Hydraulic press constant power control structure and controlling means thereof

A technology of constant power control and hydraulic press, applied in the field of hydraulic press, can solve the problem of wasting motor power, etc., and achieve the effect of saving motor cost, saving energy and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

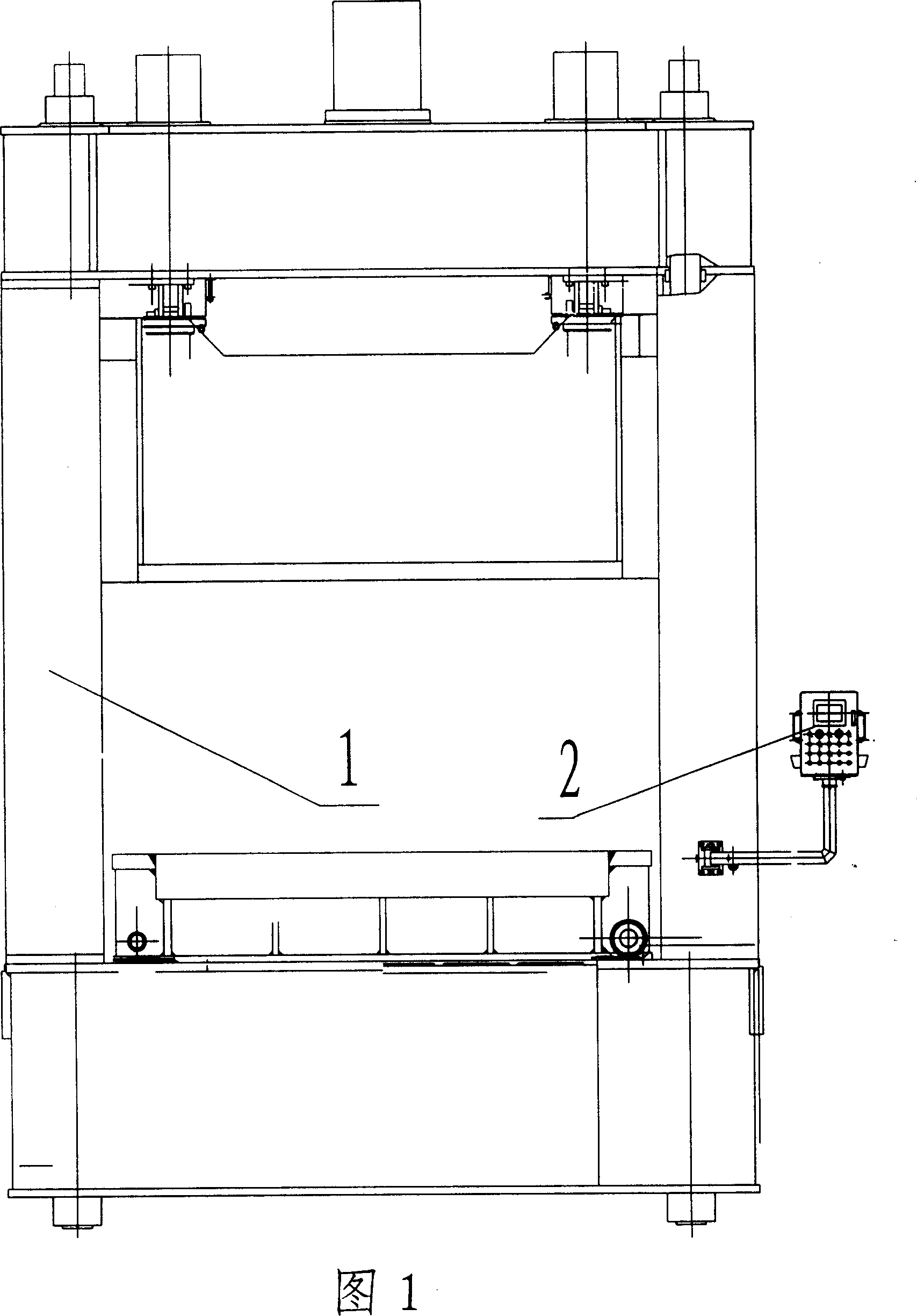

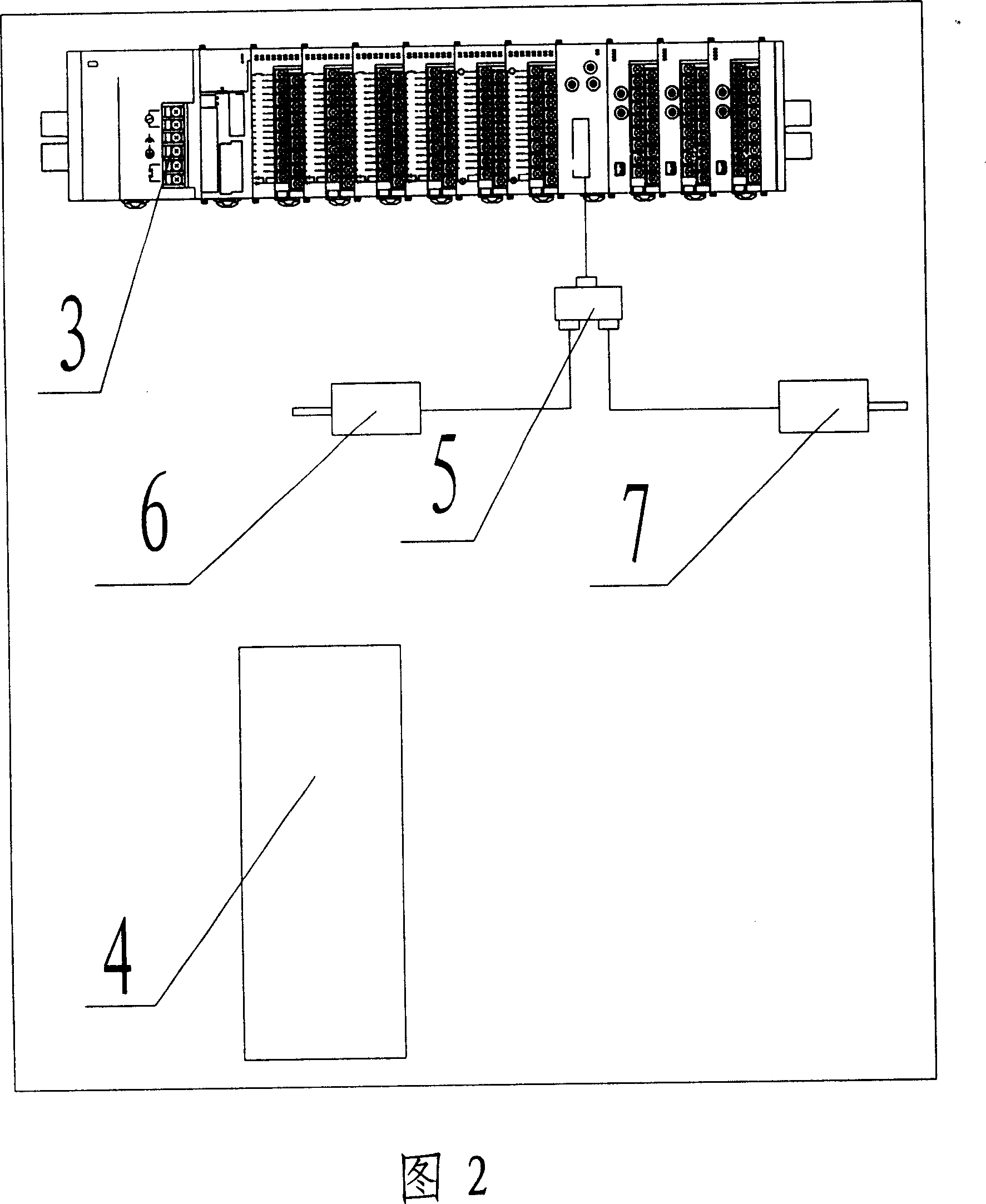

[0017] As shown in Figure 1 and Figure 2, the constant power control structure of the hydraulic press includes a PLC (programmable logic controller) 3 set in the control system of the hydraulic press for controlling the hydraulic press 1, and a rotatable operation box set on the hydraulic press 1 2 (a touch screen with a programmable control terminal is arranged on it), a splitter 5 connected to a PLC (programmable controller) 3, a slider rotary encoder 6 and a hydraulic cushion rotary encoder 7 branched out from the splitter 5, A proportional amplification board 4 is also provided on the hydraulic machine 1 .

