Patents

Literature

341results about How to "Improve emission performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer and method providing for illumination of keyboard

InactiveUS6911971B2Avoid problemsAvoids any increase in the workloadInput/output for user-computer interactionLegendsComputer hardwareComputer graphics (images)

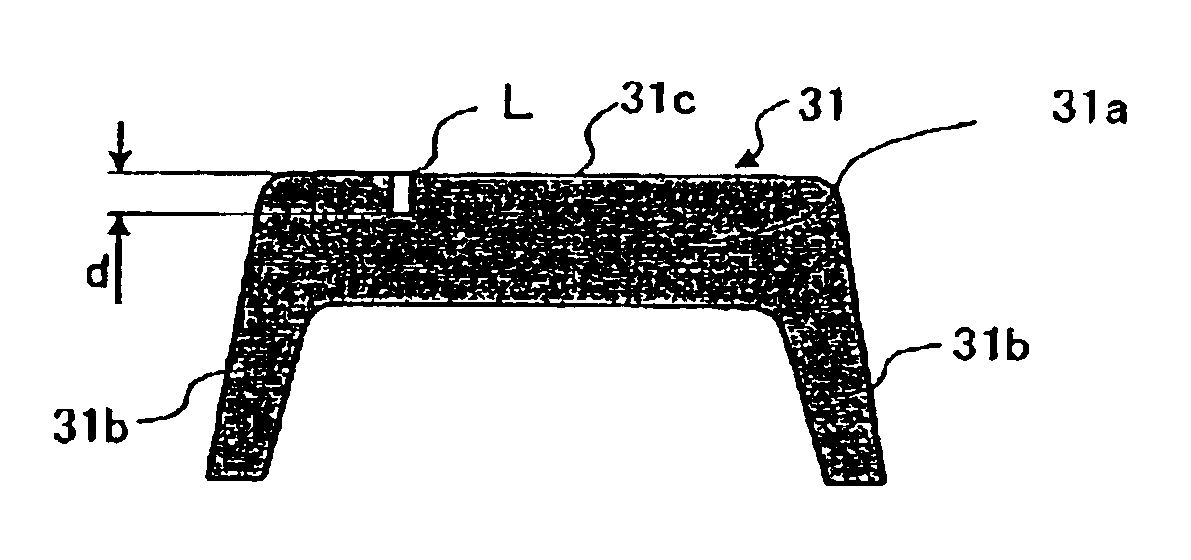

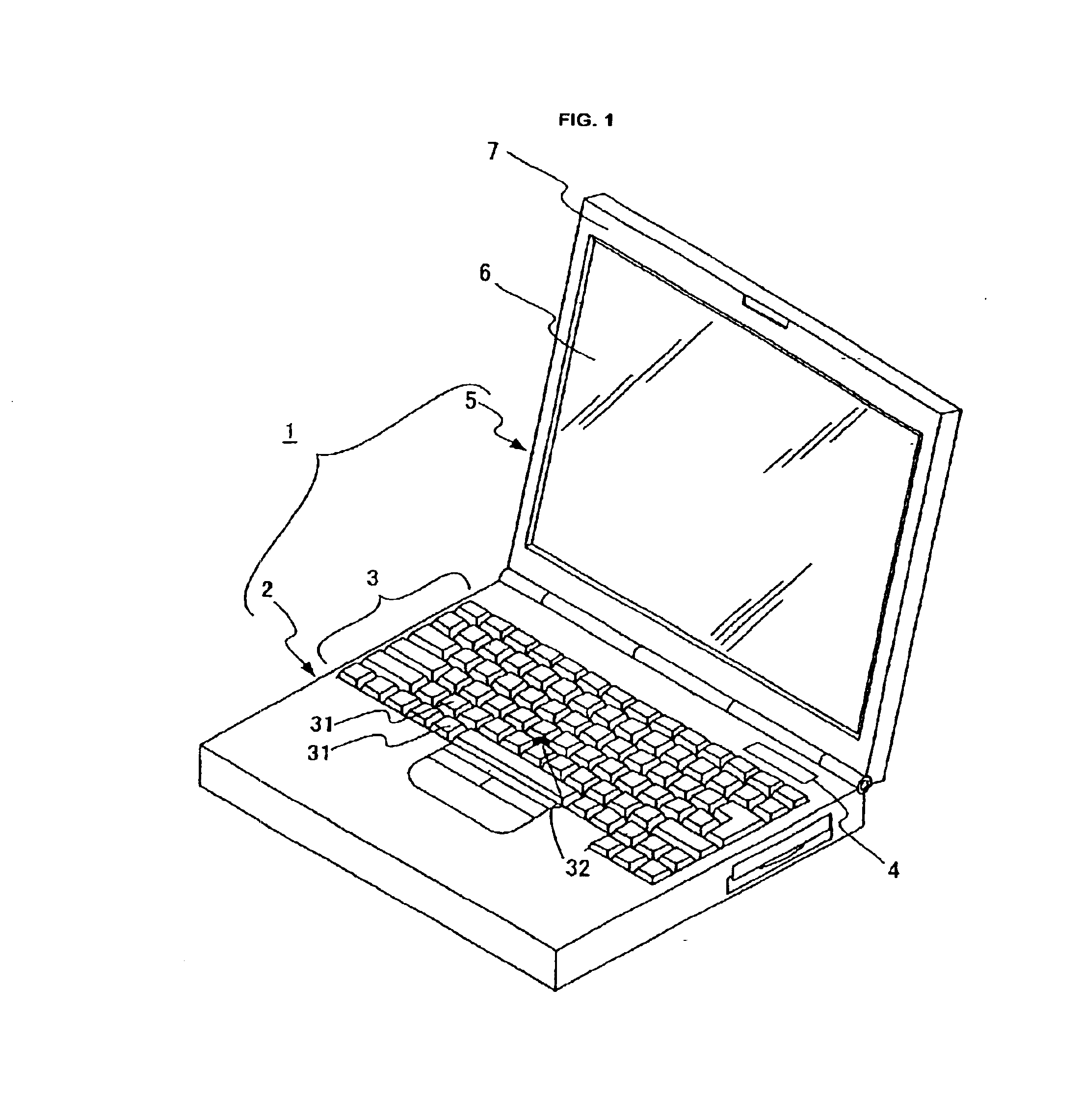

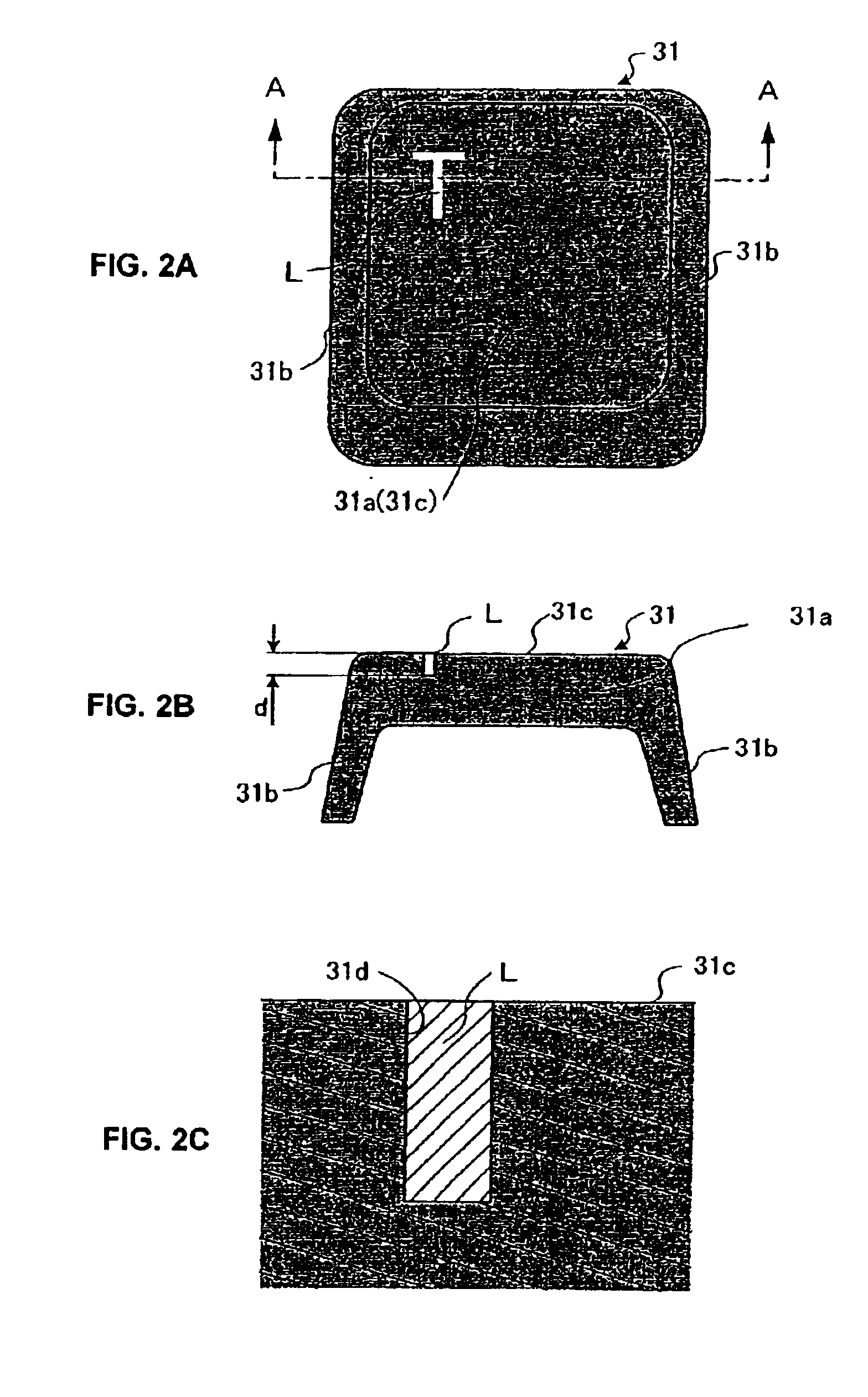

The computer of the present invention is provided with a main body on which keys to be operated by the user are disposed and a display unit that displays an image in accordance with each operation executed for the main body. Each key disposed on the main body is composed of its body having a key top and a light accumulator recess opened in the key top. The light accumulator recess is formed in a manner indicative of the character or symbol associated with such key. The light accumulator recess has embedded in it a light accumulating material such that the character or symbol associated with the key is illuminated by the residual light emission of the light accumulating material when the computer is operated in a location with little or no ambient light.

