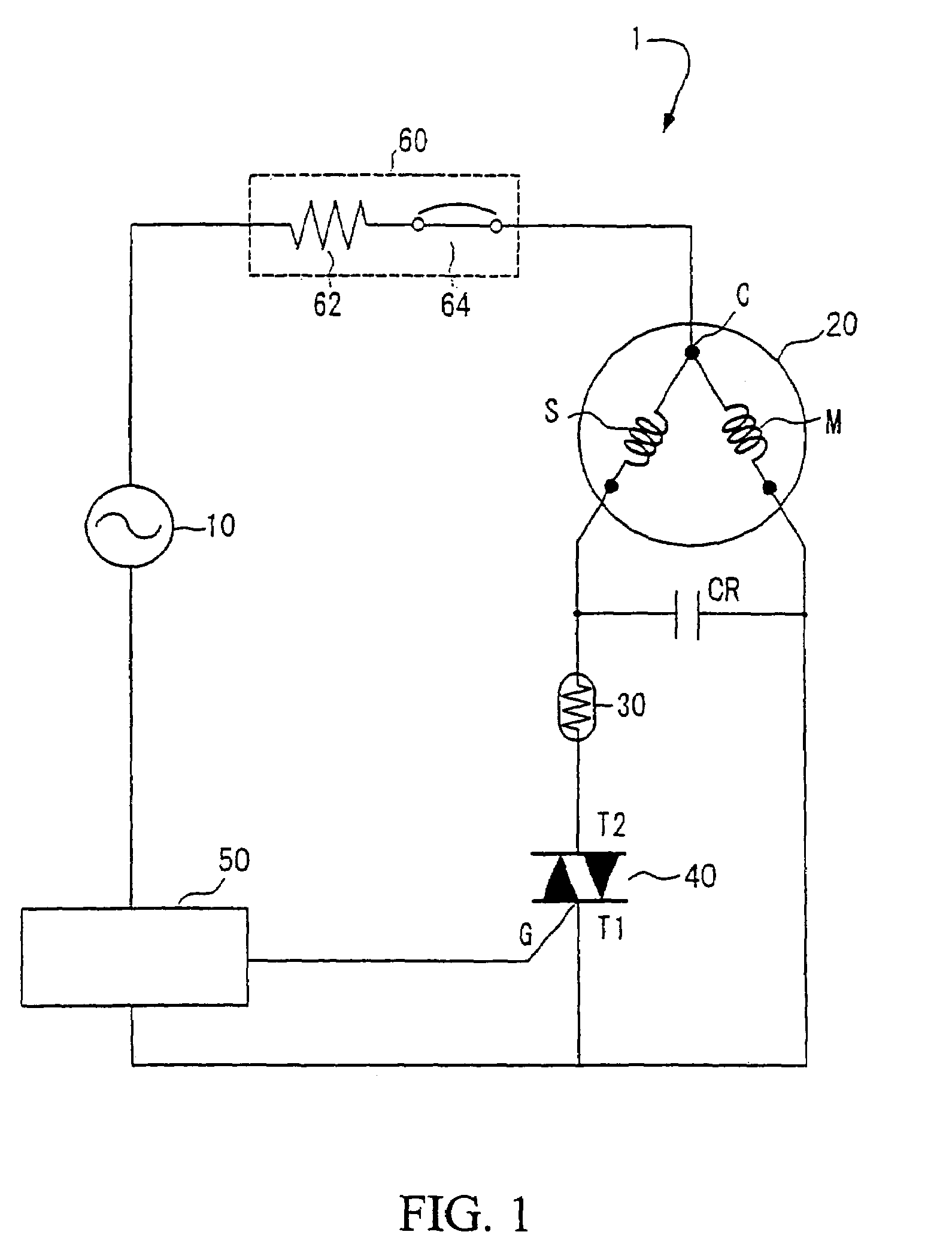

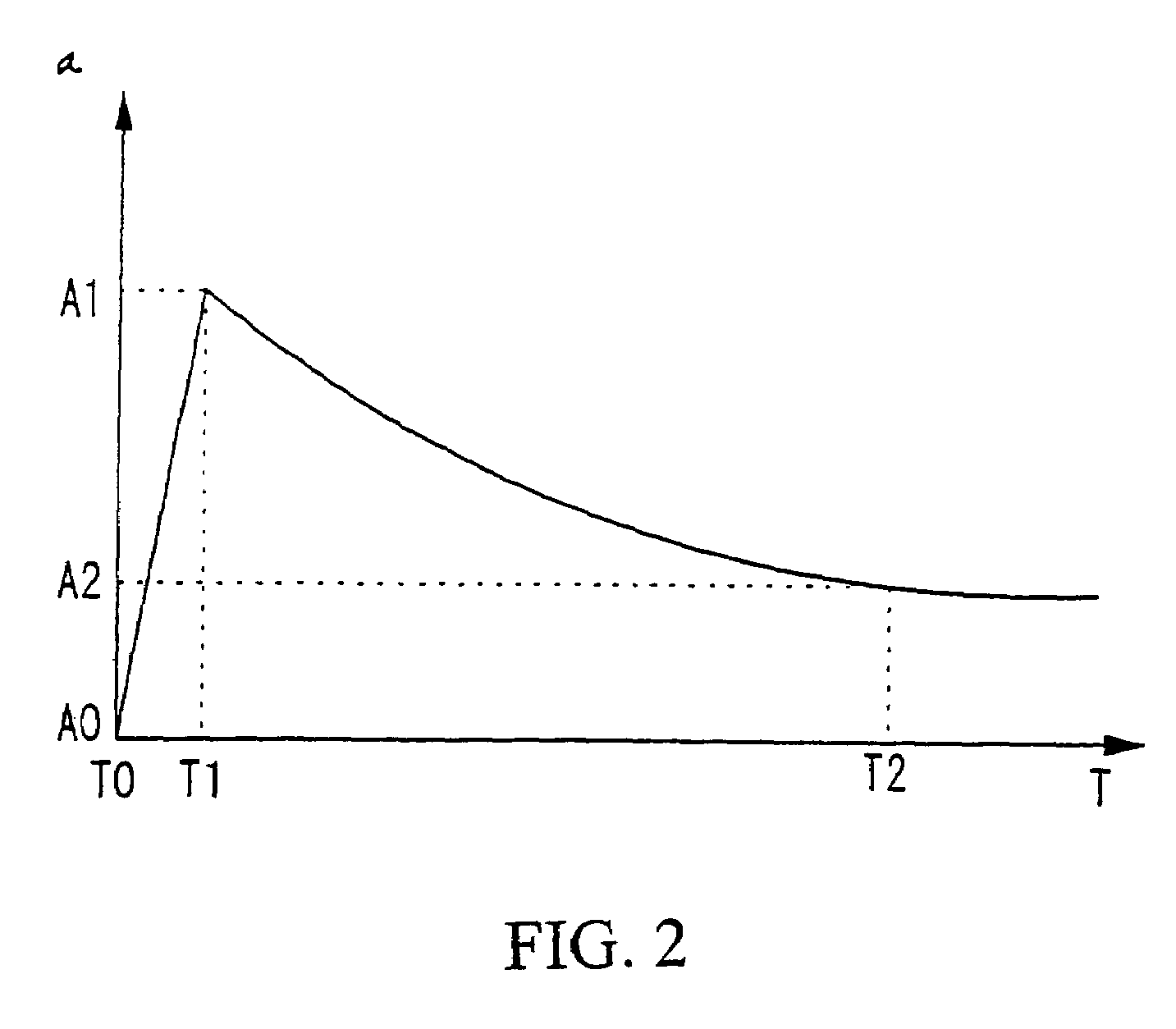

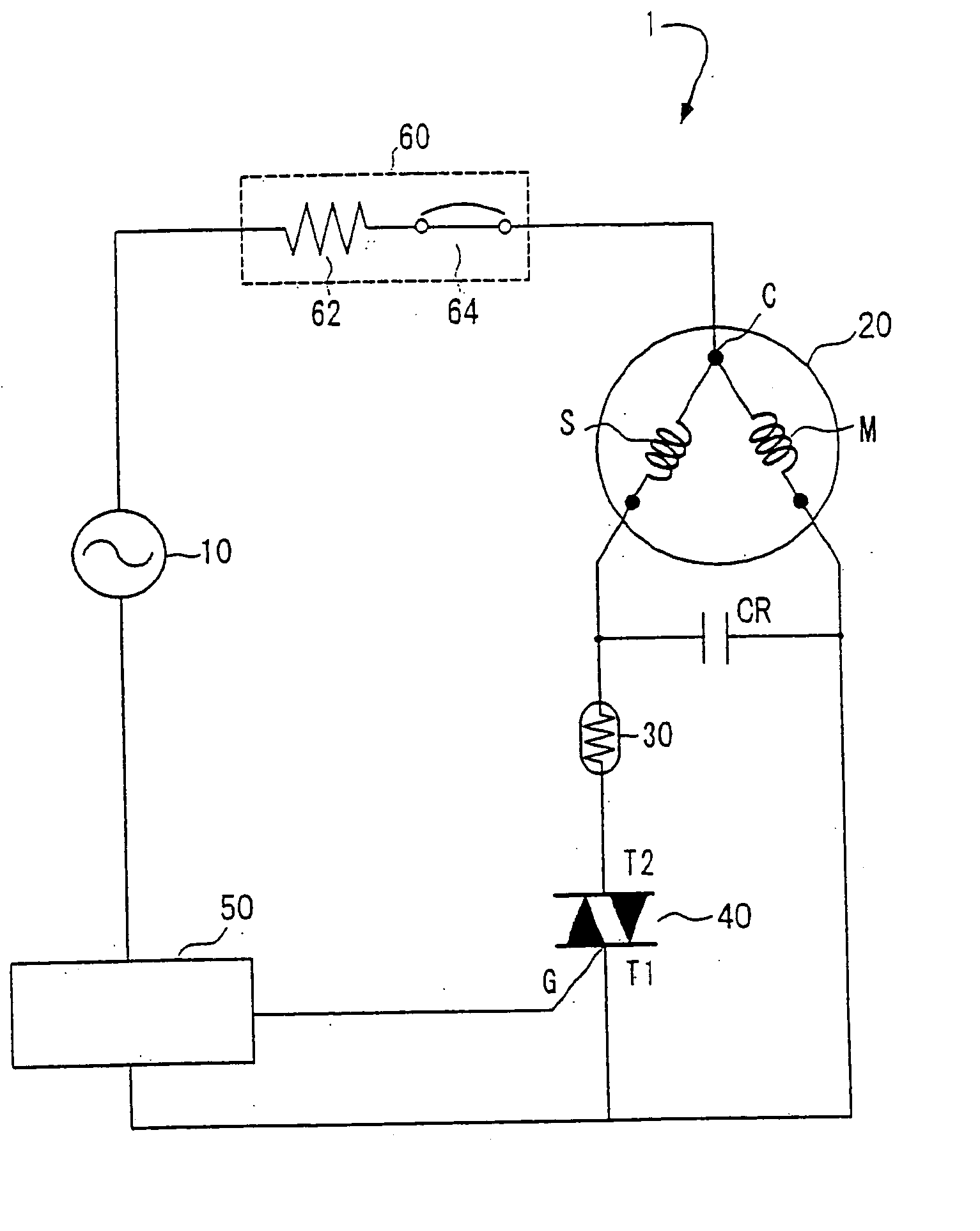

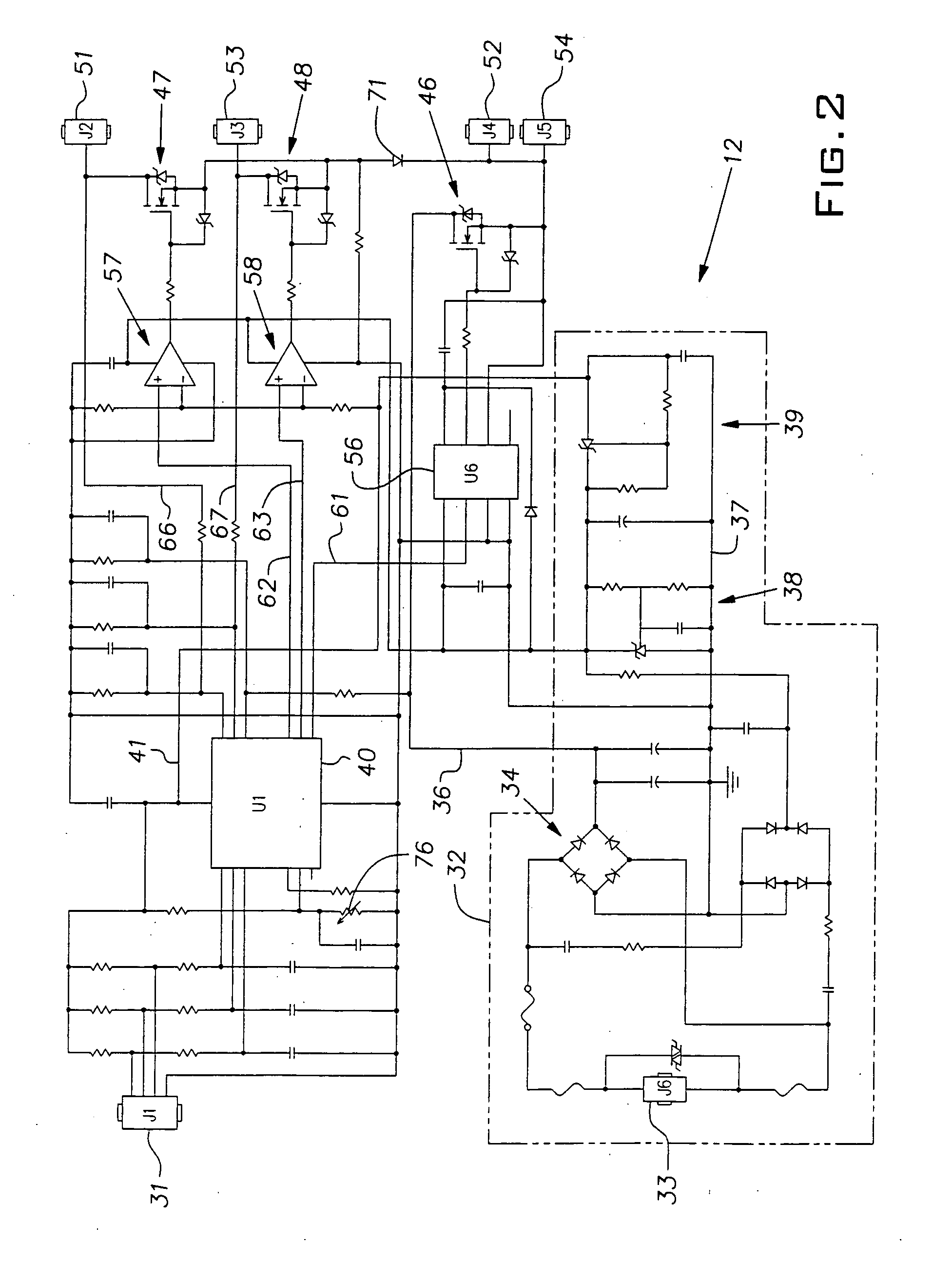

A motor starter for use with a motor (20) having a main winding (M) and a start winding (S). The starter has a PTC thermistor (30) connected in series with the start winding (S). A triac (40) is connected between PTC thermistor (30) and a power source line. A control circuit (50) is connected to the power source line for providing a voltage for a gate terminal (G) of triac (40) and an overload relay (60) is connected between the power source (10) and the motor (20). The control circuit (50) preferably includes a current detecting circuit (52) for detecting the inrush current and a voltage generating circuit (54) for generating the voltage in response to the detected inrush current. At the startup of motor (20) the control circuit (50) allows triac (40) to turn on by providing the gate terminal (G) with the voltage based on the inrush current. According to this invention, the power consumption of the start winding S after the startup of the motor (20) can be almost zero thus providing low power consumption. In another embodiment not employing a PTC thermistor, a current detecting circuit and a voltage generating circuit are used to control the on and off states of a first triac (90) which in turn controls the on and off states of a second triac (92) connected in series with the start winding.

Owner:SENSATA TECH MASSACHUSETTS INC

Motor starter device having reduced power consumption

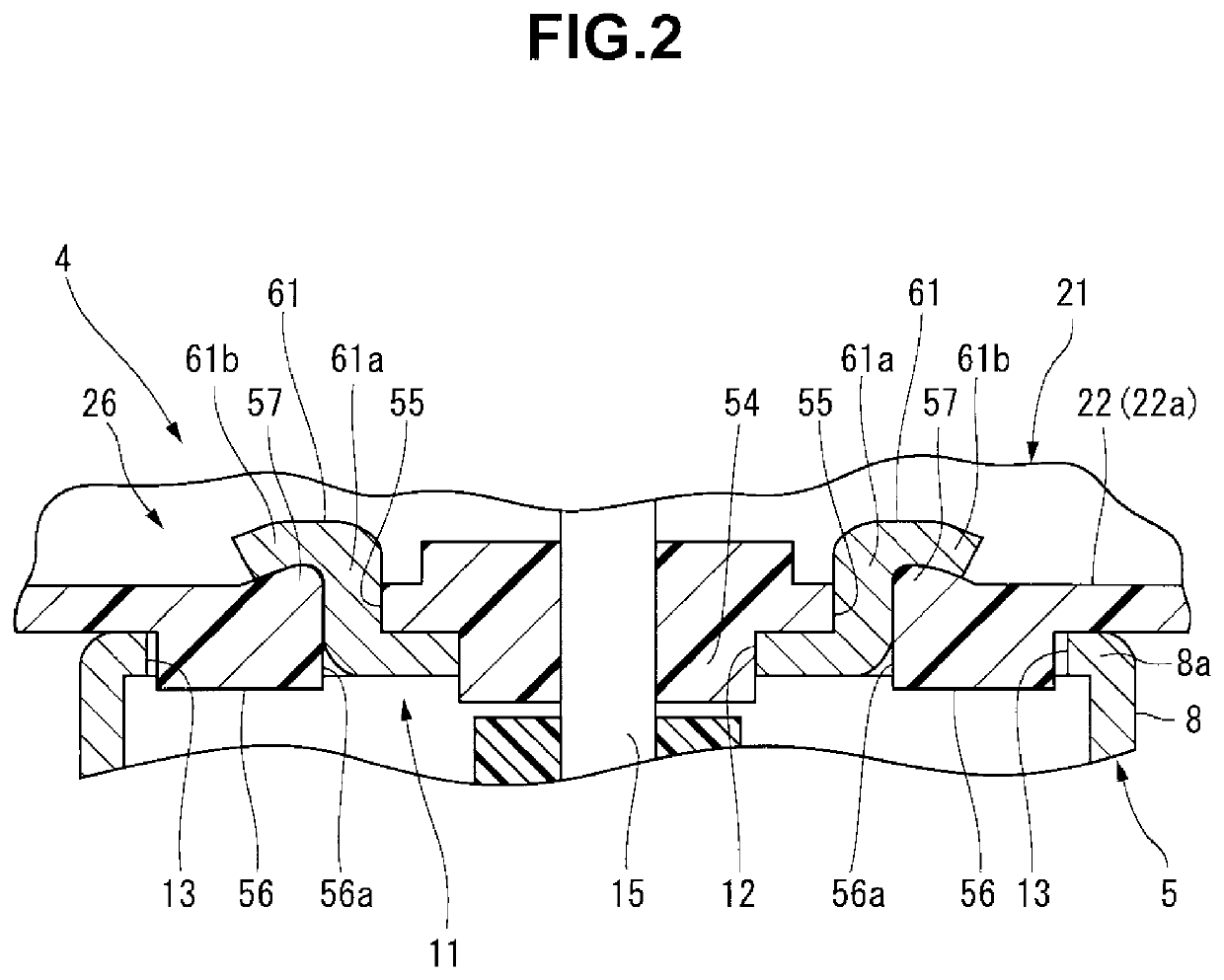

ActiveUS20050184699A1Good power savingReduce power consumptionSingle-phase induction motor startersSynchronous motors startersSilicon-controlled rectifierTRIAC

A motor starter for use with a motor (20) having a main winding (M) and a start winding (S). The starter has a PTC thermistor (30) connected in series with the start winding (S). A triac (40) is connected between PTC thermistor (30) and a power source line. A control circuit (50) is connected to the power source line for providing a voltage for a gate terminal (G) of triac (40) and an overload relay (60) is connected between the power source (10) and the motor (20). The control circuit (50) preferably includes a current detecting circuit (52) for detecting the inrush current and a voltage generating circuit (54) for generating the voltage in response to the detected inrush current. At the startup of motor (20) the control circuit (50) allows triac (40) to turn on by providing the gate terminal (G) with the voltage based on the inrush current. According to this invention, the power consumption of the start winding S after the startup of the motor (20) can be almost zero thus providing low power consumption. In another embodiment not employing a PTC thermistor, a current detecting circuit and a voltage generating circuit are used to control the on and off states of a first triac (90) which in turn controls the on and off states of a second triac (92) connected in series with the start winding.

Owner:SENSATA TECH MASSACHUSETTS INC

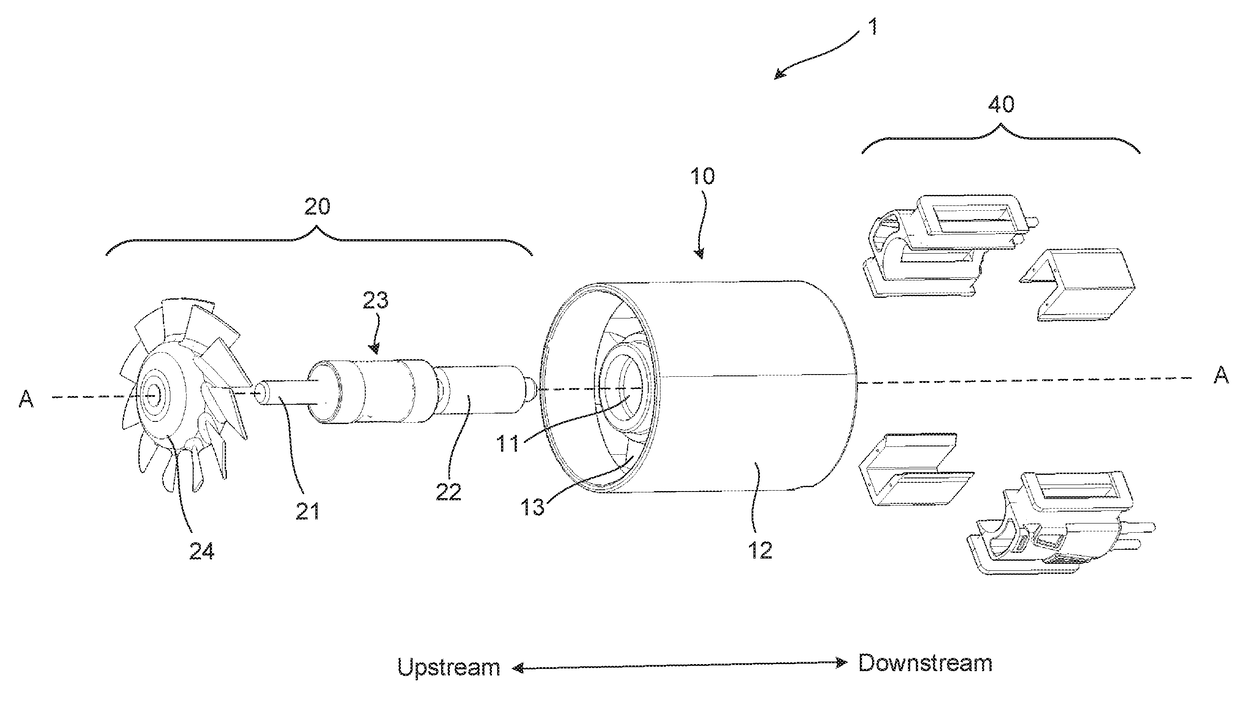

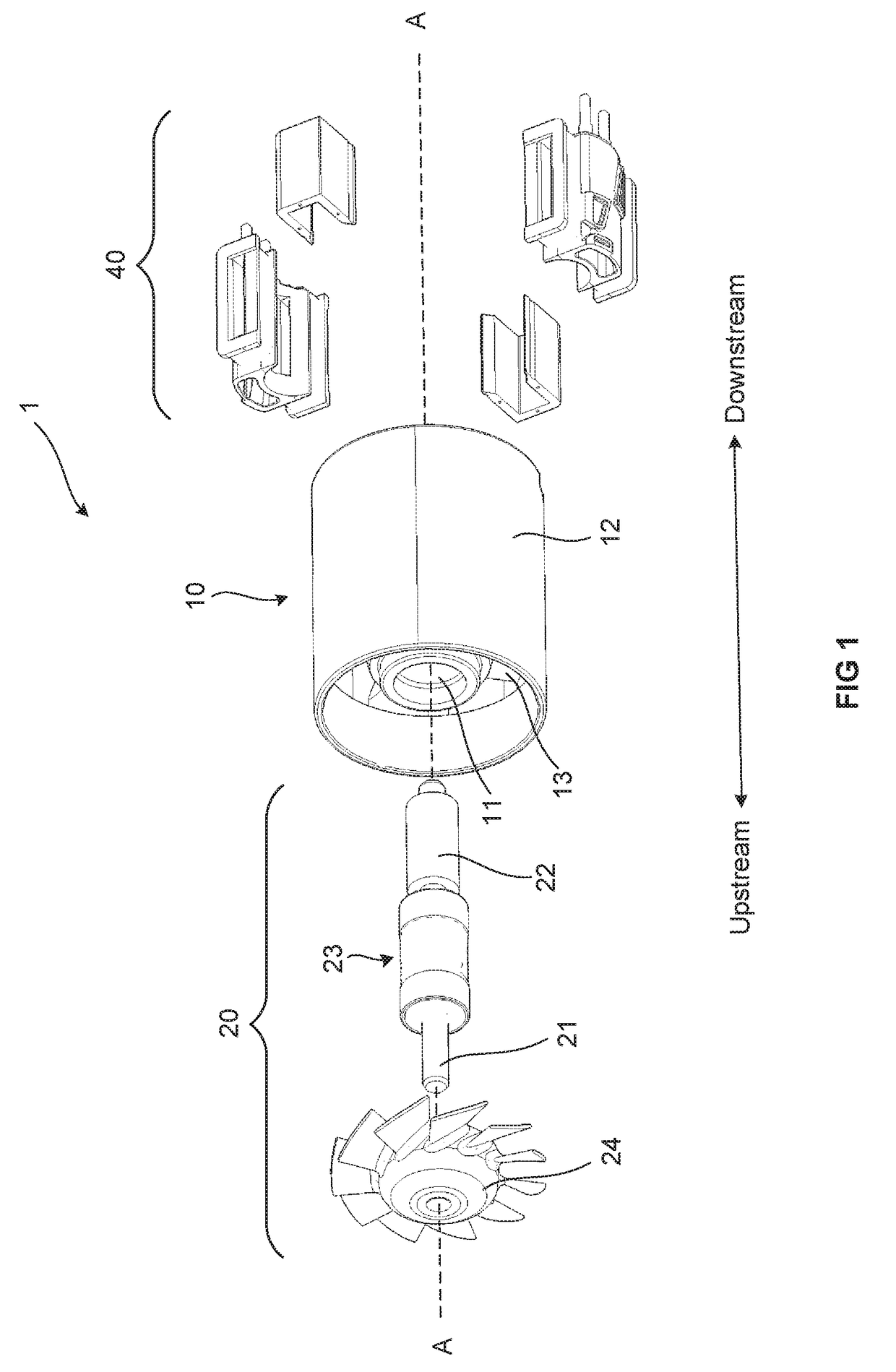

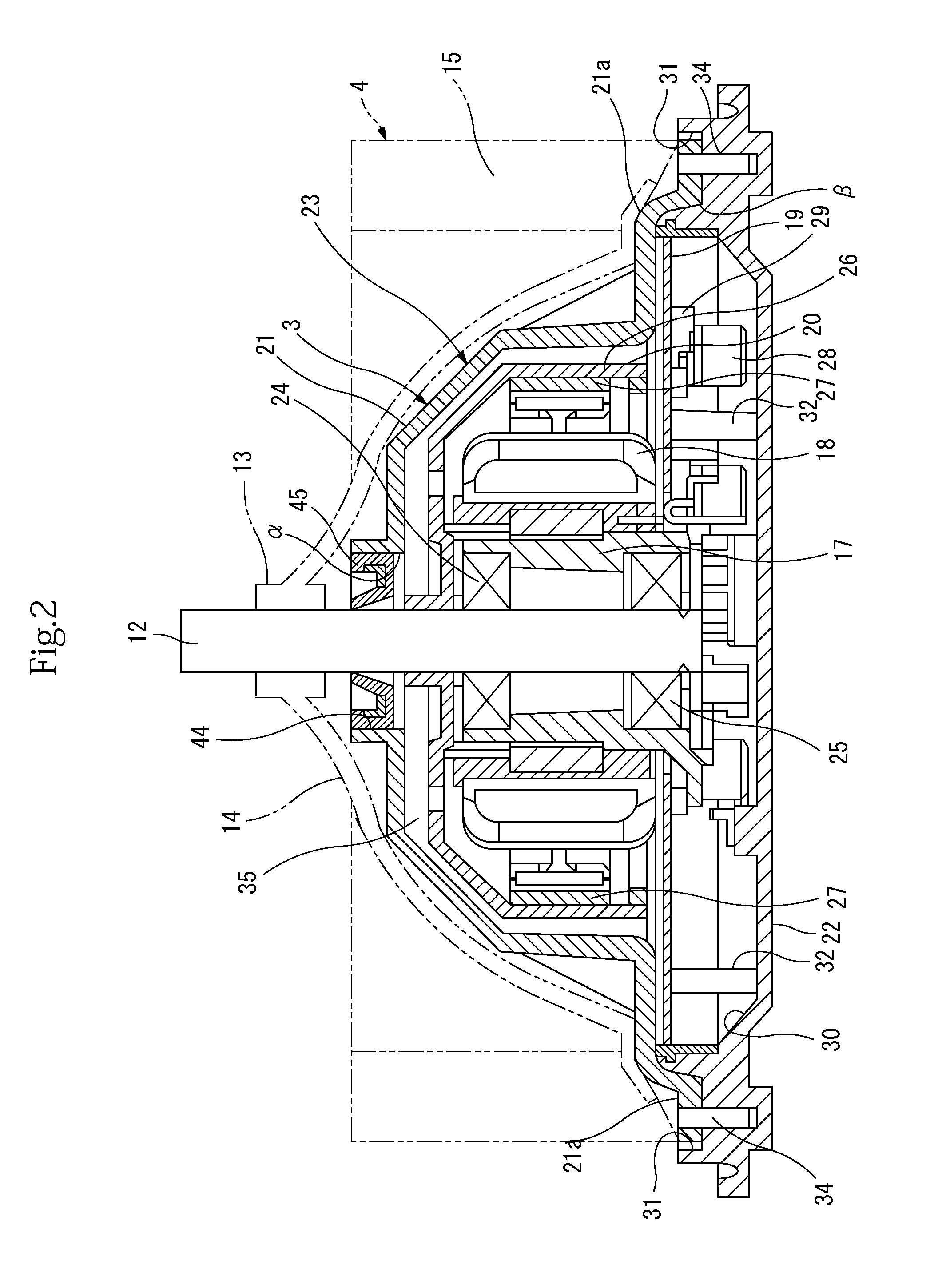

Electric motor

ActiveUS20170170709A1Reduce motor costLess componentsWindingsMagnetic circuit rotating partsImpellerBobbin

An electric motor including: a frame; a rotor assembly including a magnet, a bearing assembly, an impeller, and a shaft; and a stator assembly including a stator core and a bobbin. The frame has an inner wall and an outer wall, the outer wall surrounds the inner wall and defines an annular channel between the inner wall and the outer wall, and diffuser vanes extend from the inner wall to the outer wall through the annular channel. The inner wall defines a bore for supporting the rotor assembly, and the outer wall defines a substantially cylindrical outer casing of the motor.

