Method for Controlling Rear Axle Clutch of Hybrid Electric Vehicle

A hybrid vehicle, clutch control technology, applied in transmission control, components with teeth, belts/chains/gears, etc. Affect the service life of the motor and other issues, to achieve the effect of facilitating ride comfort, improving drivability, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

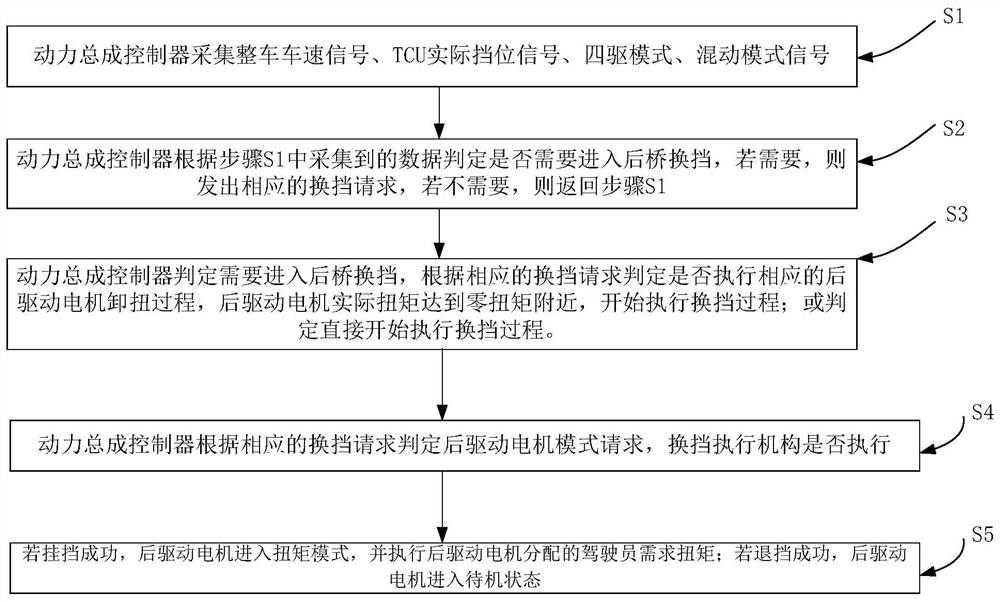

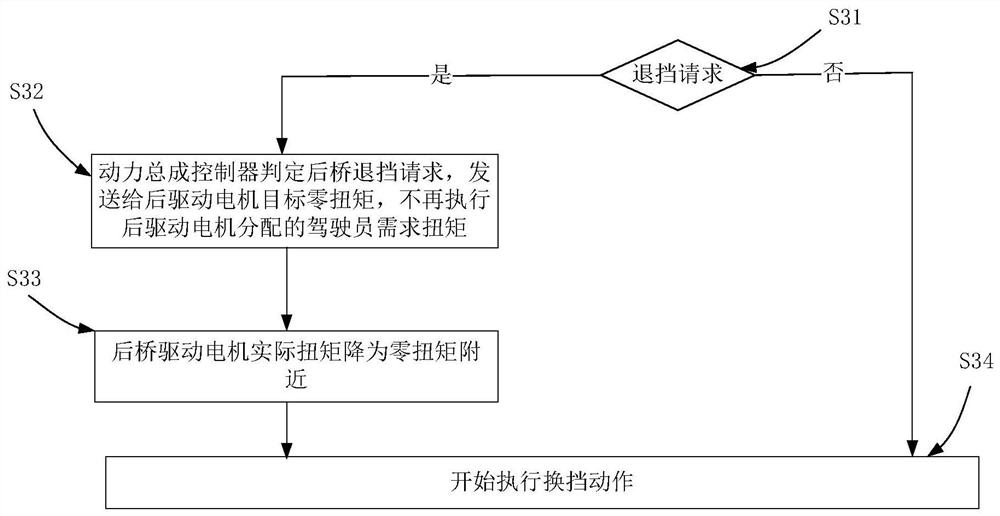

[0040] The present invention will be further described below in conjunction with accompanying drawing.