Owner:LENOVO (SINGAPORE) PTE LTD

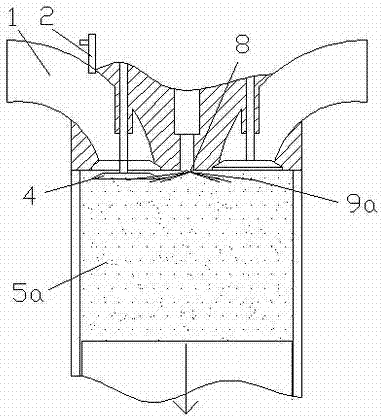

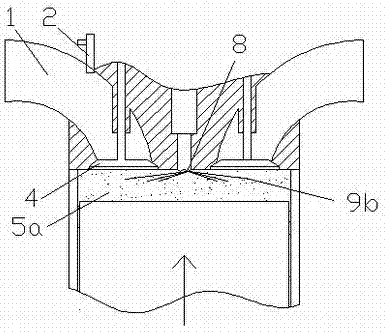

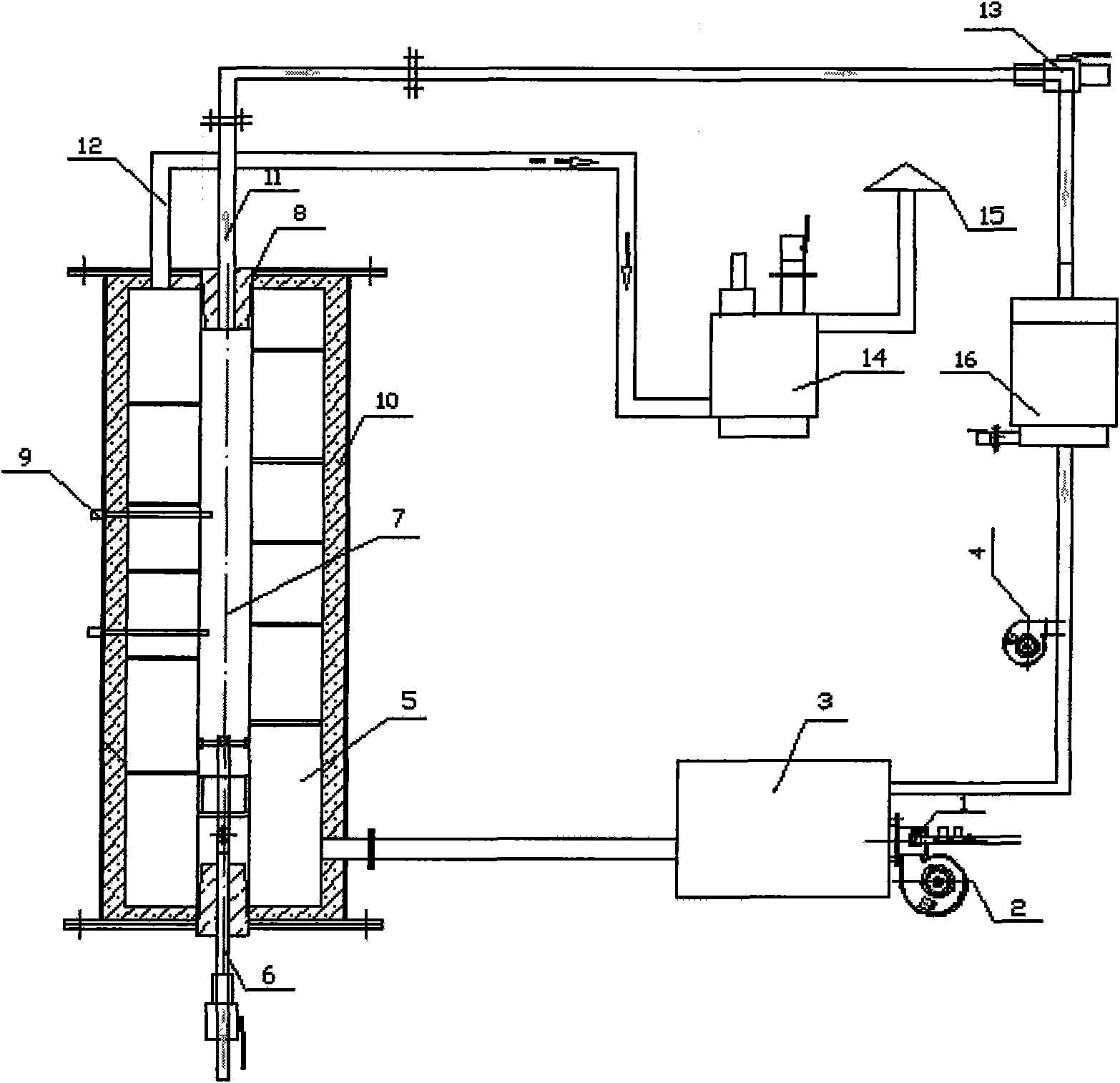

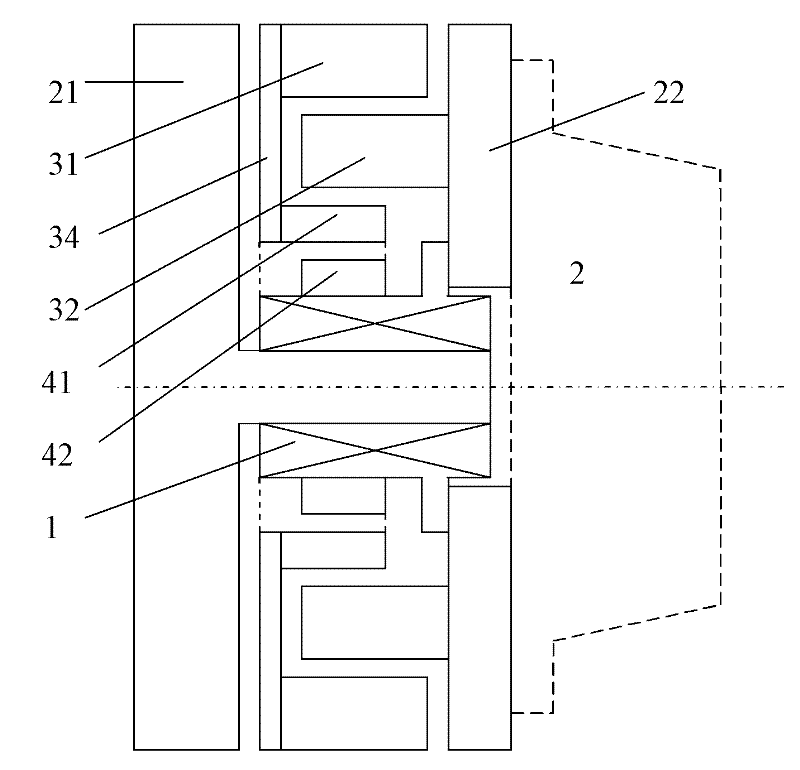

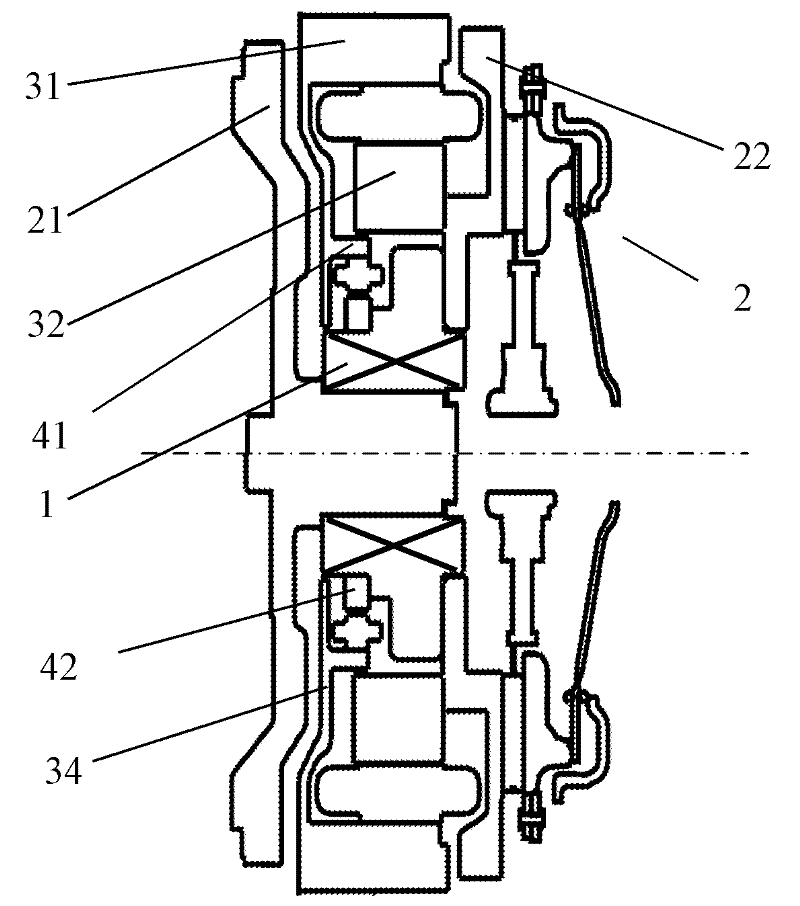

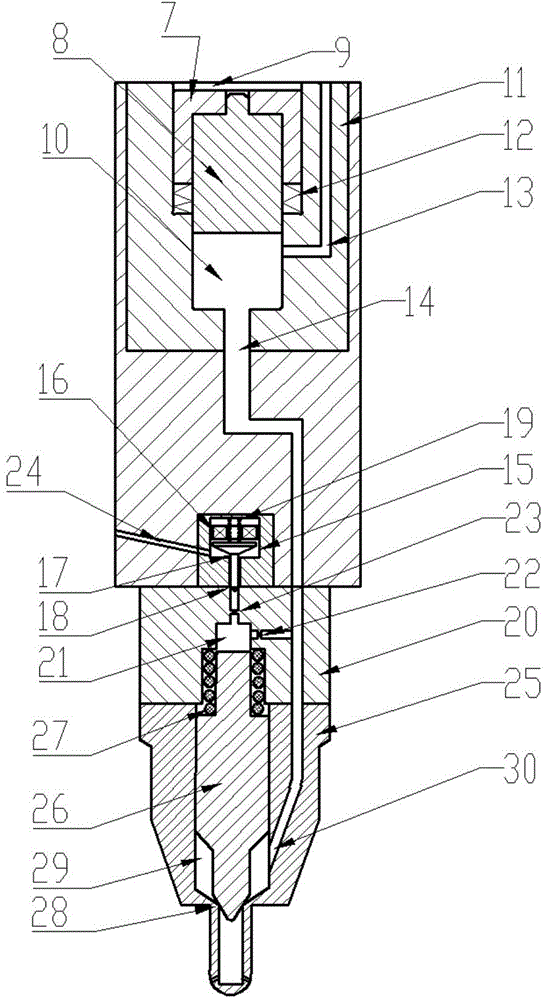

Common-rail fuel oil jet system controlled by double electromagnetic valves and applied to low-speed diesel engine for ship

InactiveCN104632485ASimple structureReduce processing costsFuel injection apparatusMachines/enginesLow speedCommon rail

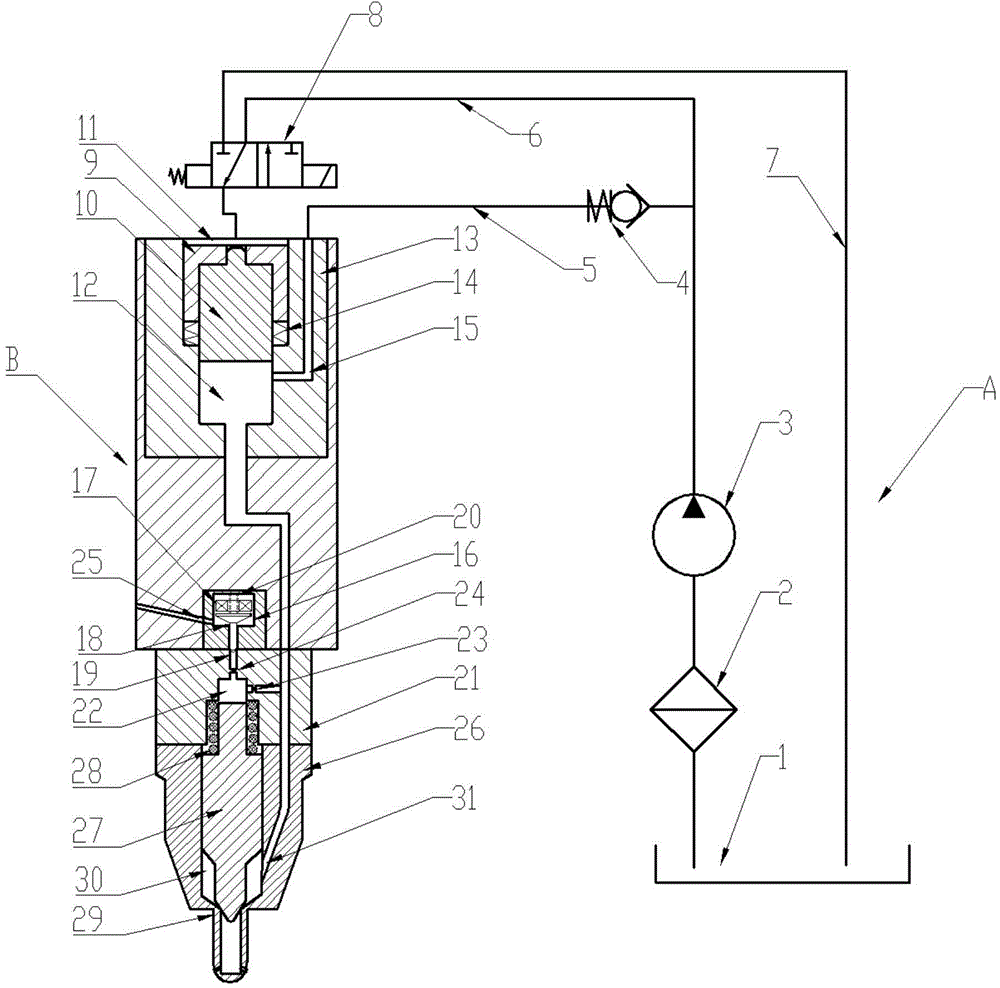

The invention provides a common-rail fuel oil jet system controlled by double electromagnetic valves and applied to a low-speed diesel engine for a ship. The common-rail fuel oil jet system comprises a fuel oil supply portion and a common-rail jet device. The fuel oil supply portion supplies fuel oil and servo oil to the common-rail jet device. In the common-rail jet device, an upper pressurizing piston cavity and a lower pressurizing piston cavity are formed between a pressurizing piston and a pressurizing piston body, and the pressurizing piston control valve controls the fuel oil supply portion to be communicated or not communicated with the upper pressurizing piston cavity, so that fuel oil pressurization or fuel oil suction is achieved; the electromagnetic fuel oil jet control valve conducts fuel oil-working-condition accurate flexible control over fuel oil jet timing and the circulation jet amount, a pressurized high-pressure fuel oil path in the lower pressurizing piston cavity is divided into two paths, one path reaches a control cavity, and the other path reaches a fuel oil containing groove. According to the common-rail fuel oil jet system, the two electromagnetic valves are used for control, fuel oil is used as fuel and servo oil at the same time, the structure is simplified, cost is reduced, mutual independence between fuel oil pressurization and jet and repeated jet are achieved, fuel oil jet timing, the fuel oil jet rule and the circulating fuel oil jet amount are more accurately controlled, the fuel oil economical efficiency and the emission performance of the diesel engine are improved.