Owner:DYSON TECH LTD

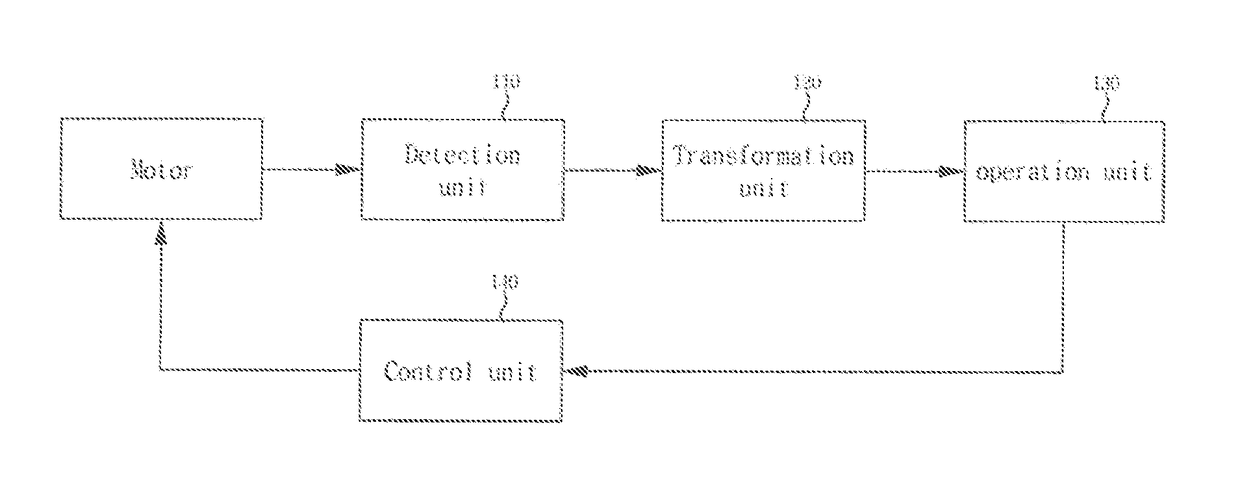

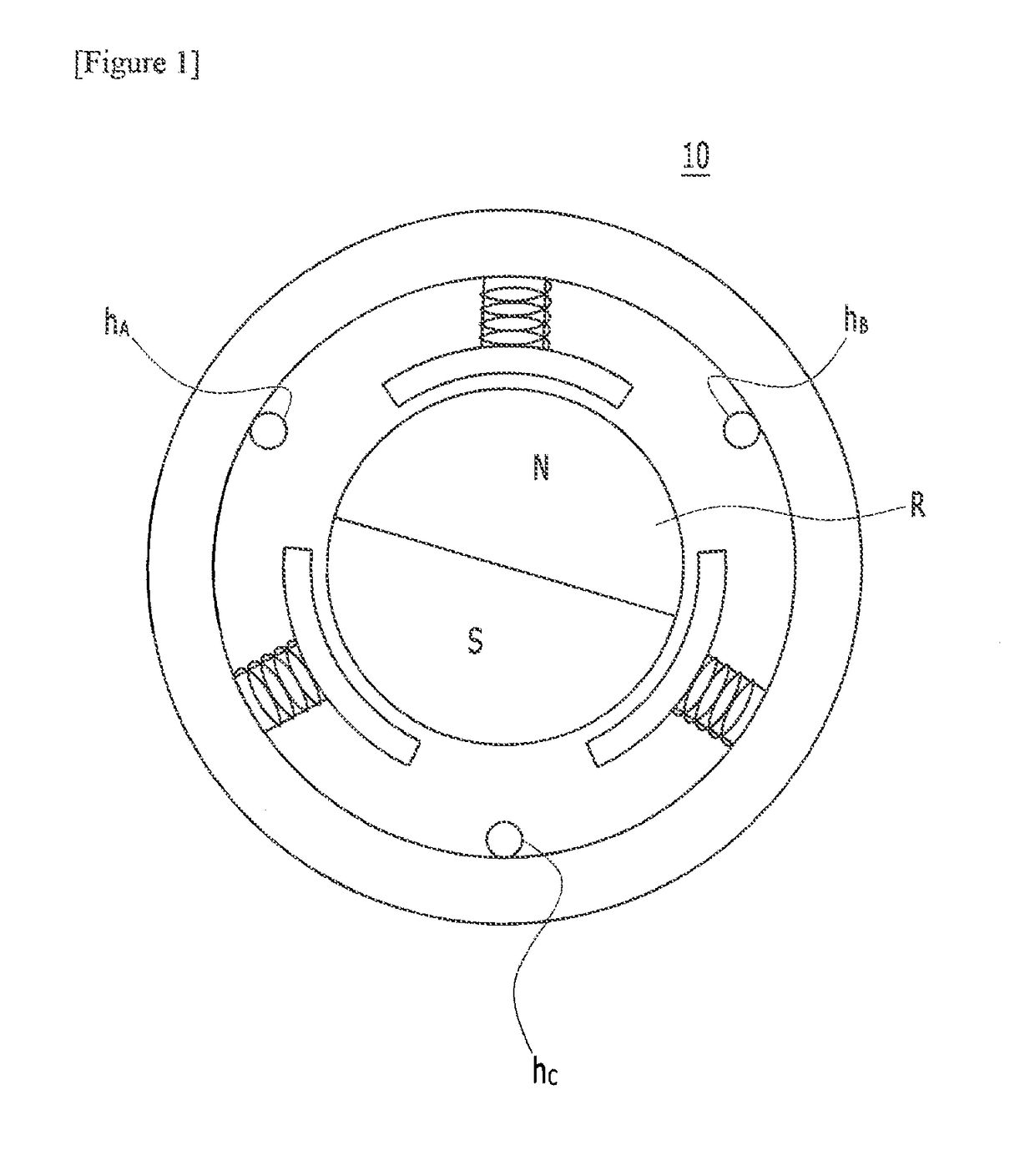

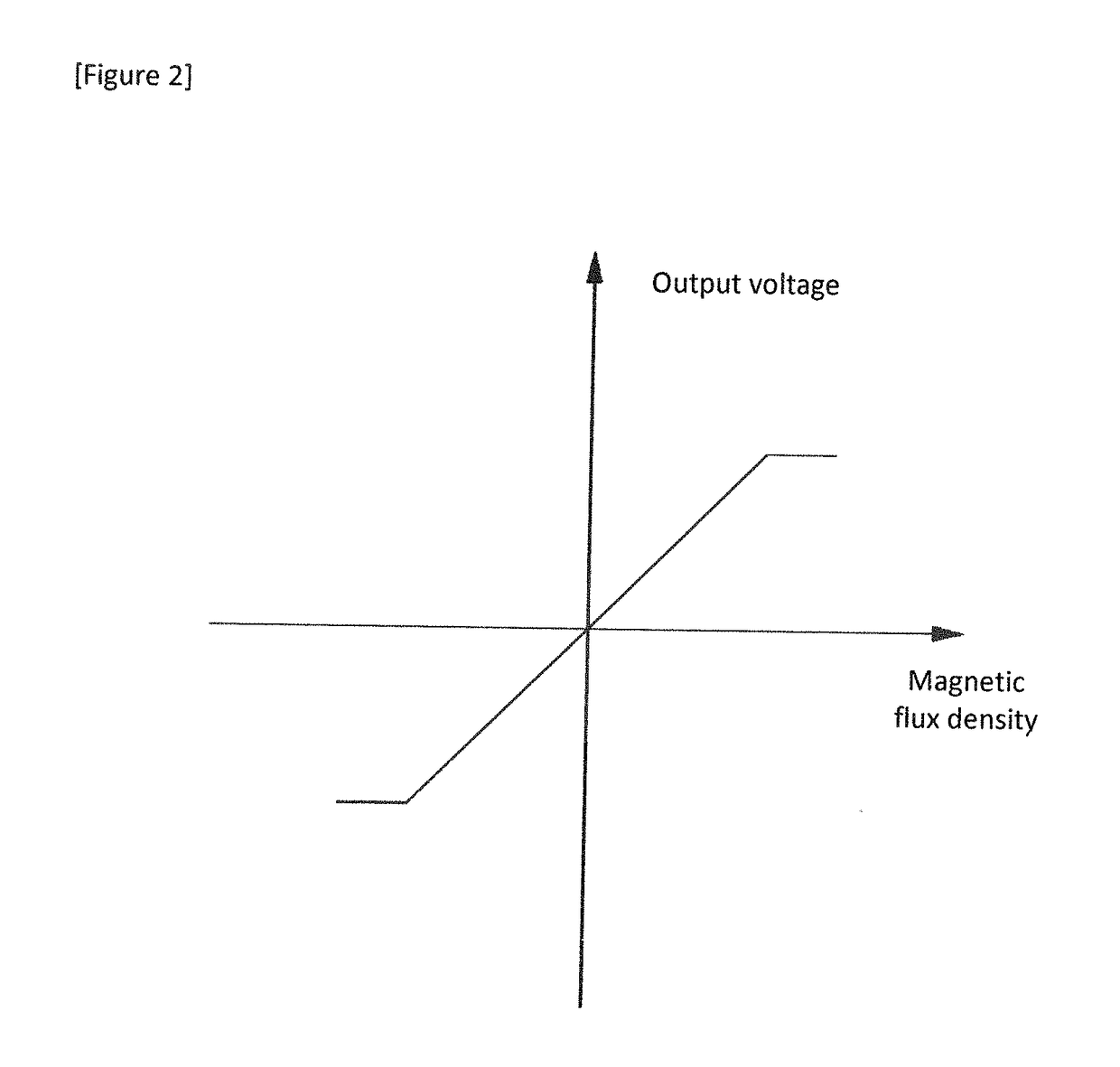

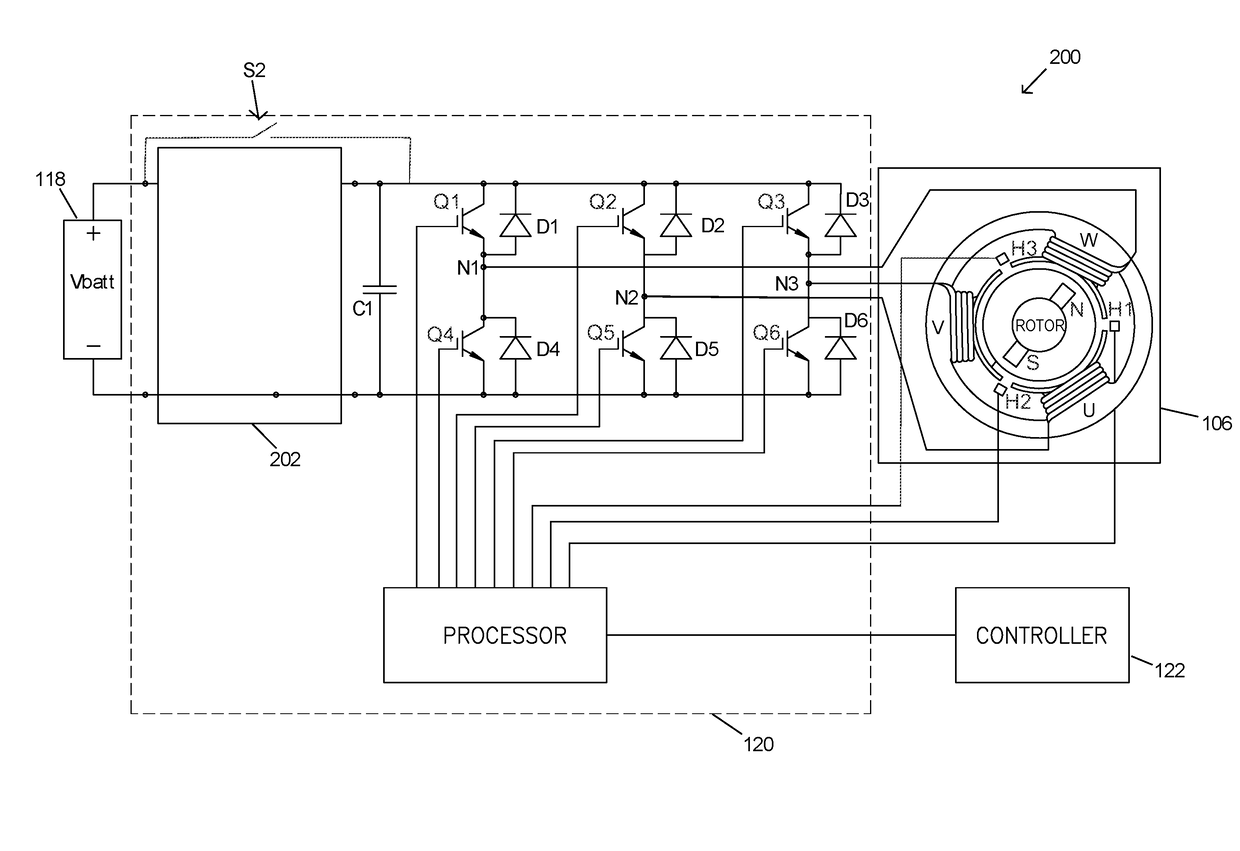

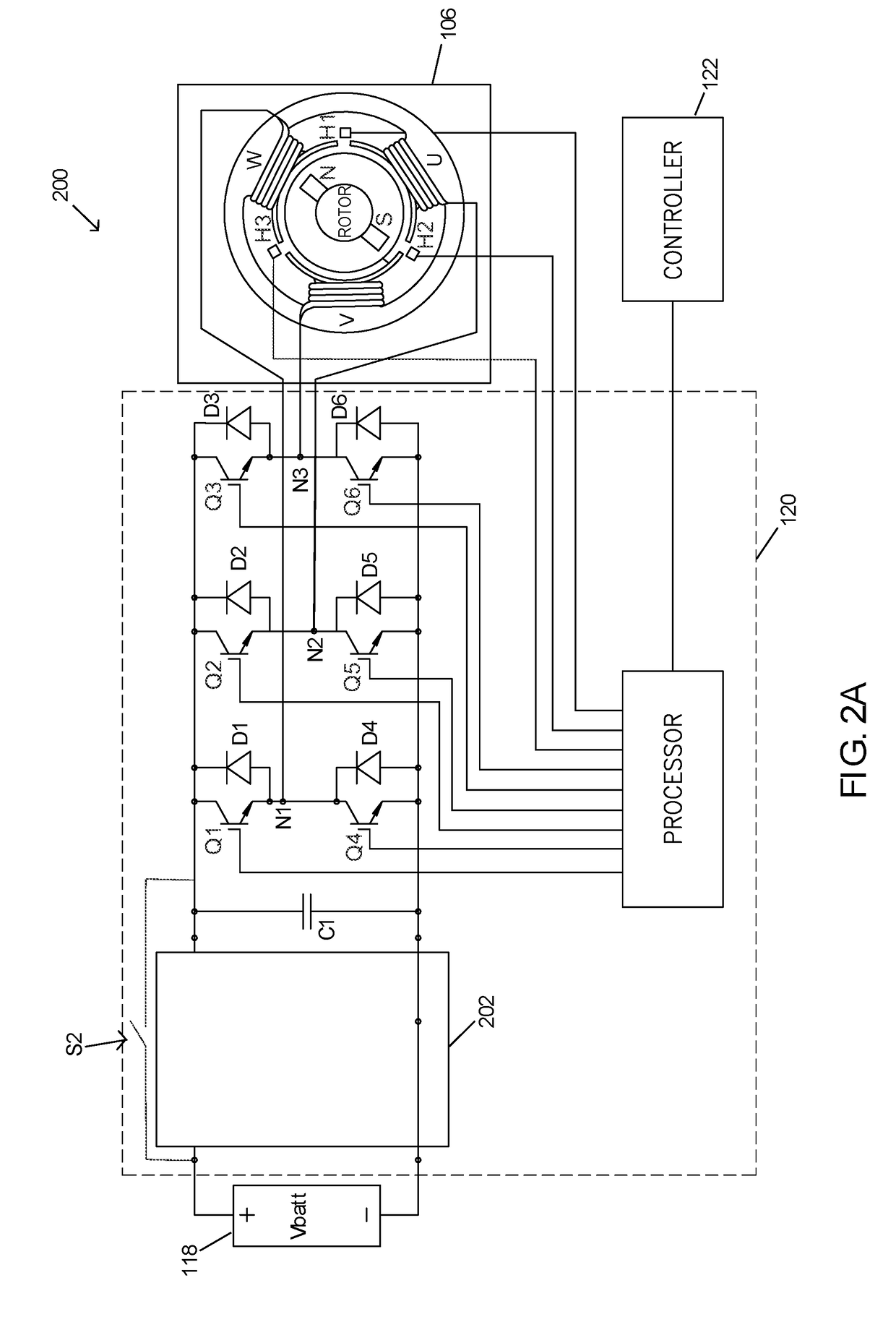

Device for correcting hall sensor installation position error of BLDC motor having linear hall sensor, and method thereof

InactiveUS20170353130A1Accurate calculationReduce motor costVector control systemsElectronic commutatorsStator coilTransformation unit

There is provided a device for correcting a Hall sensor installation position error in a BLDC motor which includes a rotor with a permanent magnet, a stator wound with coils to form a magnetic field around the rotor, and three linear Hall sensors installed outwardly around the rotor to generate output signals by the Hall-Effect, the device comprising: a detection unit to detect output signals H1, H2, H3 output from the three linear Hall sensors; a transformation unit to transform the output signals H1, H2, H3 detected in the detection unit to orthogonal two-phase transformation signals Ha, Hb and to transform the transformation signals Ha, Hb to normalized transformation signals Han, Hbn; an operation unit to calculate a rotation angle of the motor from the normalized transformation signals Han, Hbn output in the transformation unit; and a control unit to control the current supplied to the coils winding the stator based on information of the rotation angle transmitted from the operation unit, wherein the transformation unit transforms the output signals H1, H2, H3 to the orthogonal two-phase transformation signals Ha, Hb by Clarke Transformation.

Owner:FIRSTEC CO LTD

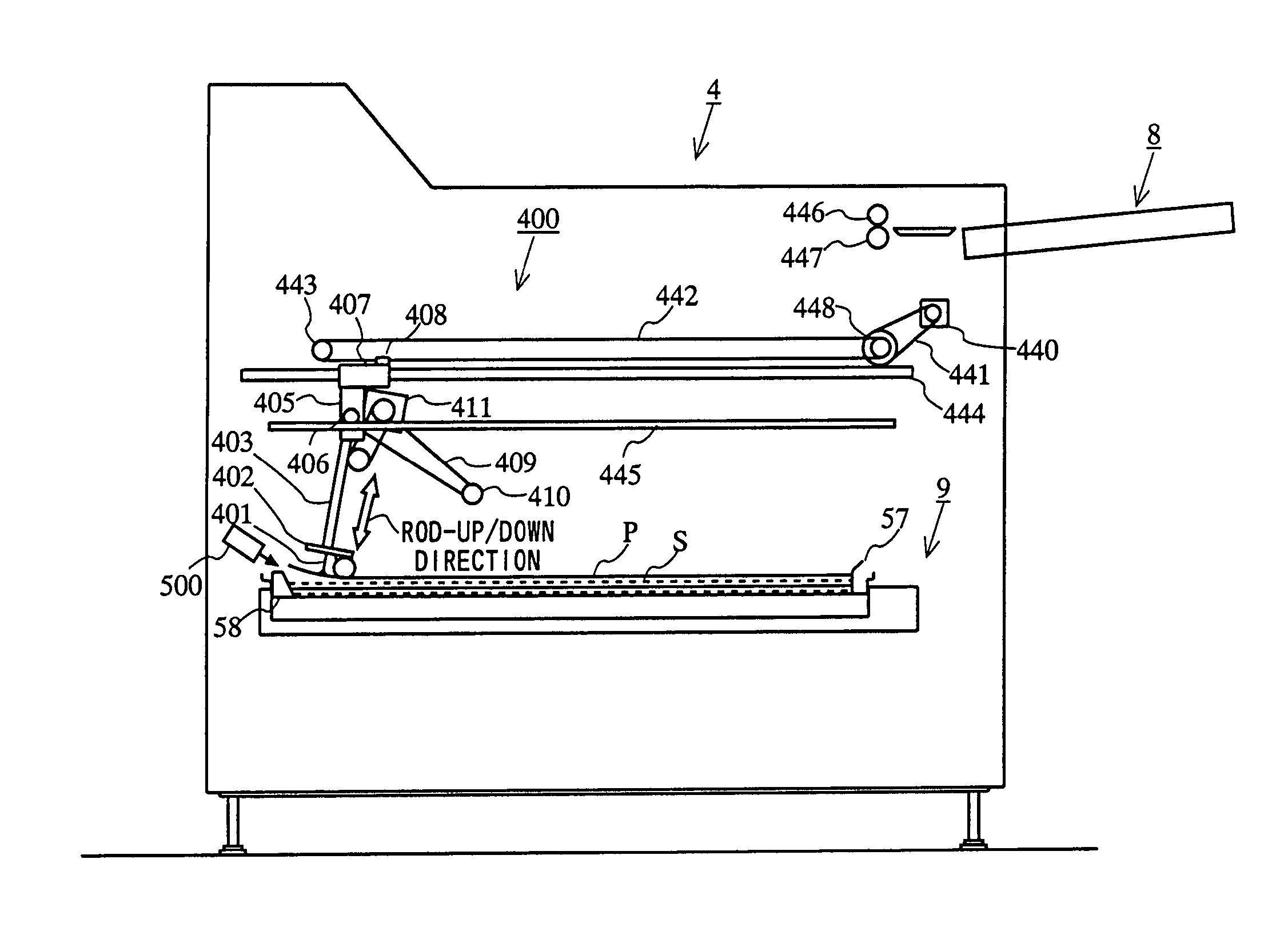

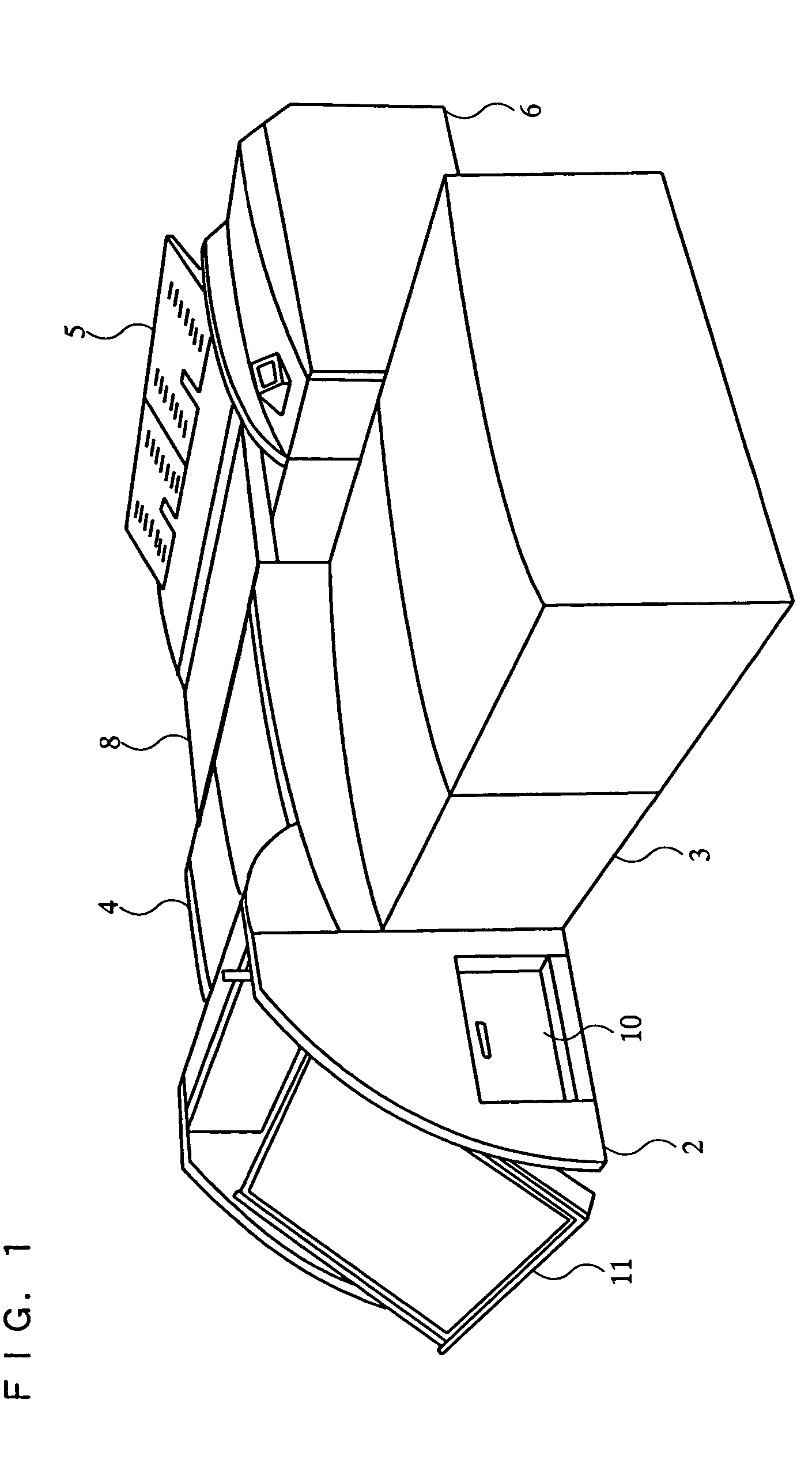

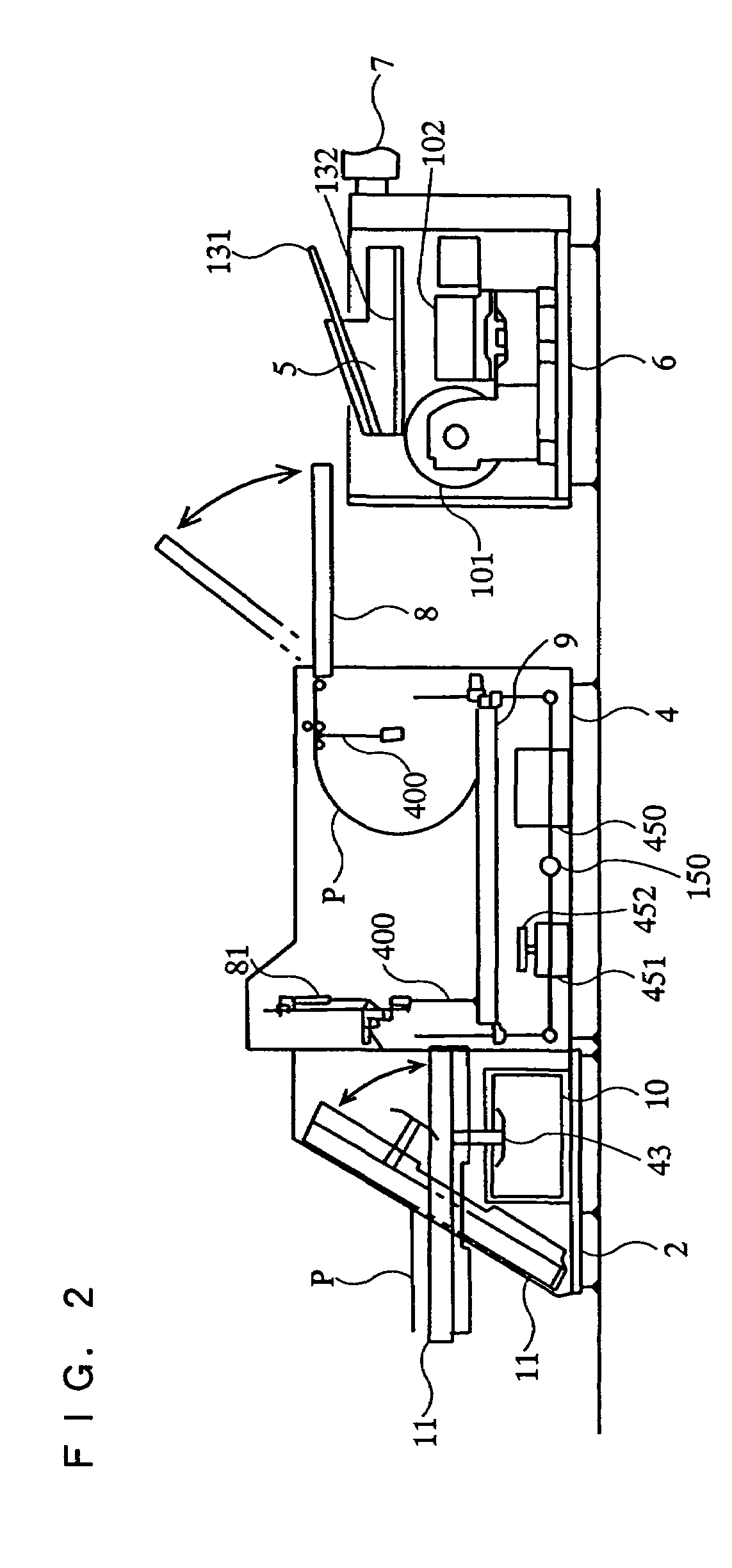

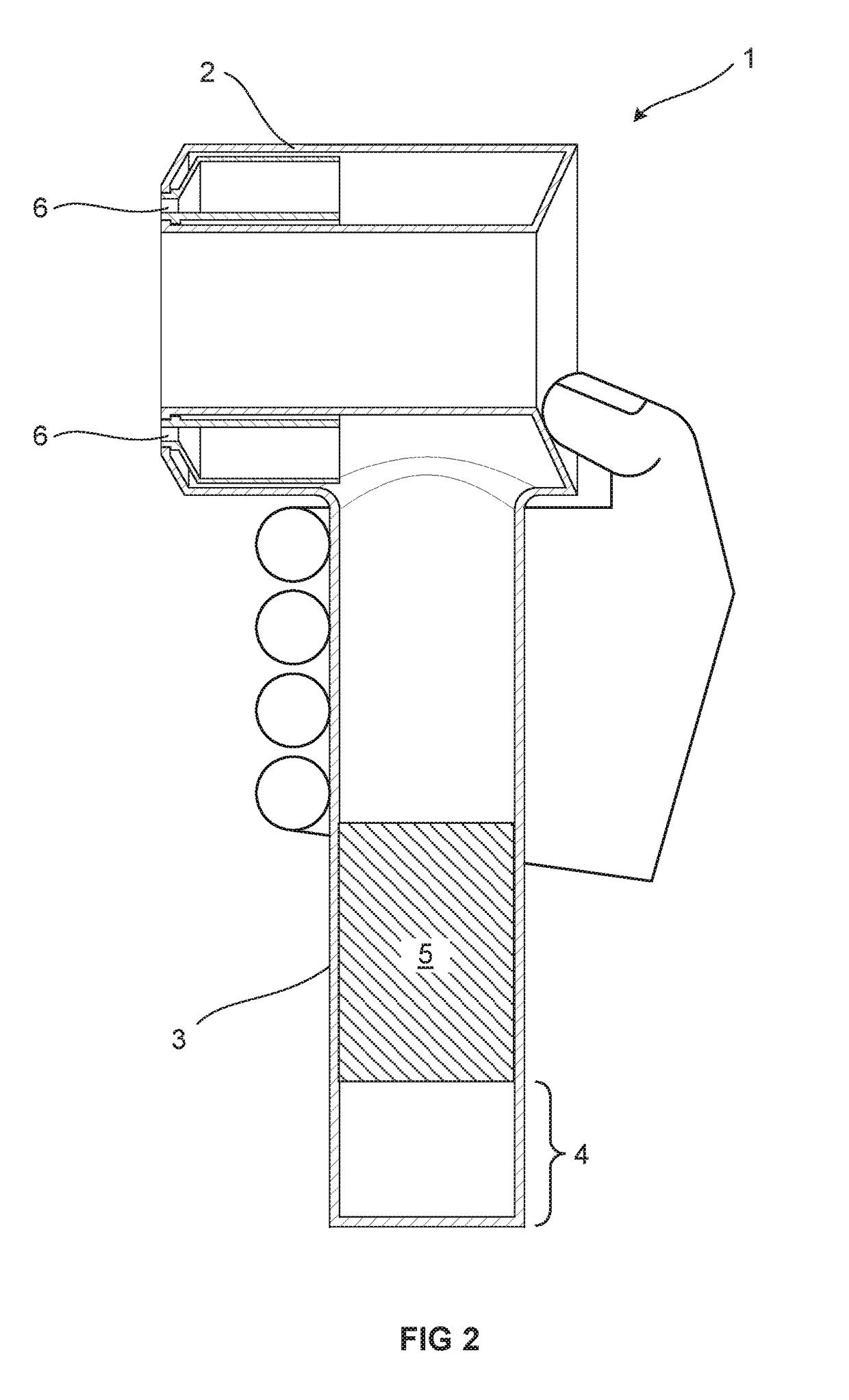

Plate supplying apparatus

InactiveUS6978716B2Preventing an image recording layer of a plate from being damagedReduce torqueAddressographsLetterpress printingSlip sheetEngineering

In the plate supplying apparatus of the present invention, various vibrations are provided to a plate secured via suction during a separating operation by causing pad rods 403 to repeat a slight ascent and a pause, and thereafter causing the pad rods 403 to make an abrupt descent, thereby reliably peeling off a slip sheet adhering to the back face of the plate. Further, vibration in the rod-up / down direction is provided to the plate during the separating operation, and the plate is not pushed hard. Thus, it is possible to prevent the plate from being damaged. A raising and lowering motor 52 is driven to lower the cassette 9. A separating operation for peeling off a slip sheet S adhering to the back face of the plate P is performed, and thereafter the plate P secured via suction is turned over and transferred.