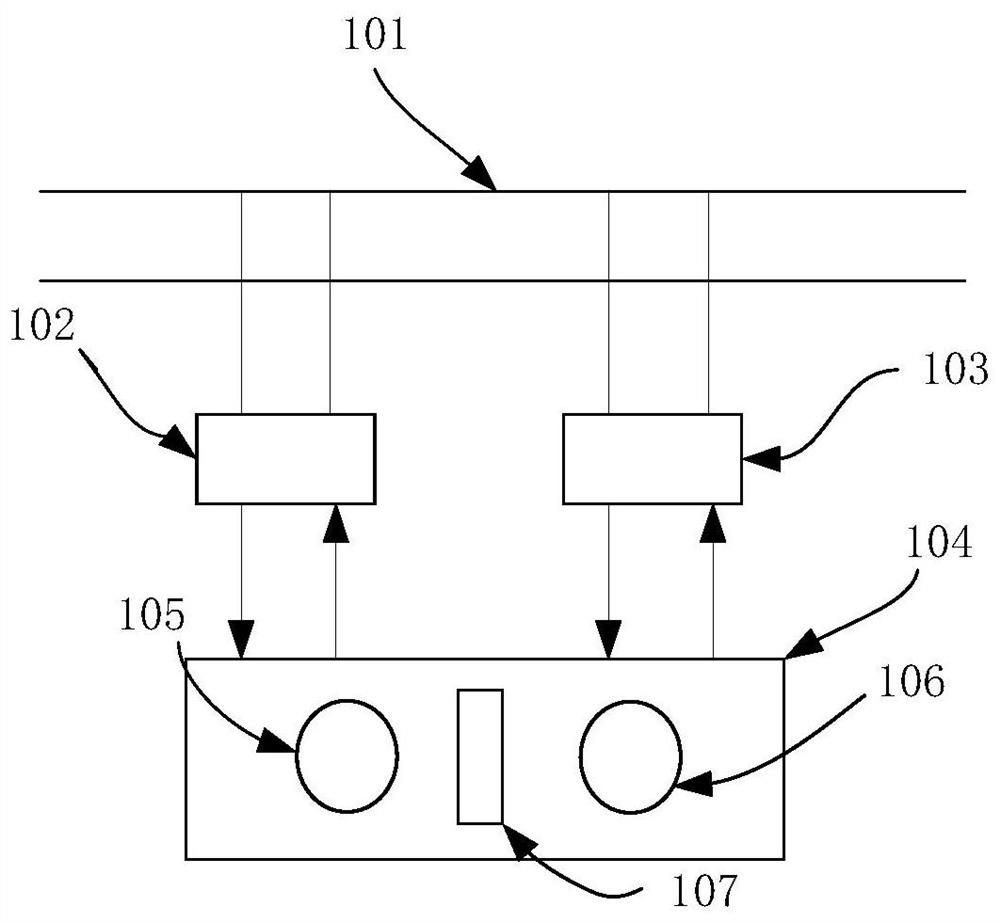

[0041] Such as figure 1 As shown, in this embodiment, a hybrid vehicle rear axle clutch control system includes a powertrain controller 102, a drive motor controller 103, and a differential assembly 104, wherein the differential assembly includes a rear drive motor 105, shift control mechanism 106 and clutch 107.

[0042] The powertrain controller 102 and the driving motor controller 103 are connected and transmit data through the CAN bus 101 . The drive motor controller 103 and the differential gear assembly 104 are connected through a high voltage line and a communication harness. The powertrain controller 102 and the differential assembly 104 are connected through a communication harness.

[0043] The powertrain controller 102 is mainly used to collect the vehicle speed signal, the influence factor of the actual gear signal of the front axle transmission, the four-whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com