Owner:HUDONG HEAVY MACHINERY +2

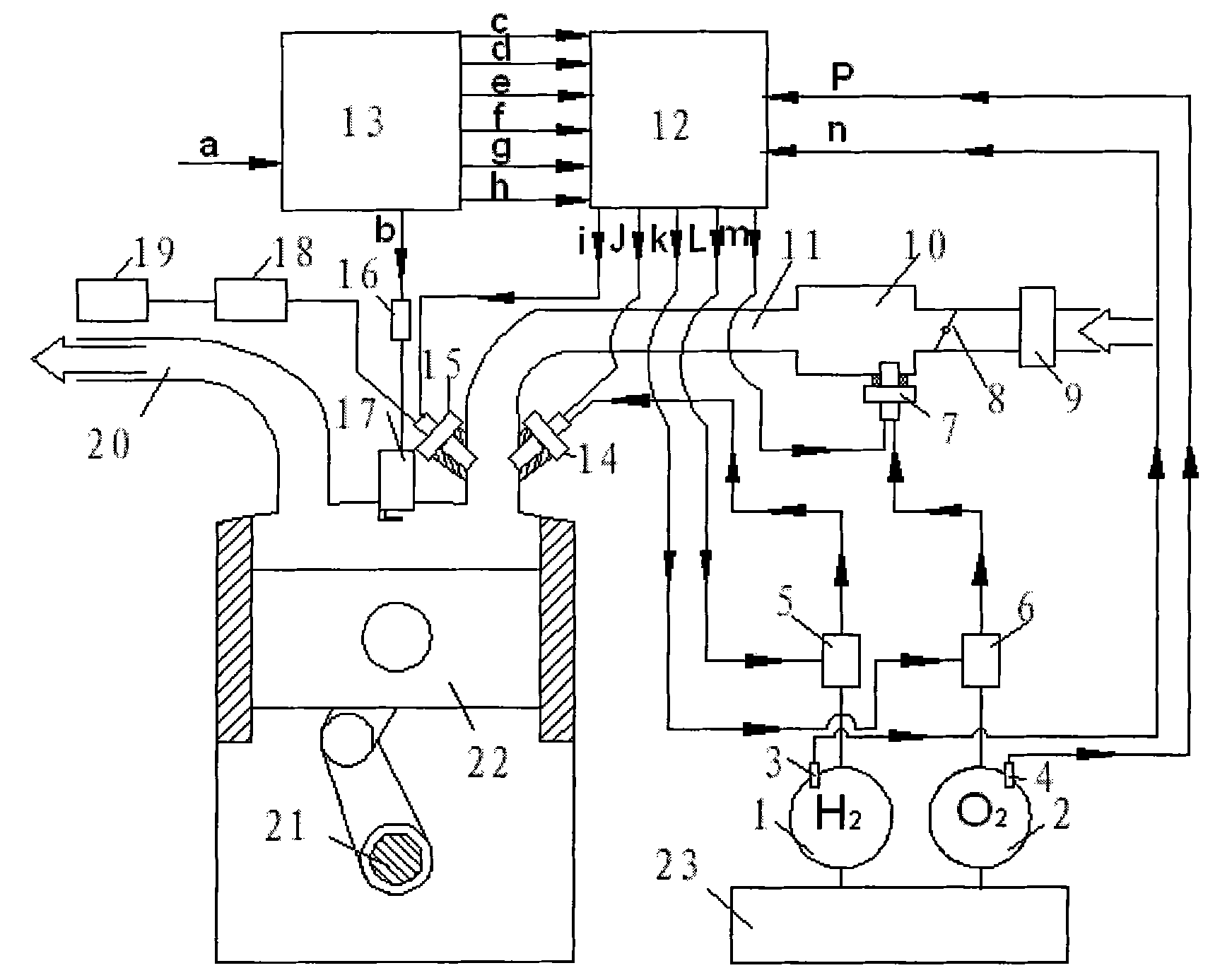

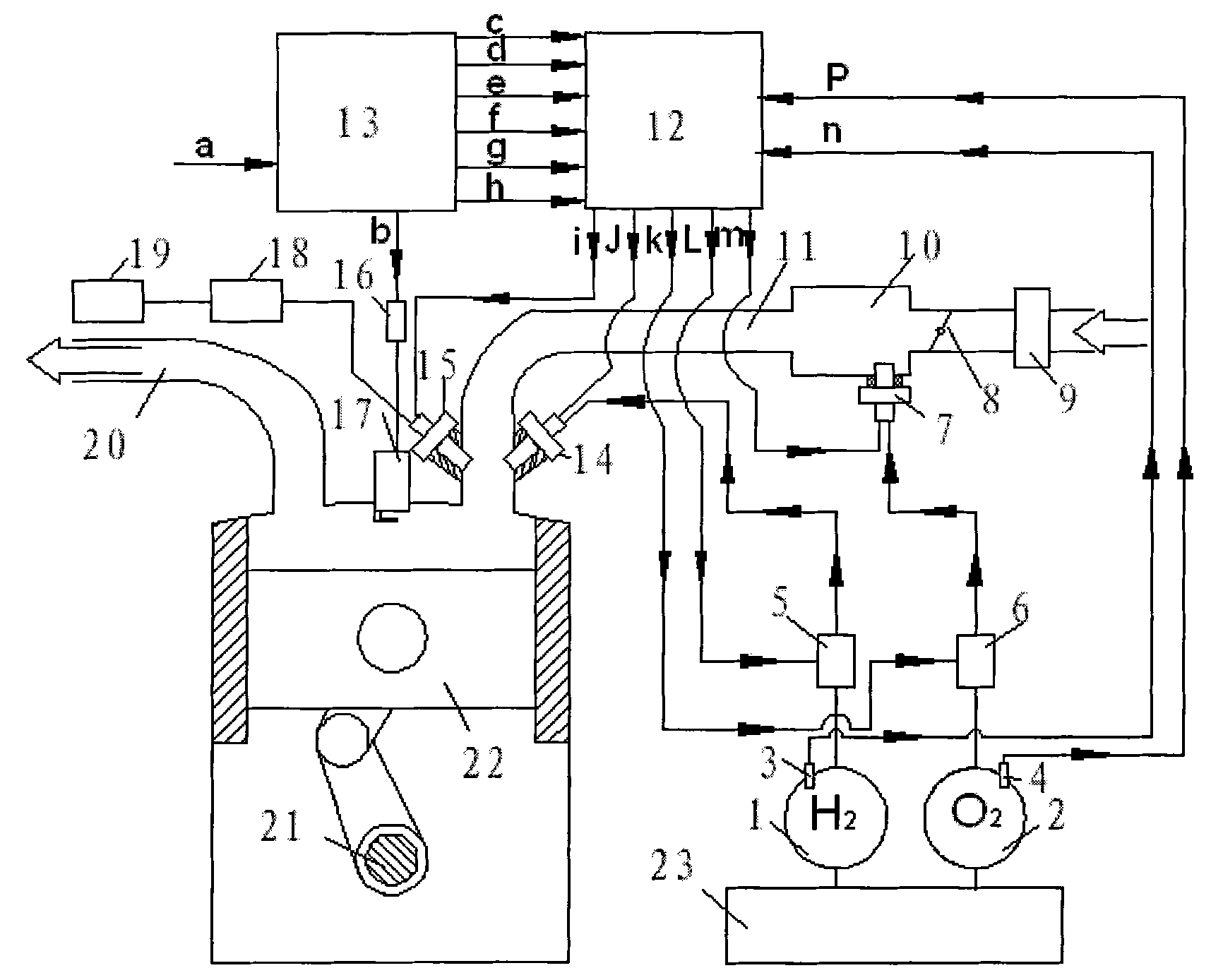

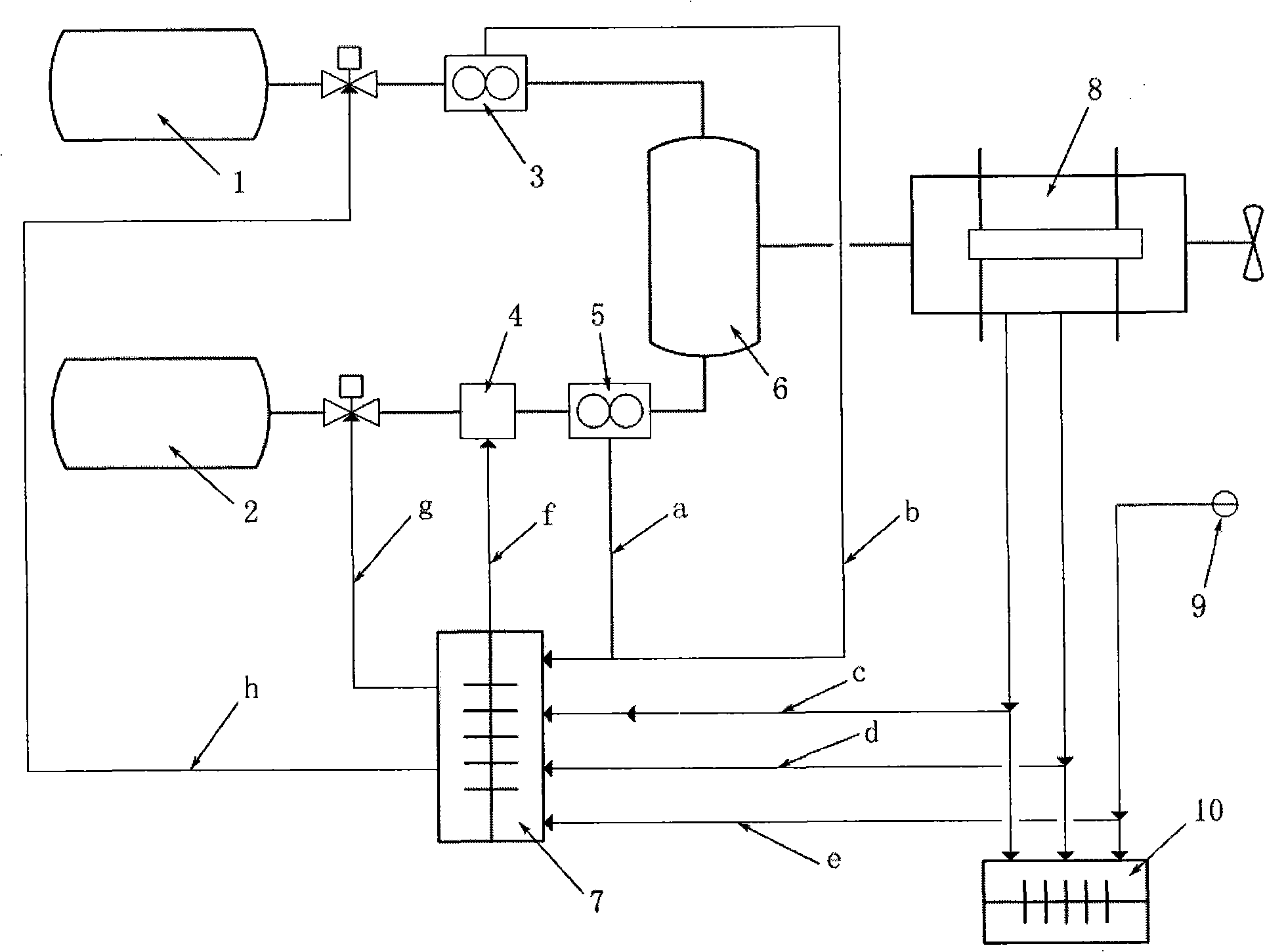

Hydrogen-oxygen-mixed high-octane fuel ignition combustion engine and control method thereof

ActiveCN101975108AReduce consumptionImprove economyElectrical controlInternal combustion piston enginesOn boardLow load

The invention provides an ignition combustion engine by the mode of mixing hydrogen and oxygen with high-octane fuel and a control method thereof, and particularly relates to a fuel storage and supply system of the ignition combustion engine by the mode of mixing the hydrogen and the oxygen with the fuel, fuel proportional distribution and combustion process control, wherein, a set of on-board hydrogen and oxygen production, a storage and supply device is added to the system on the basis of retaining main parts and an electronic control unit of the original engine. The hydrogen and oxygen mixed fuel electronic control unit (12) can