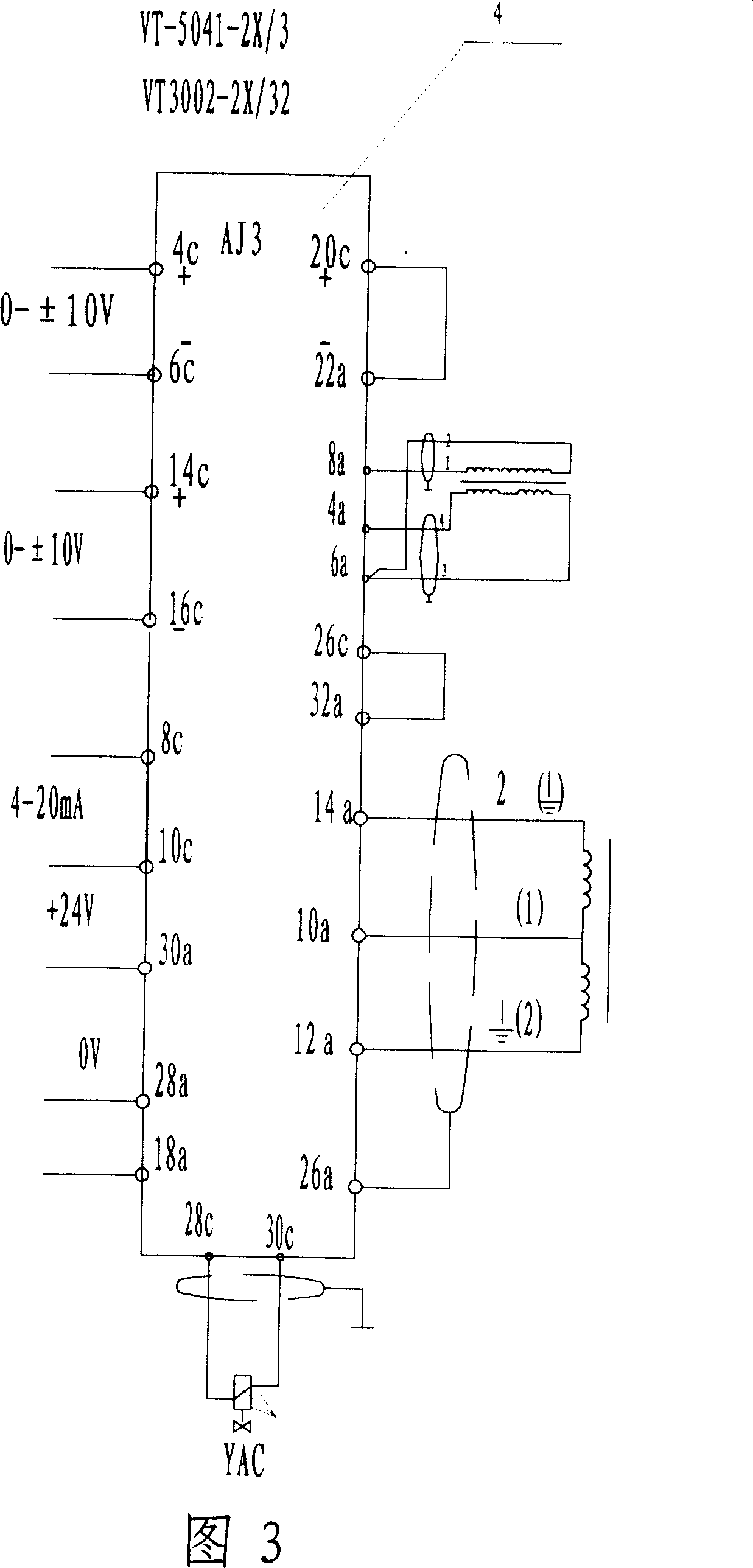

[0018] As shown in FIG. 3 , the model of the proportional amplification board 4 is VT-5041-2X / 3, and the model of its bracket is VT3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com