Axial non-uniform air gap hybrid excitation synchronous machine

A mixed excitation synchronous and non-uniform technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, magnetic circuit rotating parts, etc., can solve the problem of increasing the length of the armature winding and its copper loss , low brush and power density, increasing the axial length of the motor, etc., to achieve a wide magnetic field adjustment range, reduce the cost of the motor, and reduce the volume of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

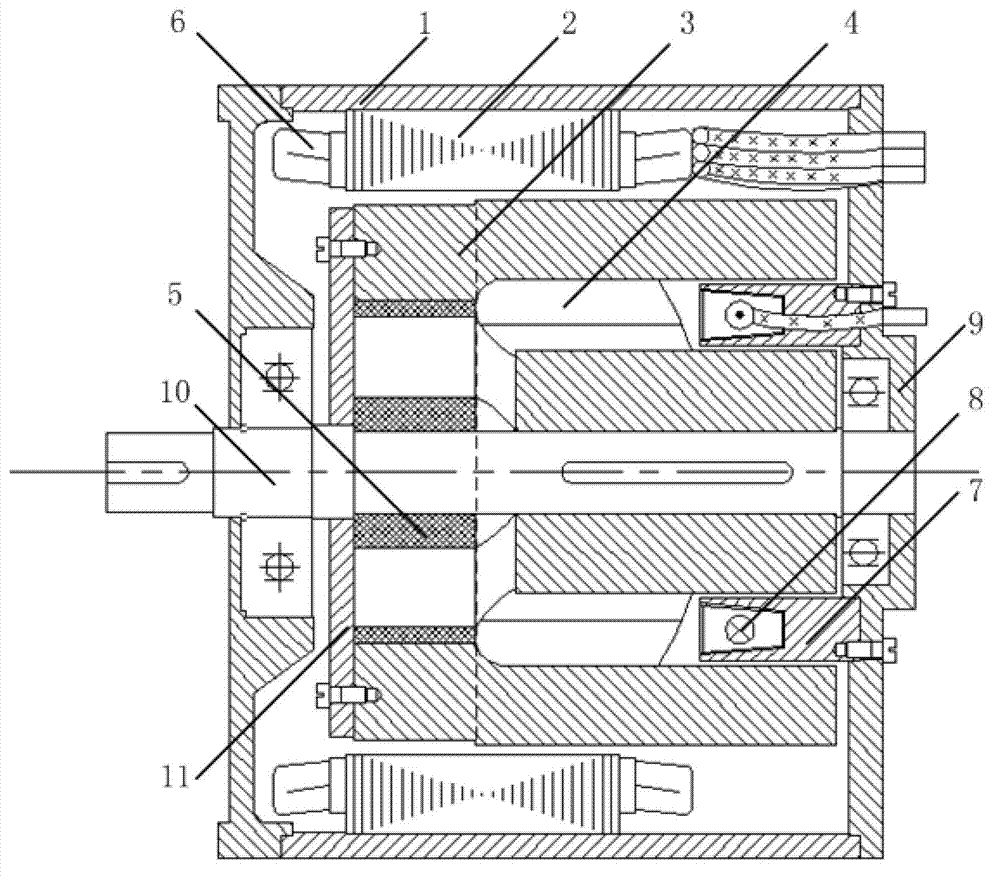

[0025] Such as figure 1 As shown, the present invention provides a hybrid excitation synchronous motor with an axial non-uniform air gap, including a casing 1 and a stator, a rotor, a rotating shaft 10 arranged in the casing 1, and an annular magnetic bridge 7 fixed on the end cover 9 , wherein the stator includes a stator core 2 and an armature winding 6 embedded in the stator slot, and the stator core 2 is fixed on the casing 1 .