control the opening and closing of a hydrogen nozzle and an oxygen nozzle according to sensor signals c-h so that the engine can run in three combustion modes such as pure hydrogen and oxygen mixed gas, hydrogen-oxygen-high-octane fuel mixed gas and pure high-octane fuel according to different operating conditions, thus greatly lowering HC and CO emission in the case of cold starting and idling of the high-octane fuel combustion engine and improving the thermal efficiency and emission level of the high-octane fuel combustion engine in middle and low load stages.

Owner:BEIJING UNIV OF TECH

Fuel injection method for dual-fuel engine

InactiveCN106870186ANot easy to knockIncrease concentrationElectrical controlMachines/enginesExhaust valveCombustion

Owner:DALIAN UNIV OF TECH

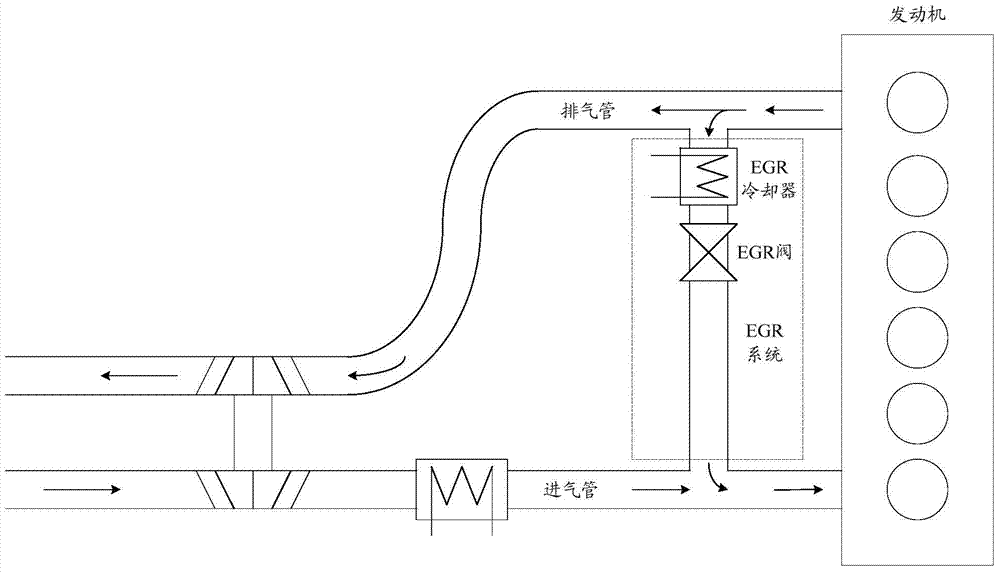

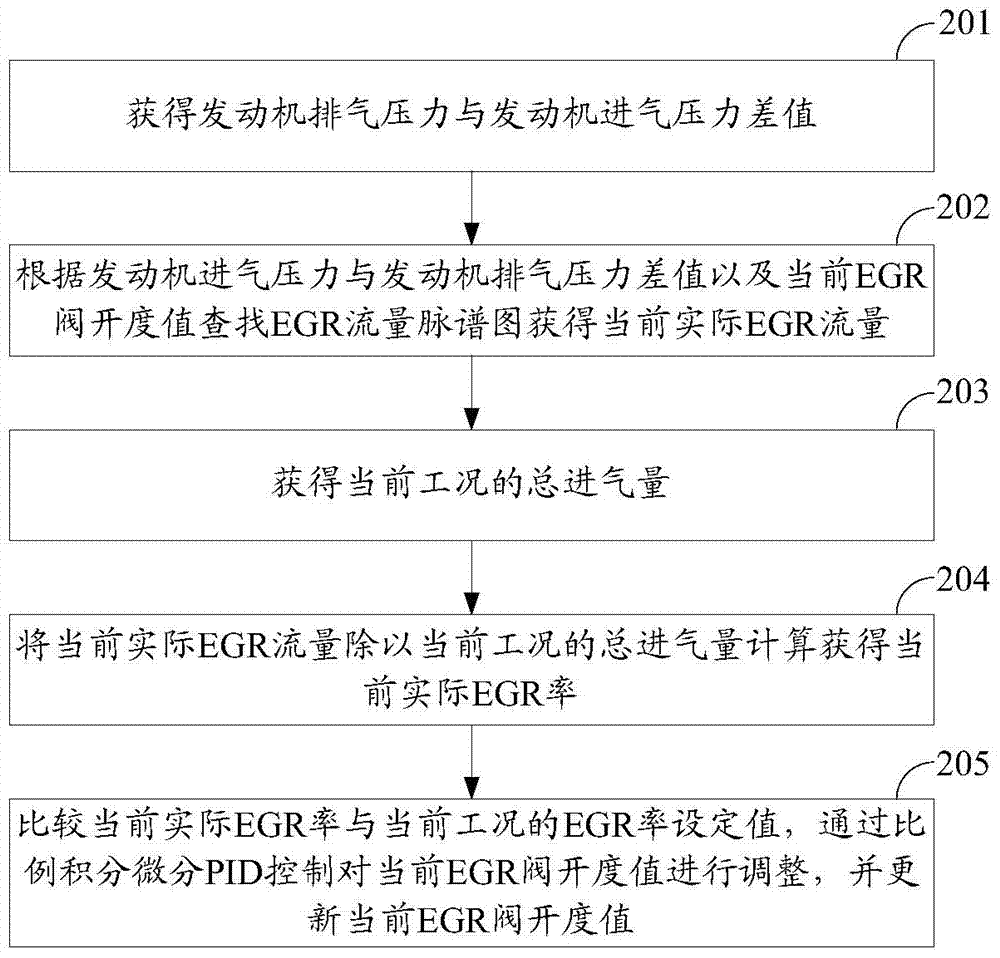

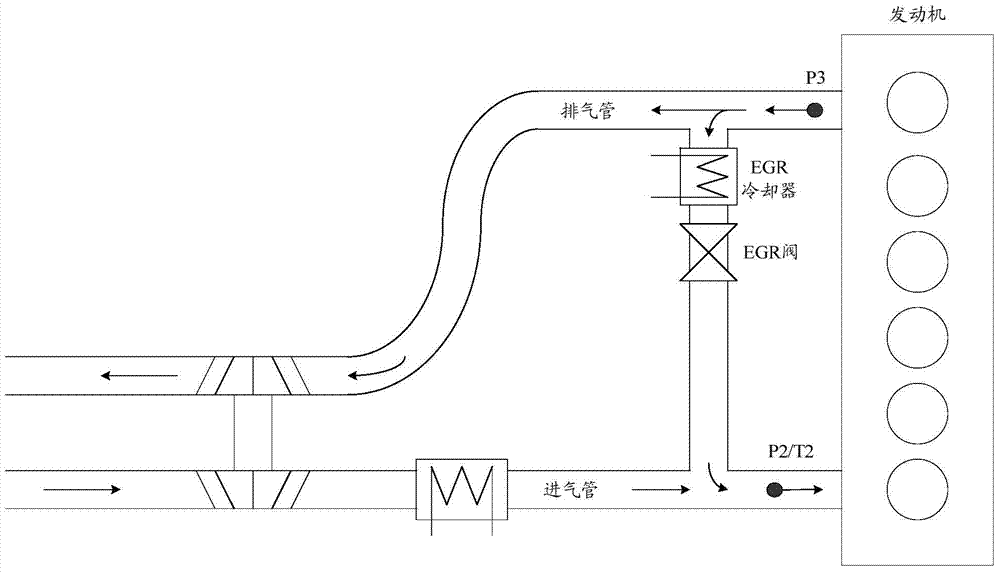

Method for realizing opening control of EGR (Exhaust Gas Recirculation) valve, device and system