Owner:DAINIPPON SCREEN MTG CO LTD

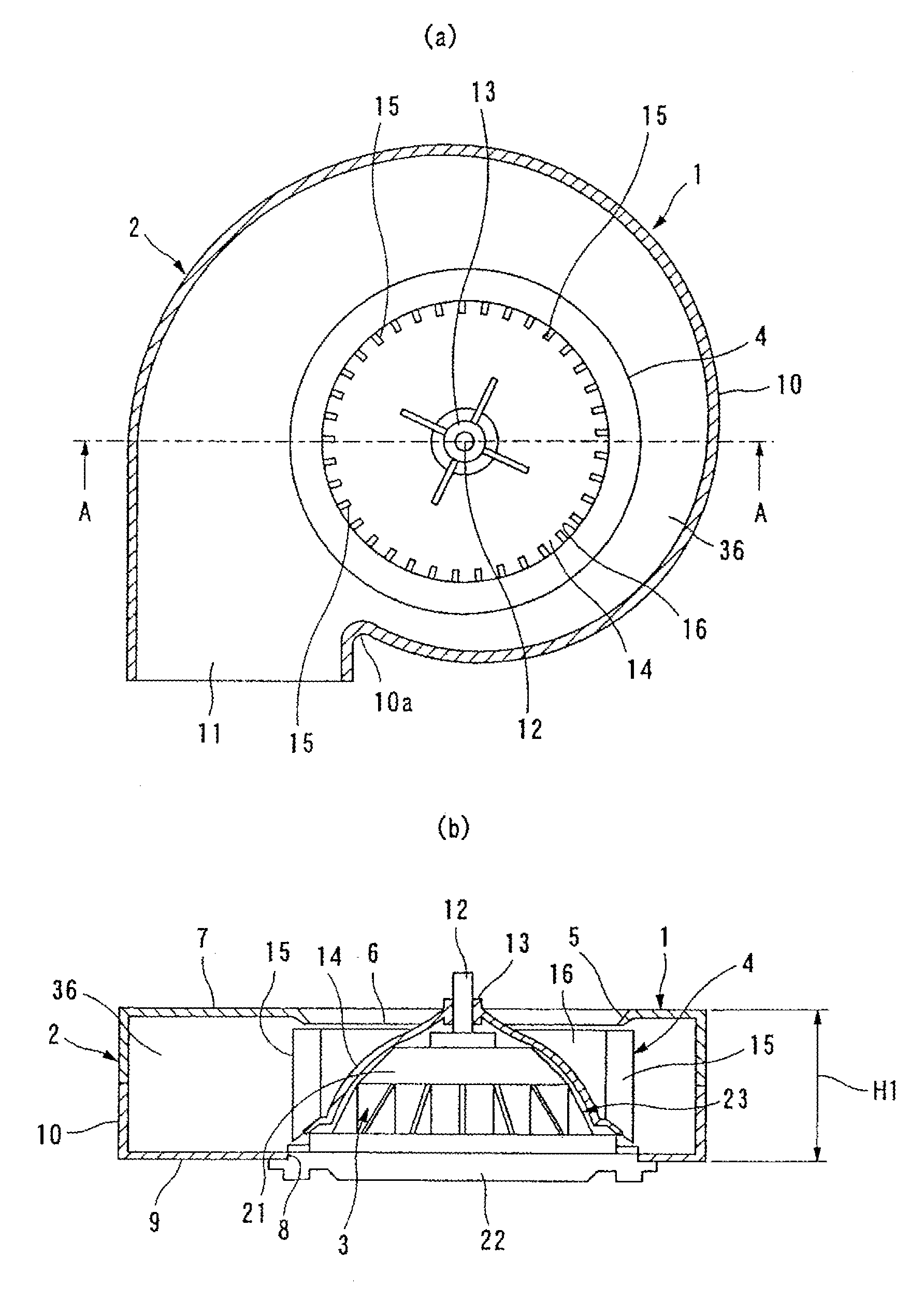

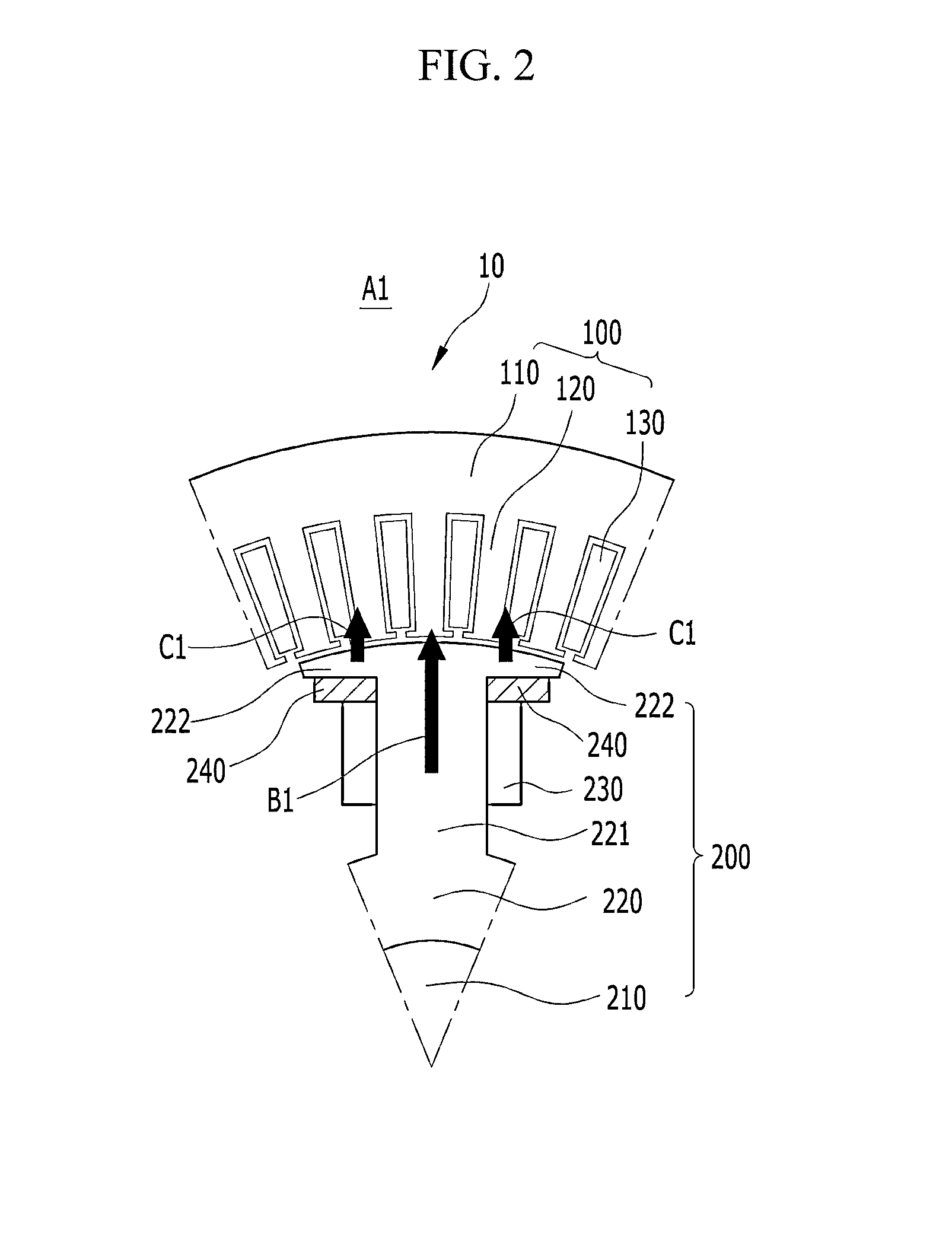

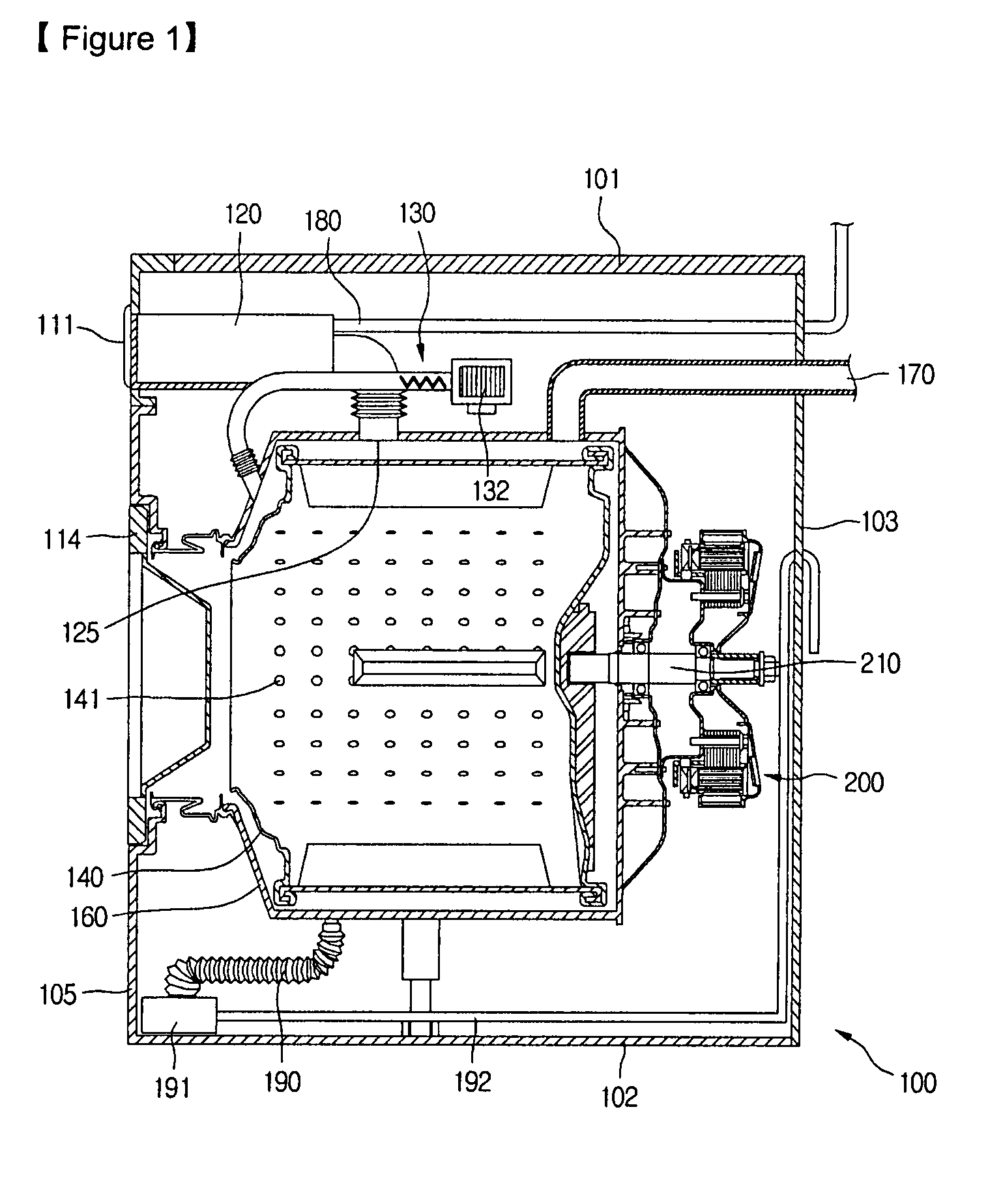

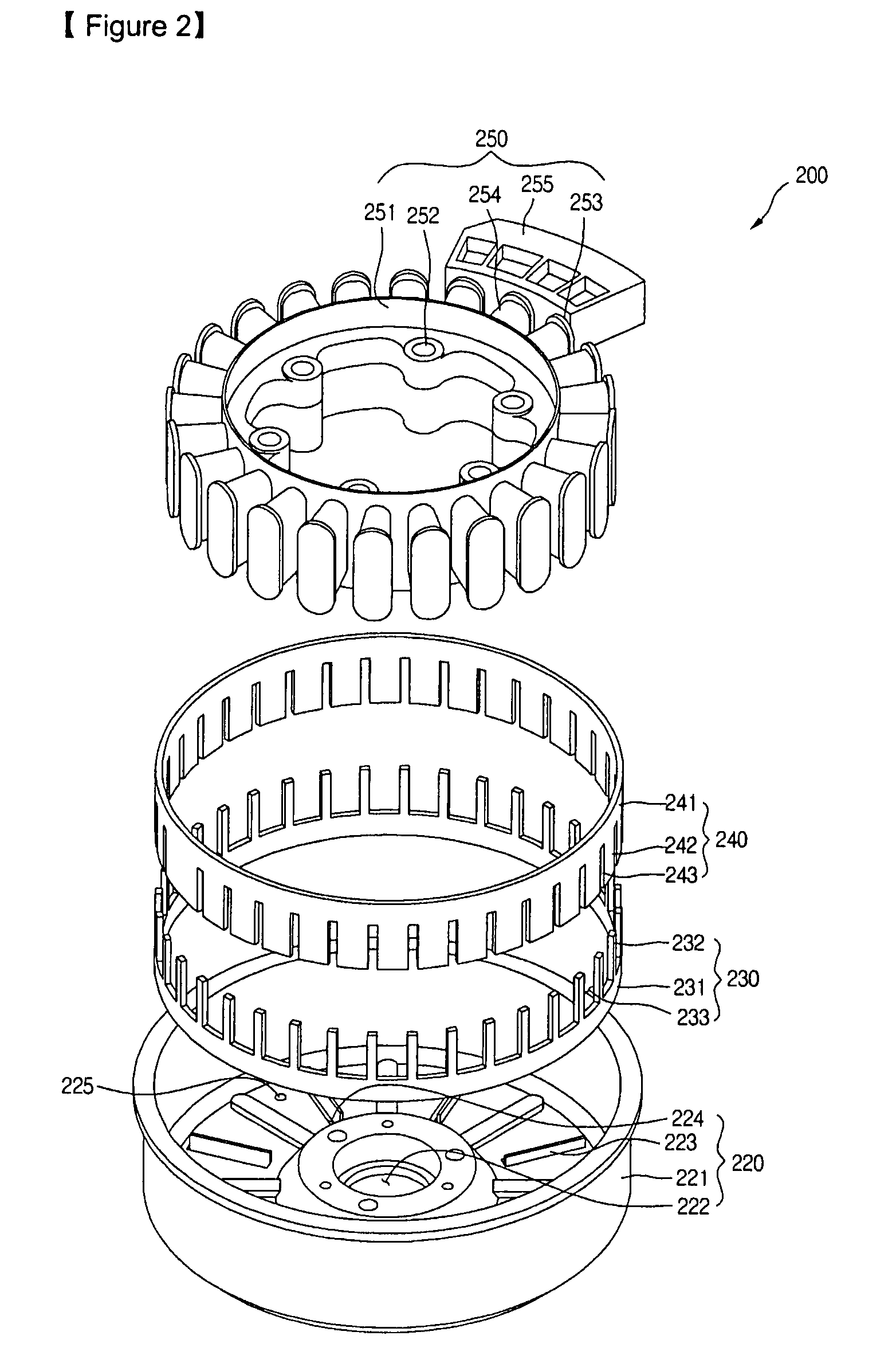

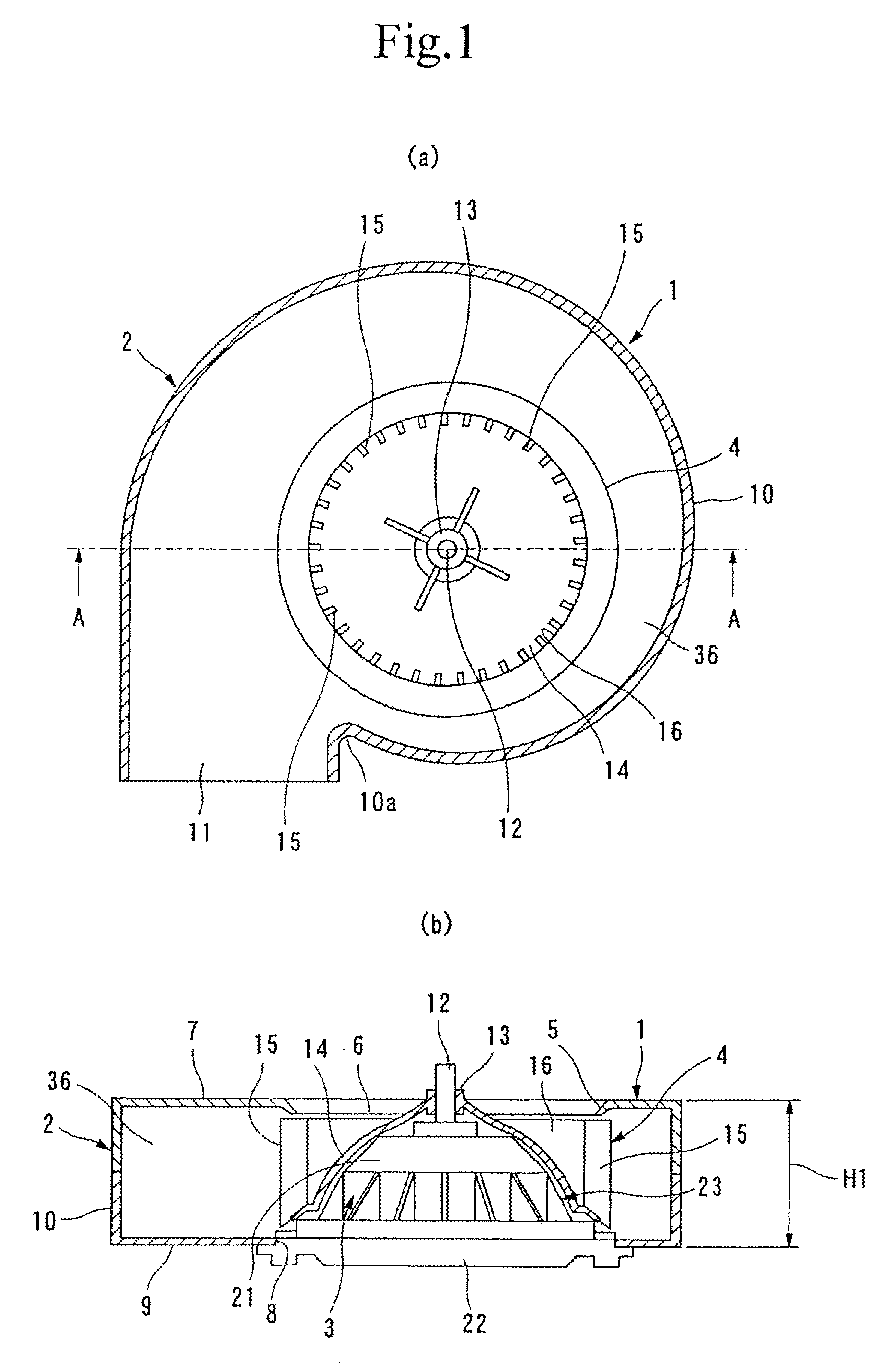

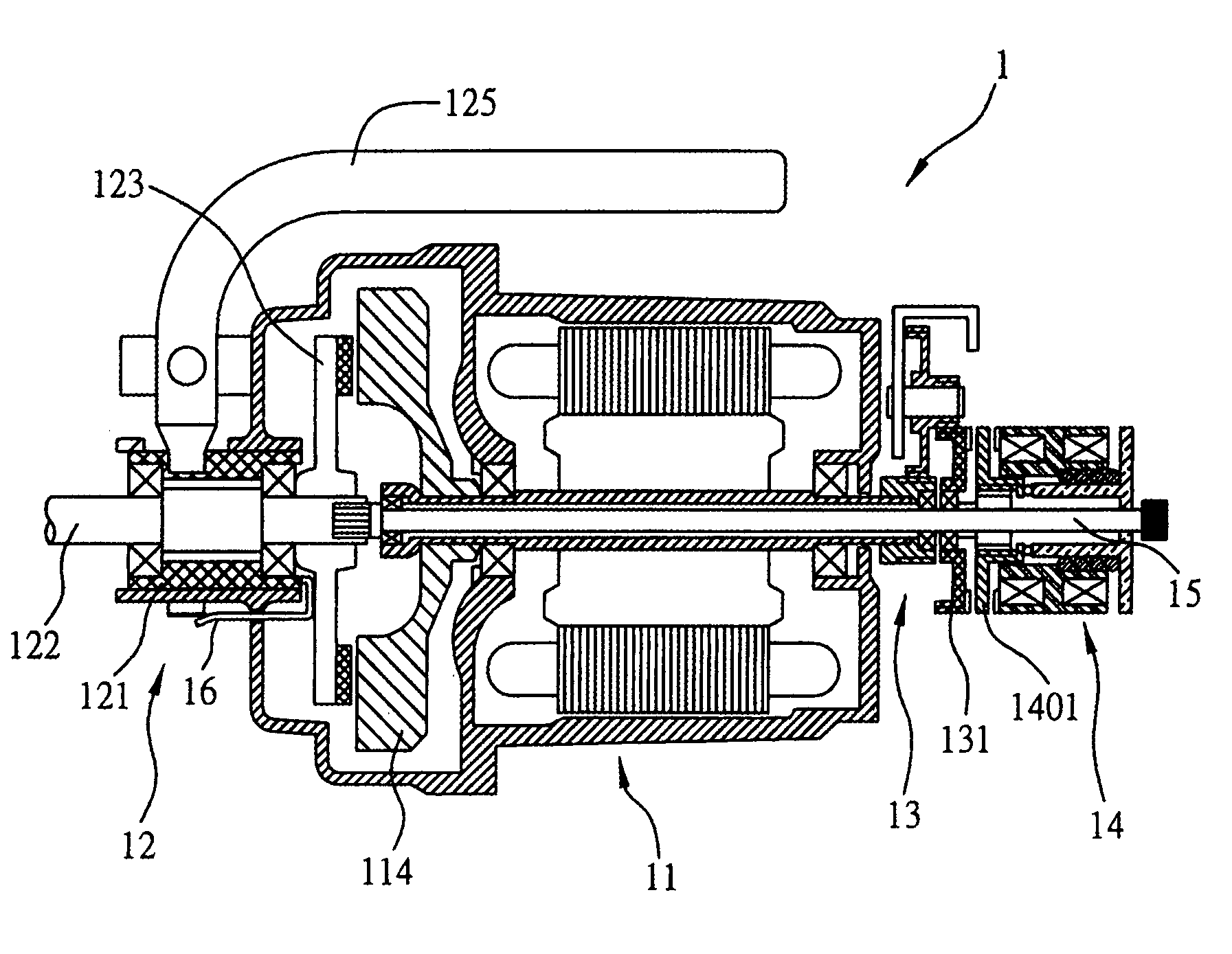

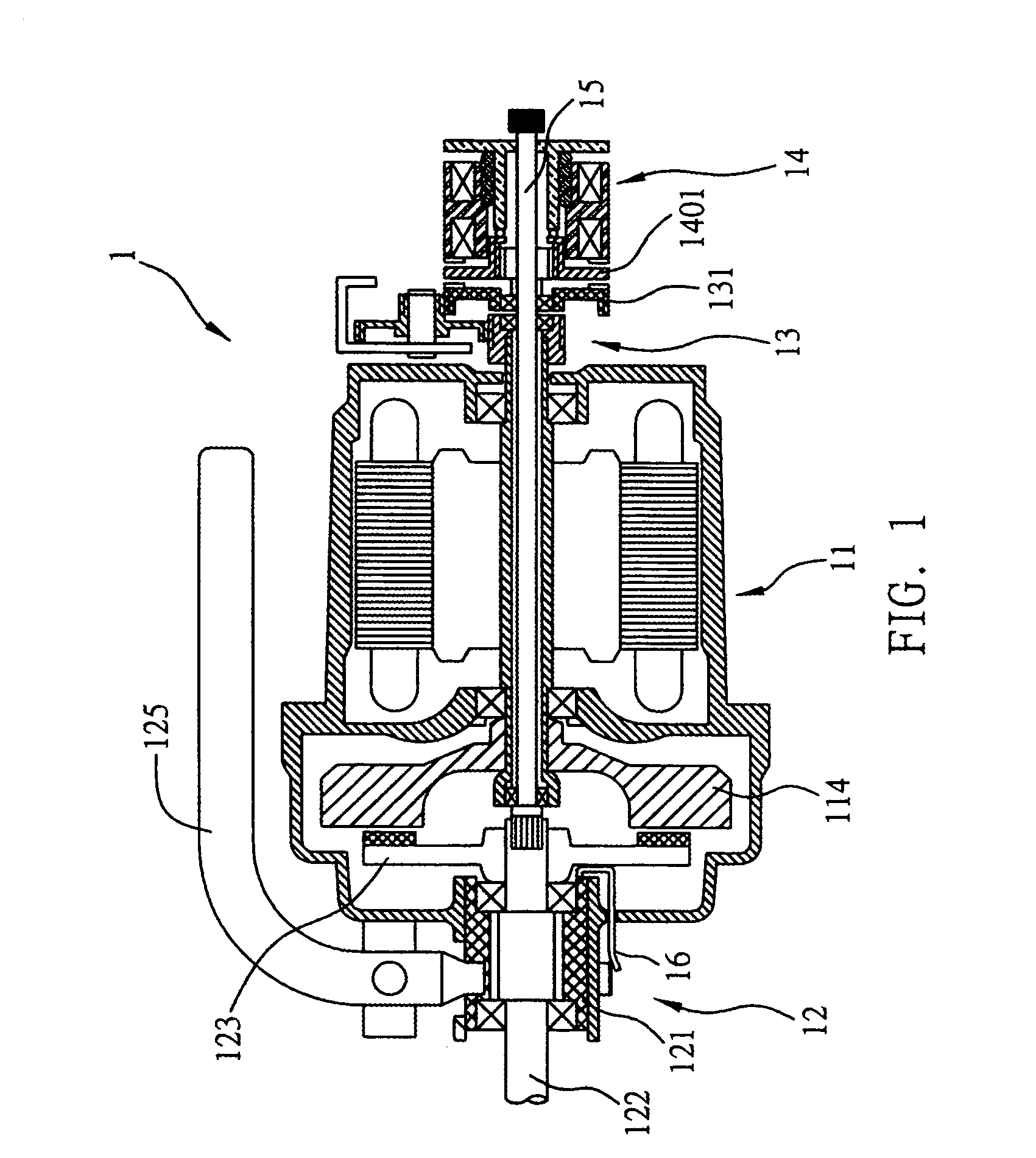

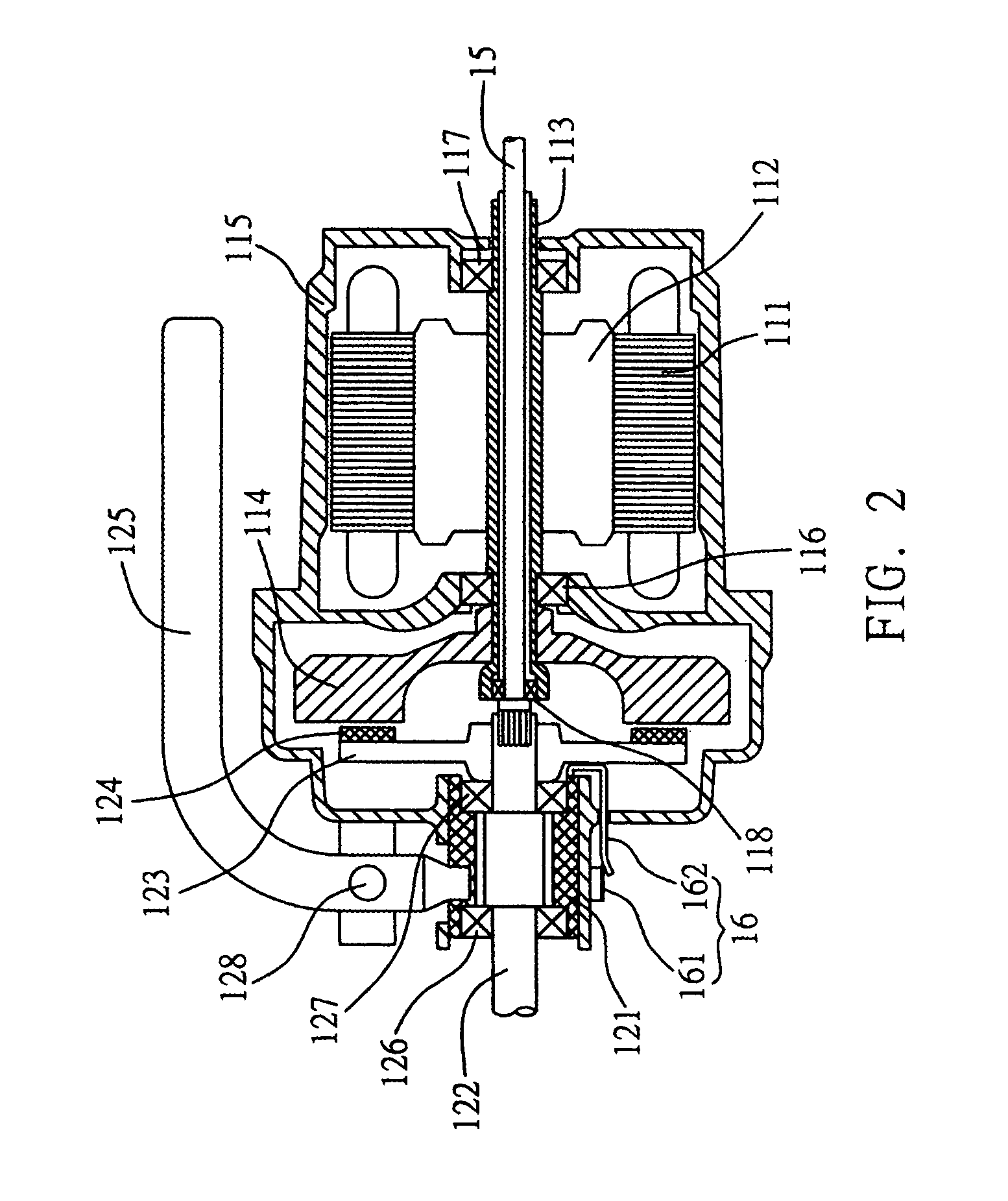

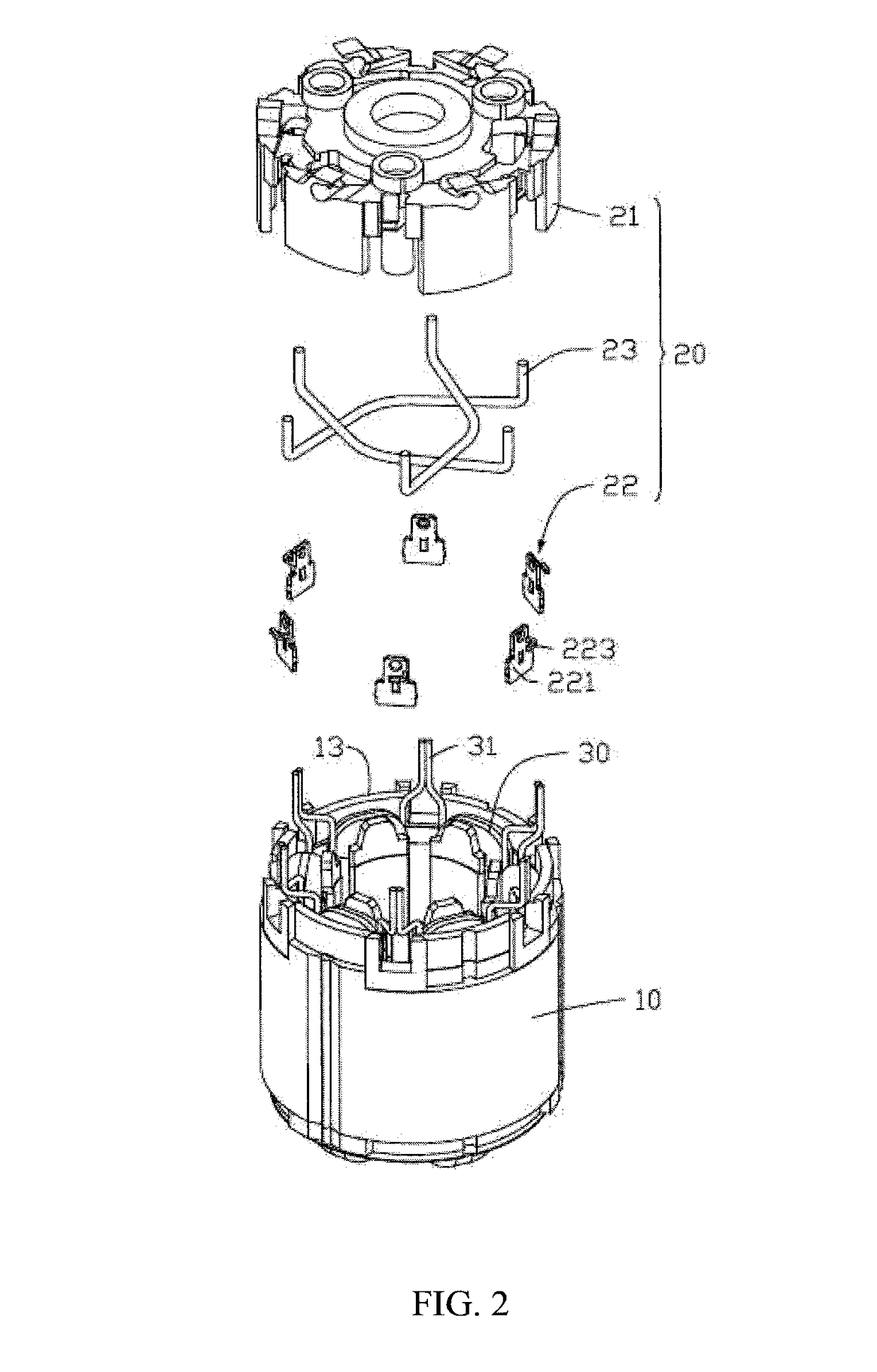

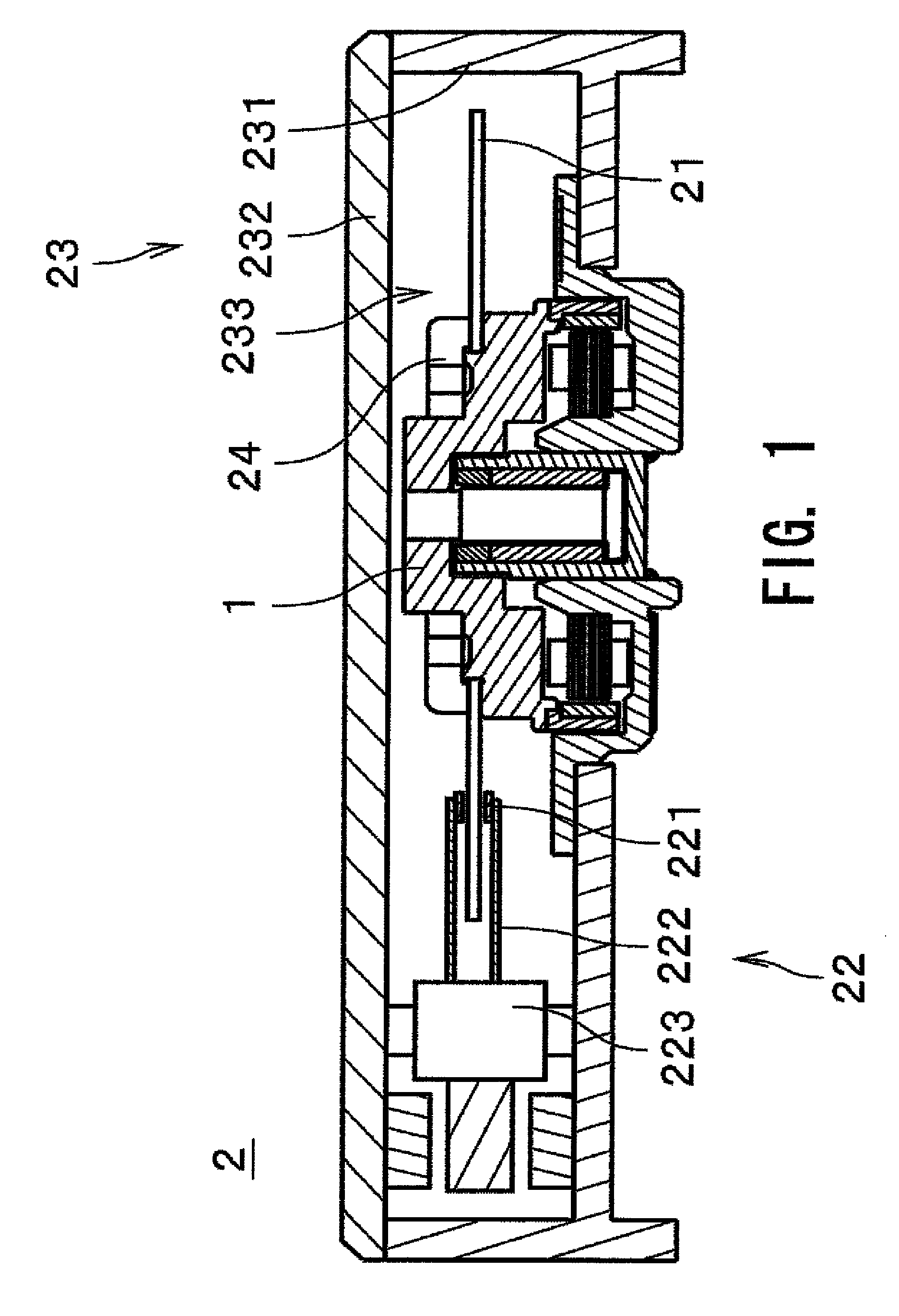

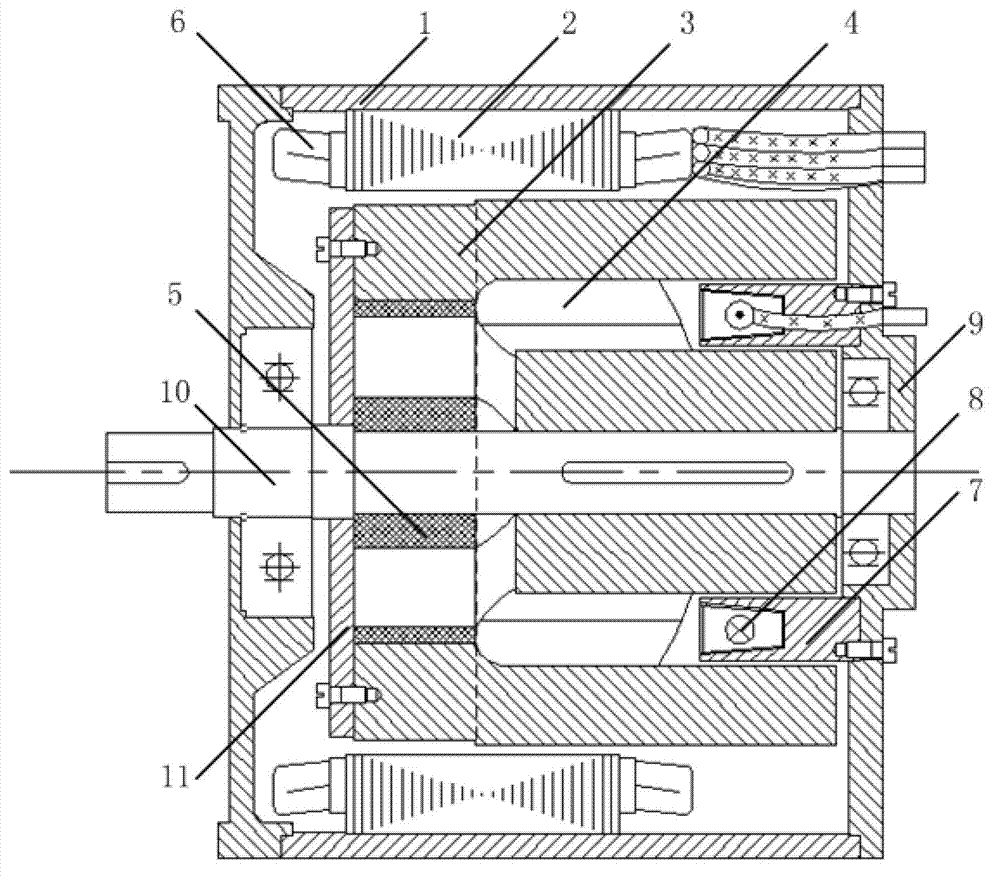

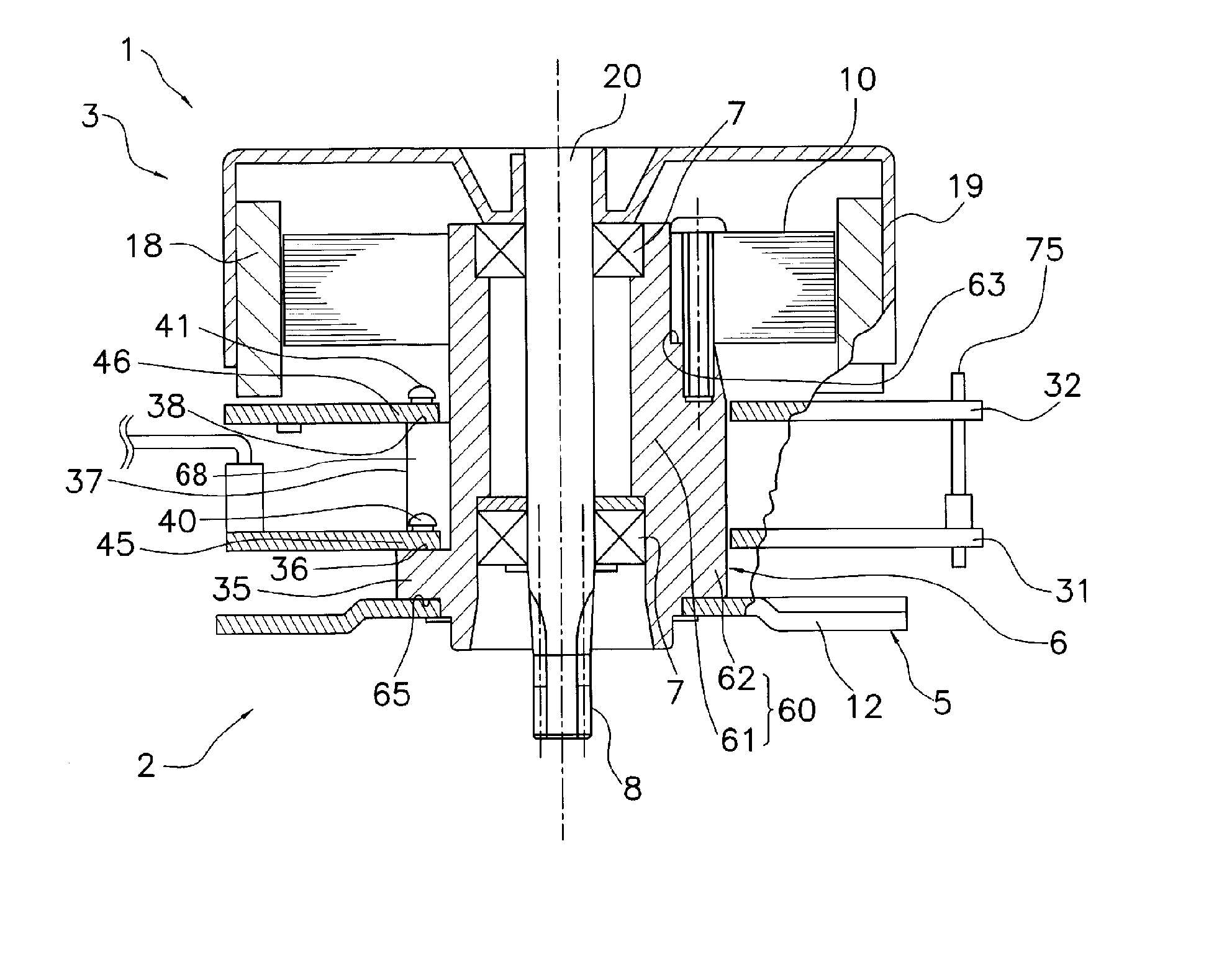

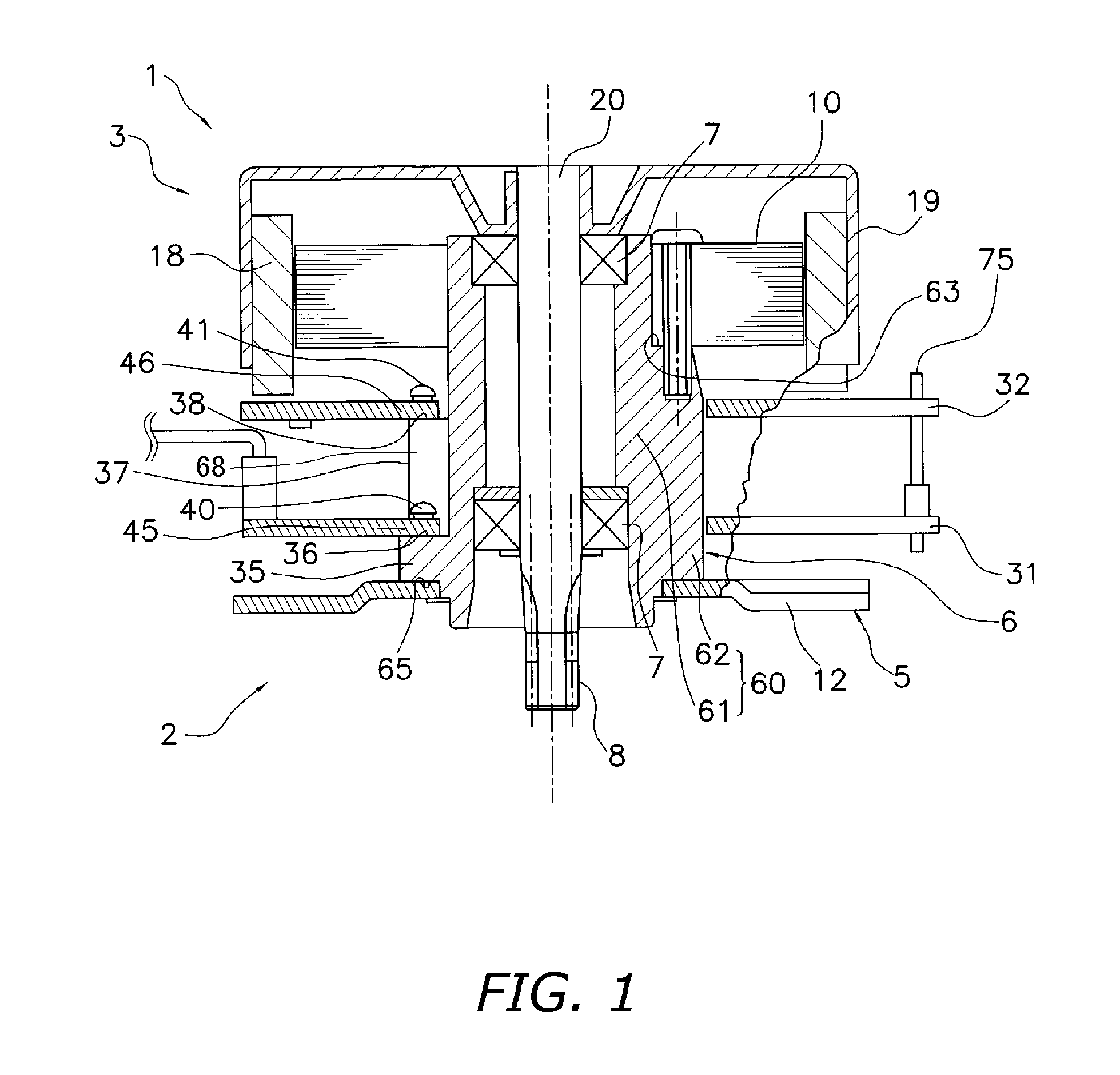

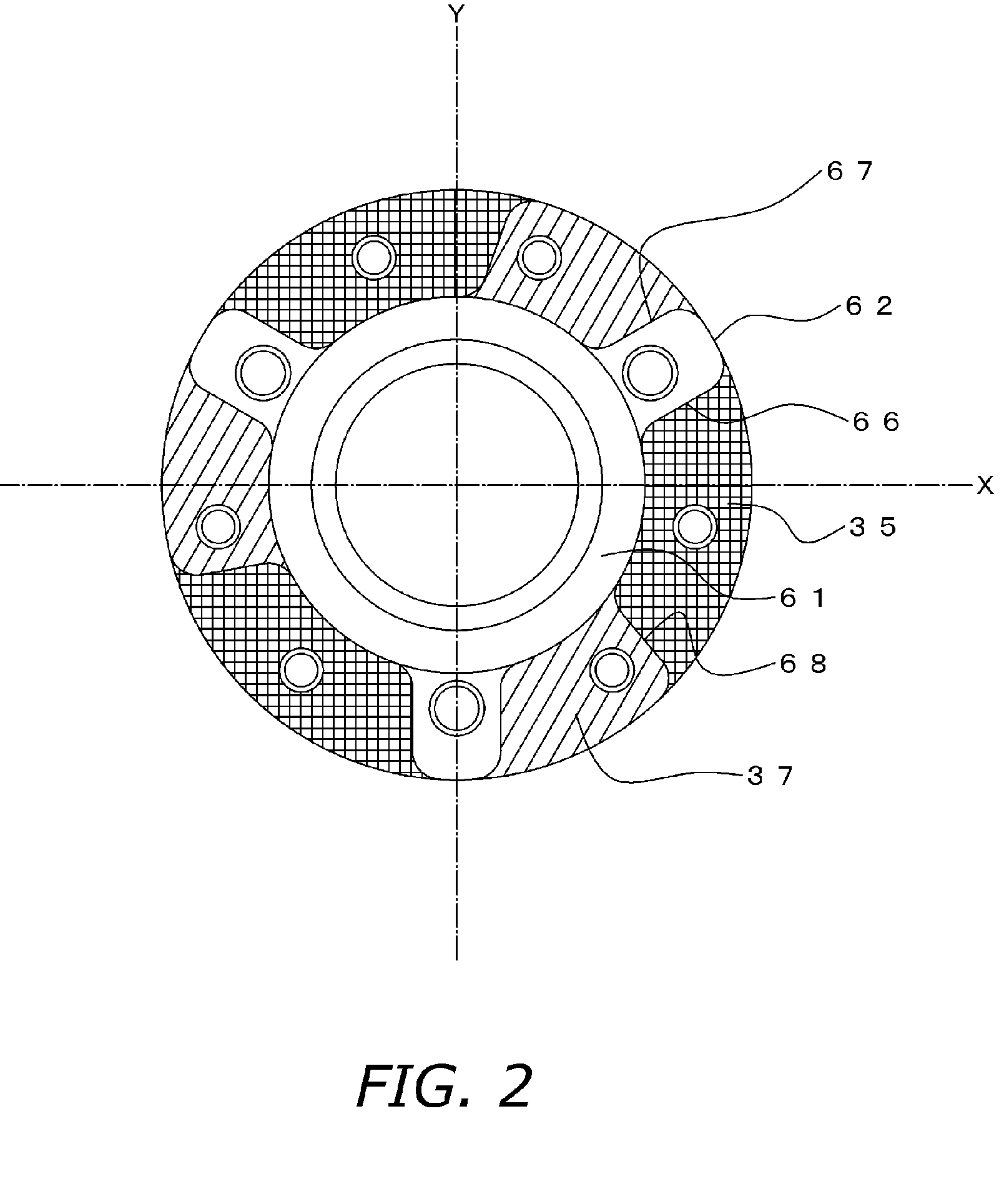