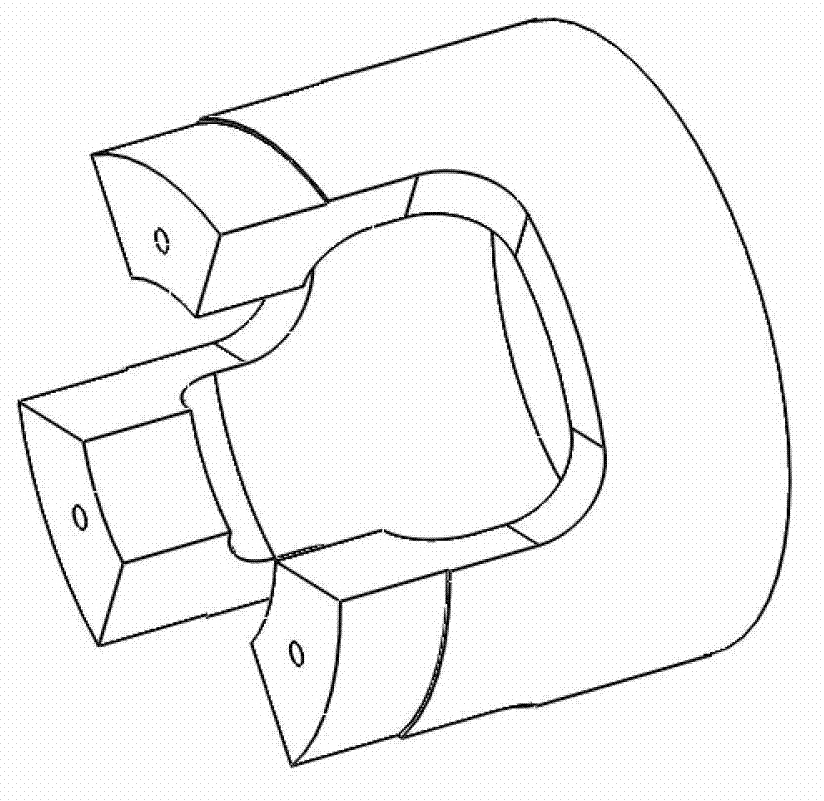

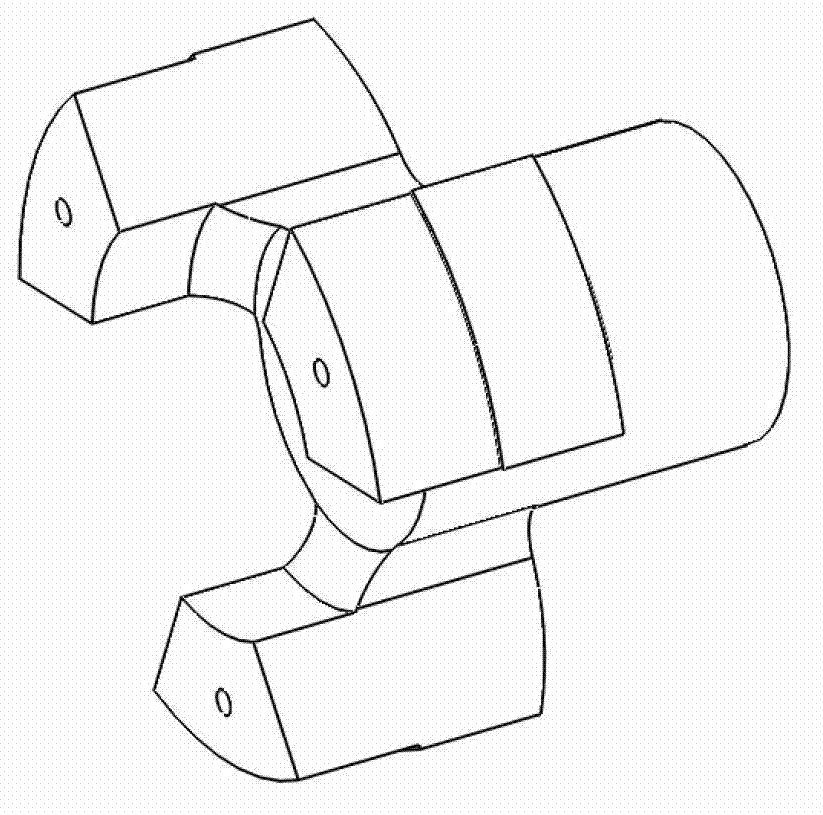

[0026] The rotor is fixed on the rotating shaft 10 and includes rotor N pole shoe 3 , rotor S pole shoe 4 and tangentially magnetized permanent magnet 5 , which will be introduced separately below.

[0027] The part adjacent to the permanent magnet 5 on the rotor N pole shoe 3 and the rotor S pole shoe 4 is called the permanent magnet side, while the rotor N pole shoe 3 and the rotor S pole shoe 4 are not in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com