ActiveCN103696862AImprove powerImprove economyEngine controllersMachines/enginesProportional integral differentialExhaust gas recirculation

The invention discloses a method for realizing opening control of an EGR (Exhaust Gas Recirculation) valve, a device and a system, which are used for lowering the cost and increasing the accuracy in the opening control of the EGR valve. The method comprises the following steps: acquiring the difference value between the discharge pressure of an engine and the intake pressure of the engine; searching for an EGR flow pulse spectrogram according to the difference value between the discharge pressure of the engine and the intake pressure of the engine and the current opening value of the EGR valve to obtain the current practical EGR flow; acquiring the total air inflow under a current working condition; dividing the current practical EGR flow by the total air inflow under the current working condition to obtain the current practical EGR rate; comparing the current practical EGR rate with an EGR rate set value under the current working condition, adjusting the opening value of the EGR valve through proportional-integral-differential (PID) control, and updating current opening value of the EGR valve.

Owner:WEICHAI POWER CO LTD

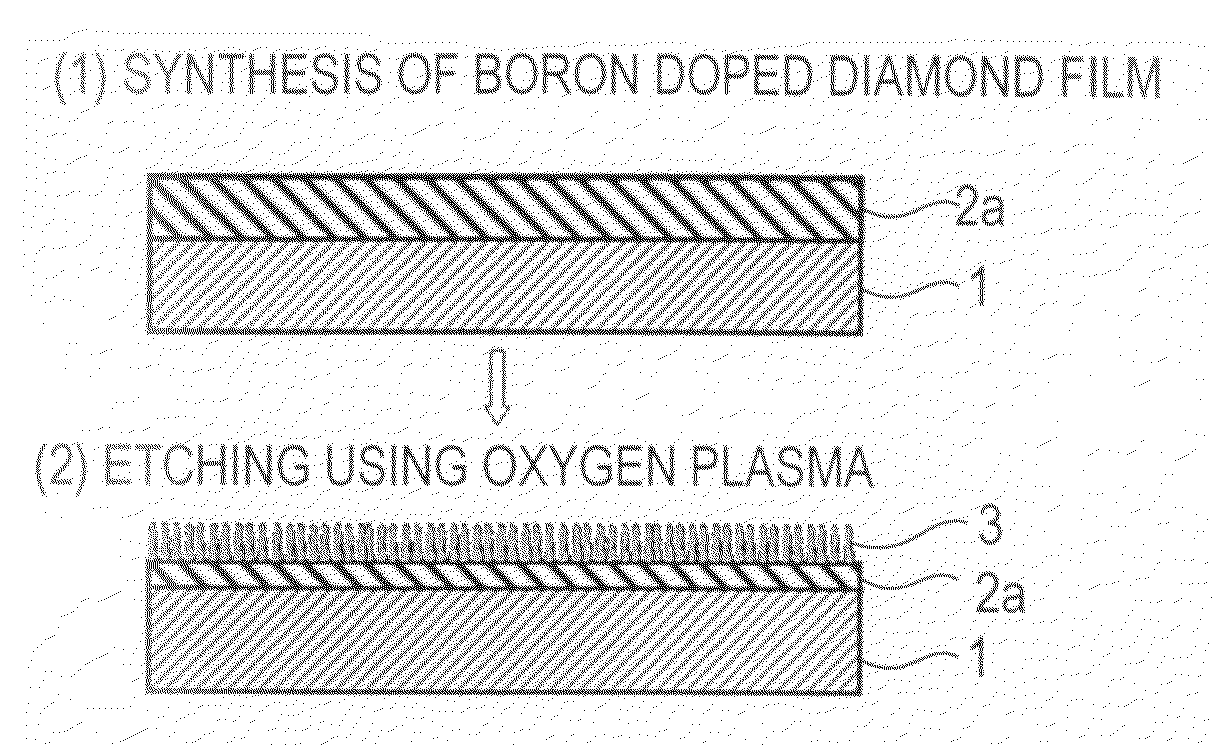

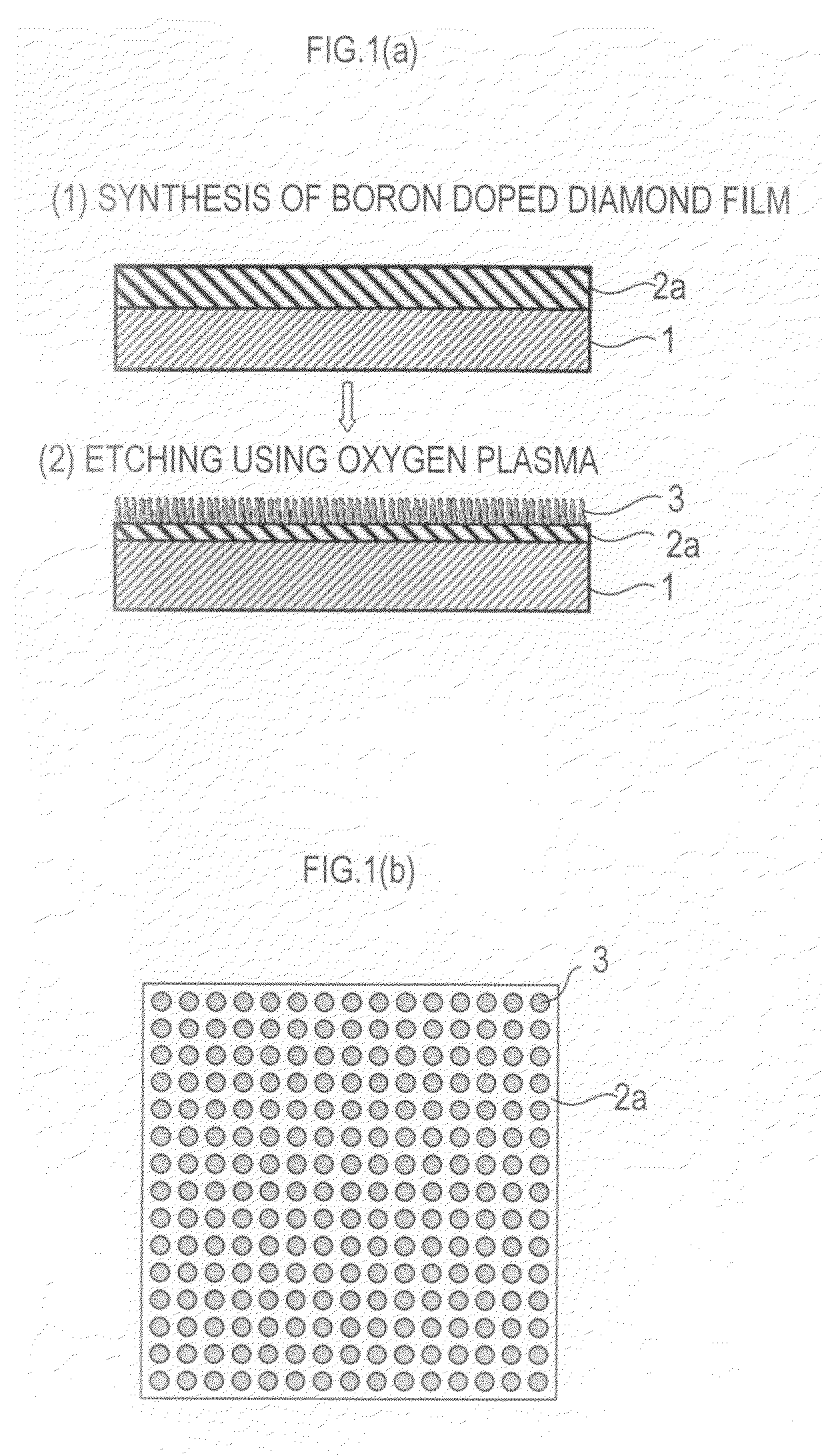

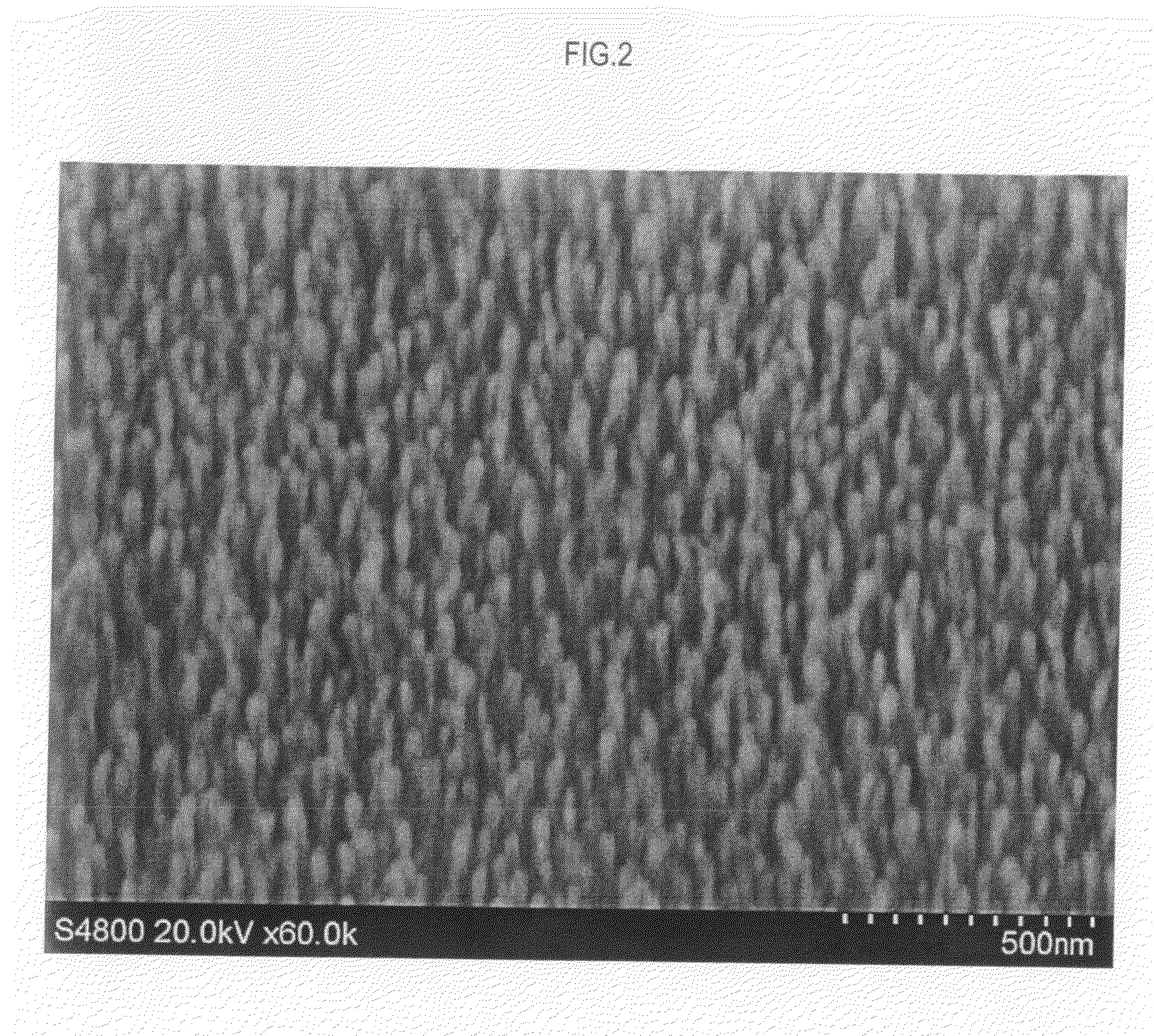

Method for Producing Diamond Having Acicular Projection Array Structure on Surface thereof, Diamond Material, Electrode and Electronic Device

InactiveUS20090258255A1Higher negative electron affinity electronImprove emission effectElectrode manufacturing processesDecorative surface effectsPt elementElectron