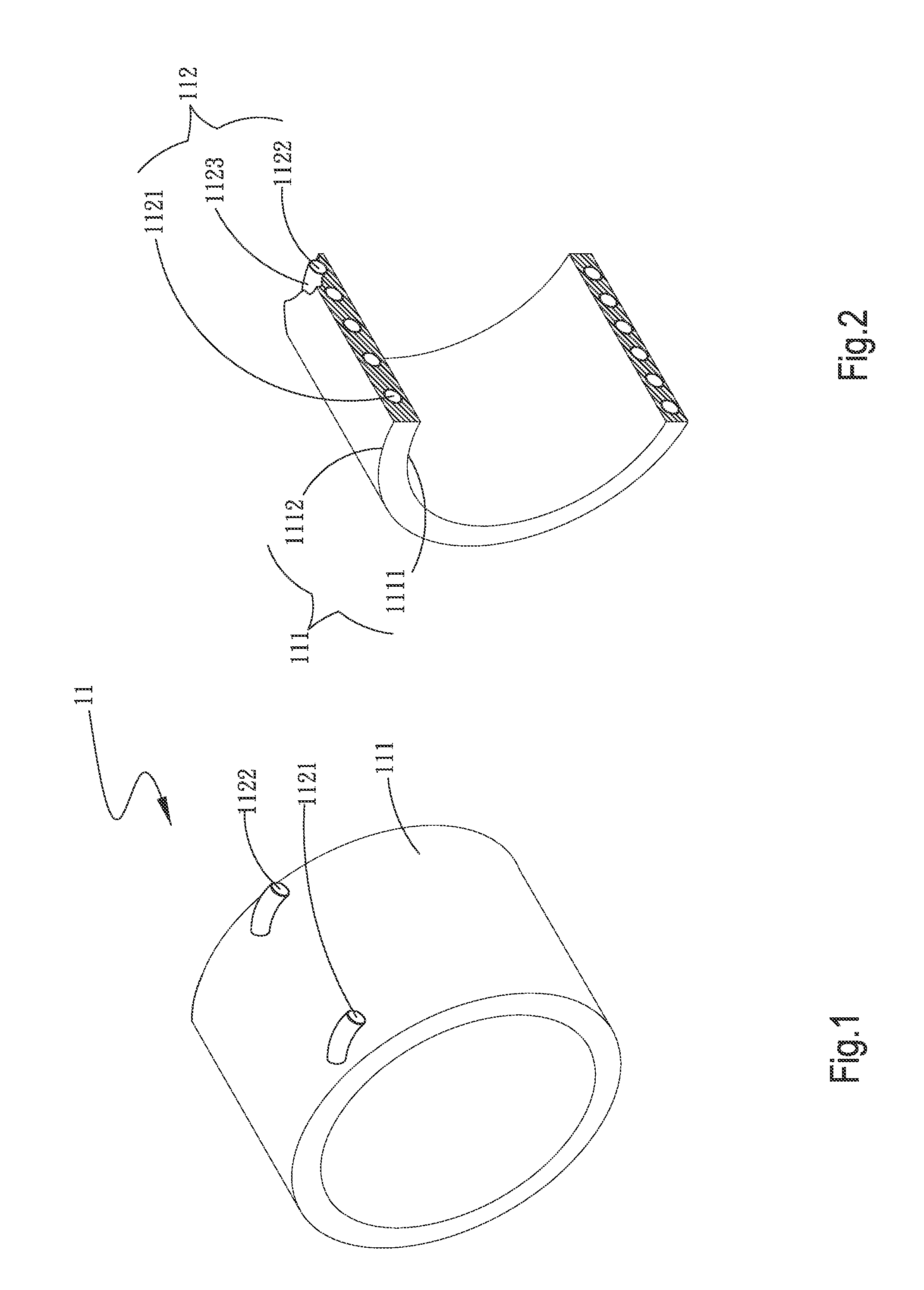

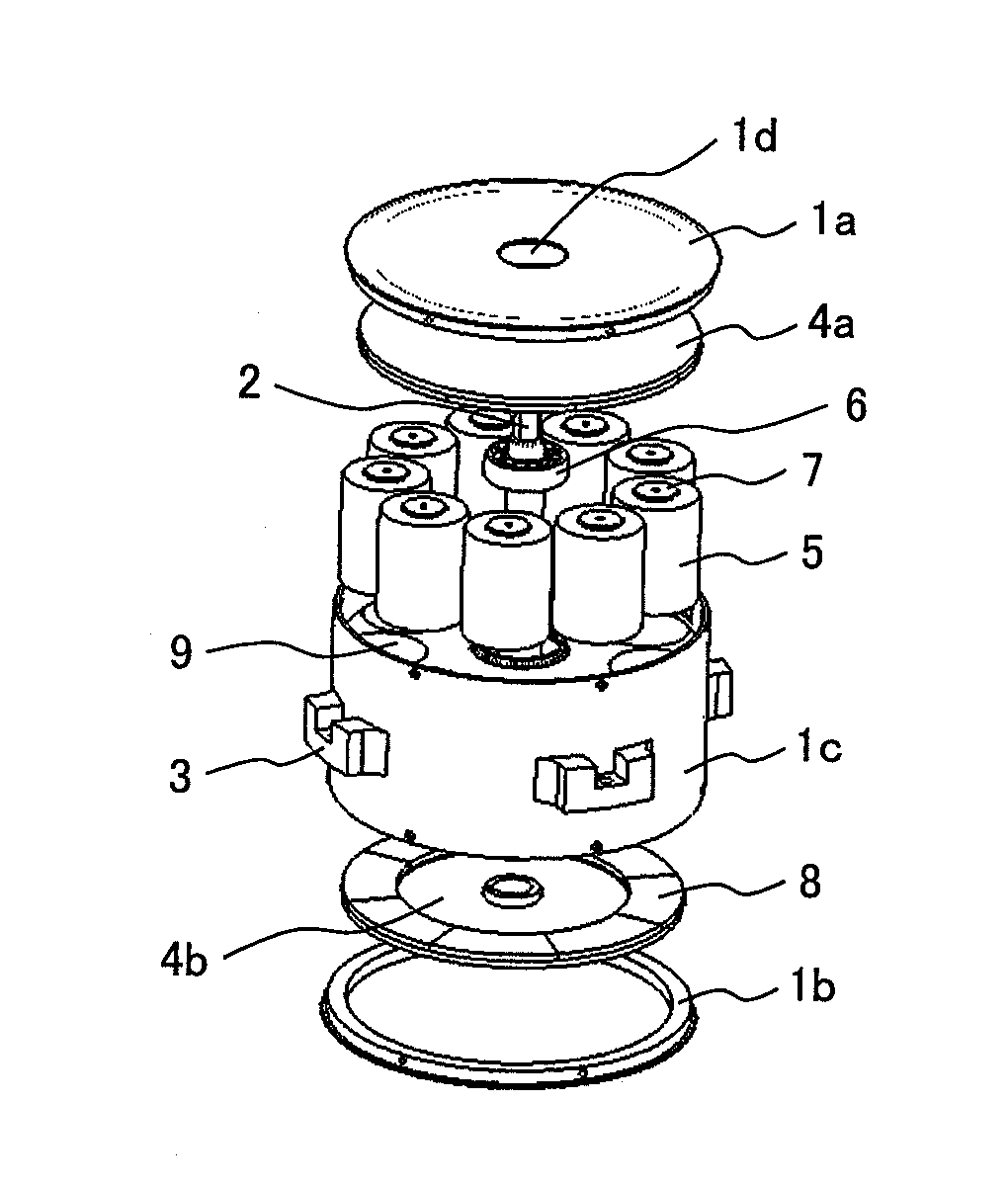

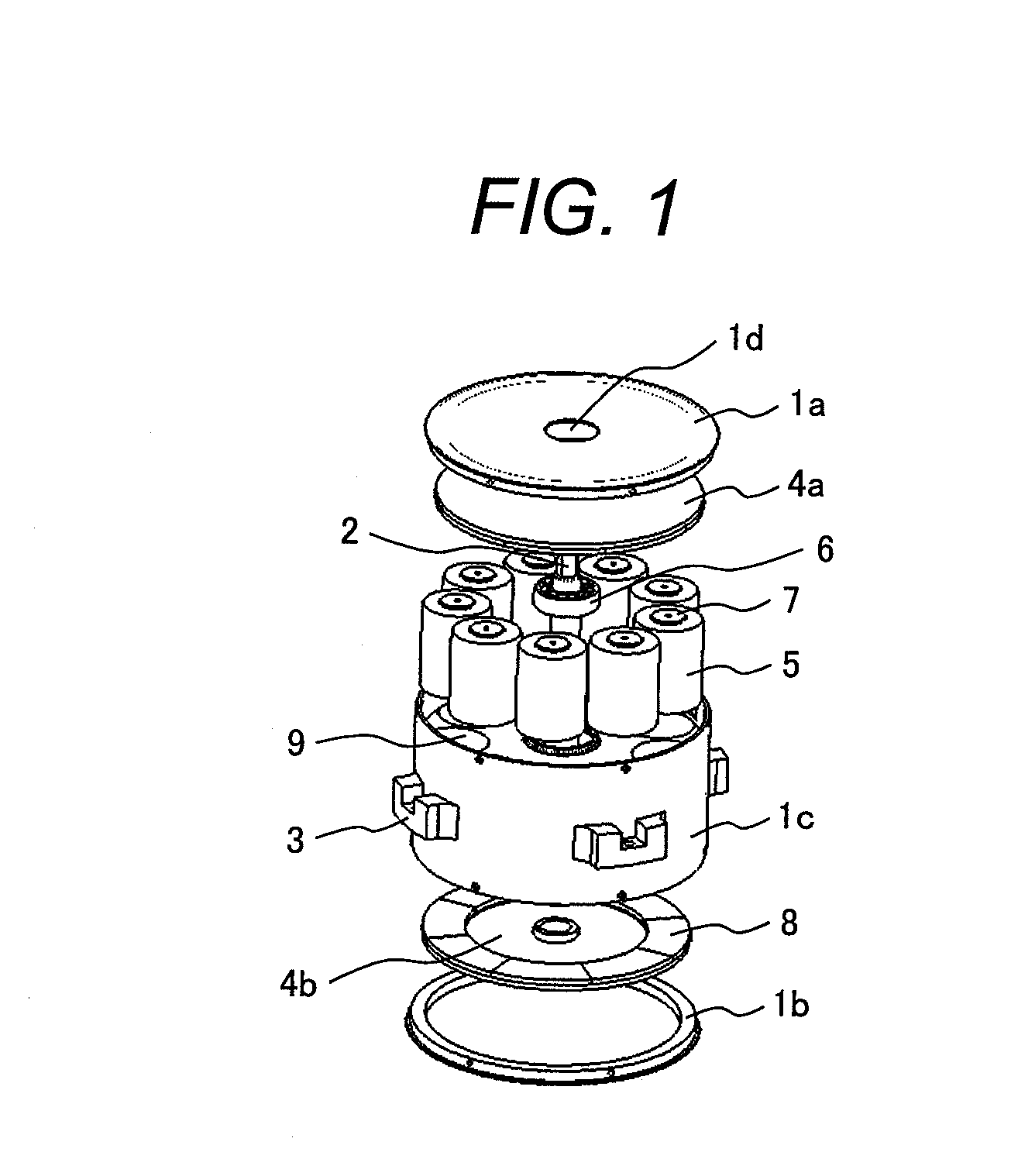

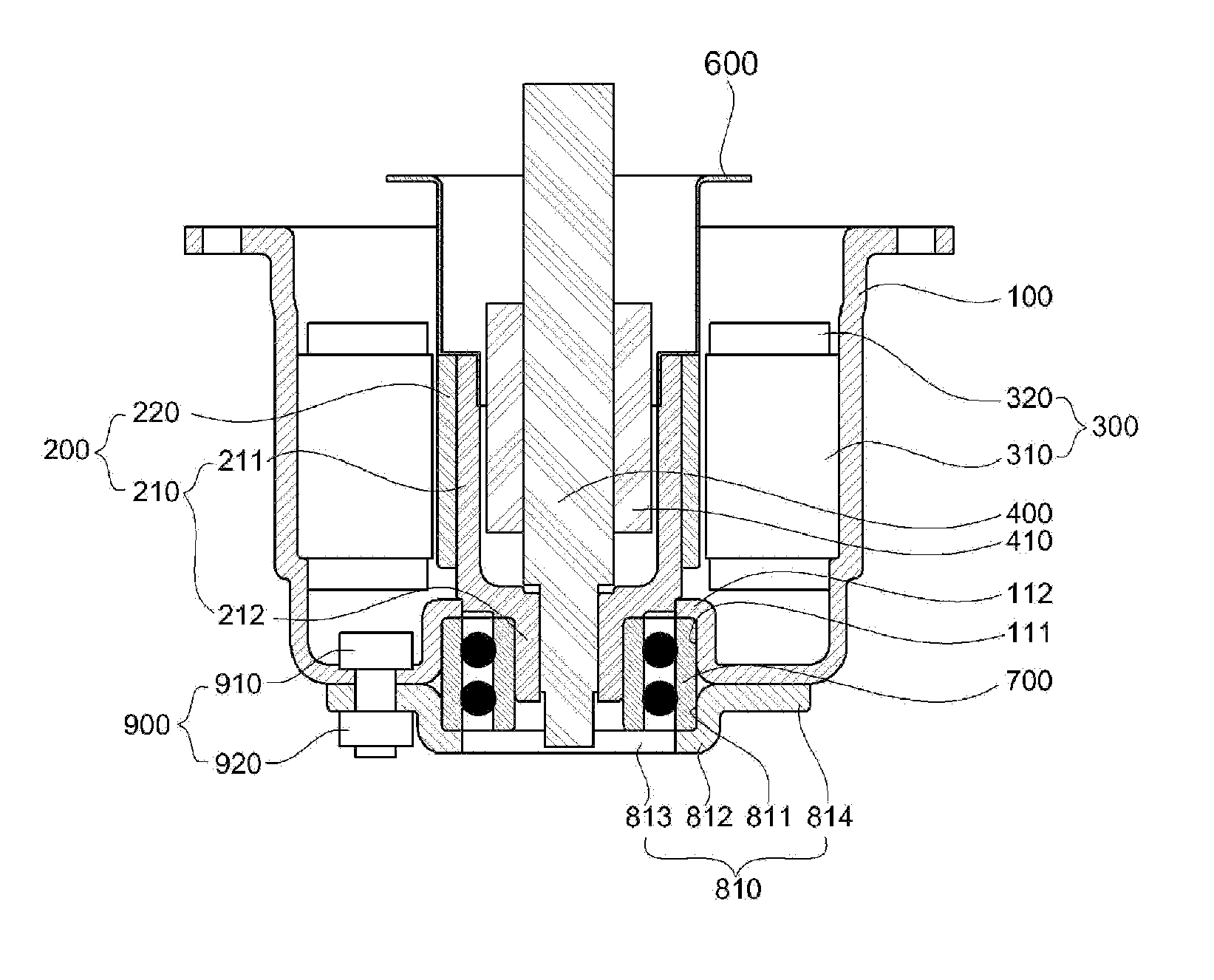

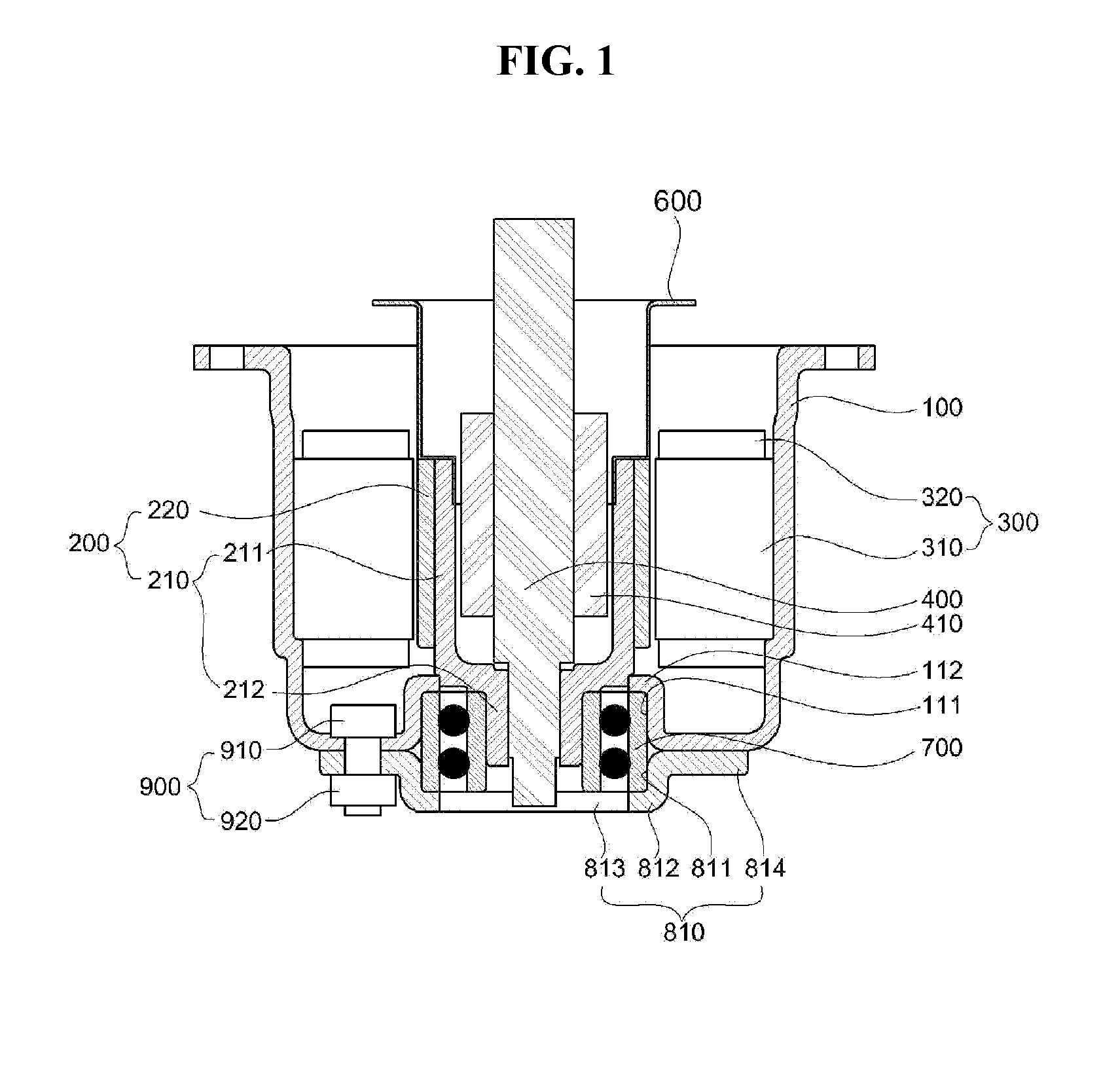

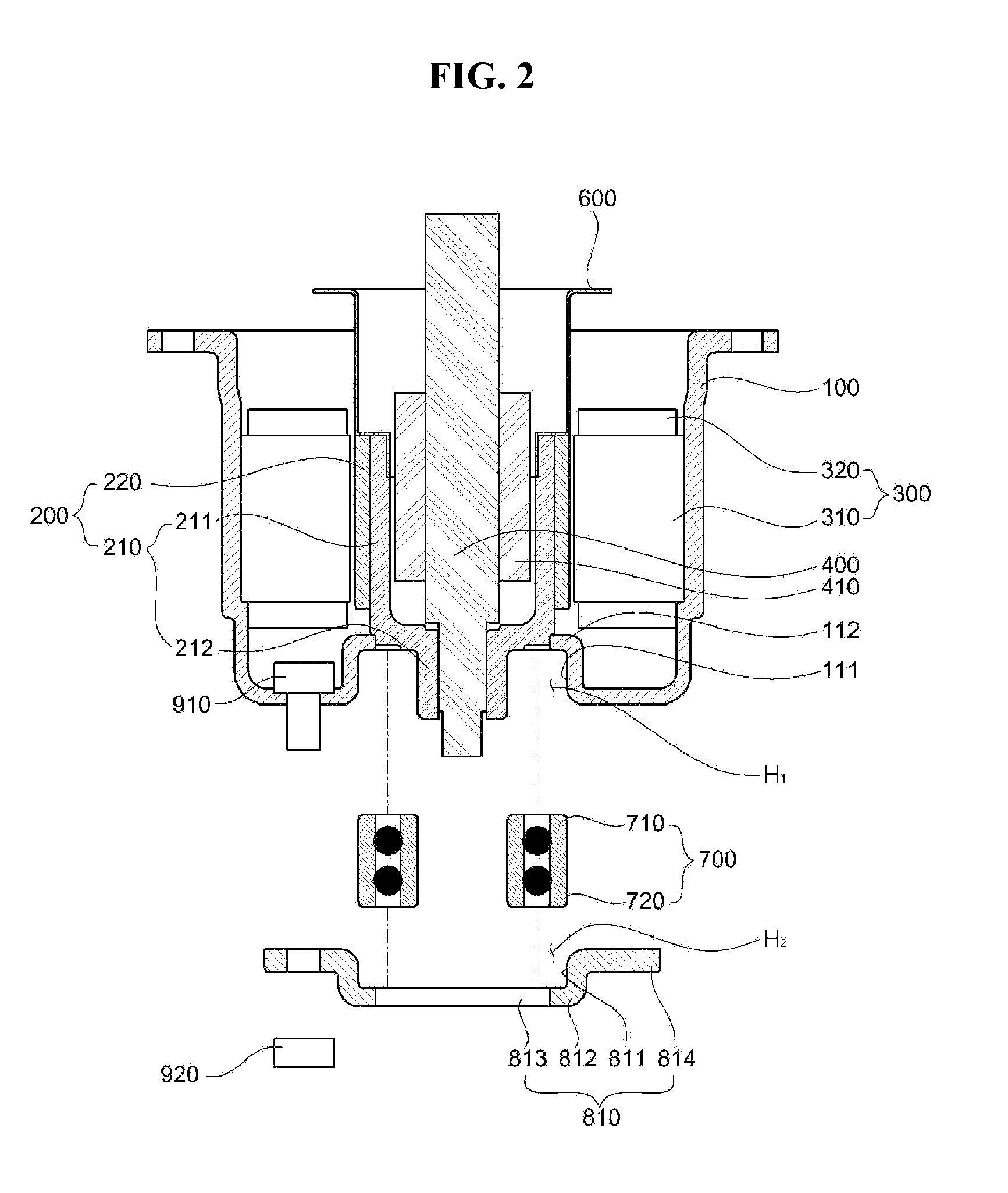

Driving Motor

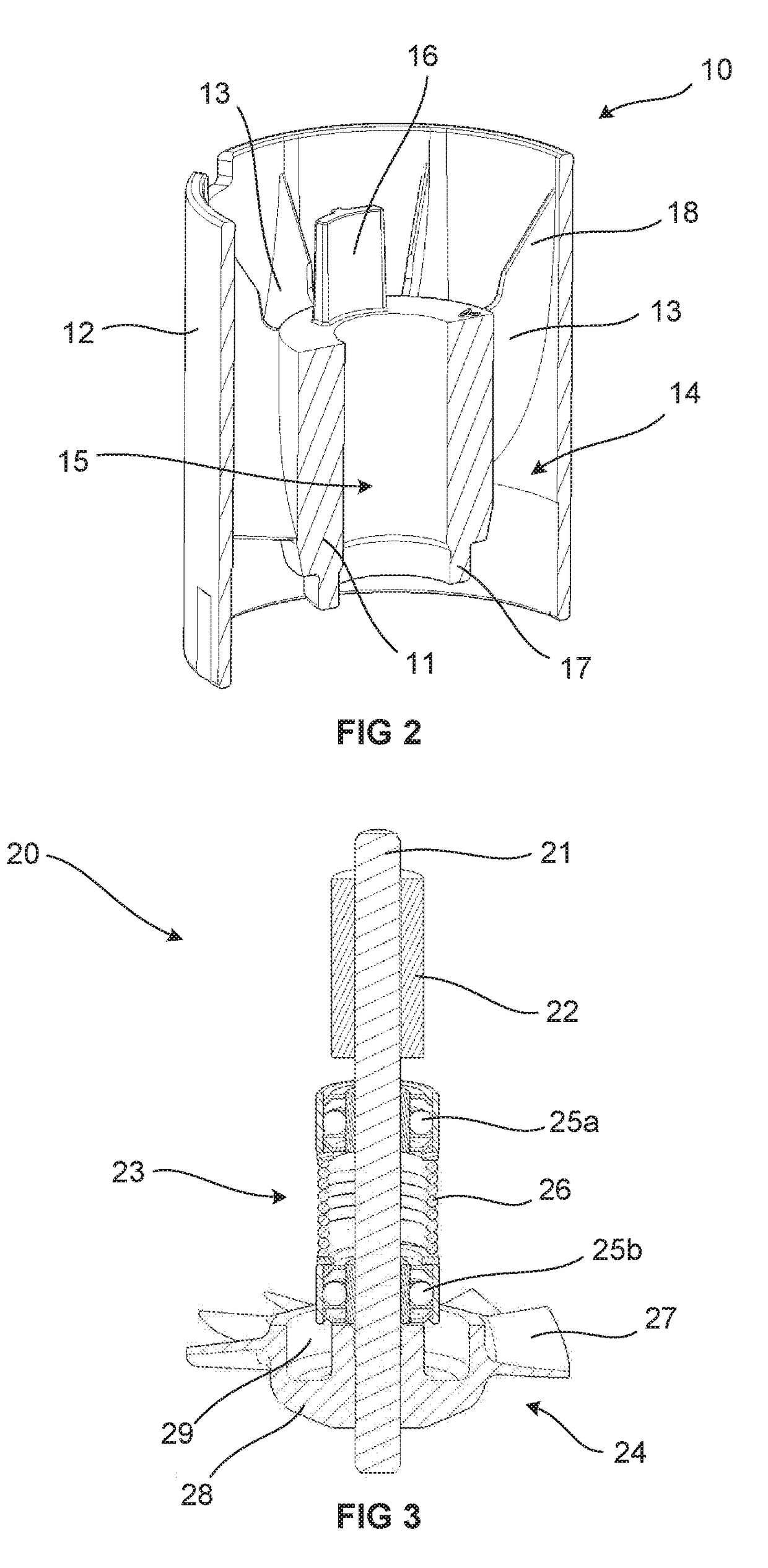

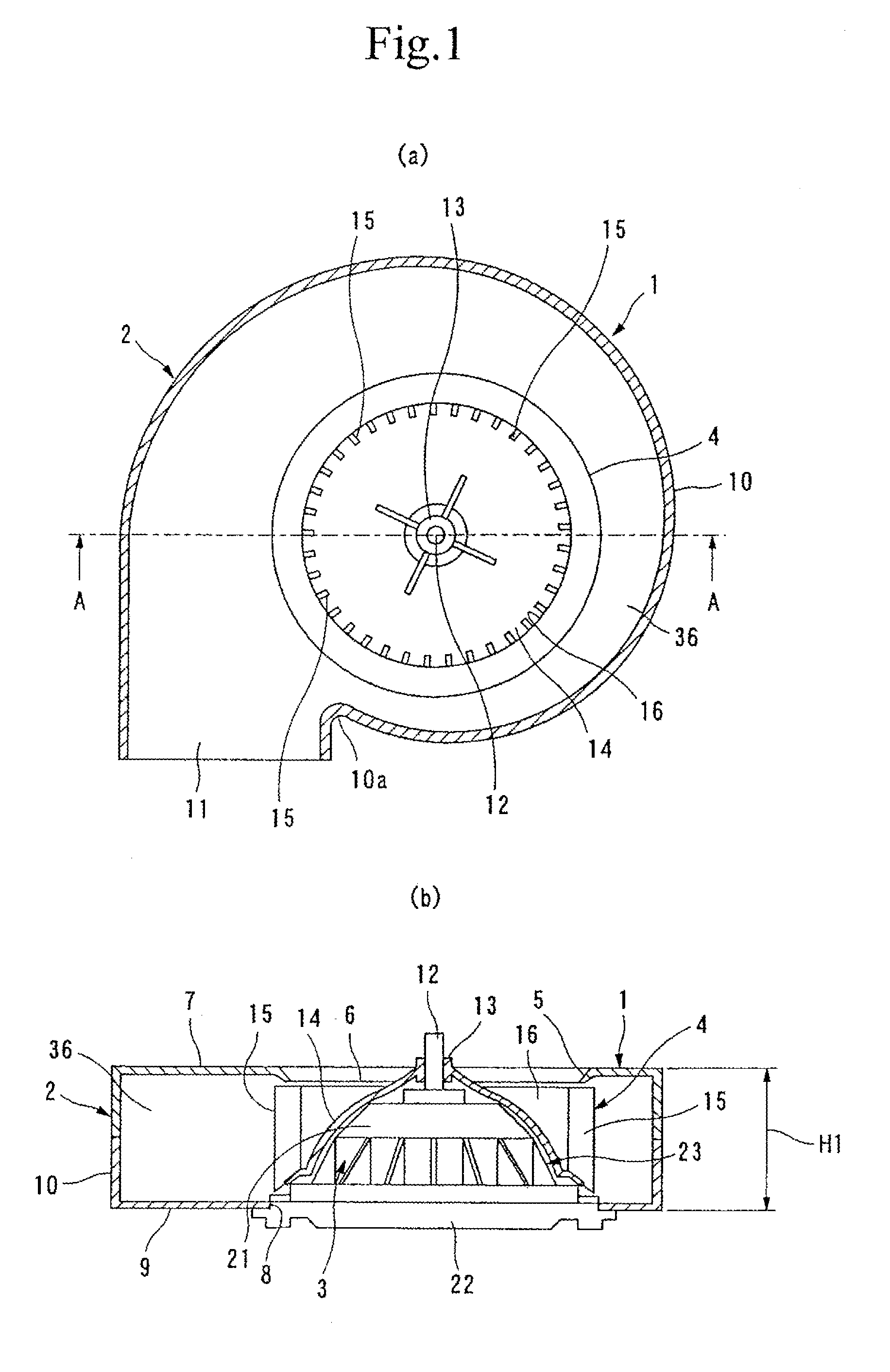

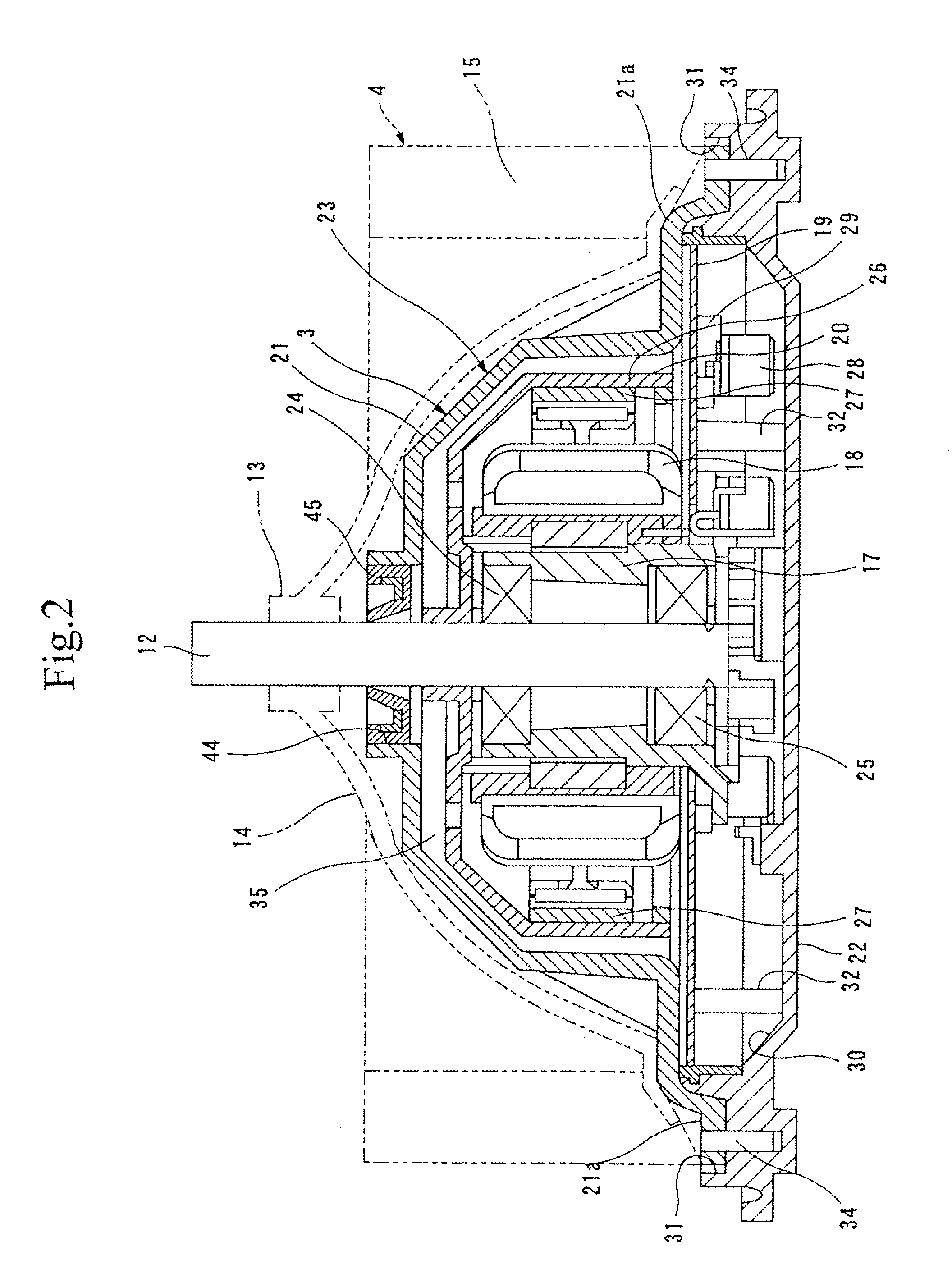

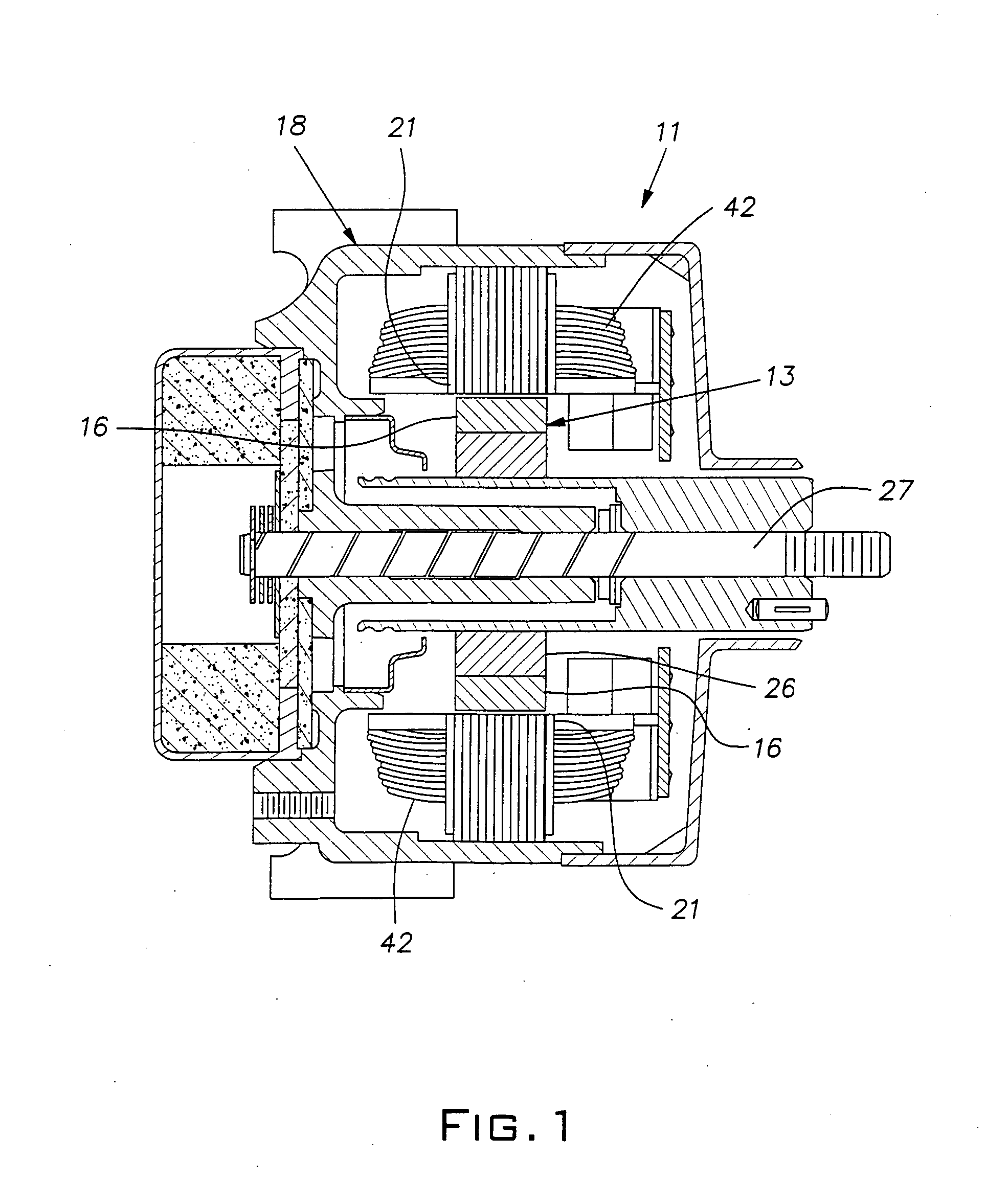

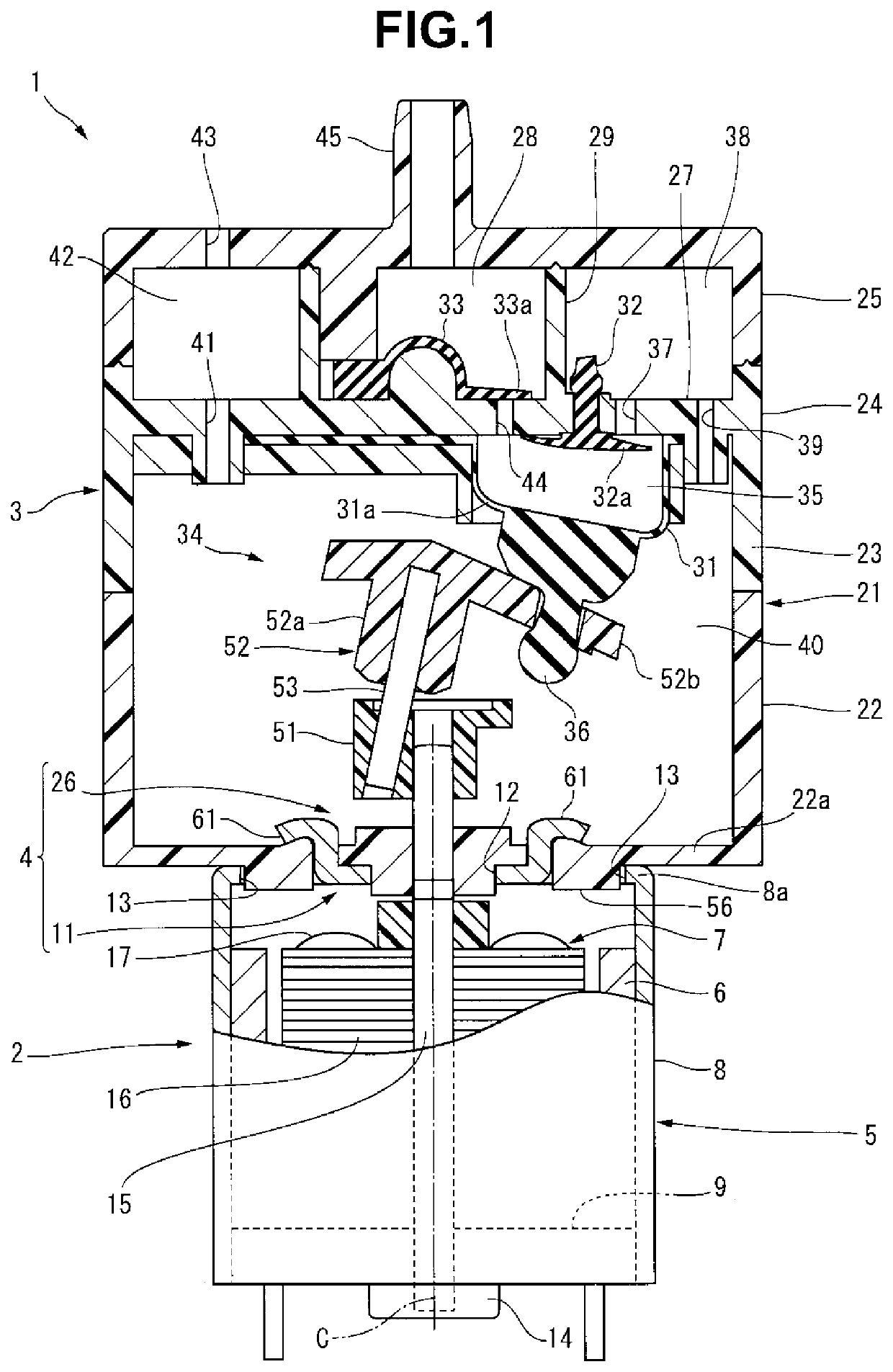

InactiveUS20120074802A1Accelerated dissipationImprove thermal conductivityAssociation with control/drive circuitsMagnetic circuit rotating partsInterior spaceEngineering

