Motor

a technology for motors and motor parts, applied in the field of motors, can solve the problems of increasing the number of components and the corresponding cost, and ensuring such sufficient space on the circuit board, so as to improve the productivity of the motor, reduce the cost, and simplify the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

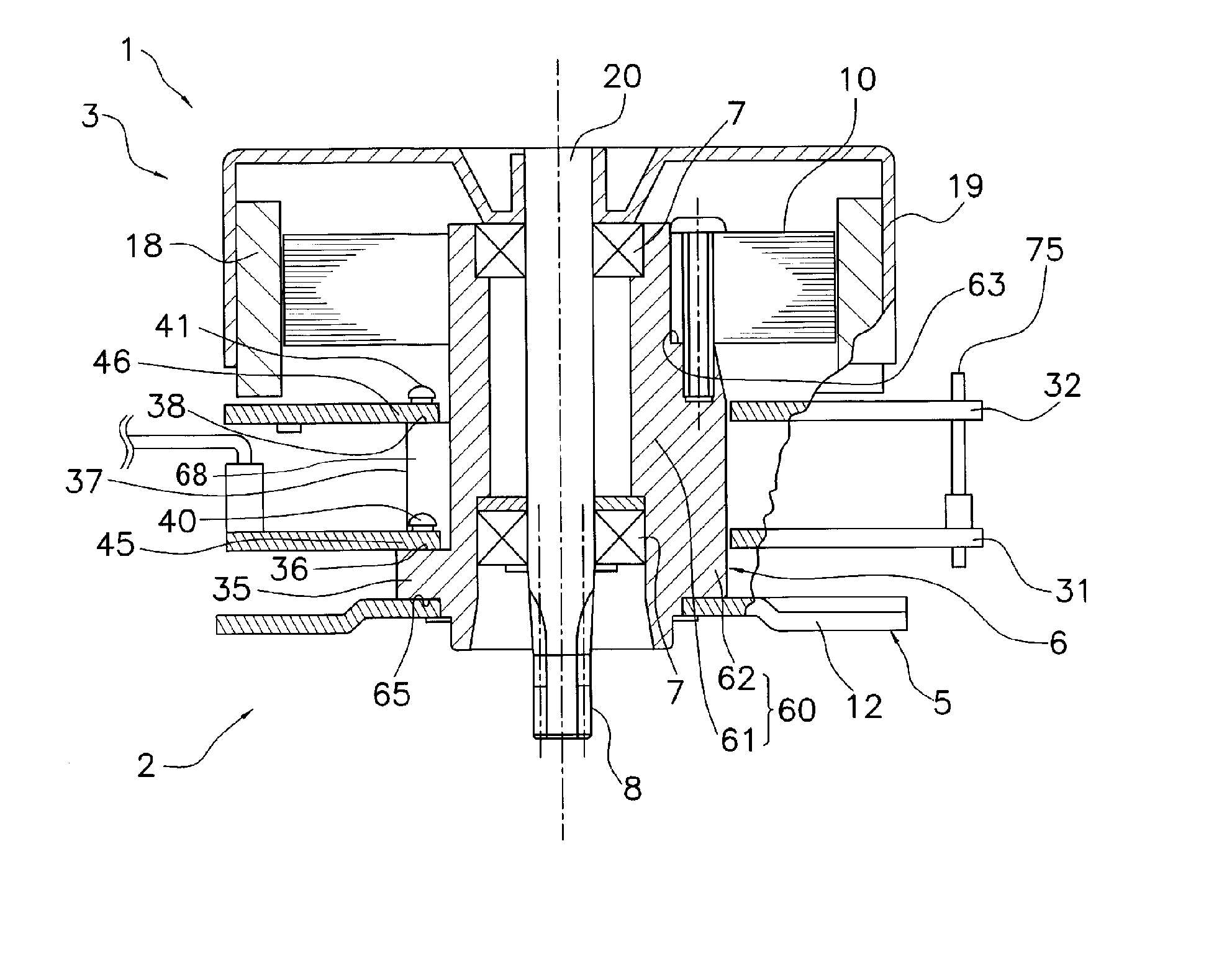

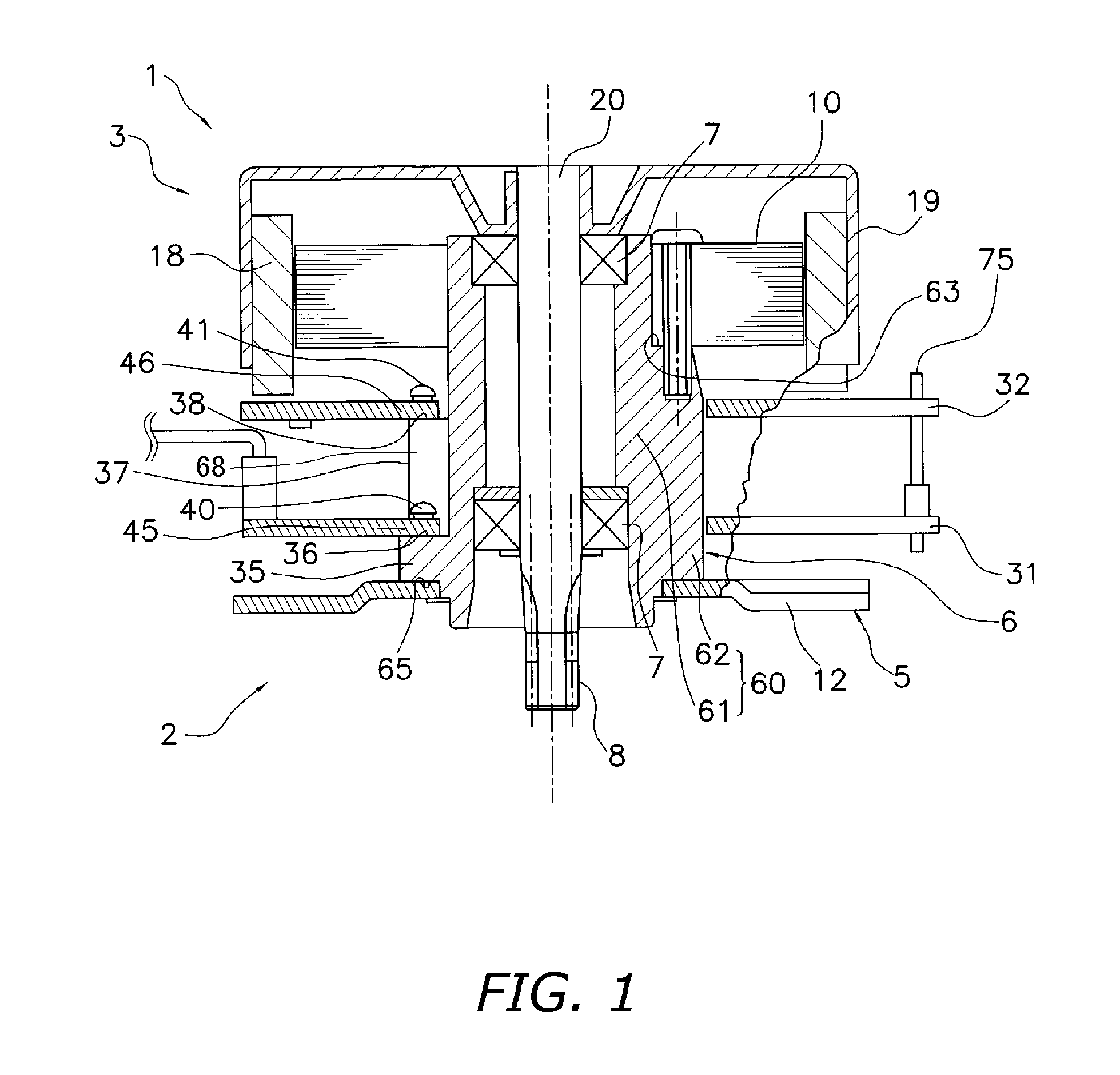

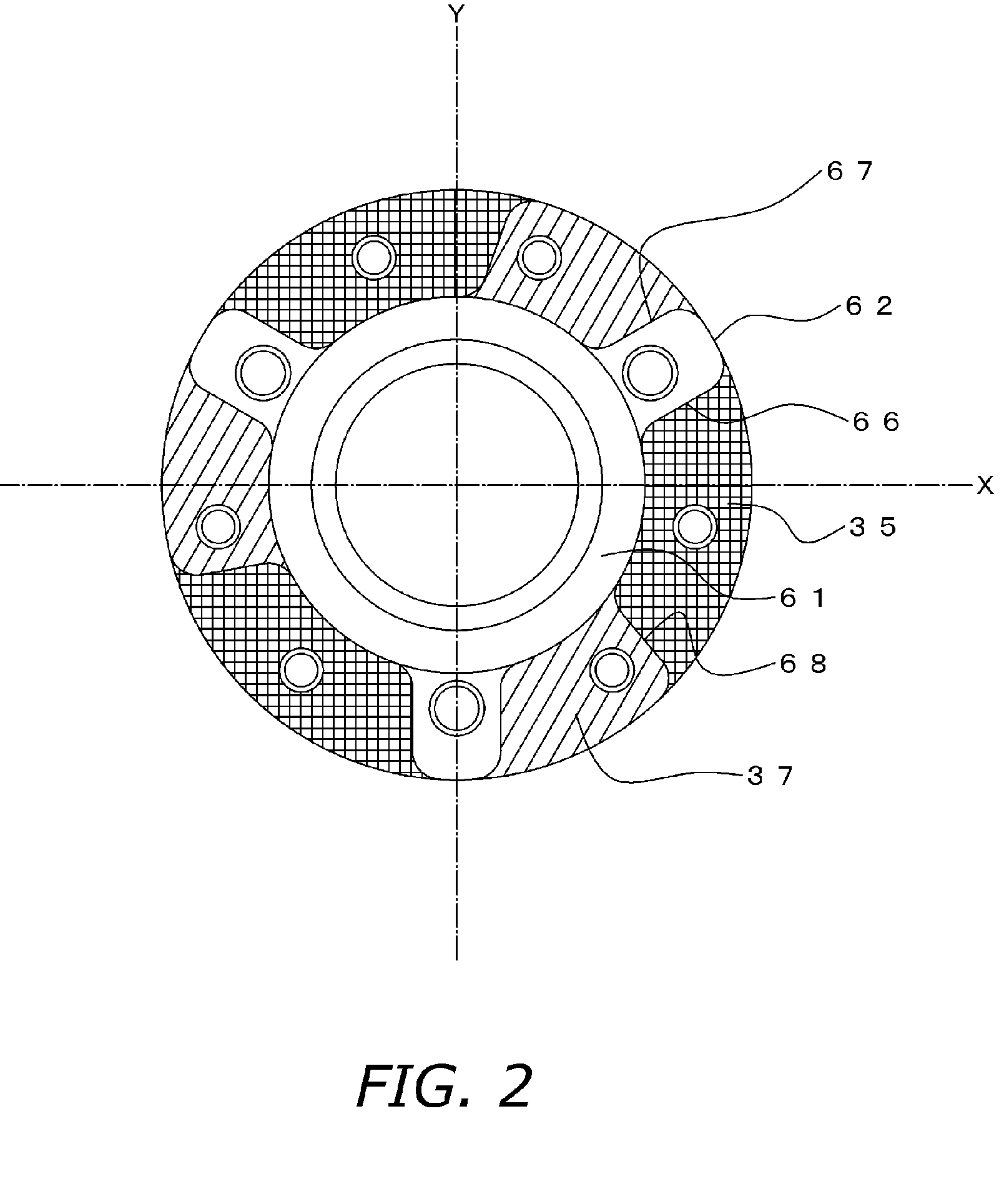

[0030] A motor in accordance with an embodiment of the present invention will be described with reference to FIG. 1 to FIG. 7.

[0031] Configuration—FIG. 1 is a cross-sectional view showing configuration of a motor 1 in accordance with the embodiment of the present invention, which is used for LBPs, copying machines, etc. The motor 1 has a static member 2 fixed to products such as LBPs and PPCs, a bearing 7 fixed to the static member 2 and a rotational member 3 rotatably supported with respect to the static member 2 through the bearing 7. The motor 1 is characterized by that the static member 2 comprises circuit boards in two layers (2 units). Parts and components corresponding to those of the conventional motor 11 in FIG. 8 are designated by the same reference numerals and description thereof is omitted.

[0032] The static member 2 as a characterizing part of the present invention will be described below.

[0033] Static member 2—The static member 2 has a bracket 5 for fixing the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com