A method for producing a diamond having an acicular projection array structure on a surface thereof comprises the step of forming the acicular projection array structure on a surface of a diamond base material by treating the surface of the diamond base material by dry etching using oxygen gas. At least one dopant selected among boron (B), nitrogen (N), aluminum (Al), silicon (Si), phosphorus (P), sulfur (S), copper (Cu), arsenic (As), molybdenum (Mo), platinum (Pt) and gold (Au) is doped with a concentration of 1×1019 atoms / cm3 and more at least in a region near the surface of the diamond base material.

Owner:CENTRAL JAPAN RAILWAY COMPANY

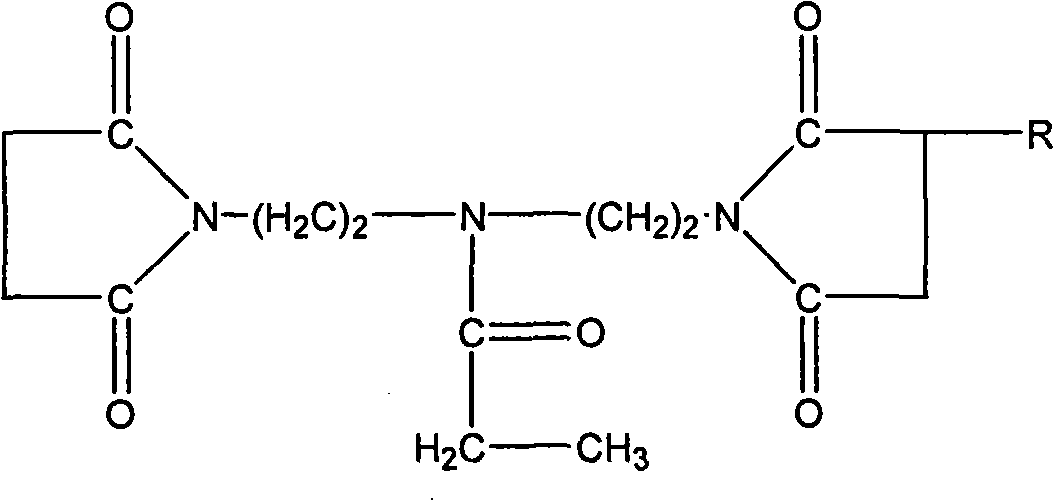

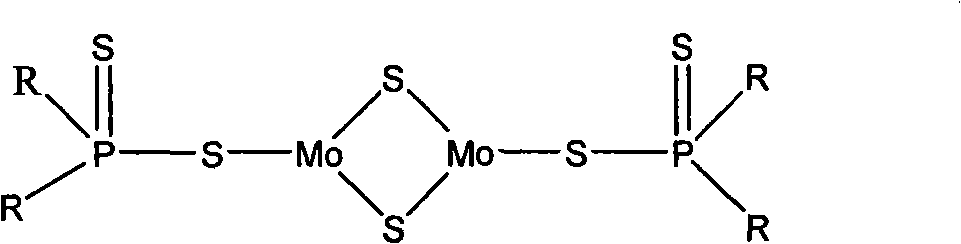

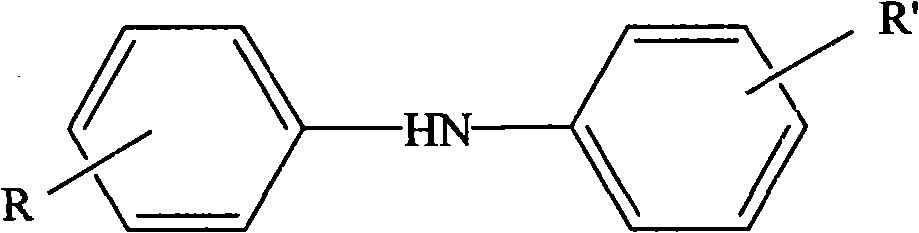

Composite of engine lubricant and preparation method thereof

The invention relates to a composite of lubricant and a preparation method thereof, in particular to a composite of engine lubricant and a preparation method thereof, which belong to the lubricant technical field. Alkyl naphthalene and naphthenic bright stock are added to base oil and at the same time thiophosphoric acid molybdenum additive containing nitrogen, a shless dispersing agent boride, hydrostyrene-isoprene VI improver (Infineum SV 261) and the like are added. Through the mutual coordination of the components, the lubricant composite has obvious compatibility adaptability of a rubber sealing ring, engine oil leakage is avoided, gas blow by is prevented, the dynamic property of the engine is improved, engine oil consumption is reduced, the emission property of the engine is improved and the oil draining period of engine oil and the service life of the engine are prolonged. The invention is particularly applicable to the vehicles which have run more than 100000km or have been overhauled.