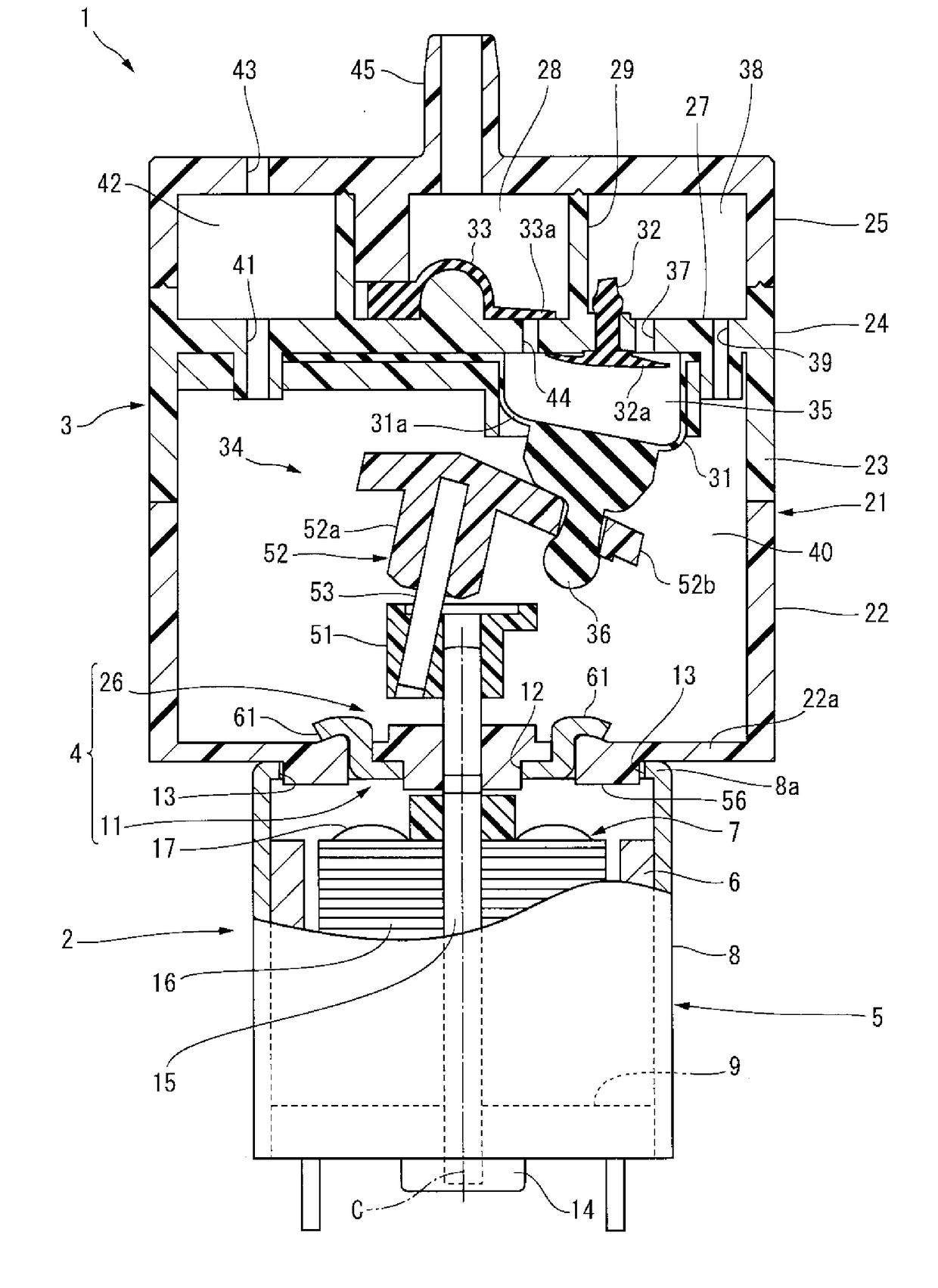

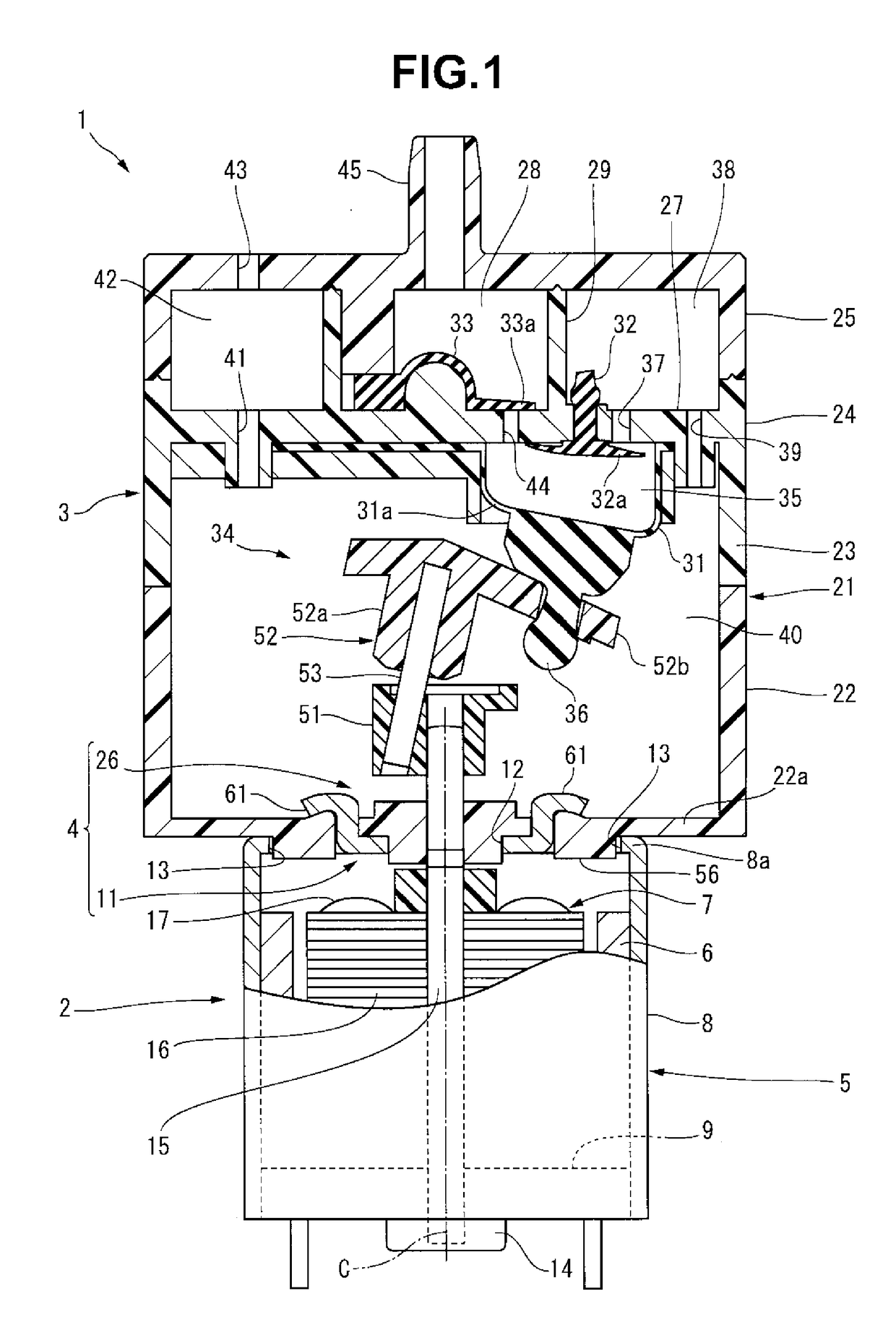

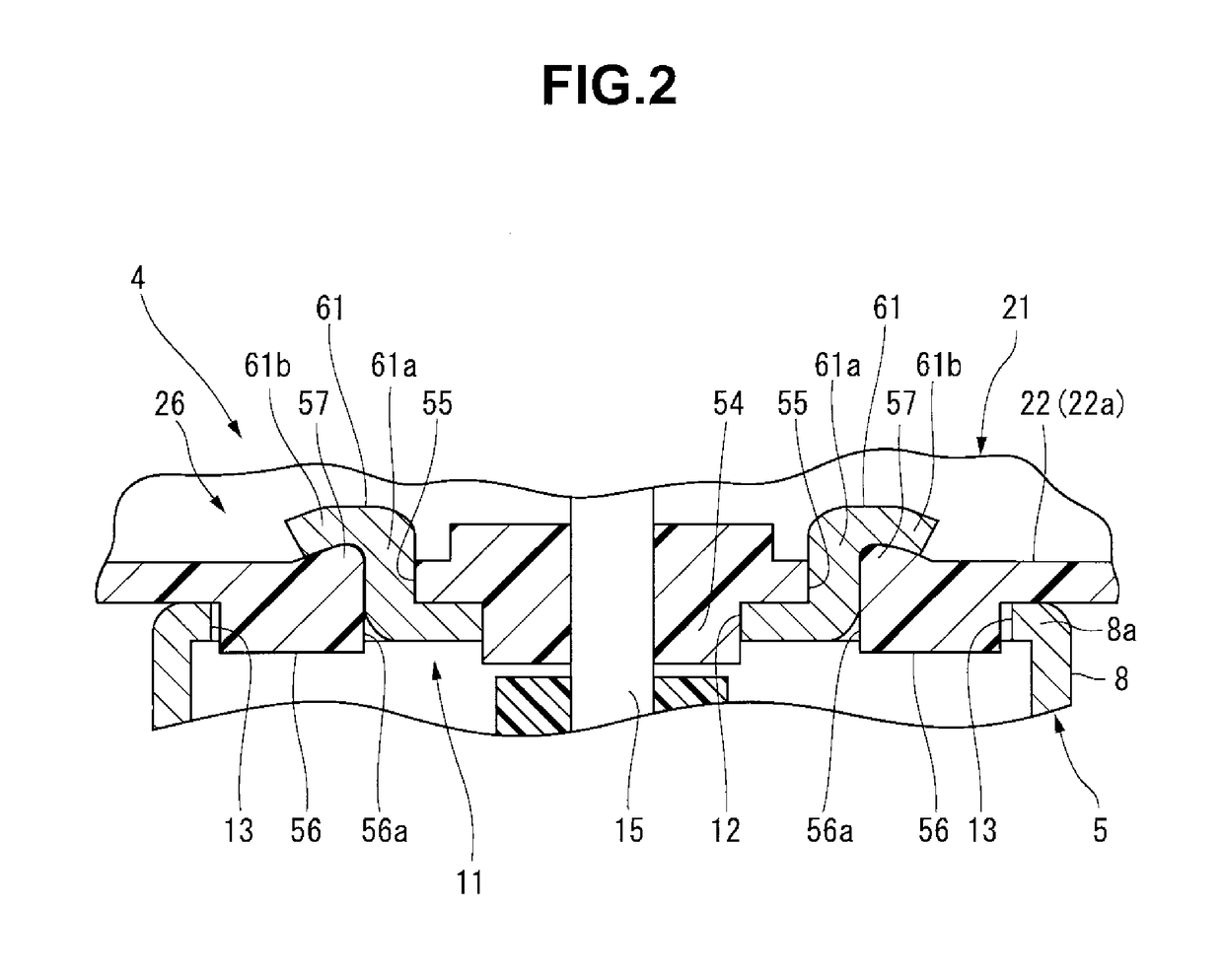

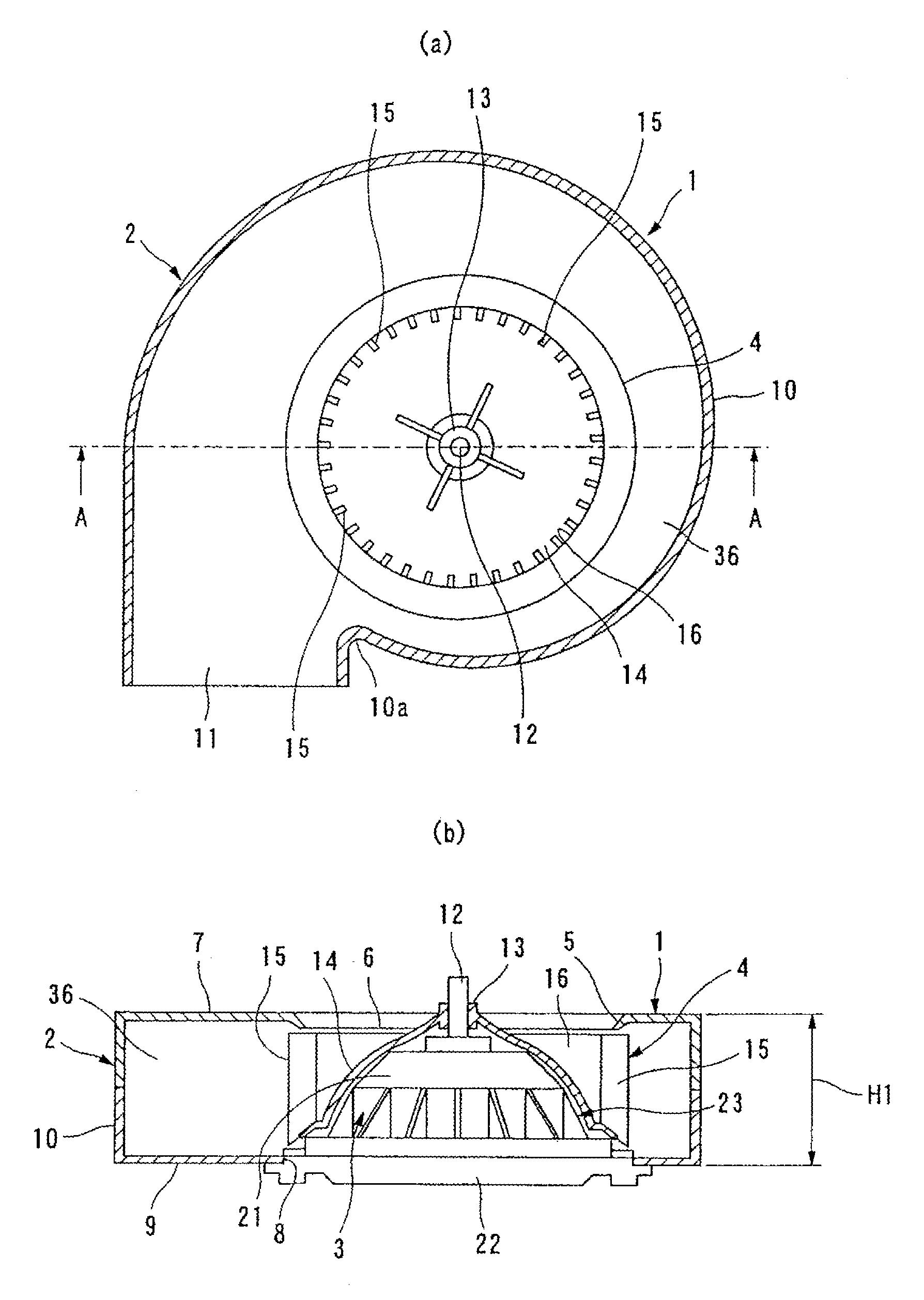

Provided is a driving motor that will meet the requests of making the length of a rotating axis of the driving motor to be shorter in the axial direction, and which will also have waterproof, vibration resistance, and soundproof characteristics. In this driving motor (3); a motor interior-space (35) is formed by a housing (21) that has a first and second opening and which is formed to be cylinder shaped, and a flange (22) that blocks the second opening of this housing (21); and a stator assembly (18), a rotor assembly (20), a lower-side end section of the rotating axis (12) that has been placed lower than the flange (22) up until now, and a control circuit-board (19) are all made to be contained in this motor interior-space (35). Furthermore, a ring-shaped elastic member (45) is made to interpose between the upper-side end section of the rotating axis (12) and the first opening of the housing (21); and the lower-side end section of the rotating axis (12), the stator assembly (18), and the rotor assembly (20) are made to be fixed to the flange (22) through a mounting elastic member (59).

Owner:VALEO JAPAN CO LTD

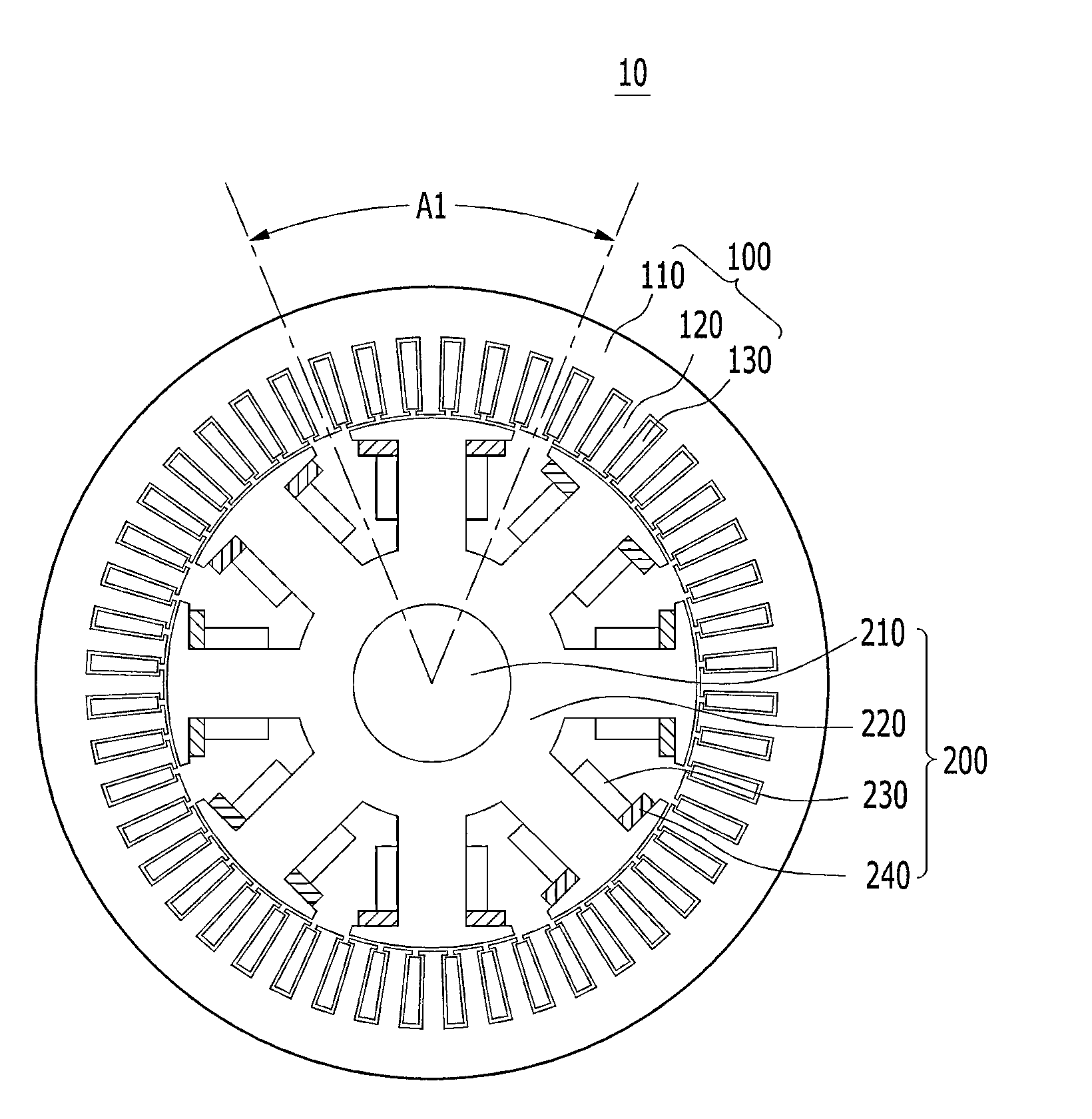

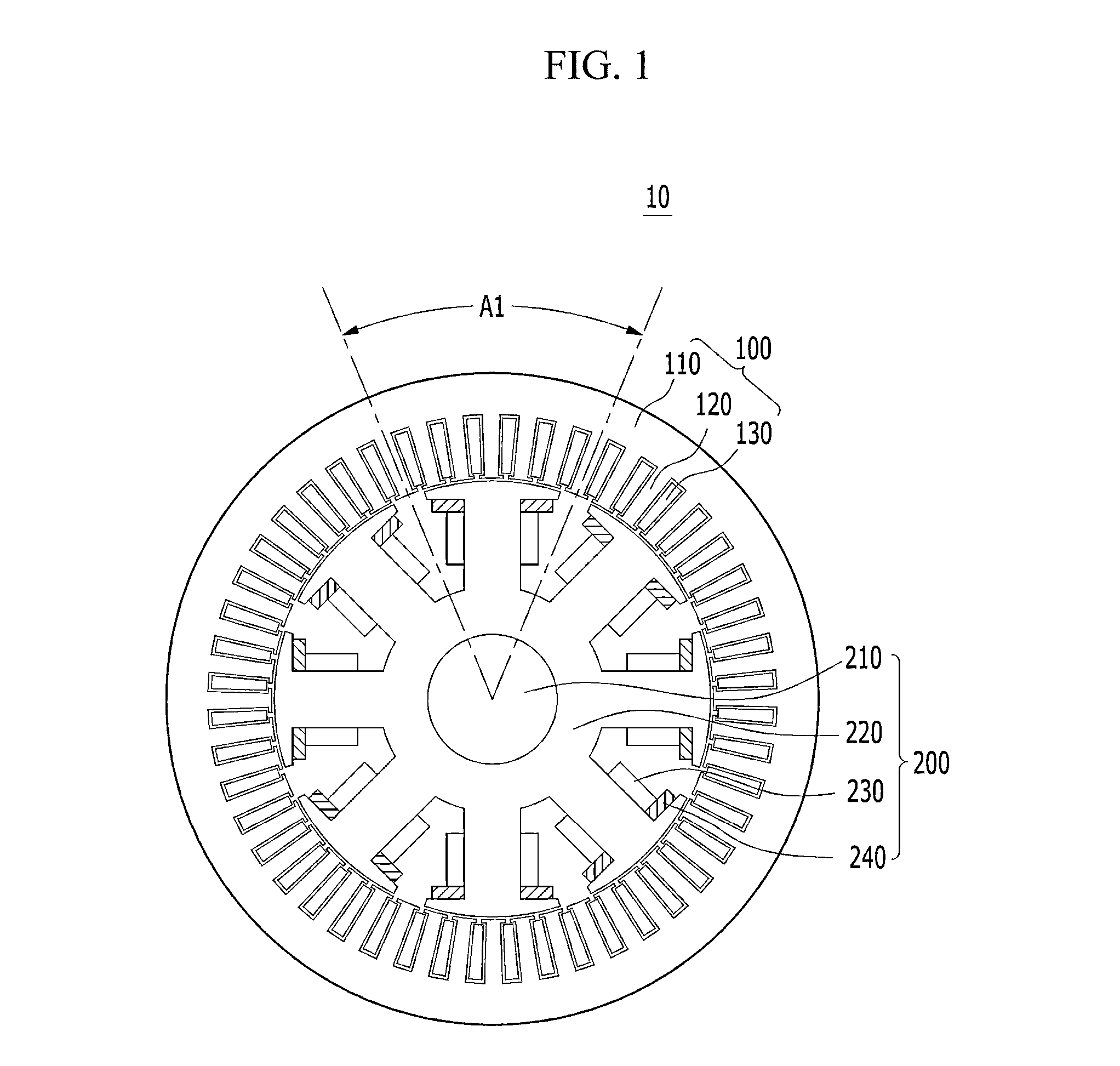

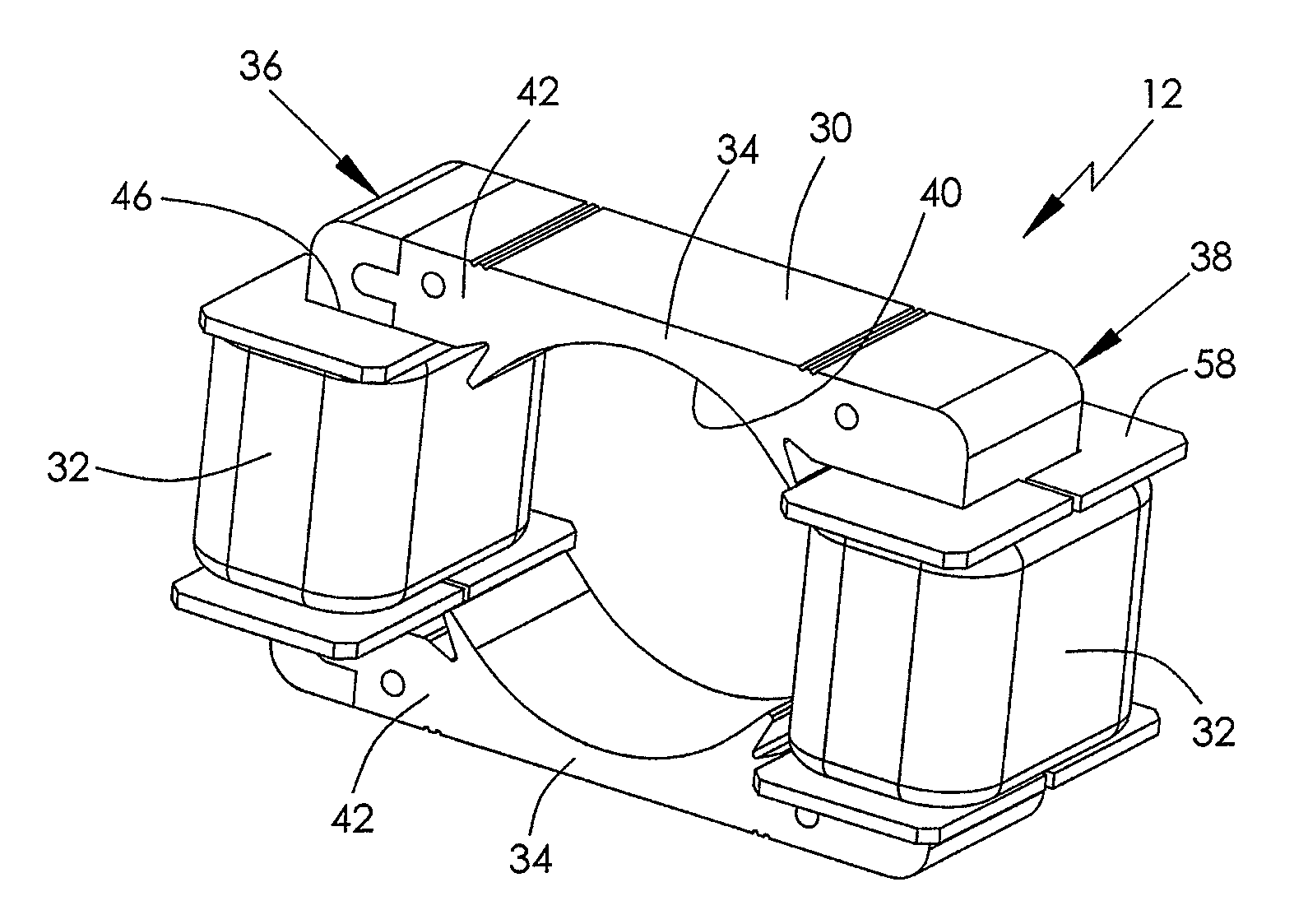

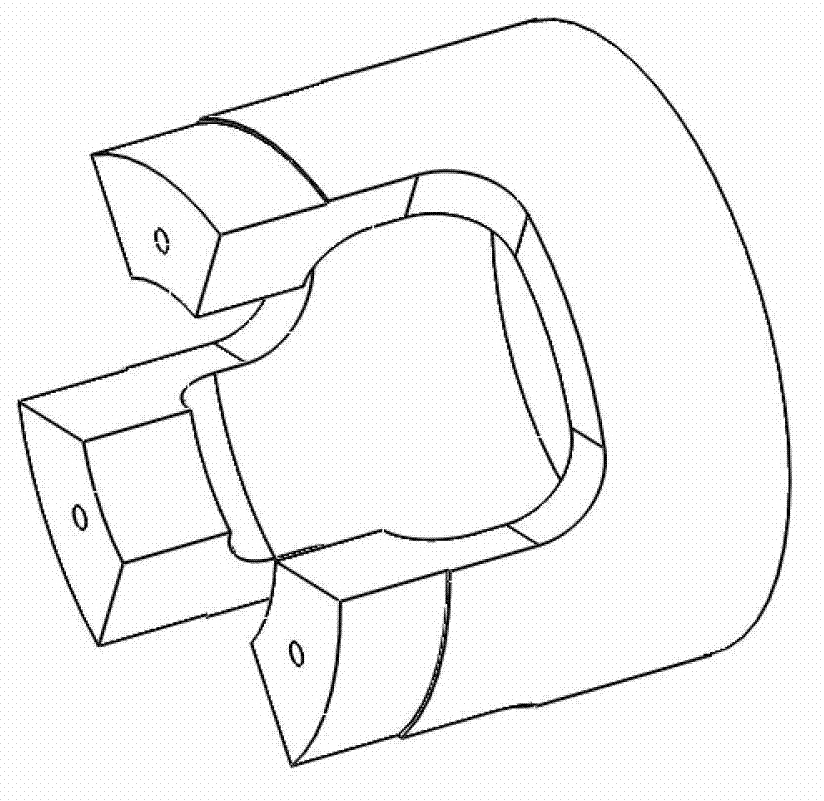

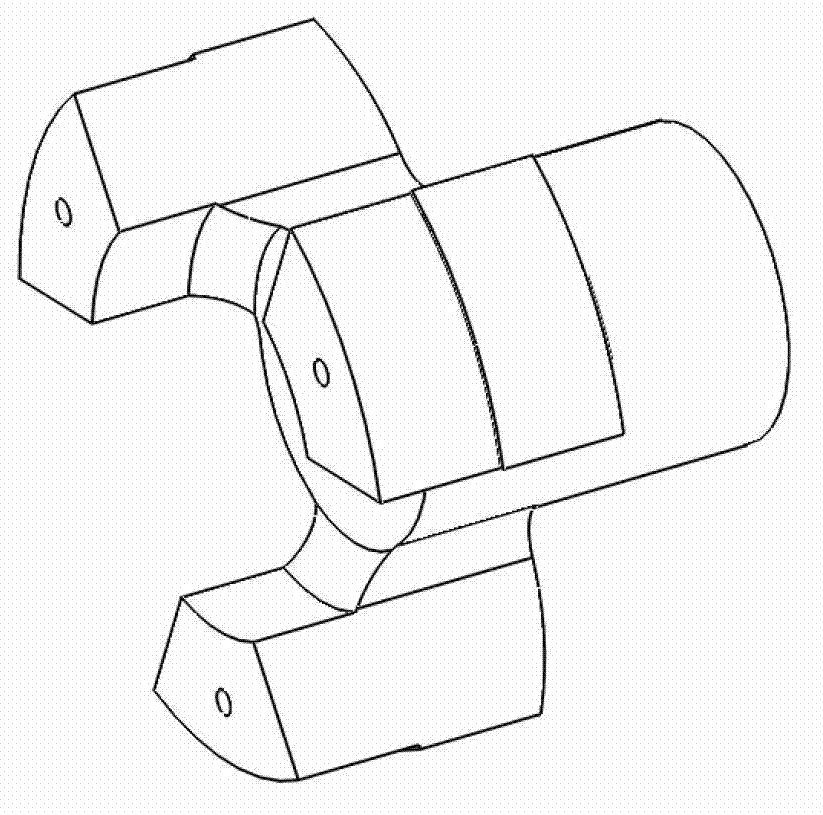

Rotor of motor and synchronous motor having the same and wound rotor synchronous motor

InactiveUS20140077654A1Reduce motor costImprove energy efficiencySynchronous generatorsWindingsSynchronous motorCentre of rotation

Disclosed is a rotor for a motor in a vehicle. More specifically, the rotor includes a rotation shaft serving as a center of rotation of the rotor, a core installed at the rotation shaft and comprising a plurality of teeth radially protruding with respect to the rotation shaft, a coil wound around the tooth to generate a magnetic field by an external power source, and a pair of permanent magnets installed at both sides of the teeth. Also disclosed is a synchronous motor including the rotor, and a wound rotor synchronous motor.

Owner:HYUNDAI MOTOR CO LTD

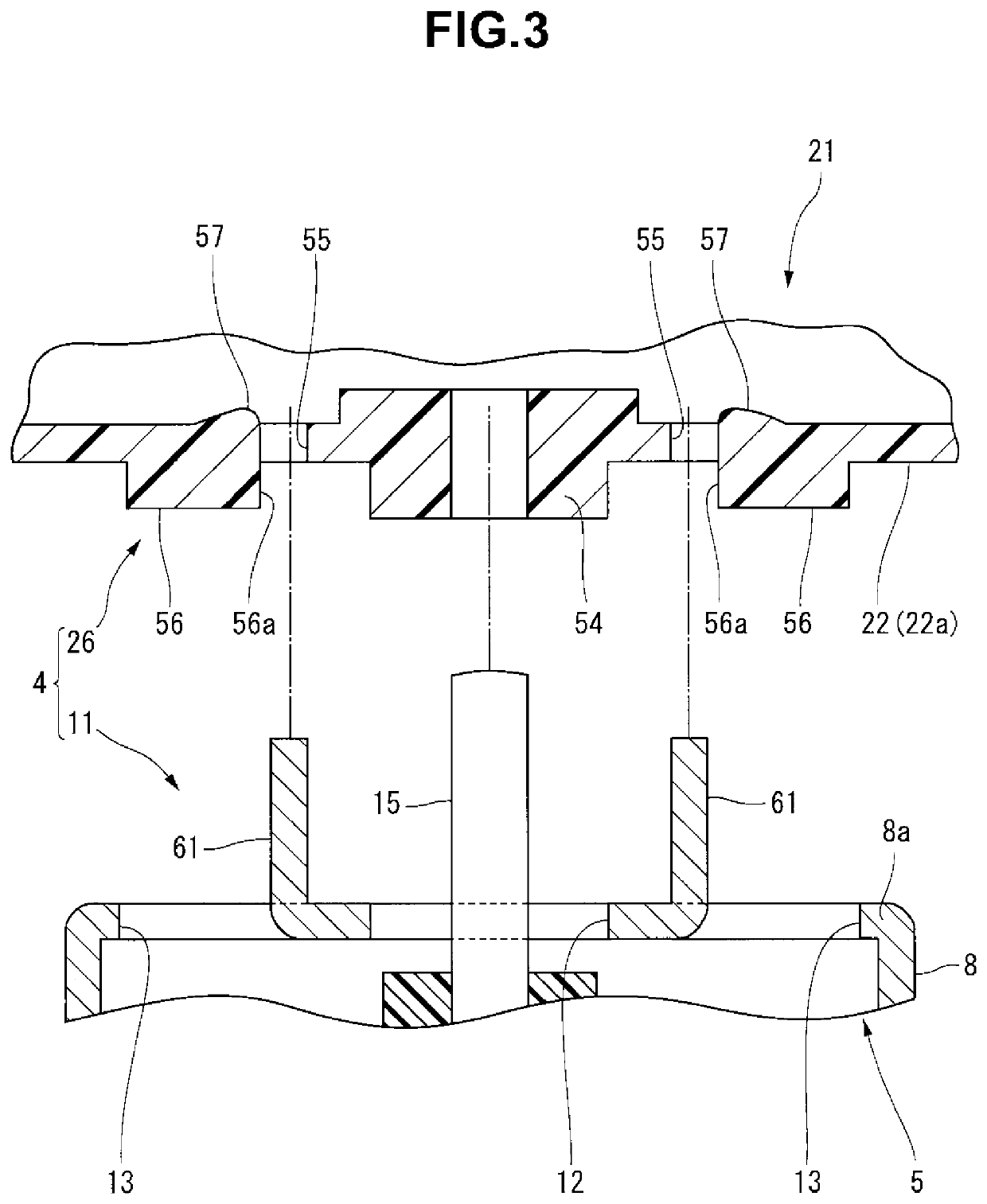

Motor water-cooling structure and manufacturing method thereof

InactiveUS20120186797A1Reduce materialReduce laborManufacturing dynamo-electric machinesCooling/ventillation arrangementWater leakageEngineering

A motor water-cooling structure and a manufacturing method thereof are disclosed. The motor water-cooling structure includes a motor case having a wall portion and a tube. The tube is embedded in the wall portion to serve as a flow passage. To manufacture the motor water-cooling structure, the tube is positioned in a mold cavity of a mold, and the motor case is formed in the mold by pour molding to embed the tube therein, so that the motor case and the tube form an integral body. With the manufacturing method, the motor water-cooling structure can be formed with reduced material, labor and time to save the manufacturing costs, and the risk of water leakage can be avoided.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Motor water-cooling structure and manufacturing method thereof

A method for assembling a heat-dissipating module includes a step of mechanically pressing one time or multiple times a heat pipe into a trough of a metallic base, whereby at least one end of the heat pipe can be pressed into the trough of the metallic base and thus firmly combined with the metallic base. In this way, the time and the cost for assembly are reduced, and the yield is increased.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

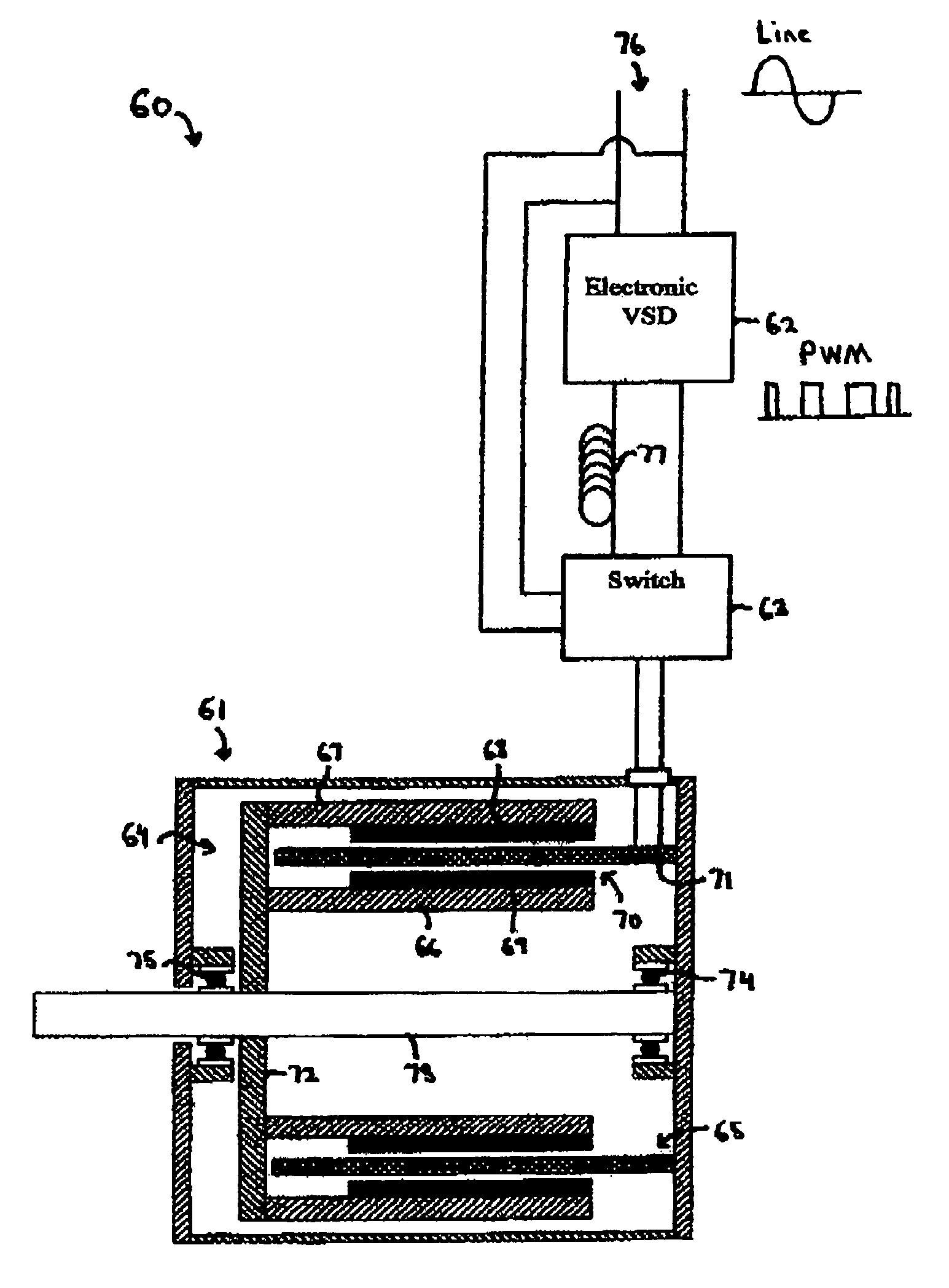

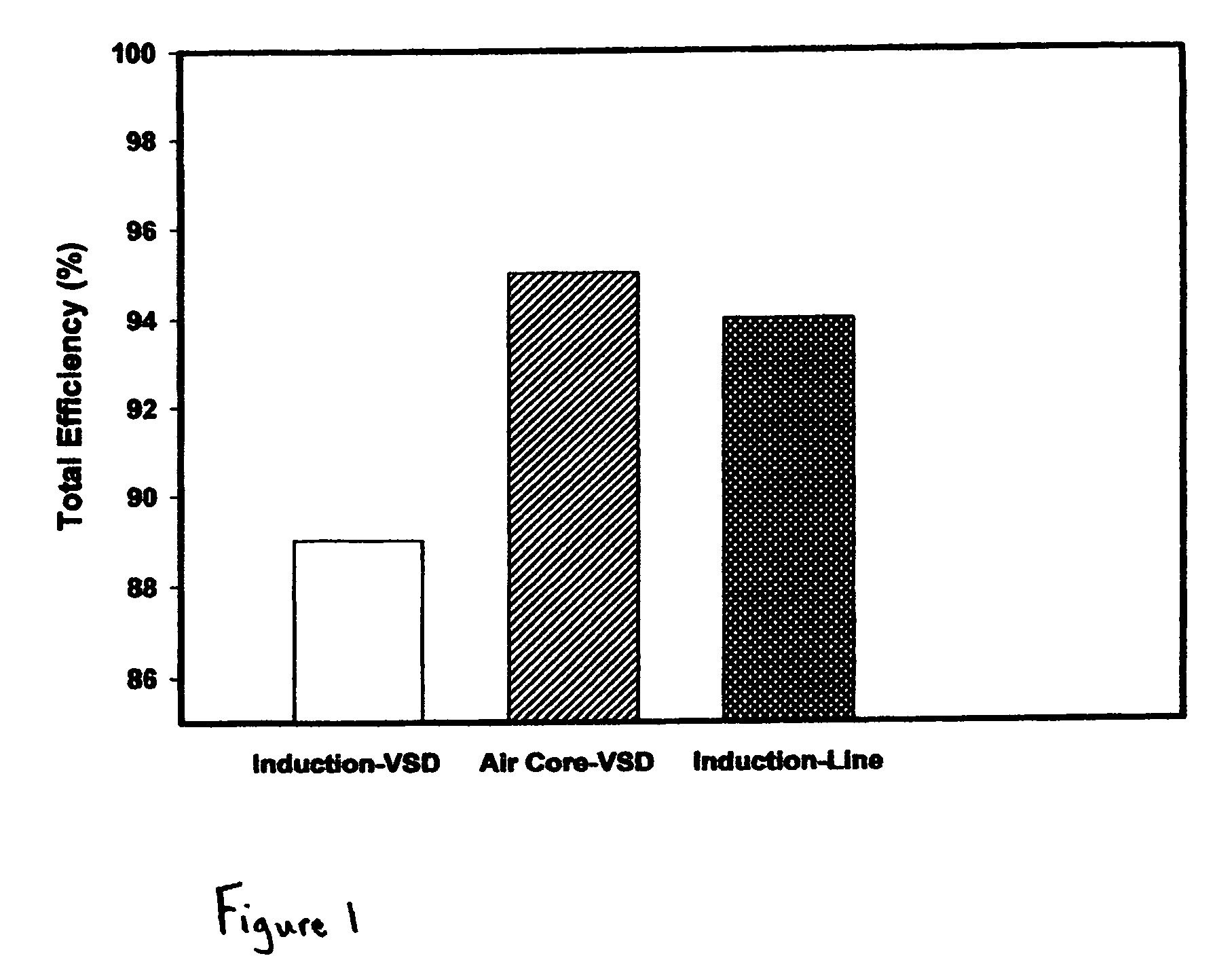

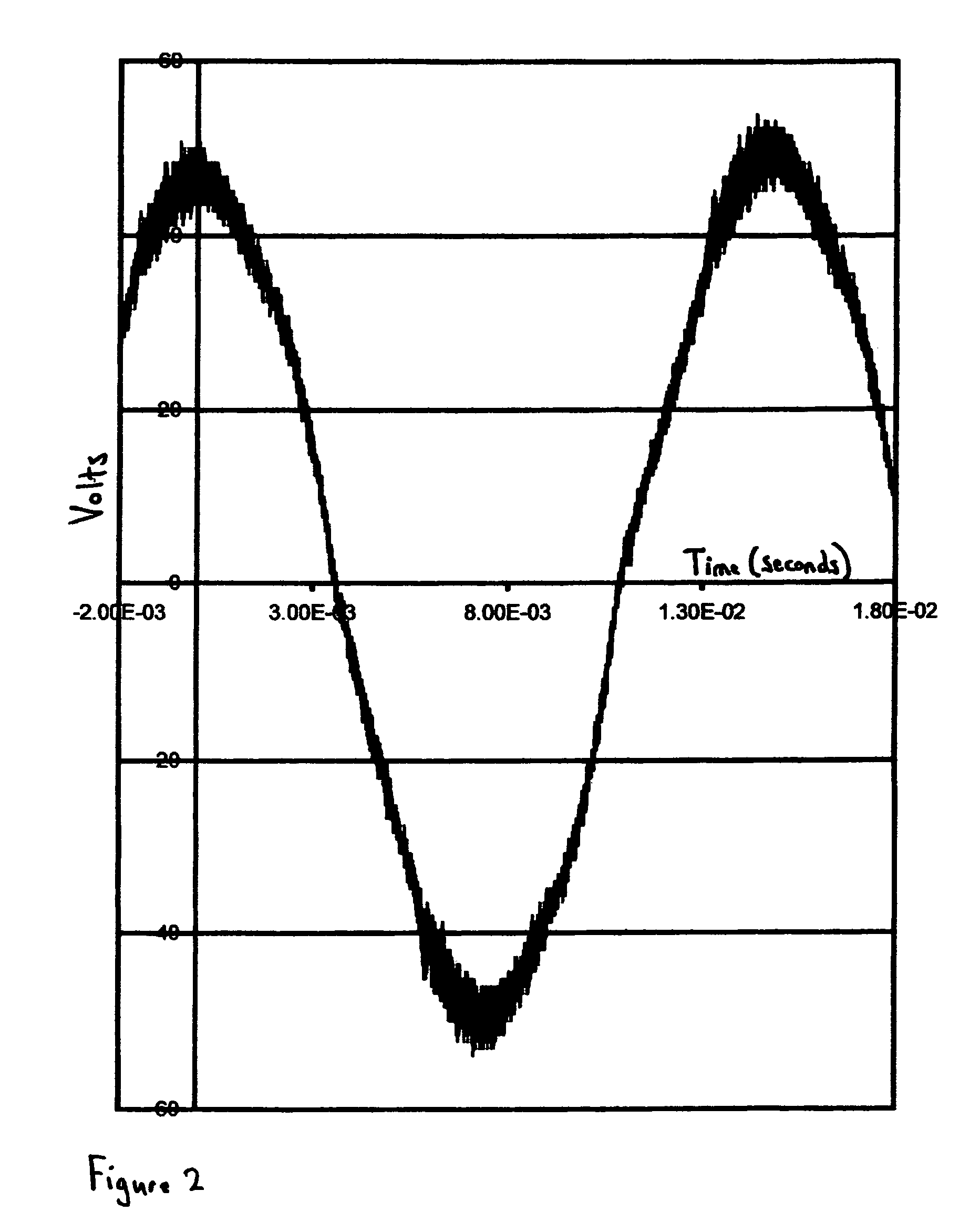

Line synchronous air core motor

InactiveUS7508157B1Easy to cutReduce motor costElectronic commutation motor controlMotor/generator/converter stoppersAir coreCounter-electromotive force

A motor system includes an air core motor having a rotor with opposed permanent magnet poles defining therebetween a magnetic airgap and driving magnetic flux across the magnetic airgap. A stationary armature with air core windings is located within the magnetic airgap. The permanent magnet poles produce a magnetic flux density through the air core windings to produce a back emf in the windings comparable to the voltage of the line power when the rotation of the permanent magnet poles is synchronous with the line power. A electronic variable speed drive coupled by a switch to the air core windings ramps up the frequency of power to the air core windings for accelerating the rotor to near line synchronous speed. When the frequency of the back emf approaches the frequency of the line power, the switch decouples the electronic variable speed drive and couples the air core windings to the line power for synchronous operation.

Owner:REVOLUTION ELECTRIC MOTOR

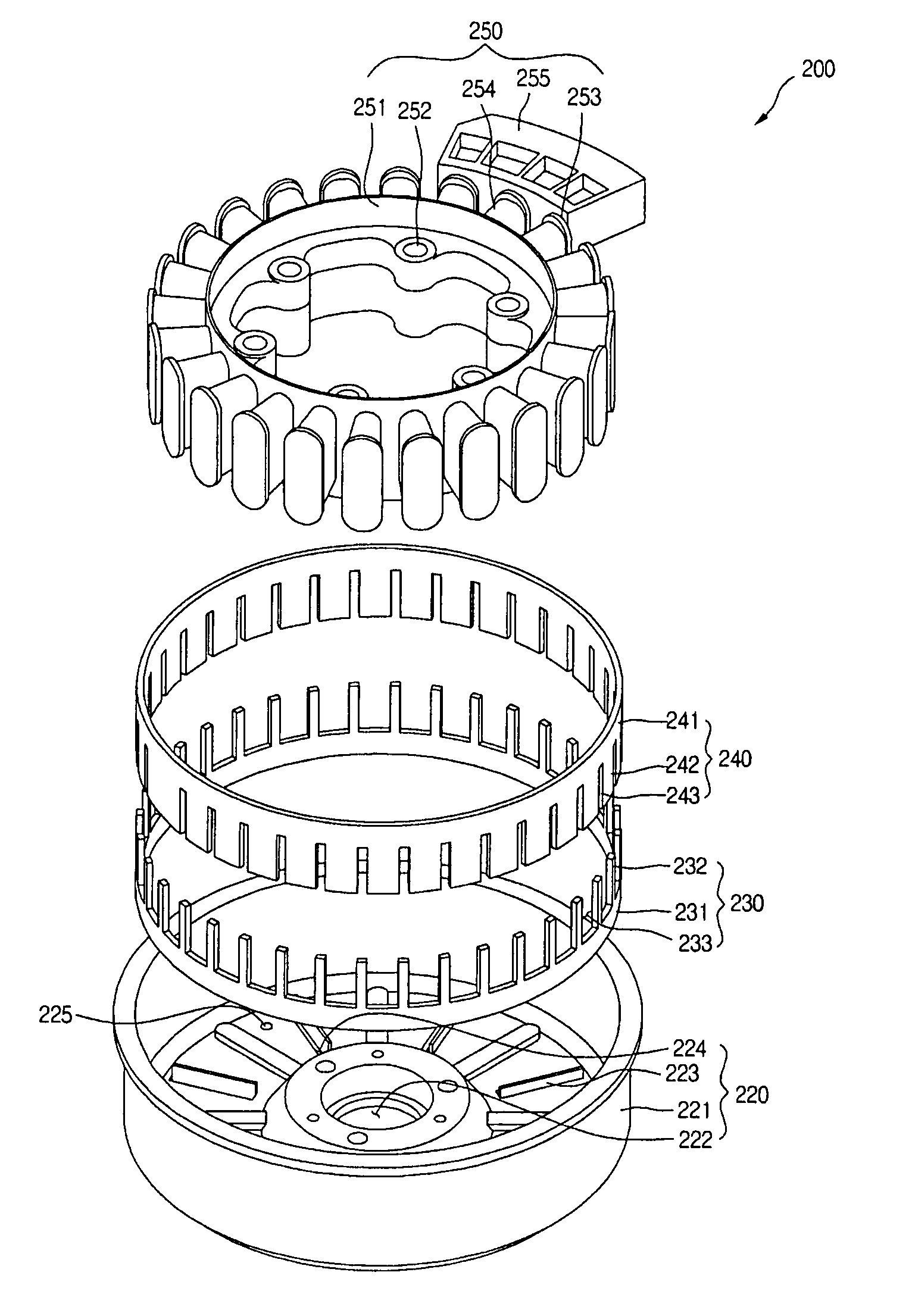

Motor and washing machine including the same

InactiveUS20070182264A1Improve performanceReduce motor costMagnetic circuit rotating partsOther washing machinesElectric machineElectrical polarity

Provided are a motor and a washing machine using the motor. The motor has a stator, a rotor, a rotor frame, a permanent magnet, and a comb polarizing ring. The rotor rotates against the stator. The permanent magnet is installed on the rotor frame and has protrusions with alternating North and South polarities. The comb polarizing ring includes a plurality of teeth disposed between the protrusions of the permanent magnet, and is formed of a material with a magnetism that is weaker than a magnetism of the protrusions.

Owner:LG ELECTRONICS INC

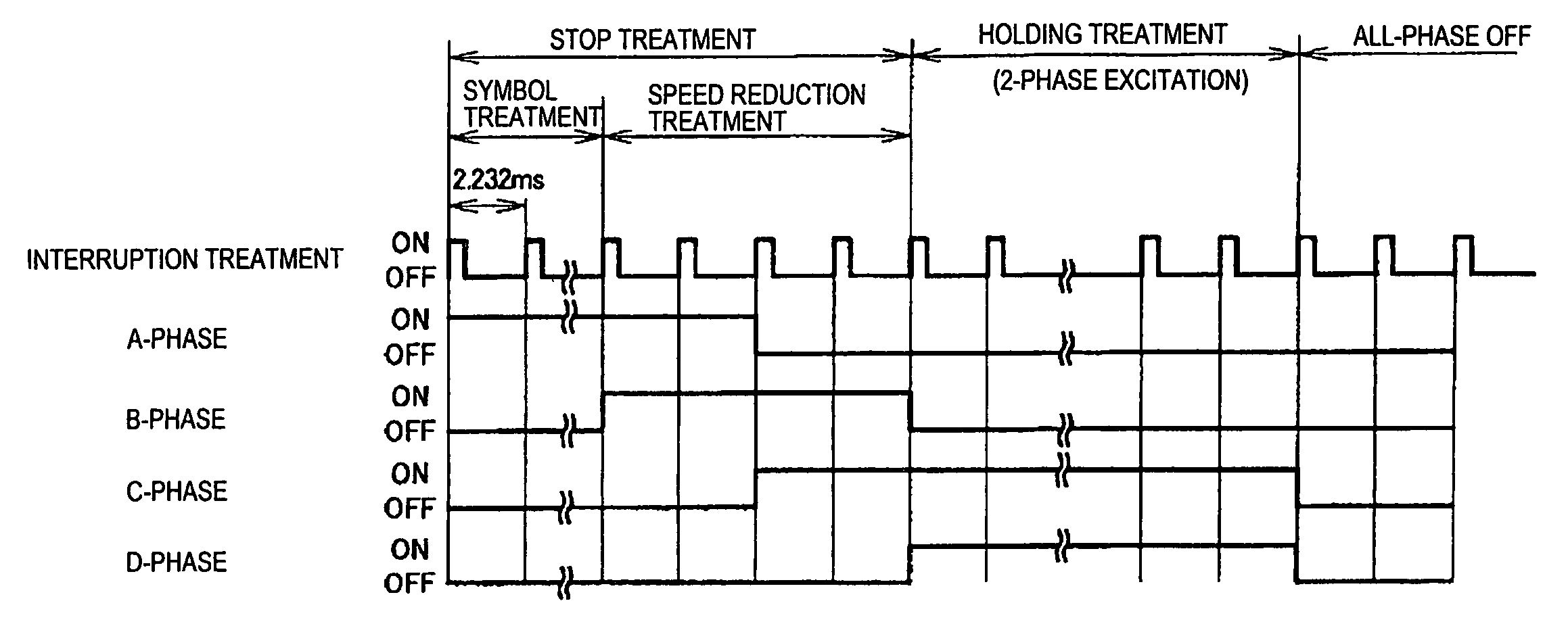

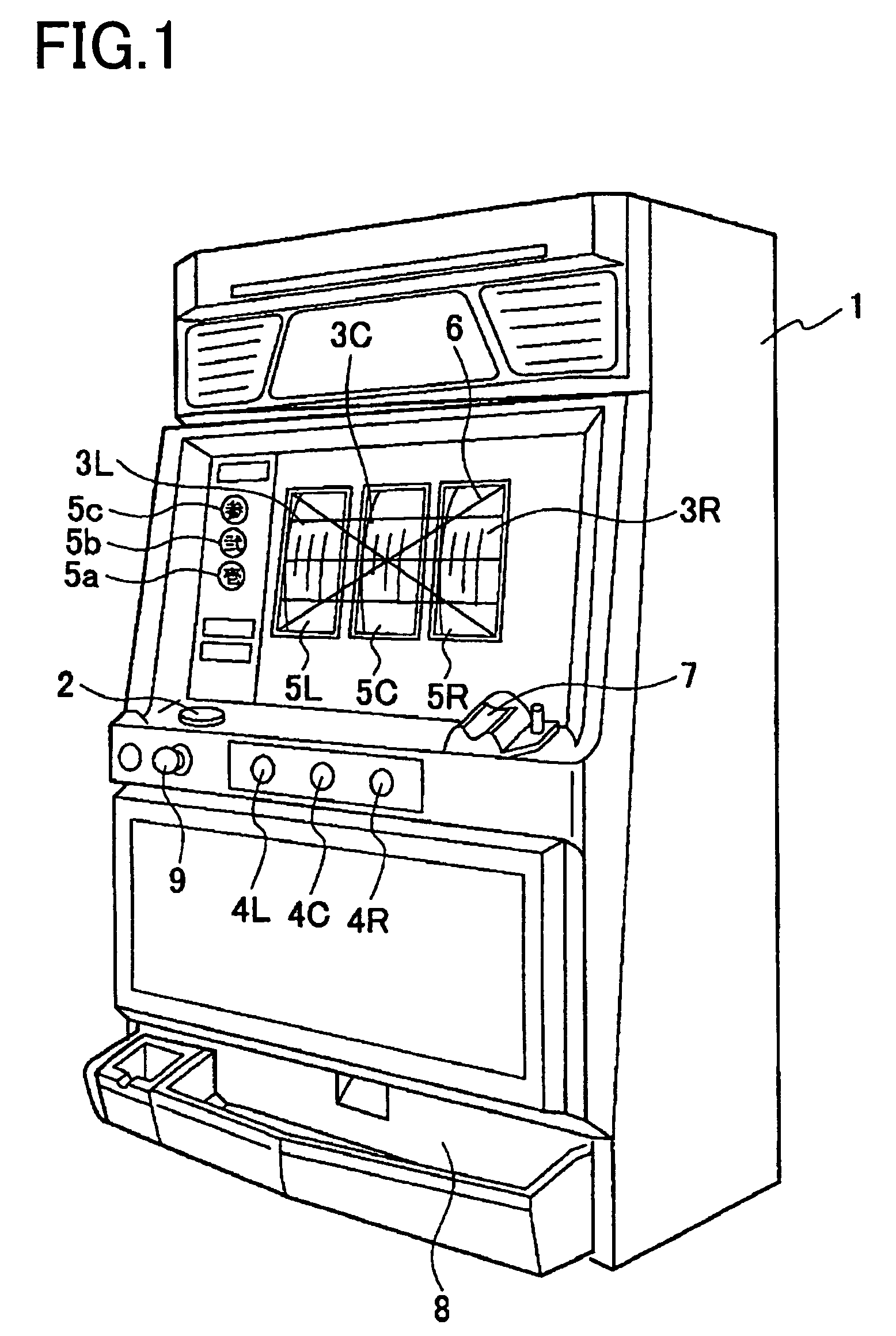

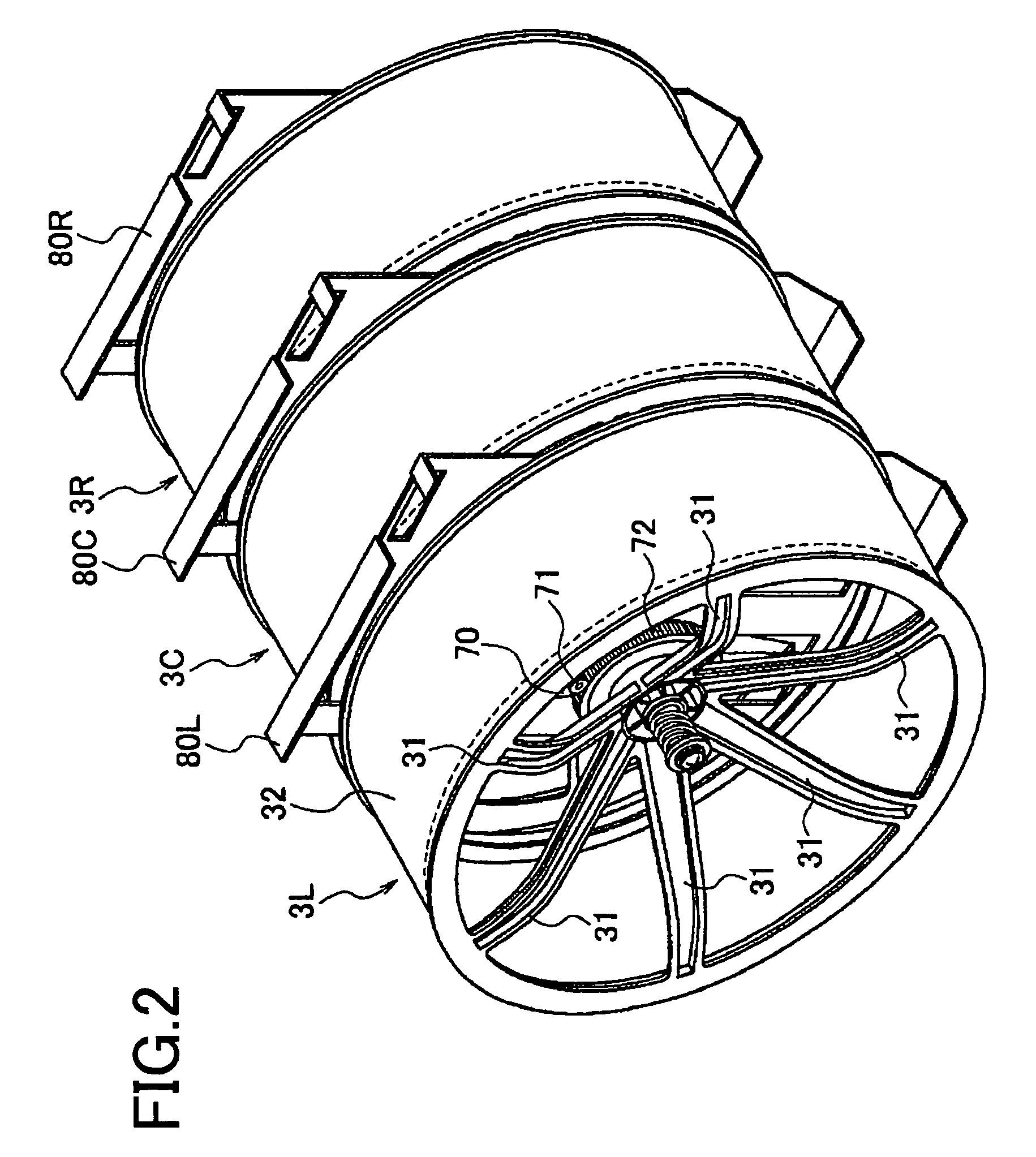

Motor stop control device utilizable for reel-type gaming machine

ActiveUS7038411B2Less mandaySmoothness is lostMotor/generator/converter stoppersElectric motor controlControl theoryStepper motor

Owner:UNIVERSAL ENTERTAINMENT CORP

Pump with motor

ActiveUS20180223824A1Facilitating caulkingReduce motor costEngine manufacturePositive displacement pump componentsEngineeringElectric motor

Owner:OKEN LTD

Driving motor

InactiveUS9103349B2Improve thermal conductivityProne to feverAssociation with control/drive circuitsMagnetic circuit rotating partsInterior spaceEngineering

Owner:VALEO JAPAN CO LTD

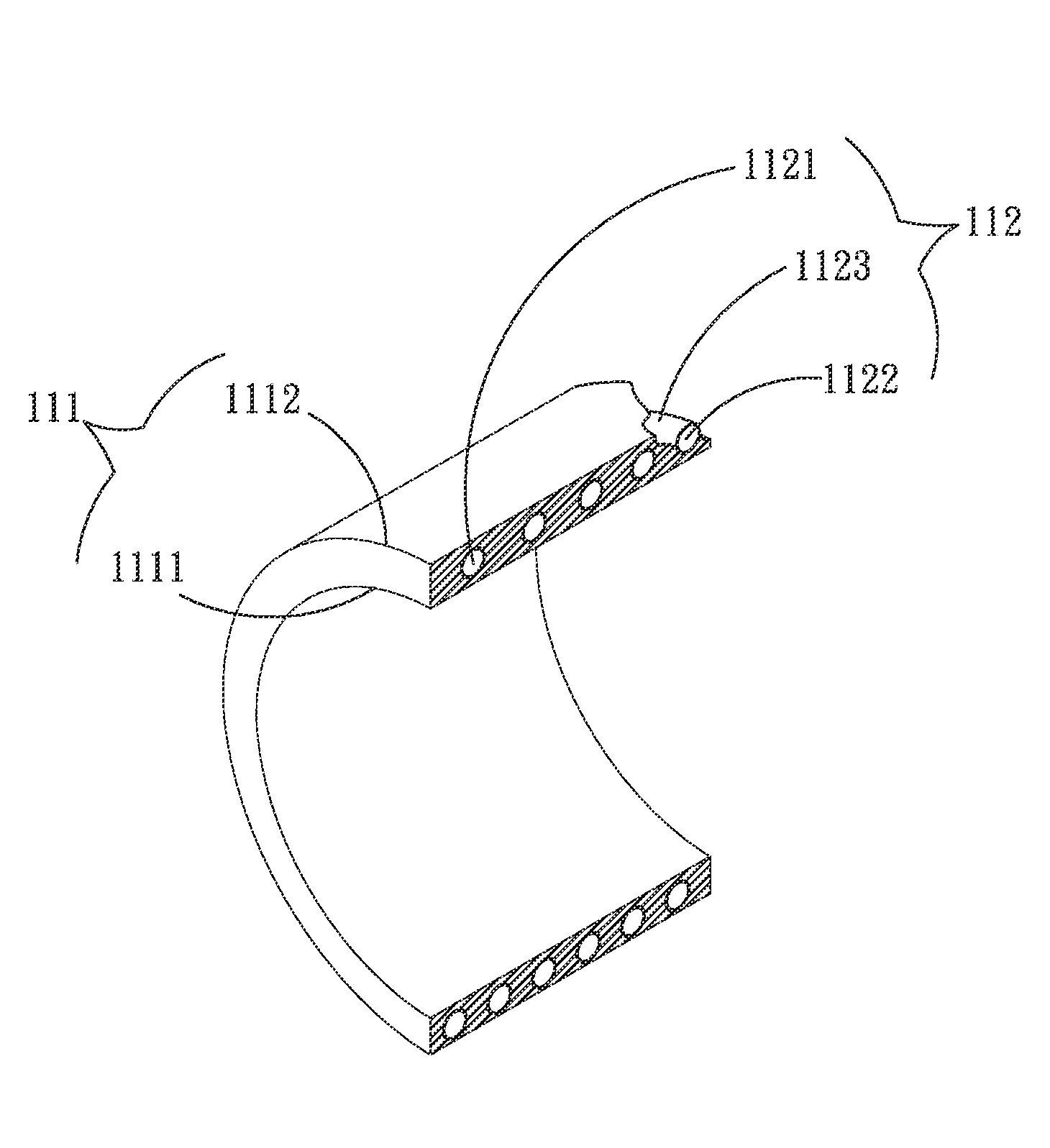

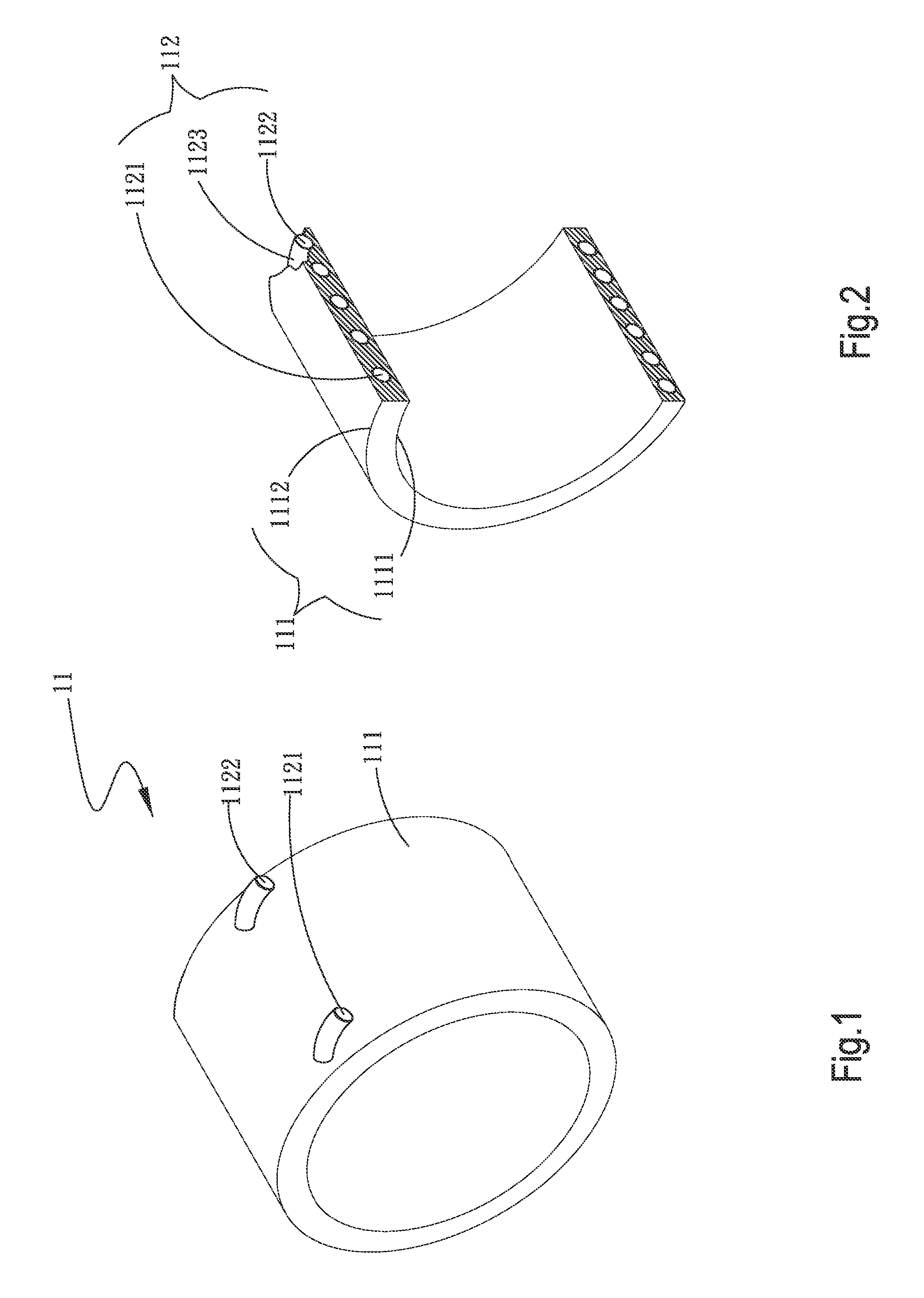

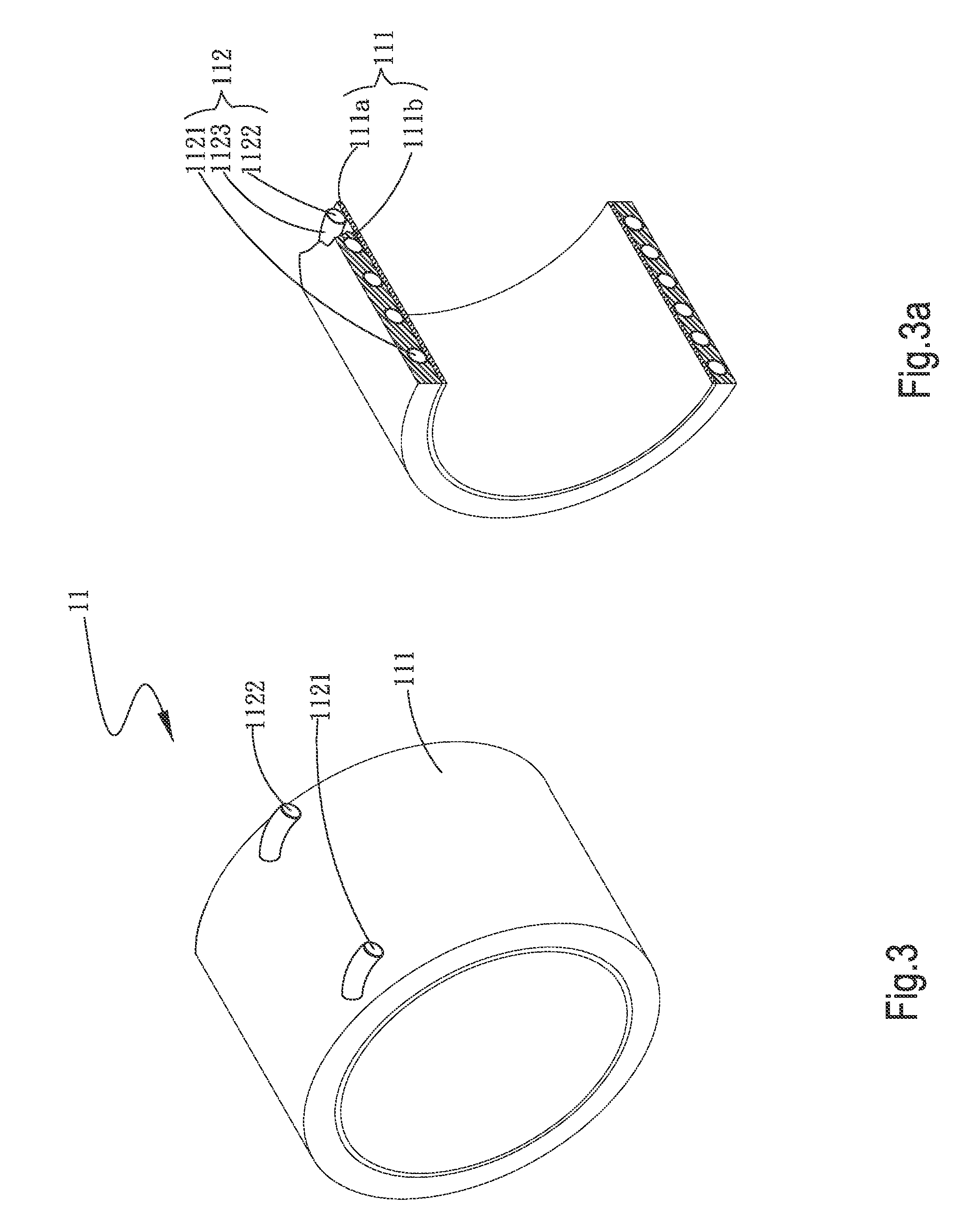

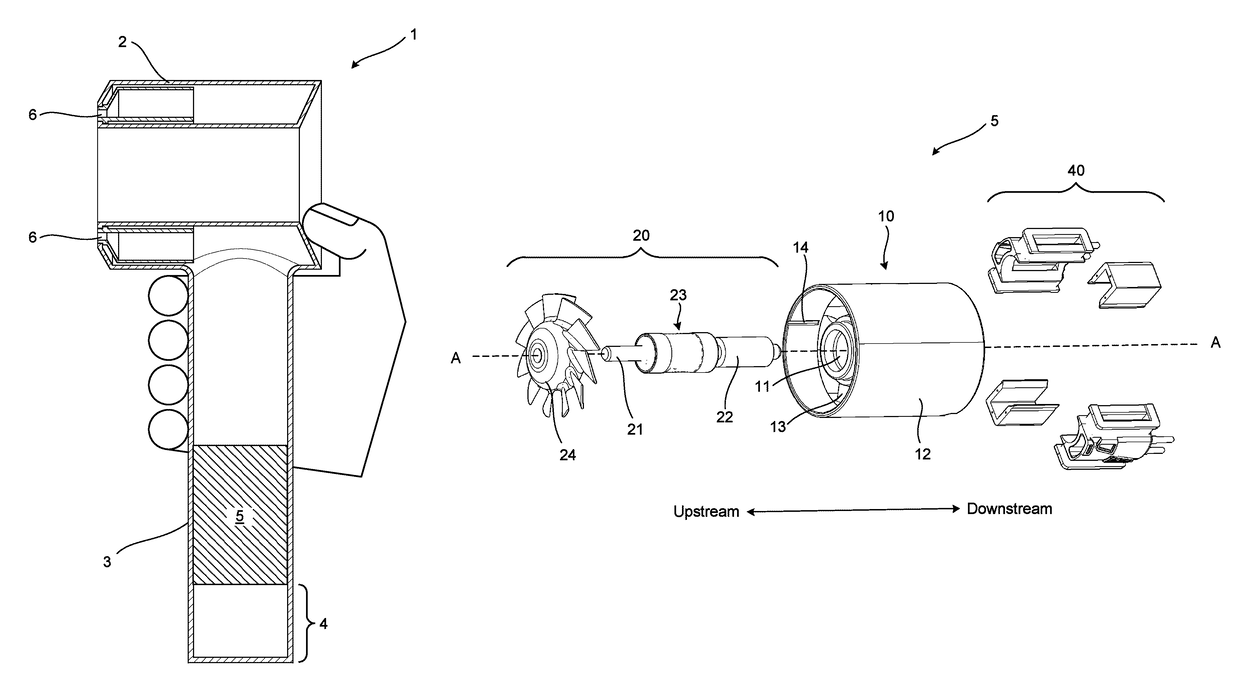

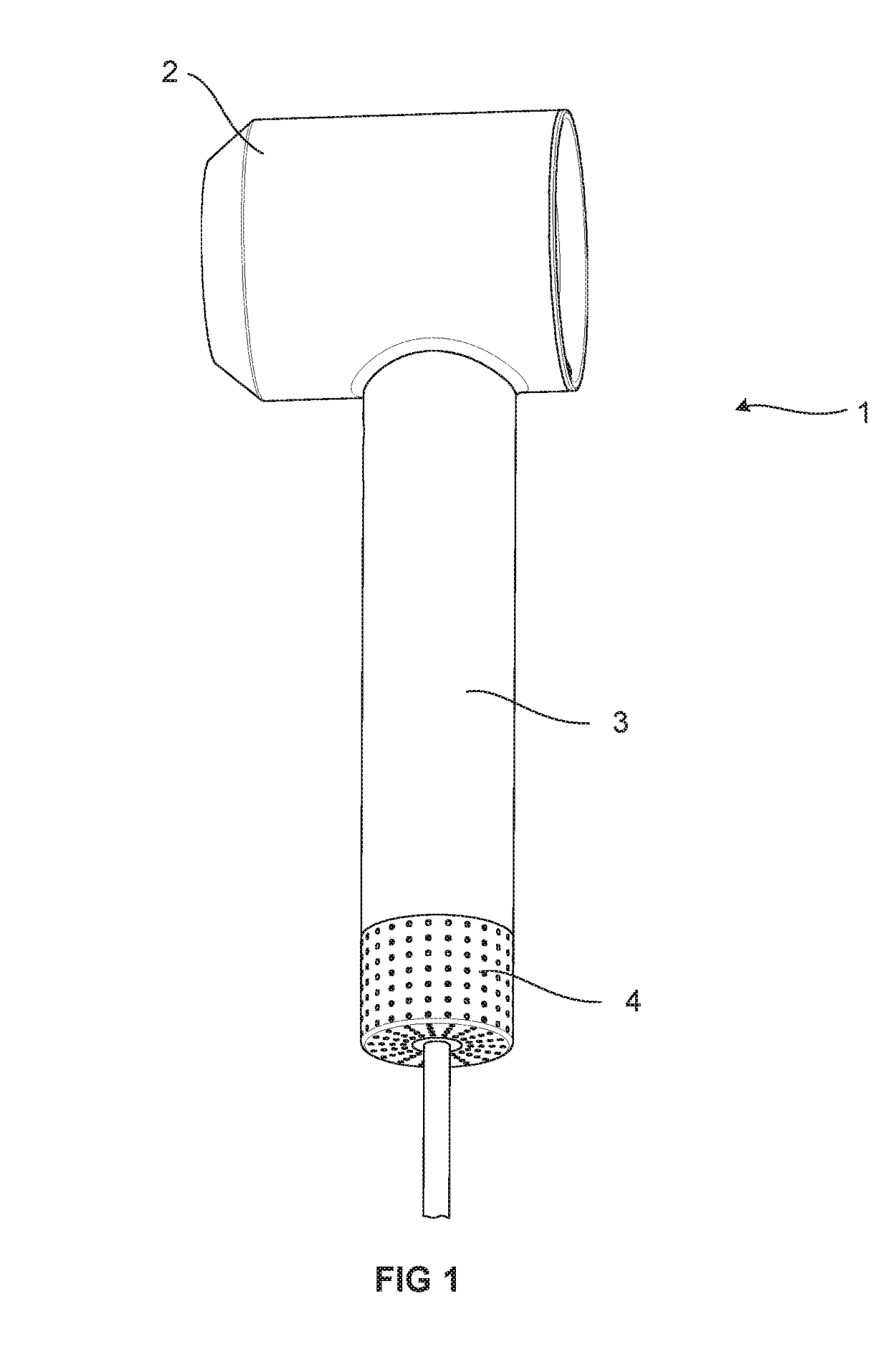

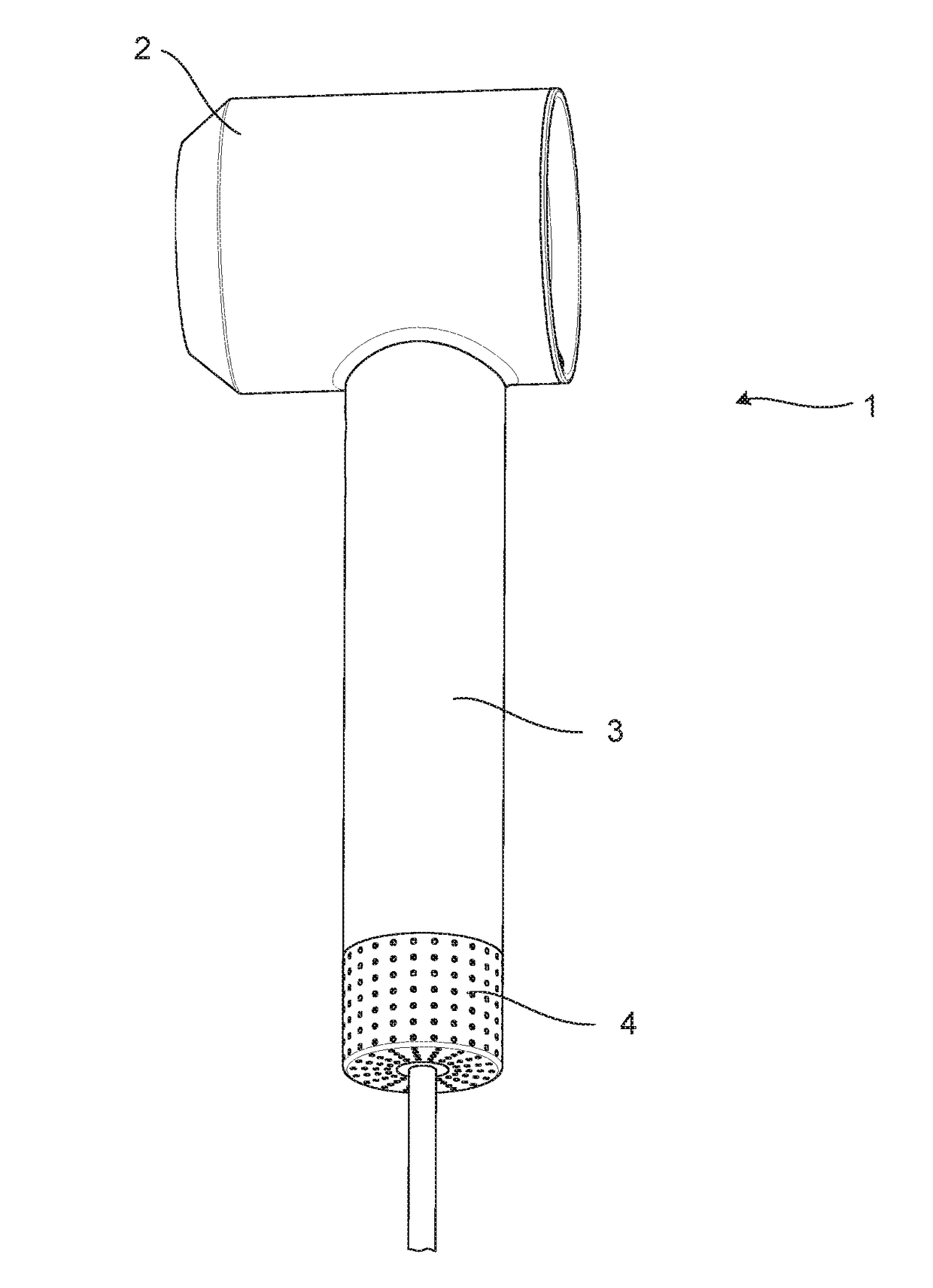

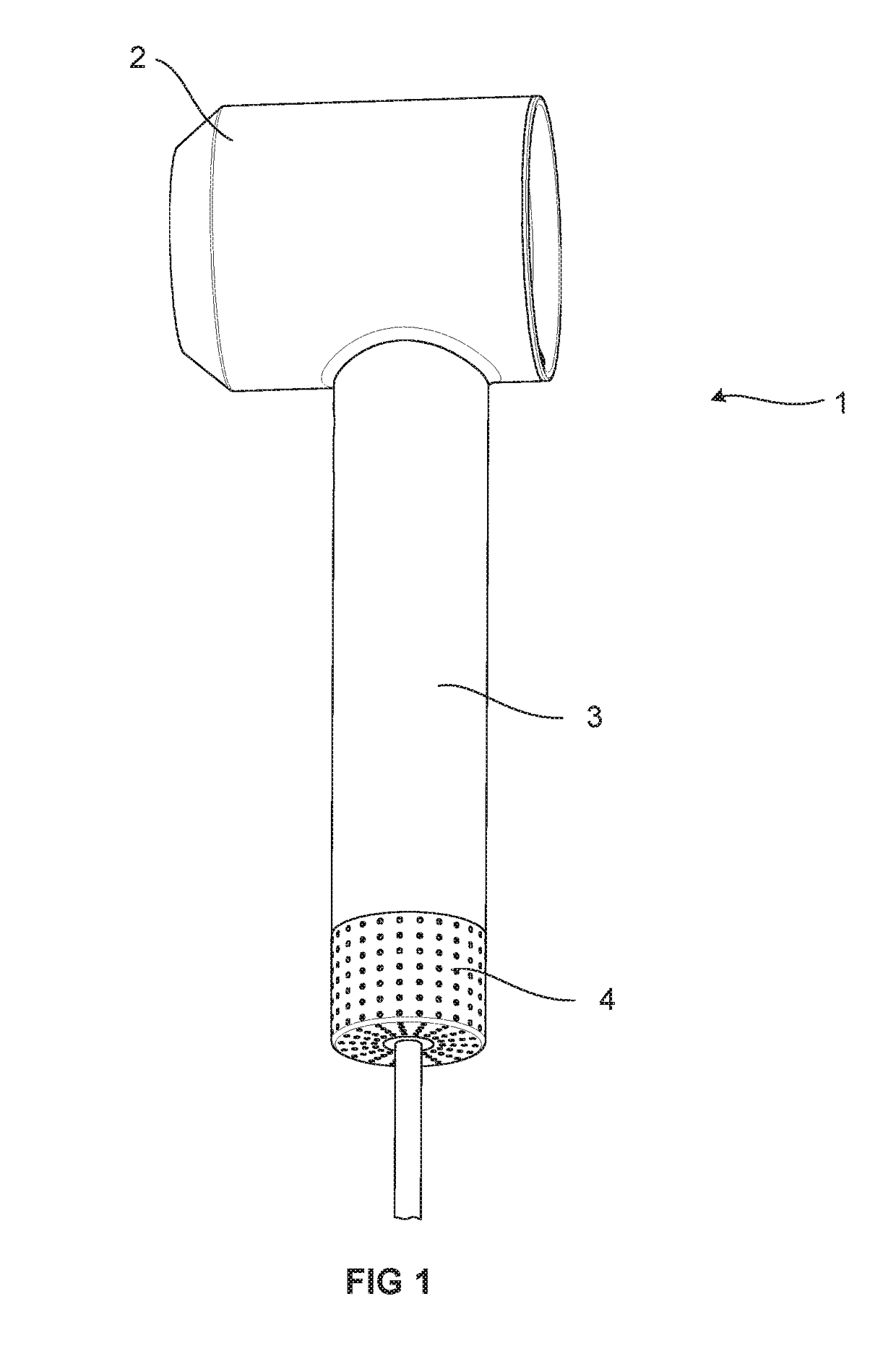

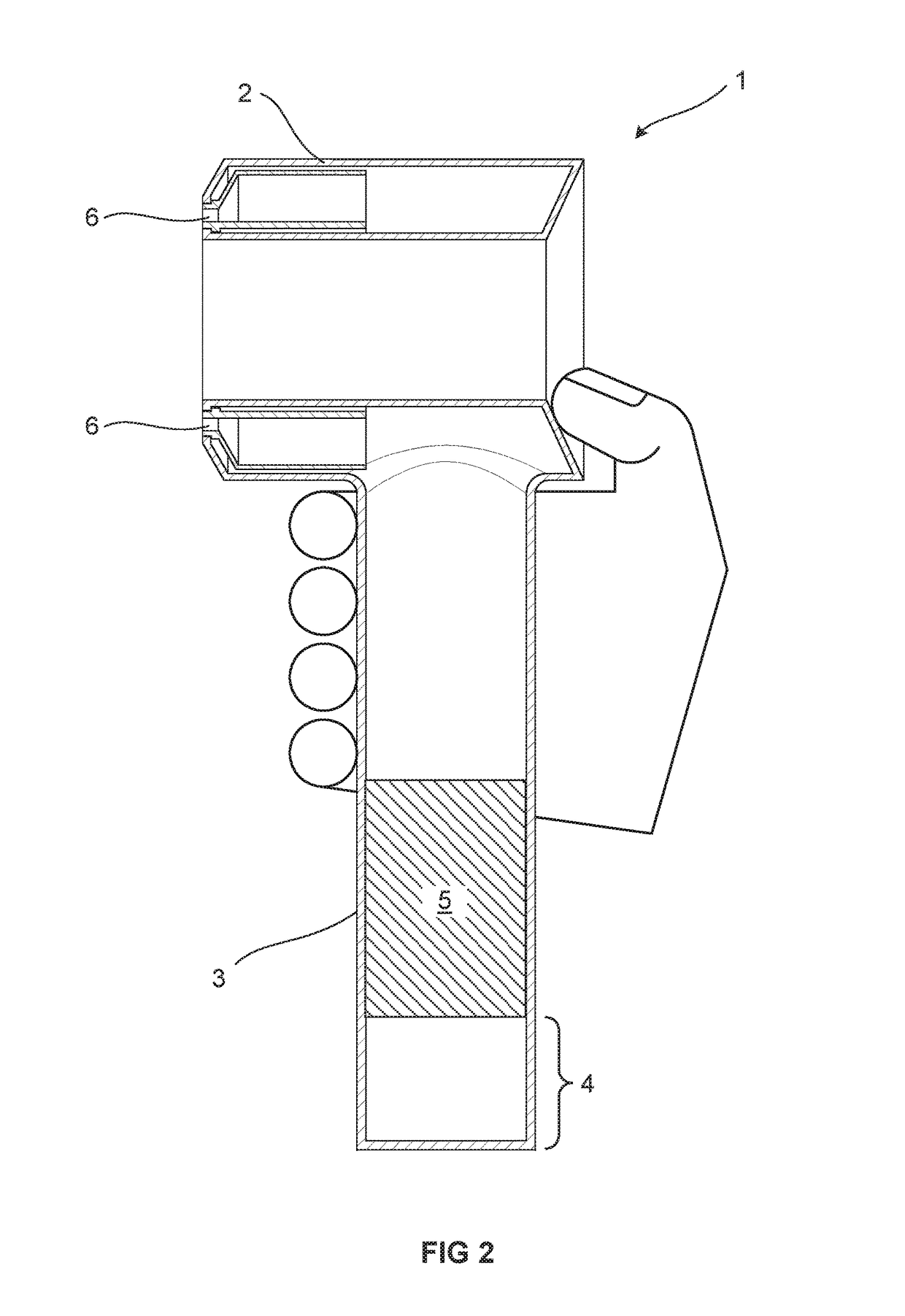

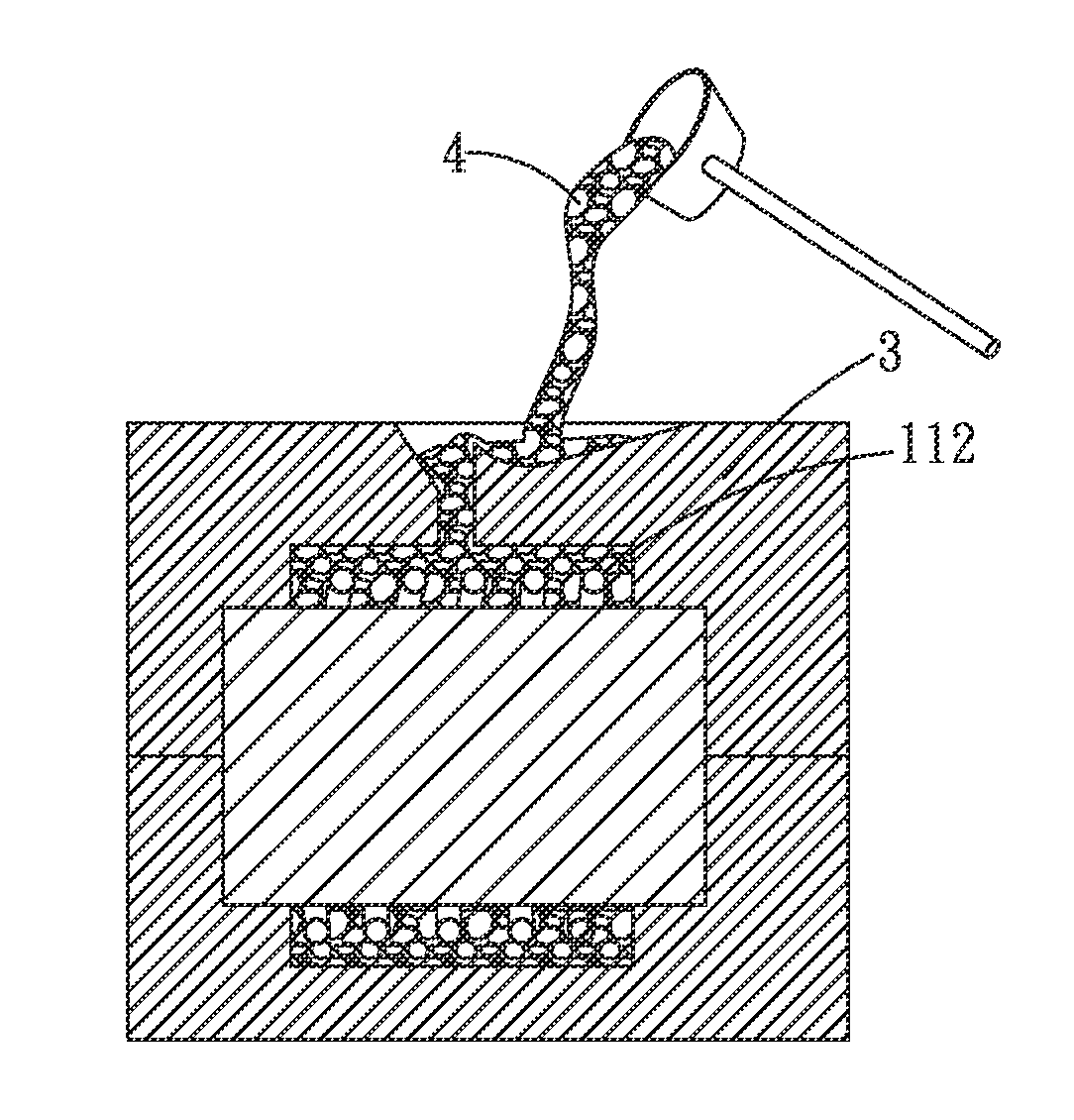

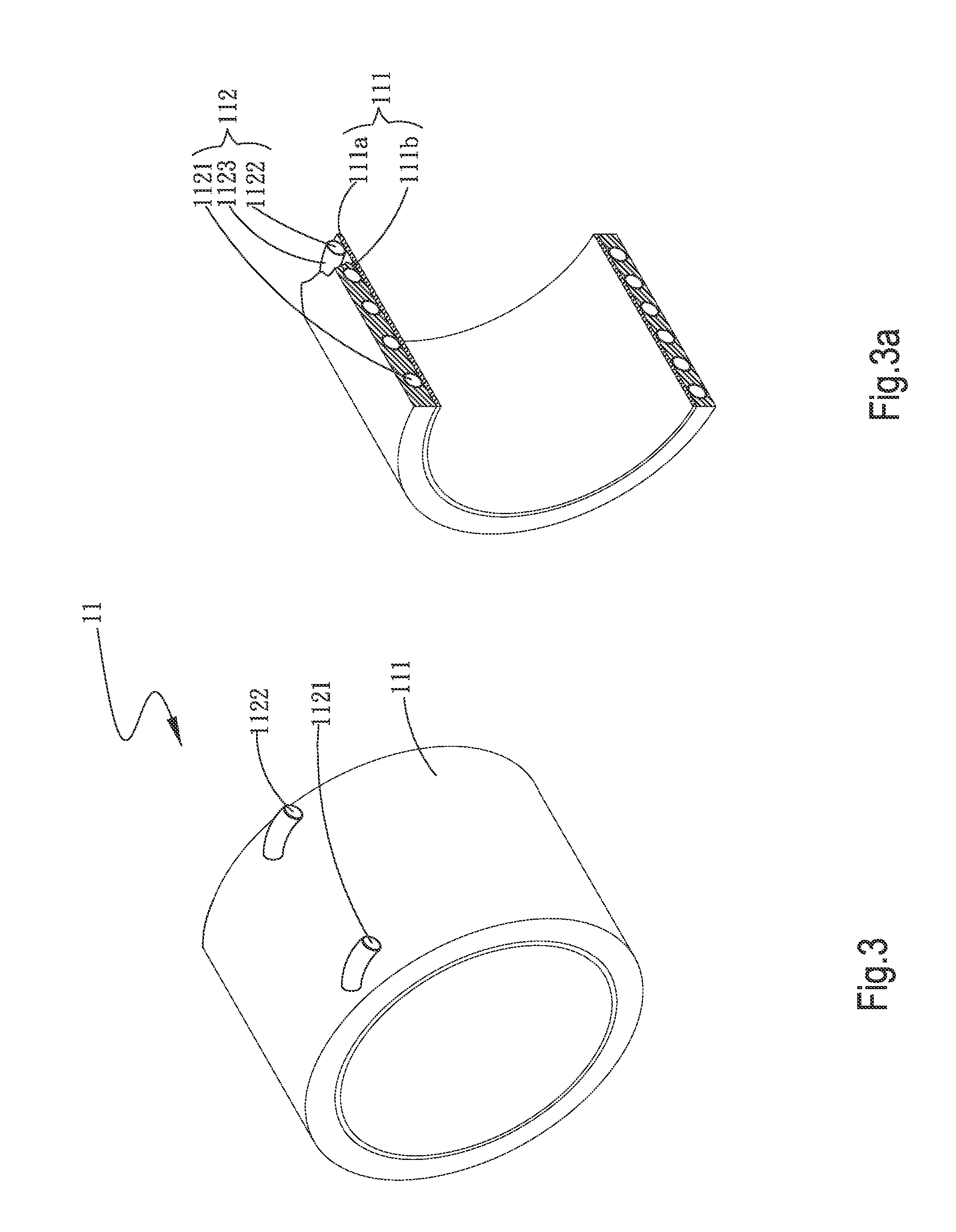

Motor and a hair care appliance comprising a motor

A hair care appliance including a motor for generating an airflow through the appliance, the motor comprising: a frame for supporting a rotor assembly, the frame including an outer wall; and a rotor assembly including a shaft and an impeller, the impeller including a plurality of blades. An impeller housing portion of the outer wall surrounds the impeller. An inner surface of the impeller housing portion includes at least one groove extending in an axial direction and positioned such that the at least one groove extends along at least the axial extent of the blades of the impeller.

Owner:DYSON TECH LTD

Motor system for sewing machine

InactiveUS7007618B1Reduce motor costLow costSewing-machine control devicesFilament handlingElectric machineryEngineering

A motor system for a sewing machine includes a motor unit rotatable at a first rotation speed; a clutch unit with an output shaft capable of being coupled to or separated from the motor unit; a speed changing unit for switching the first rotation speed to a second rotation speed; a position control unit with a sliding disk being movable to a first position, a second position or a third position, making the sliding disk rotate at the second or first rotation speed or stopped; an auxiliary driving shaft for transmitting the rotation of the sliding disk to the output shaft; a first sensor for detecting the position of the clutch unit; and a second sensor for detecting the position of a sewing mechanism of the sewing machine. Thereby, a first speed control, a second speed control and a stopping position control can be achieved for the sewing mechanism.

Owner:CHIU YUNG HO

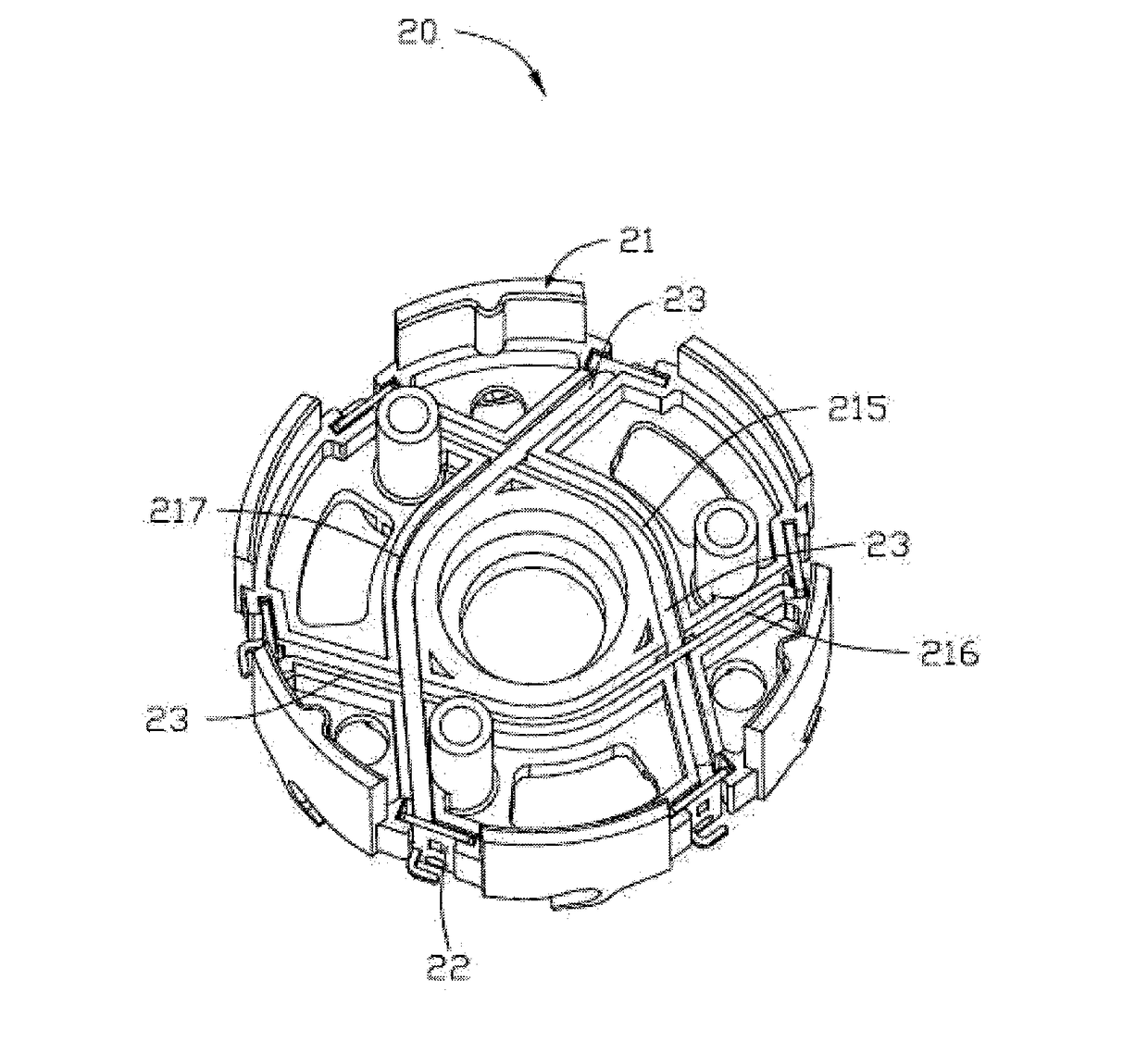

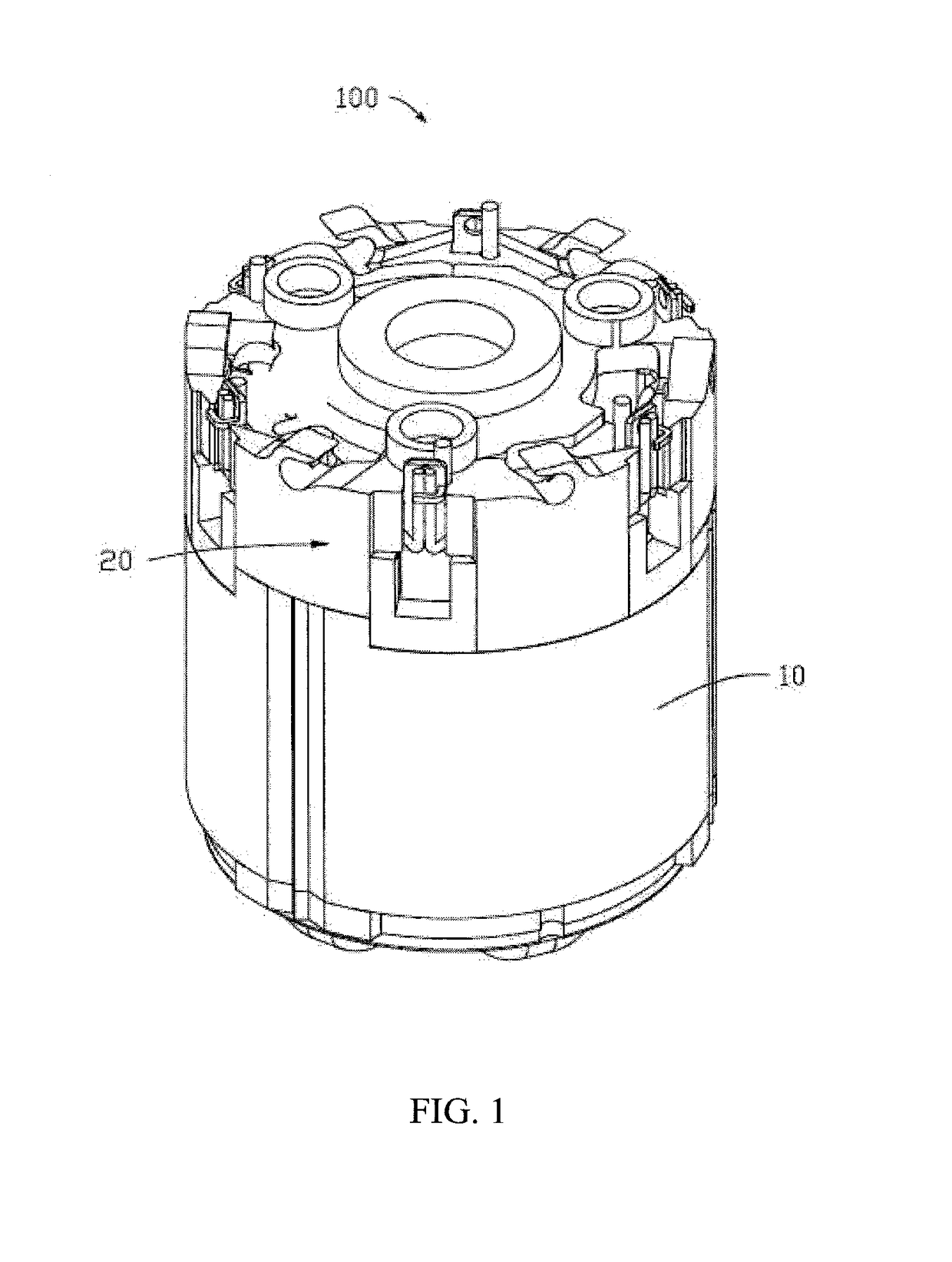

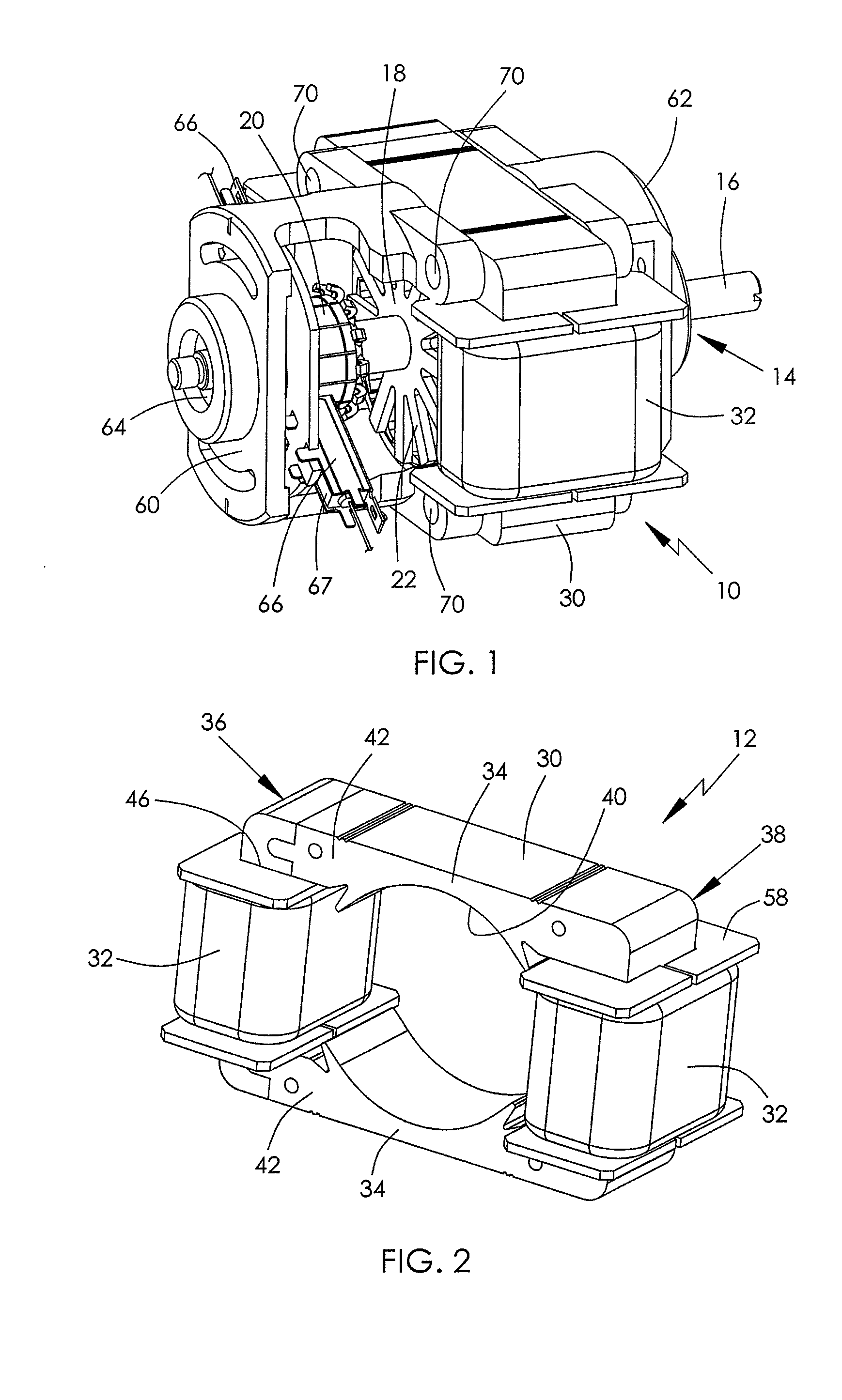

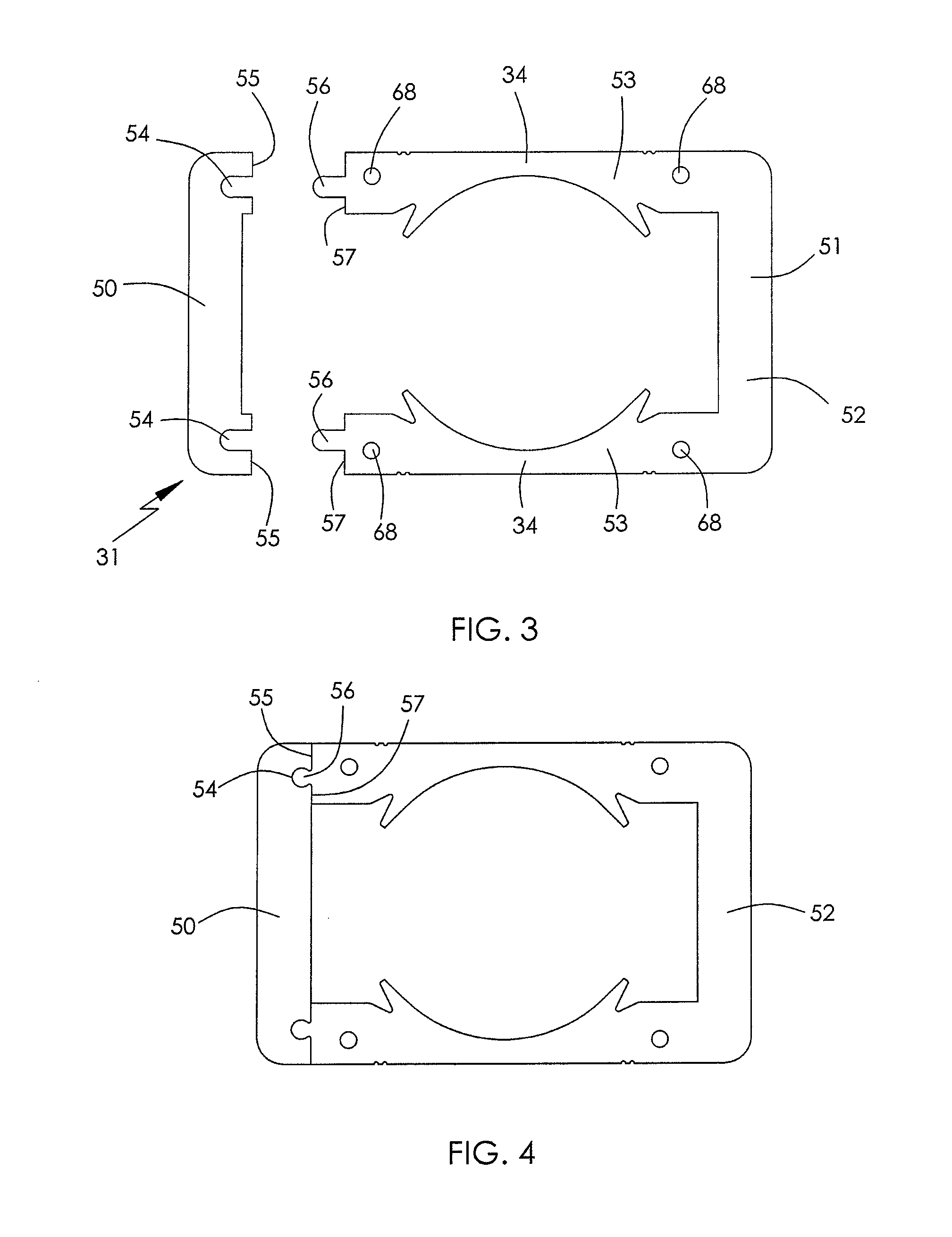

Endcap assembly for an electric motor and stator comprising same

InactiveUS20170244299A1Firmly connectedReduce motor costWindingsMagnetic circuit rotating partsConductor CoilElectric motor

An endcap assembly for an electric motor and a stator having same are provided. The endcap assembly includes an endcap, a first wire, and two terminals corresponding to the first wire. The two terminals are fixed to the endcap and configured to connect with corresponding windings of the electric motor. The endcap defines a first accommodating groove extending from one terminal to the other terminal. The first wire is received in the first accommodating groove, and two ends of the first wire are electrically connected to the two terminals, respectively.

Owner:JOHNSON ELECTRIC SA

Electric motor

An electric motor includes a stator and a rotor installed in the stator. The stator has a laminated stator core and at least two stator windings wound on the stator core. The stator core has at least two stator poles facing the rotor and at least two yokes connecting adjacent stator poles. T stator core is constituted by at least two separate members joined together. The at least two stator poles are only arranged at a single one of the at least two separate members.

Owner:JOHNSON ELECTRIC SA

Manufacturing method for motor

InactiveUS8056210B2Reduce manufacturing costReduce motor costElectrical transducersCoil arrangementsAdhesiveEngineering

A sleeve portion is inserted into a hole portion of a base bracket on which an adhesive of heat cure type is applied while a rotor portion and a stator portion are retained by a position determining jig. Then, the sleeve portion is initially affixed to the base bracket by a high frequency induction heating of an induction coil. Then, the initial affixation is cured completely in an oven. Since the adhesive of heat cure type is used, generation of outgass will be minimized and a manufacturing cost of the motor having such components will be reduced.

Owner:NIDEC CORP

Axial non-uniform air gap hybrid excitation synchronous machine

ActiveCN102832776AReduce dosageReduce motor costSynchronous machine detailsMagnetic circuit rotating partsPhysicsField weakening

The invention discloses an axial non-uniform air gap hybrid excitation synchronous machine which comprises a housing, a stator and a rotor which are arranged in the housing, an annular magnetism conducting bridge and a rotating shaft which are fixed on an end cover, wherein the stator comprises a stator iron core and an armature winding embedded in a stator groove; and the rotor is fixed on the rotating shaft and comprises a rotor N pole shoe, a rotor S pole shoe and a tangential magnetization permanent magnet. The axial length of the permanent magnet is less than that of the stator iron core. A rotor N pole and an S pole hole respectively are a permanent magnet side adjacent to the permanent magnet and an electric excitation side which is not adjacent to the permanent magnet, and the lengths of two sections of main gas gaps formed between the rotor permanent magnet side and the stator iron core and between the electric excitation side and the stator iron core are different. The motor is wide in regulating range of the magnetic fields of the air gaps, can realize field weakening control in a wide rotating speed range under a speed regulation state, voltage regulation under a power generation state, and complete field suppression protection under a failure state, and has an important application value in a new energy automobile and an independent source system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

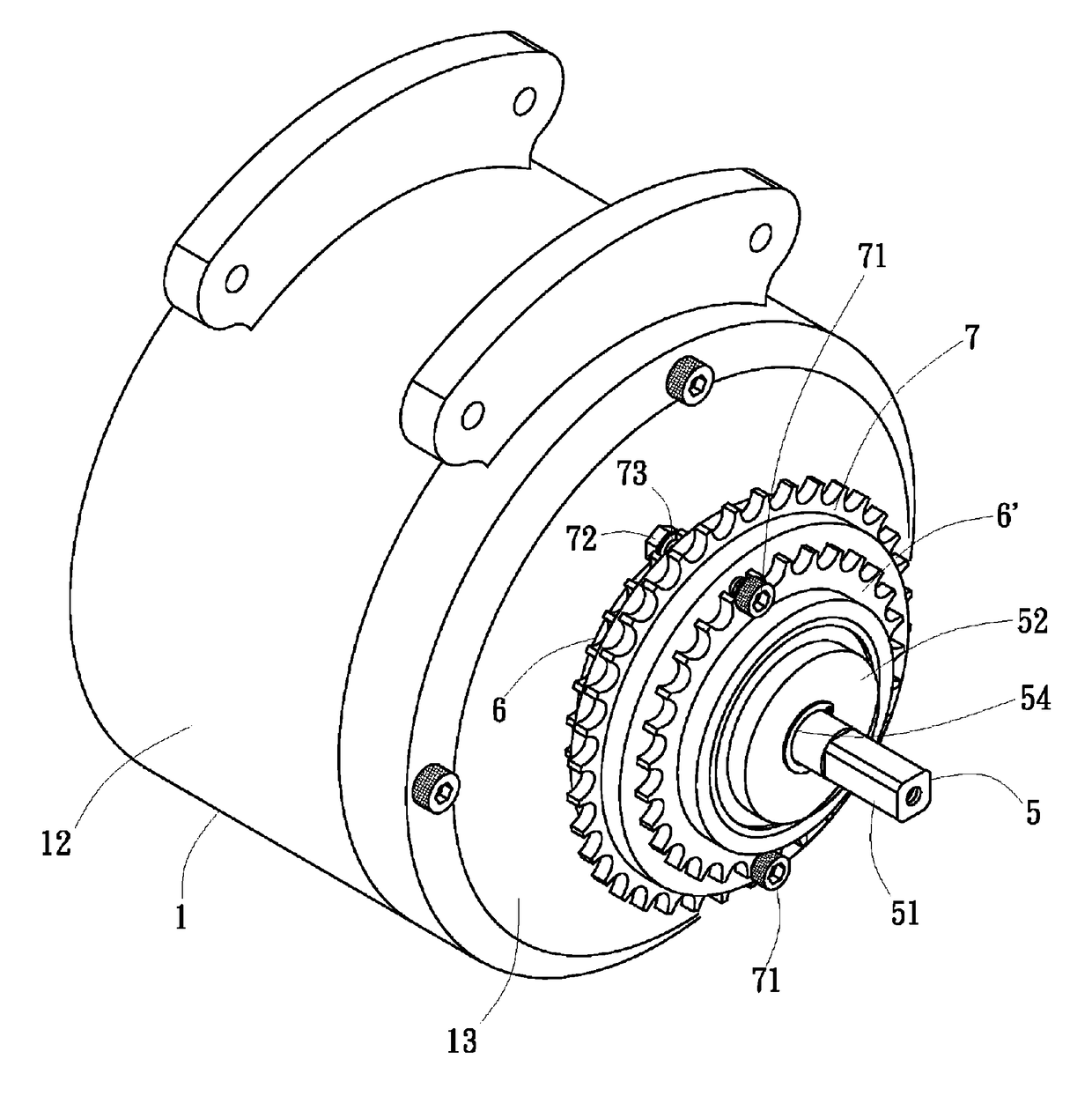

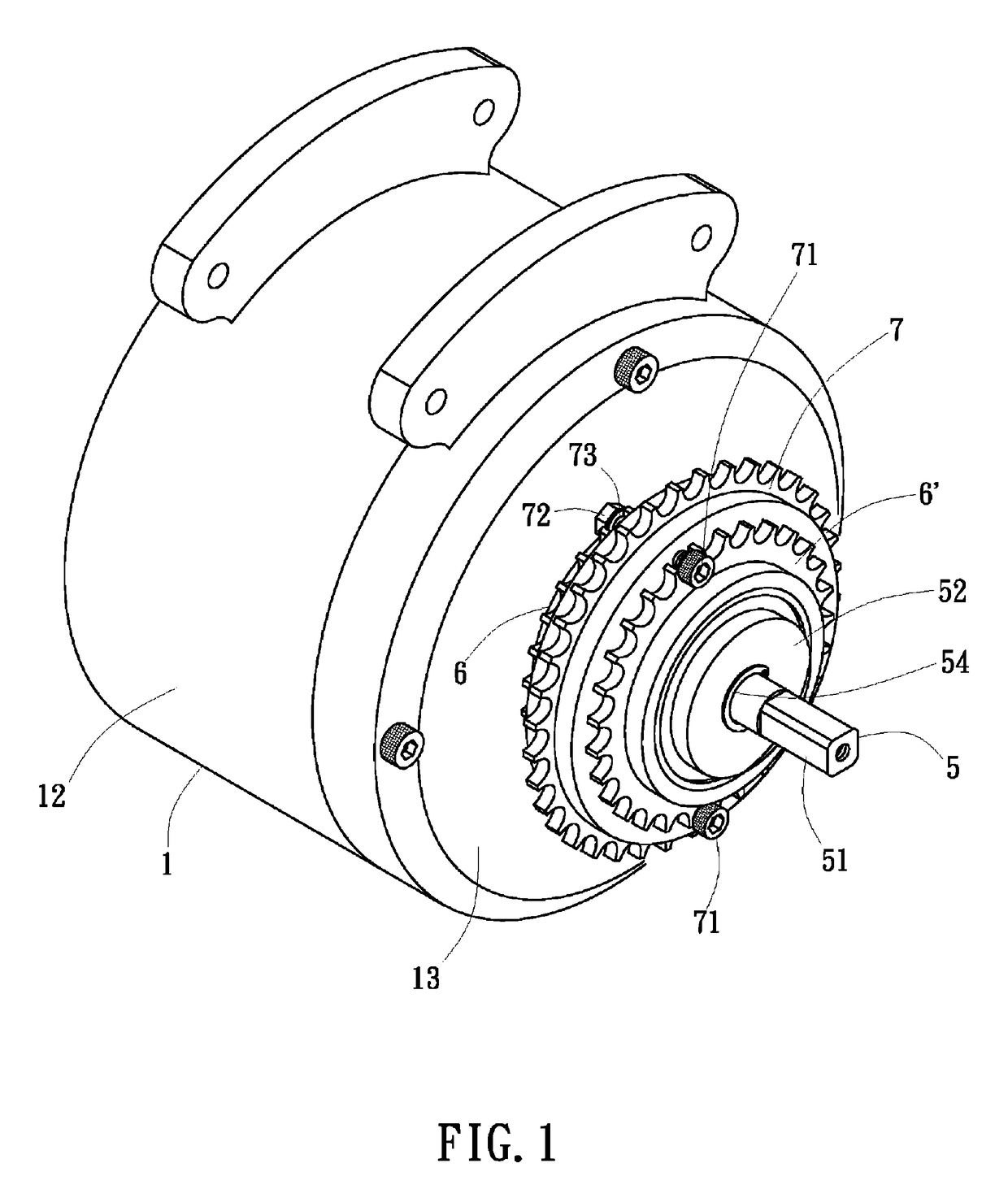

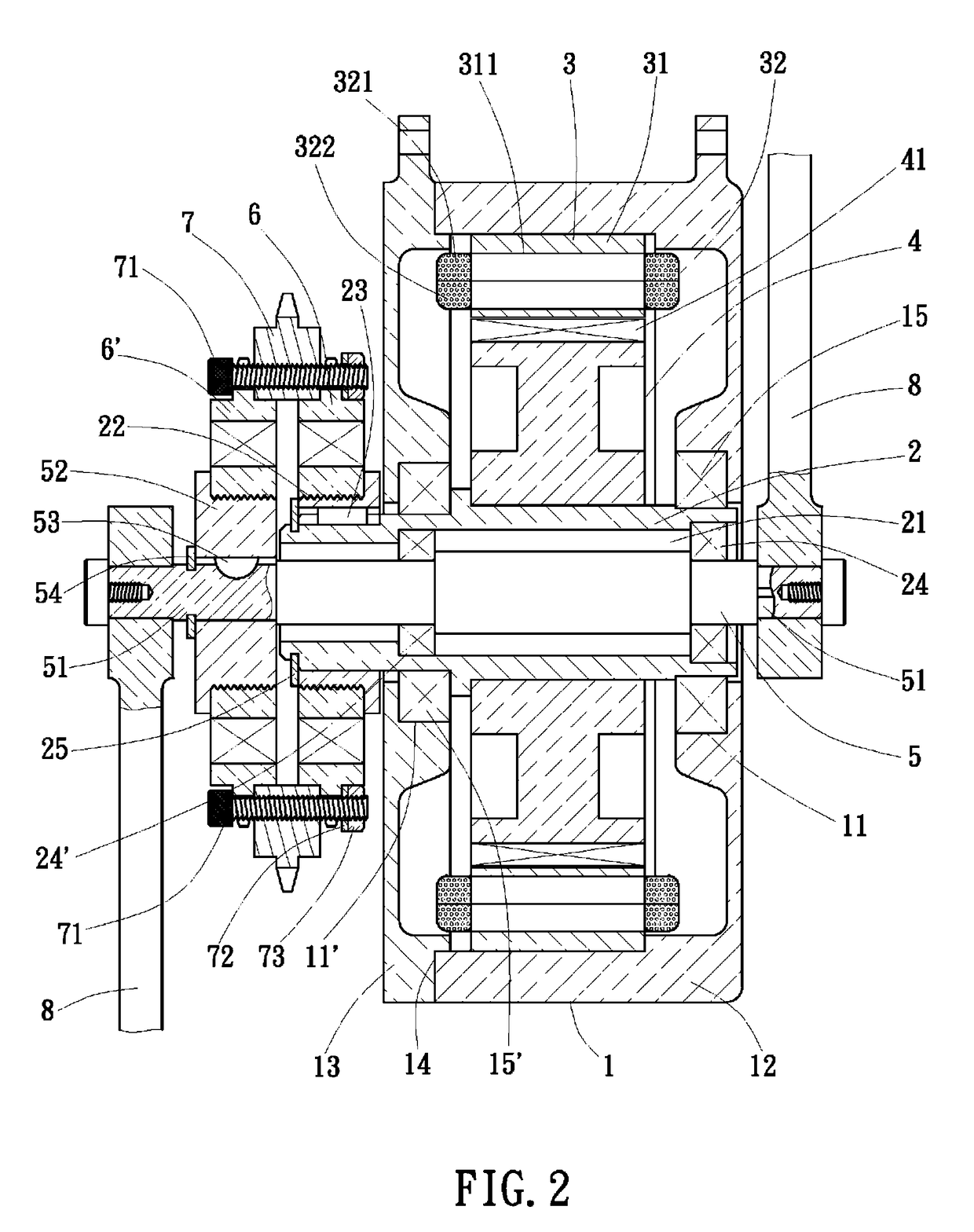

Compound power mechanism and electric bicycle

InactiveUS9789929B2Small sizeReduce manufacturing costVehicle transmissionMechanical energy handlingFreewheelMotor drive

A compound power mechanism and an electric bicycle are provided. The compound power mechanism includes a motor casing fixed to the bicycle, a motor drive shaft coupled with a rotor, and a stator provided in the motor casing. A crank drive shaft is disposed in the motor drive shaft. Two ends of the crank drive shaft extend out of the two ends of the motor drive shaft and are coupled with pedal cranks. A freewheel is coupled to a respective end of the motor drive shaft and the crank drive shaft. A drive sprocket is located between and coupled to the two freewheels and adapted to bring a bicycle chain to turn. The drive sprocket can be driven by the motor drive shaft or by the crank drive shaft when pedaled. The size of the motor is reduced and the cost of manufacture is lowered.

Owner:WU SHYANG JUN

Brushless DC permanent magnet motor

InactiveUS20080079335A1Reduce component countImprove efficiencySingle-phase induction motor startersAC motor controlMicrocontrollerManufacturing cost reduction

A brushless DC motor operated by a microcontroller has a unique pole construction that enables it to reliably start and operate as a unipolar device so that a reduced number of electronic power switches can be used to reduce cost and complexity. The microcontroller calculated rotor position to eliminate the need for a separate sensor and thereby further reduce manufacturing cost.

Owner:ELECTRIC MOTORS & SPECIALTIES

Motor and a hair care appliance comprising a motor

A hair care appliance including a motor for generating an airflow through the appliance, the motor comprising: a frame for supporting a rotor assembly, the frame including an outer wall; and a rotor assembly including a shaft and an impeller, the impeller including a plurality of blades. An impeller housing portion of the outer wall surrounds the impeller. An inner surface of the impeller housing portion includes at least one groove extending in an axial direction and positioned such that the at least one groove extends along at least the axial extent of the blades of the impeller.

Owner:DYSON TECH LTD

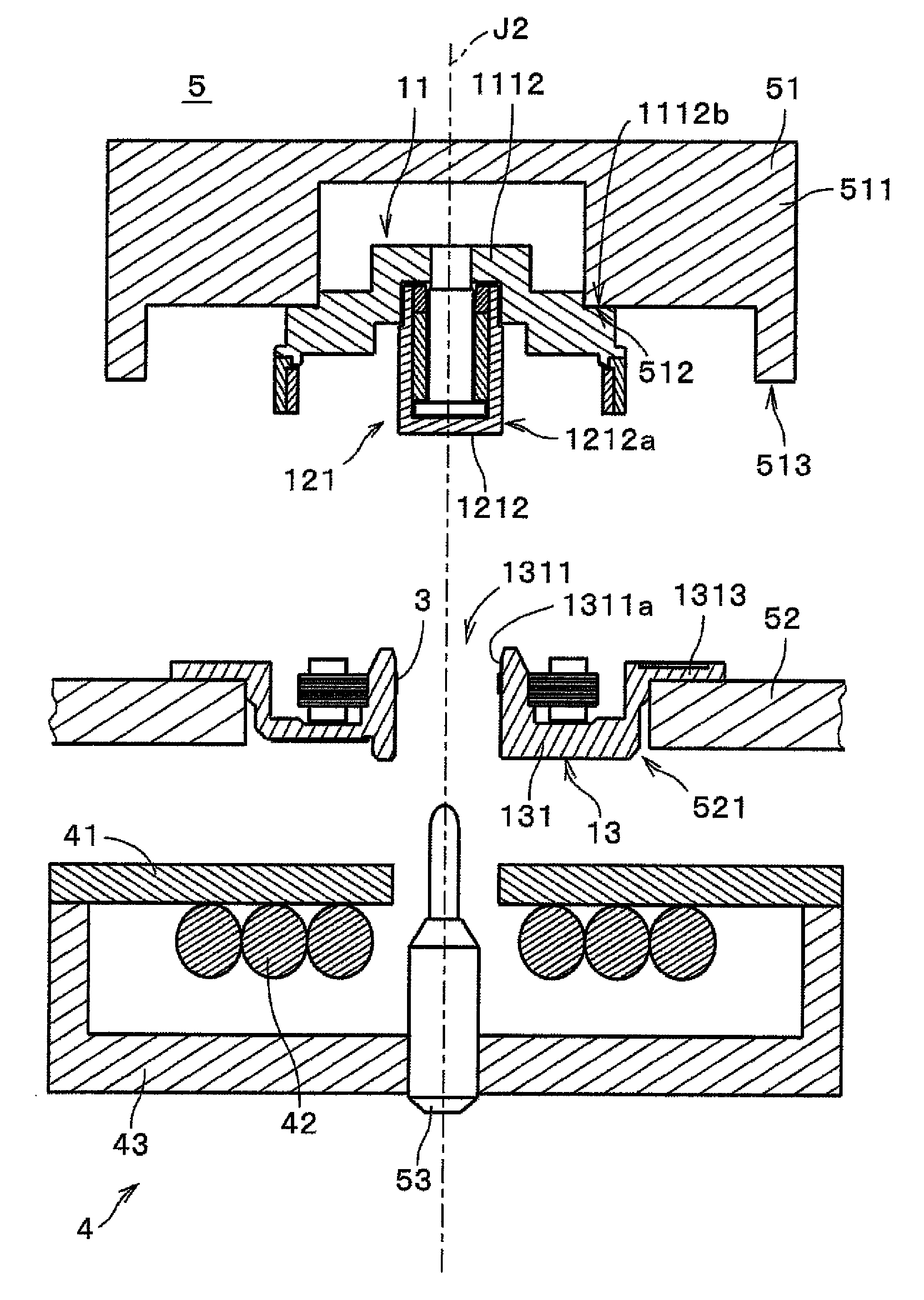

Motor

InactiveUS20050134127A1Improve productivityLow costAssociation with control/drive circuitsMagnetic circuit stationary partsEngineeringElectric motor

A motor having a sleeve, a first board, a second board, a rotating part, a stator, a bracket and a bearing. The sleeve includes a sleeve main body having a cylindrical part into which a shaft is inserted, a first board supporting part having a first board supporting area extending in a radial direction of the cylindrical part, and a second supporting part having a second board supporting area that extends in a radial direction of the cylindrical part and is formed apart from the first board supporting area in an axial direction of the cylindrical part. The first board has a first through hole into which the sleeve main body and the second board supporting part are inserted and is fixed to the first board supporting area. The second board has a second through hole into which the sleeve main body is inserted and is fixed to the second board supporting area.

Owner:NIPPON DENSAN CORP

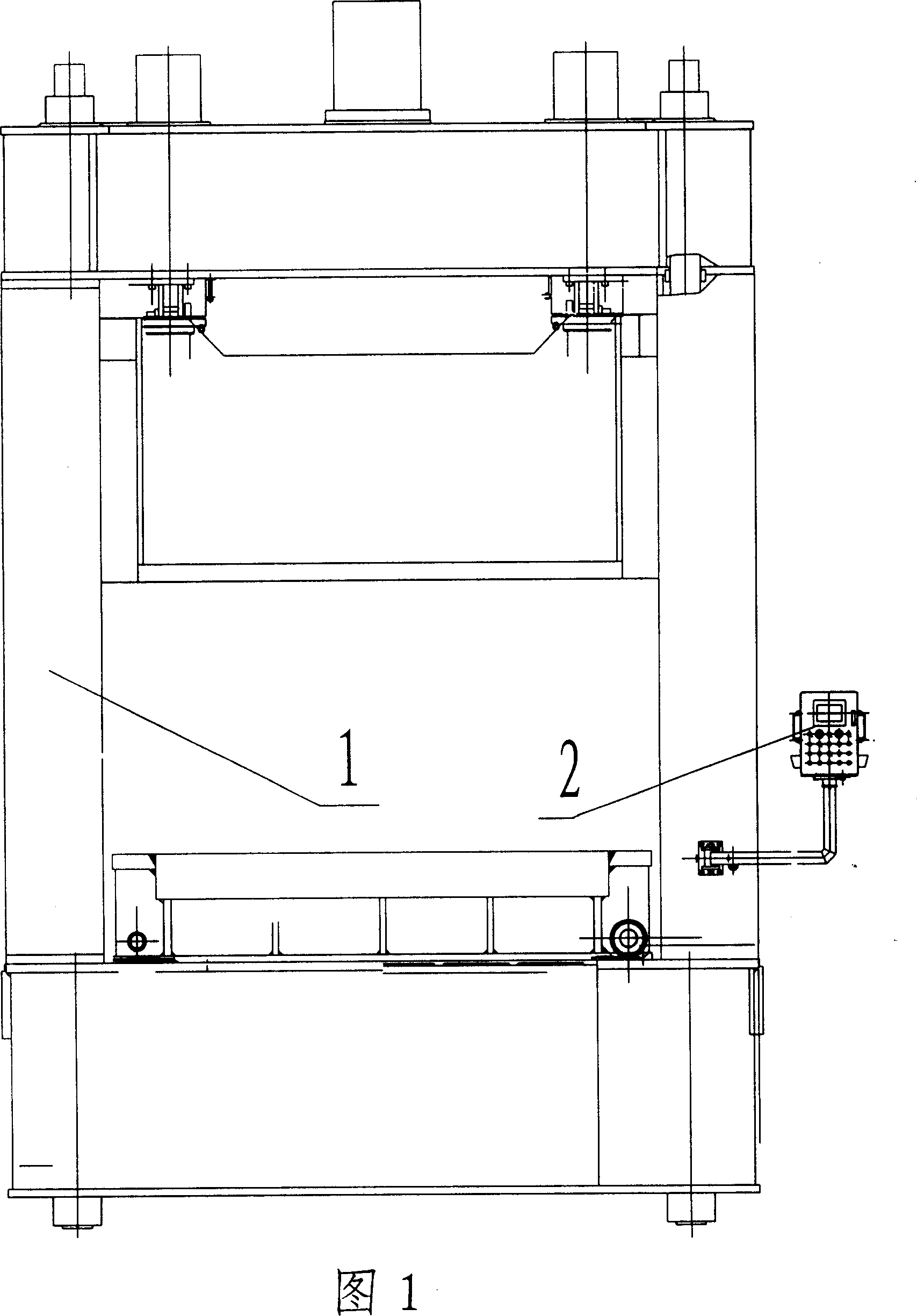

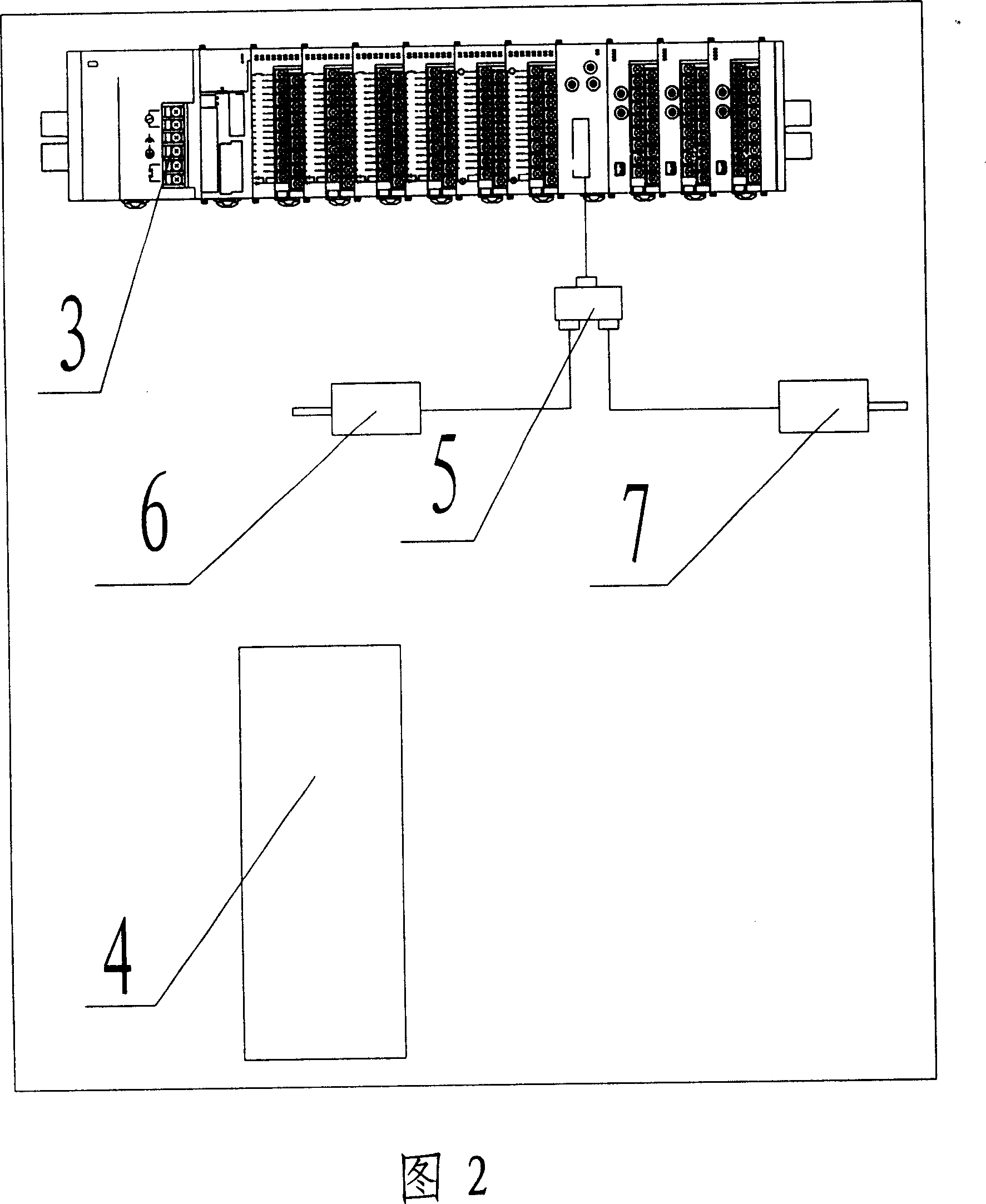

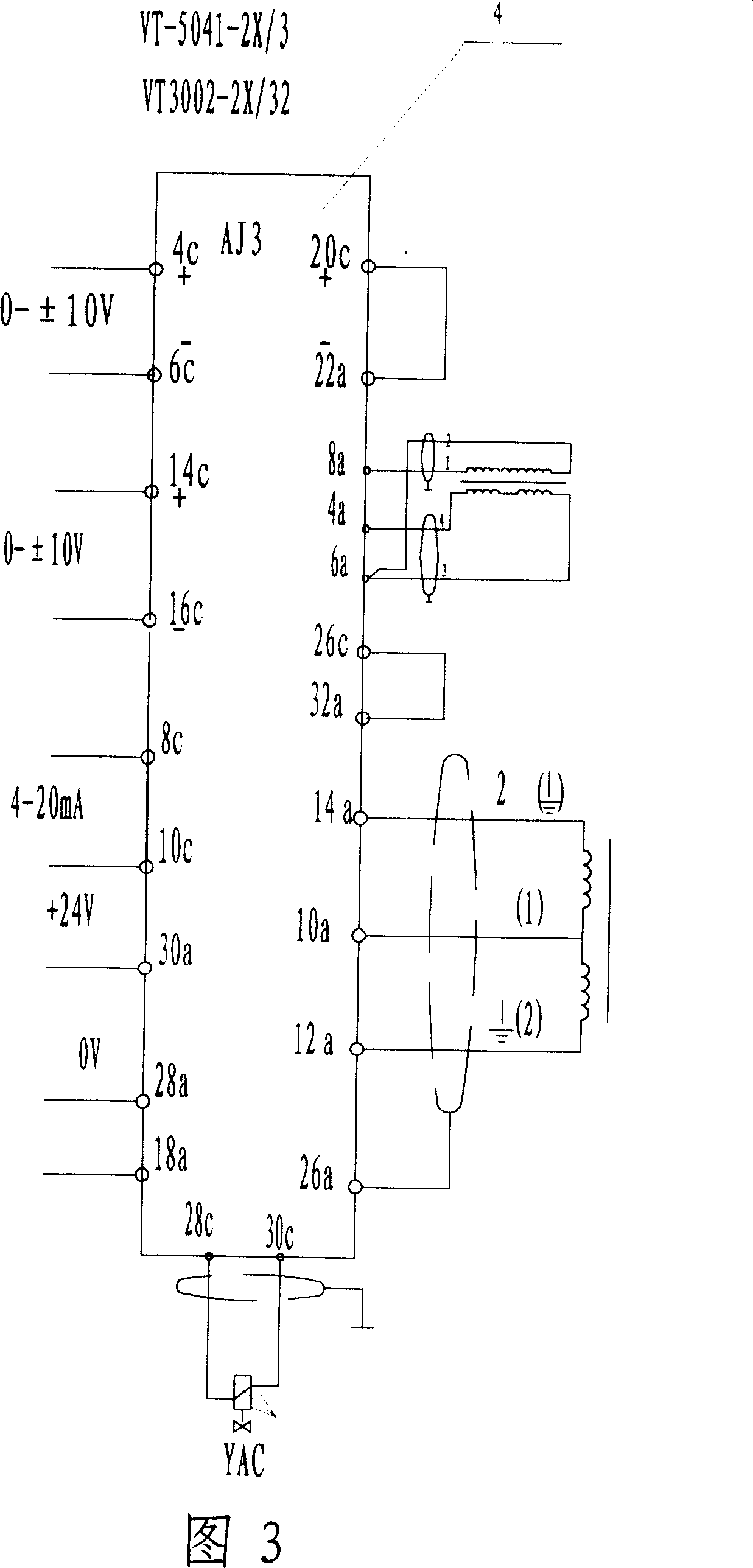

Hydraulic press constant power control structure and controlling means thereof

The present invention is one kind of constant power control structure for hydraulic press and its control process. The constant power control structure consists of one PLC, one turnable operation box, one branching unit, one slide block rotating coder, one hydraulic cushion rotating coder, and one proportional amplifier board. The proportional amplifier board is connected to one DC power source, one proportional electromagnet, one valve core displacement sensor and one swing angle sensor of the tilting mechanism. The constant power control process includes: calculating the power, regulating the voltage to obtain the calculated power and transmitting the voltage to the PLC via the RS232 port, and applying the voltage to the motor with the PLC. The present invention has low cost, saving in energy, good hydraulic press controlling effect and stable and reliable operation.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Pump with motor

ActiveUS10641261B2Facilitating caulkingReduce motor costEngine manufacturePositive displacement pump componentsRotational axisElectric machinery

Owner:OKEN LTD

Motor Water-Cooling Structure and Manufacturing Method Thereof

InactiveUS20140284845A1Prevent water leakageReduce motor costManufacturing dynamo-electric machinesCooling/ventillation arrangementWater leakageEngineering

A motor water-cooling structure and a manufacturing method thereof are disclosed. The motor water-cooling structure includes a motor case having a wall portion and a tube. The tube is embedded in the wall portion to serve as a flow passage. To manufacture the motor water-cooling structure, the tube is positioned in a mold cavity of a mold, and the motor case is formed in the mold by pour molding to embed the tube therein, so that the motor case and the tube form an integral body. With the manufacturing method, the motor water-cooling structure can be formed with reduced material, labor and time to save the manufacturing costs, and the risk of water leakage can be avoided.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

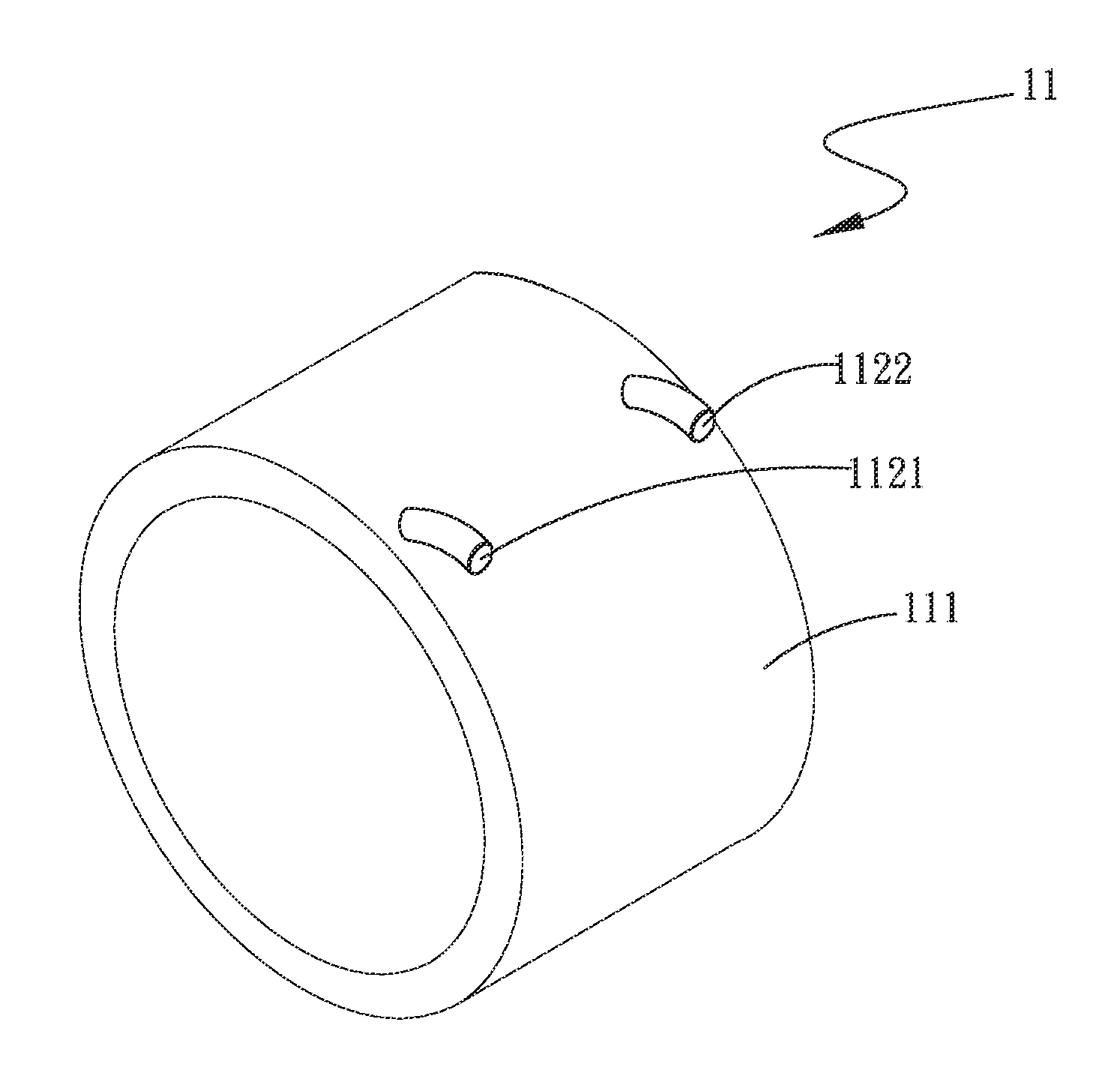

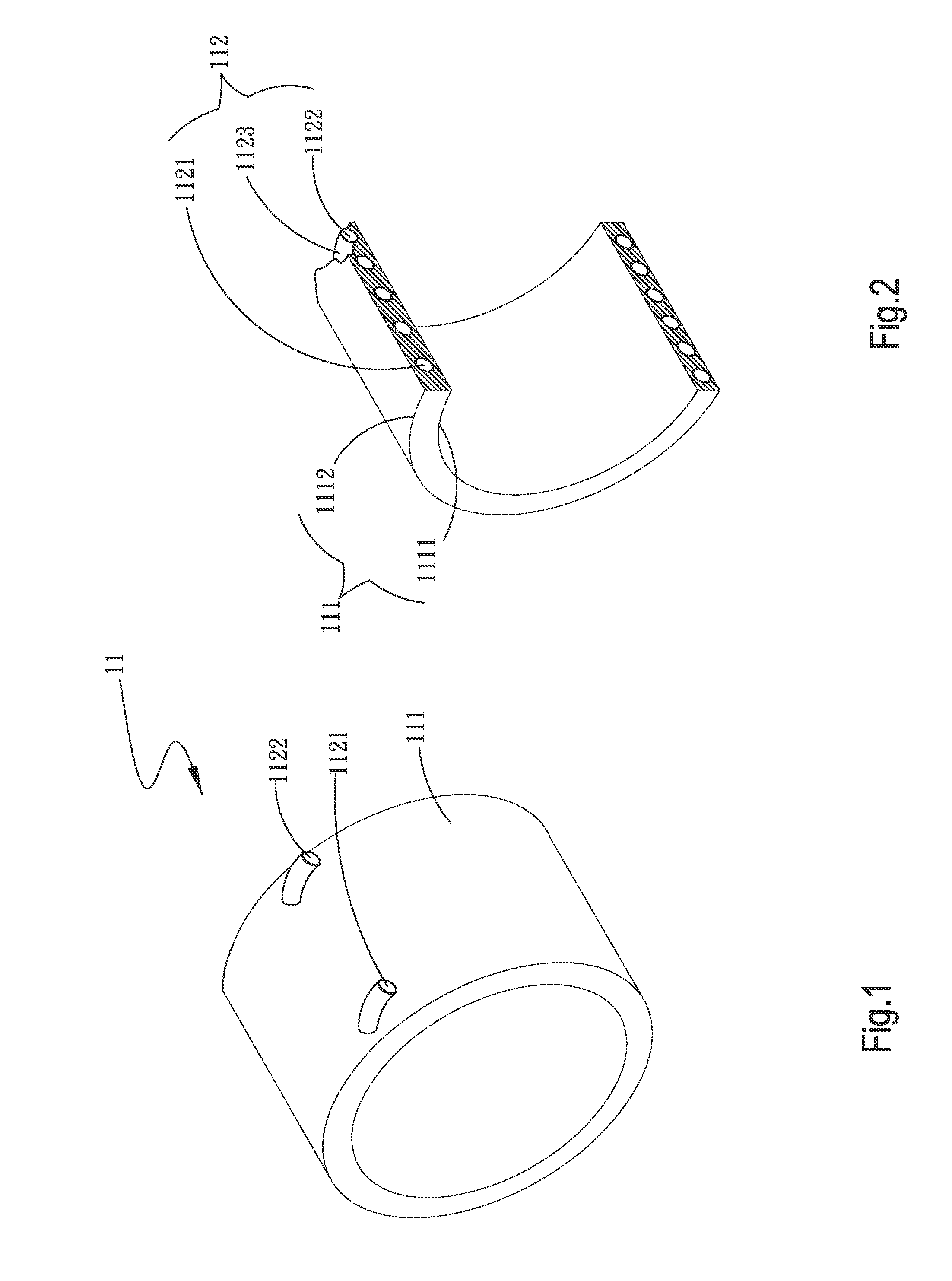

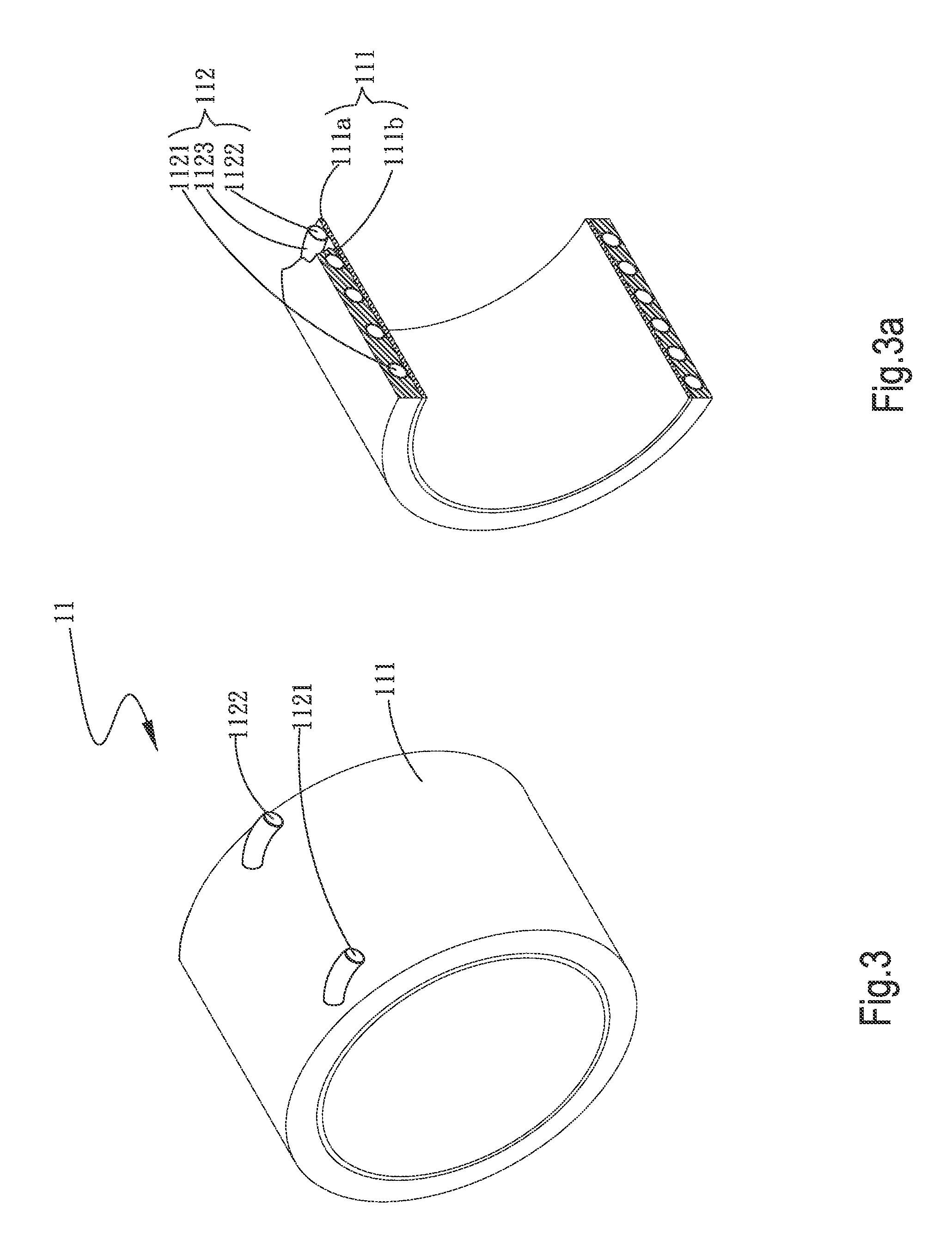

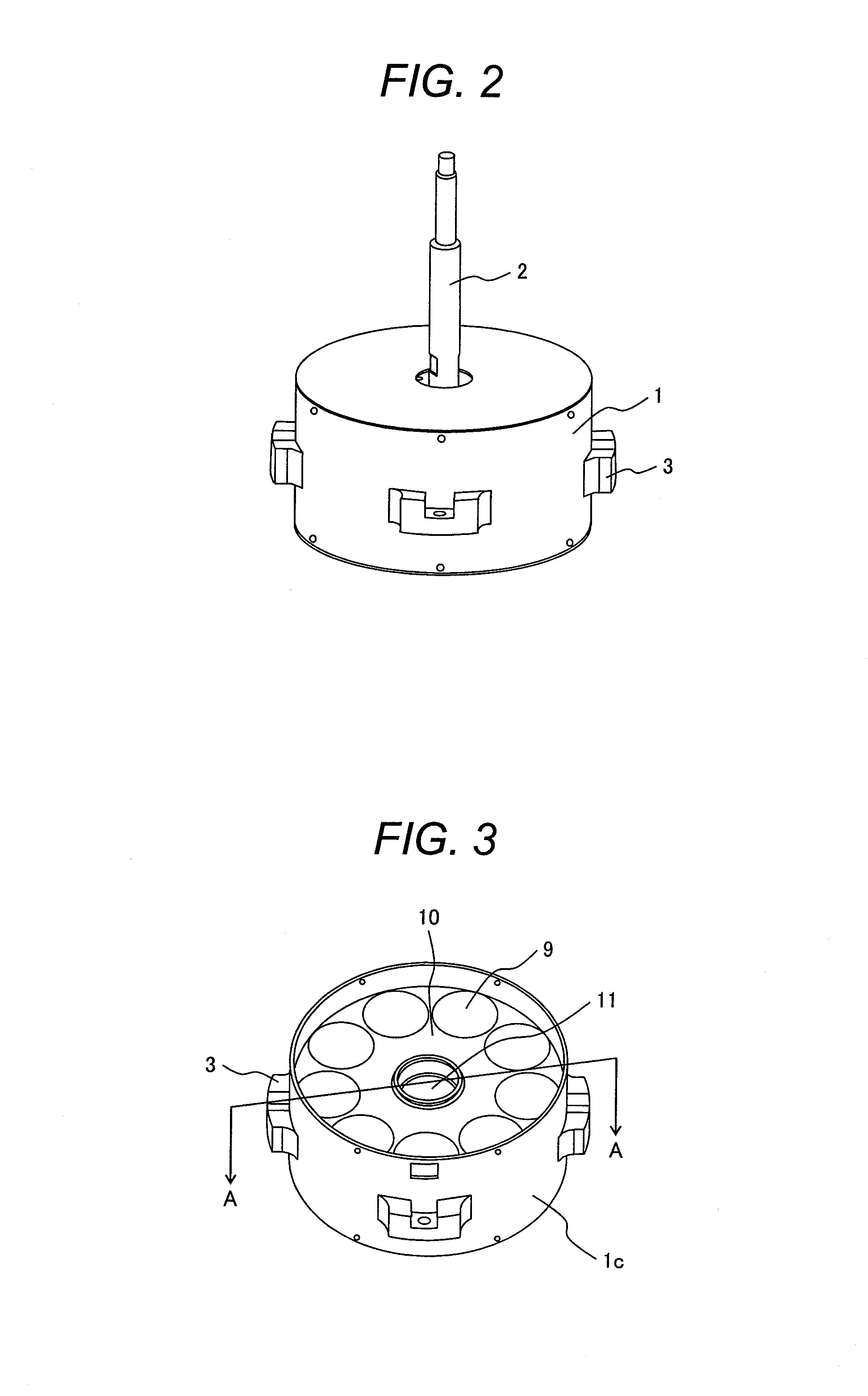

Axial gap rotating electrical machine

ActiveUS20120049685A1Reduce in quantitySimple manufacturing processMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsElectric machineEngineering

When an axial gap rotating electrical machine is assembled, stator cores are accurately positioned and a manufacturing process therefor is simplified. The axial gap rotating electrical machine is comprised of: a housing frame body having a first space in the cylindrical central part thereof and multiple second spaces located in the circumferential direction which have the same distances from the center; a shaft rotatably provided in the first space in the housing frame body; a core placed in each of the second spaces in the housing frame body and a coil arranged outside of the core; a rotor yoke fixed on the shaft, extended in the direction of the circumference thereof, and having multiple magnets arranged in circumferential positions confront the cores; and a case having a hole for the shaft and housing the housing frame body and the rotor yoke.

Owner:HITACHI METALS LTD

Motor

ActiveUS20150288244A1Small thicknessReduce motor costMechanical energy handlingSupports/enclosures/casingsEngineeringMechanical engineering

Disclosed is a motor including a housing having a first receiving part formed at one side thereof, a stator disposed in the housing, a rotor disposed in the housing, a rotating shaft rotated along with the rotor, a holder coupled to one side of the housing, and a bearing disposed between the first receiving part and the holder to support a rotation of the rotor.

Owner:LG INNOTEK CO LTD

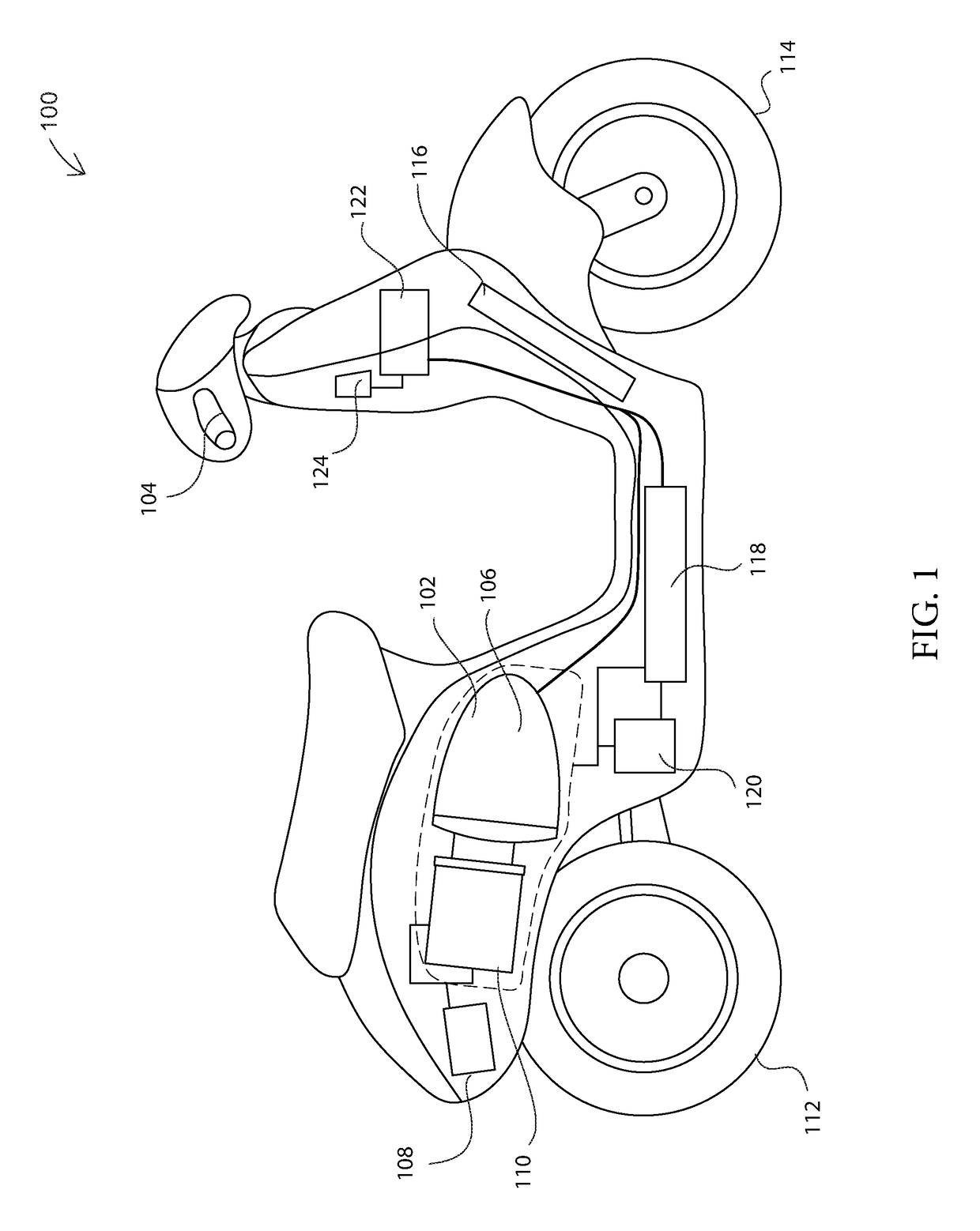

Method and system for improving the efficiency of motor vehicles

ActiveUS20180320650A1Low reliabilityImprove fuel efficiencyAc-dc conversionElectric motor startersMobile vehicleMotor vehicle crash

A method and system of improving the efficiency of motor vehicles includes stopping an engine of a motor vehicle system if the motor vehicle system is immobile for more than a predetermined period of time, according to one embodiment. The method and system includes starting the engine with a magneto system, in response to one or more vehicle conditions, such as operation of a throttle, operation of a clutch, and / or operation of a brake lever, according to one embodiment.

Owner:STMICROELECTRONICS INT NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com