Owner:JIANGSU LOPALTECH

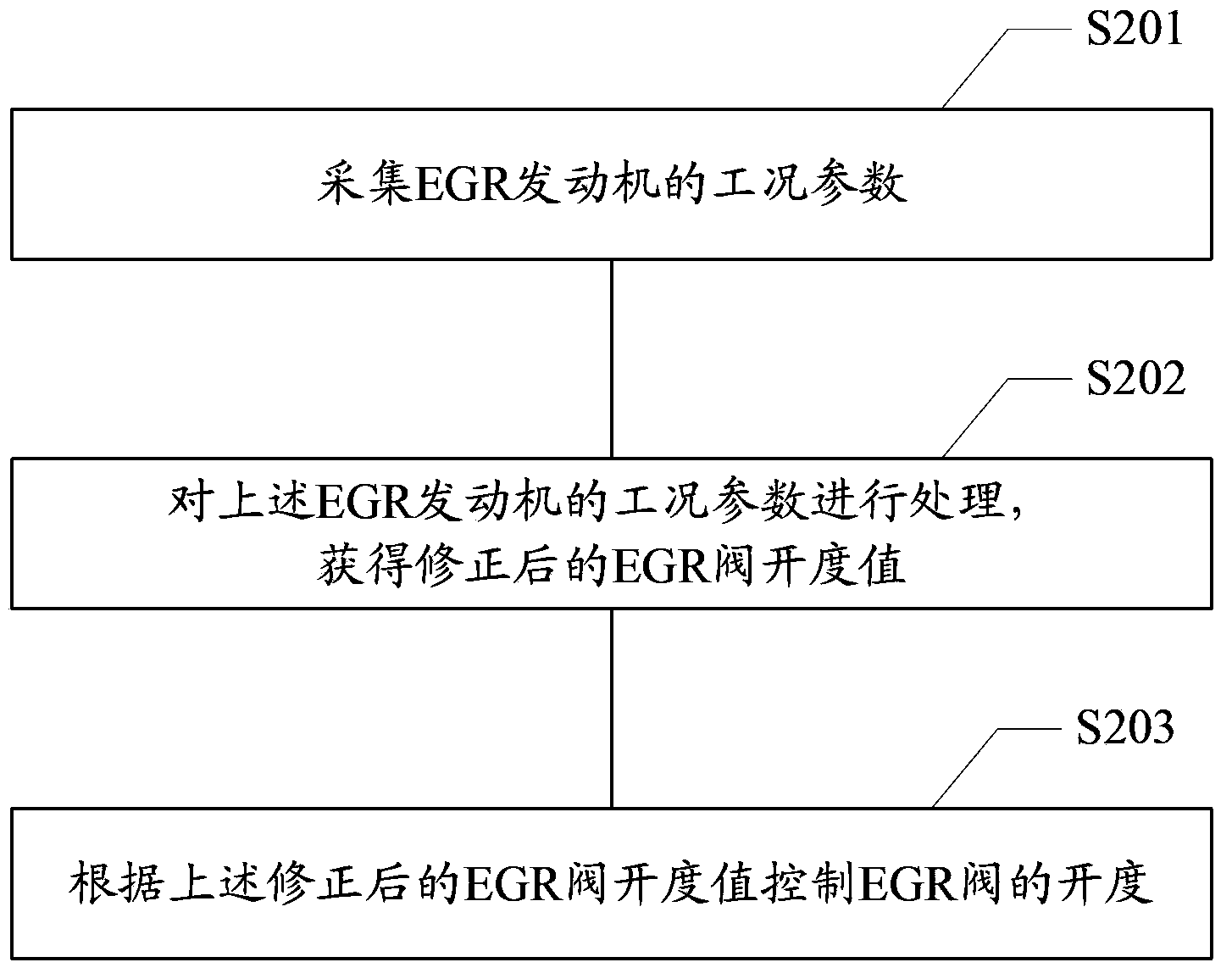

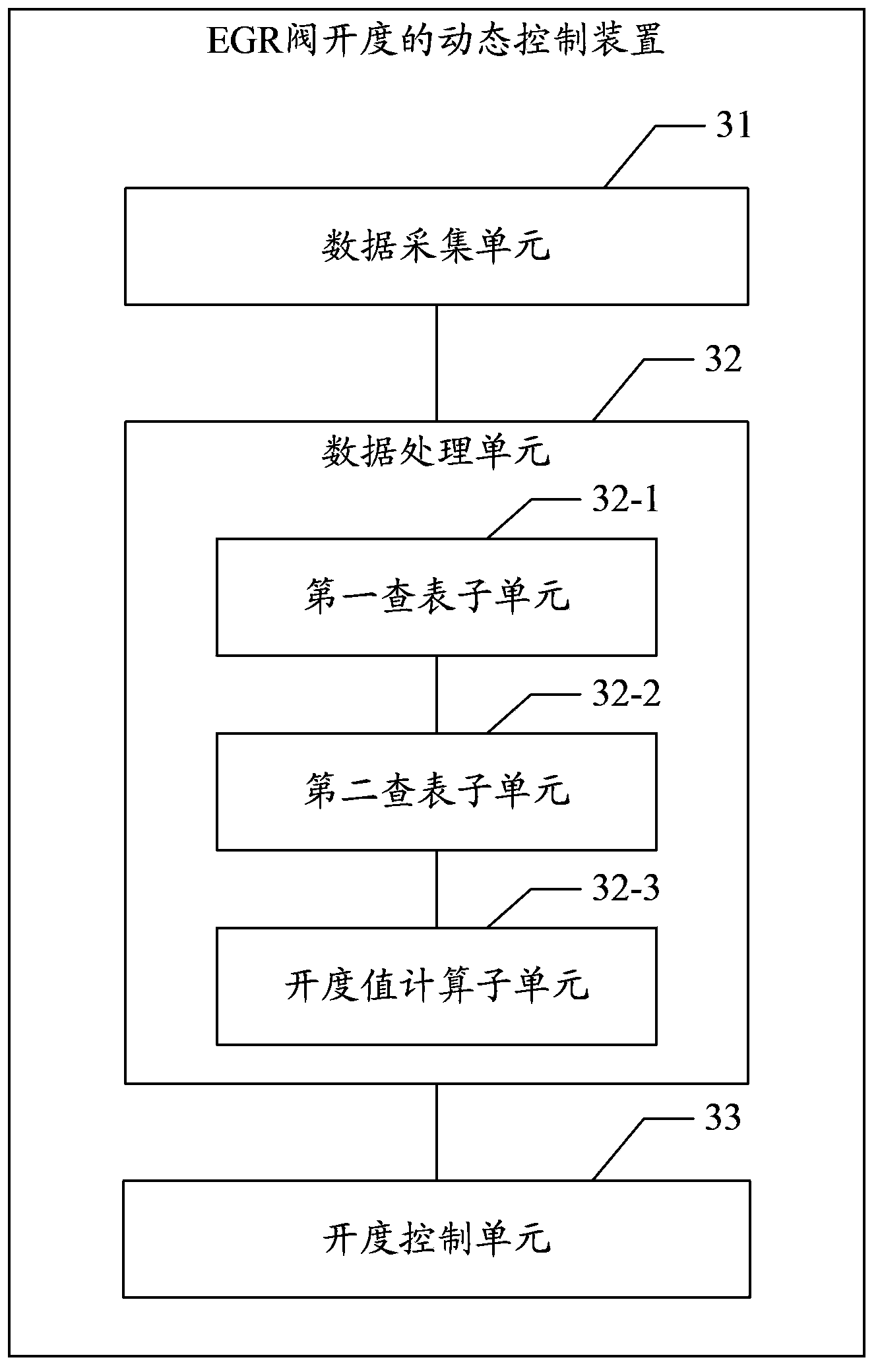

Dynamic control method and device of EGR valve opening, and EGR engine

ActiveCN103362661AImprove powerImprove economyElectrical controlMachines/enginesEngineeringExhaust gas recirculation

The invention provides a dynamic control method of EGR (exhaust gas recirculation) valve opening, which is used for dynamically controlling the EGR valve opening of an EGR engine. The method comprises the steps that a working condition parameter of the EGR engine is acquired; a corrected EGR valve opening value is obtained after the working condition parameter of the EGR engine is processed; and the EGR valve opening is controlled according to the corrected EGR valve opening value. The invention further provides a dynamic control device of the EGR valve opening and the EGR engine. With the adoption of the scheme, the opening value of an EGR valve is corrected dynamically through a pressure difference value between an exhaust pipe and a gas inlet pipe, so that accurate control on the EGR valve of the engine on an instantaneous working condition is achieved, and the power performance, the economical efficiency and the emission performance of the EGR engine can be improved effectively.

Owner:WEICHAI POWER CO LTD

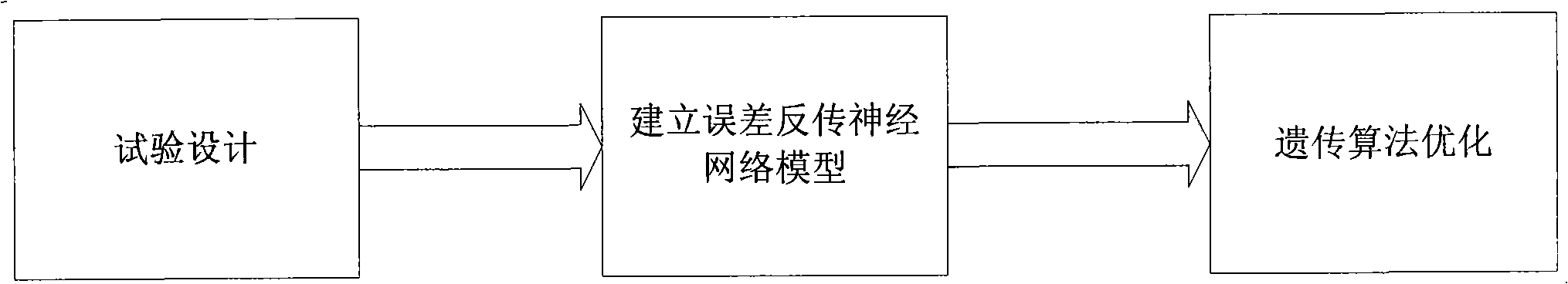

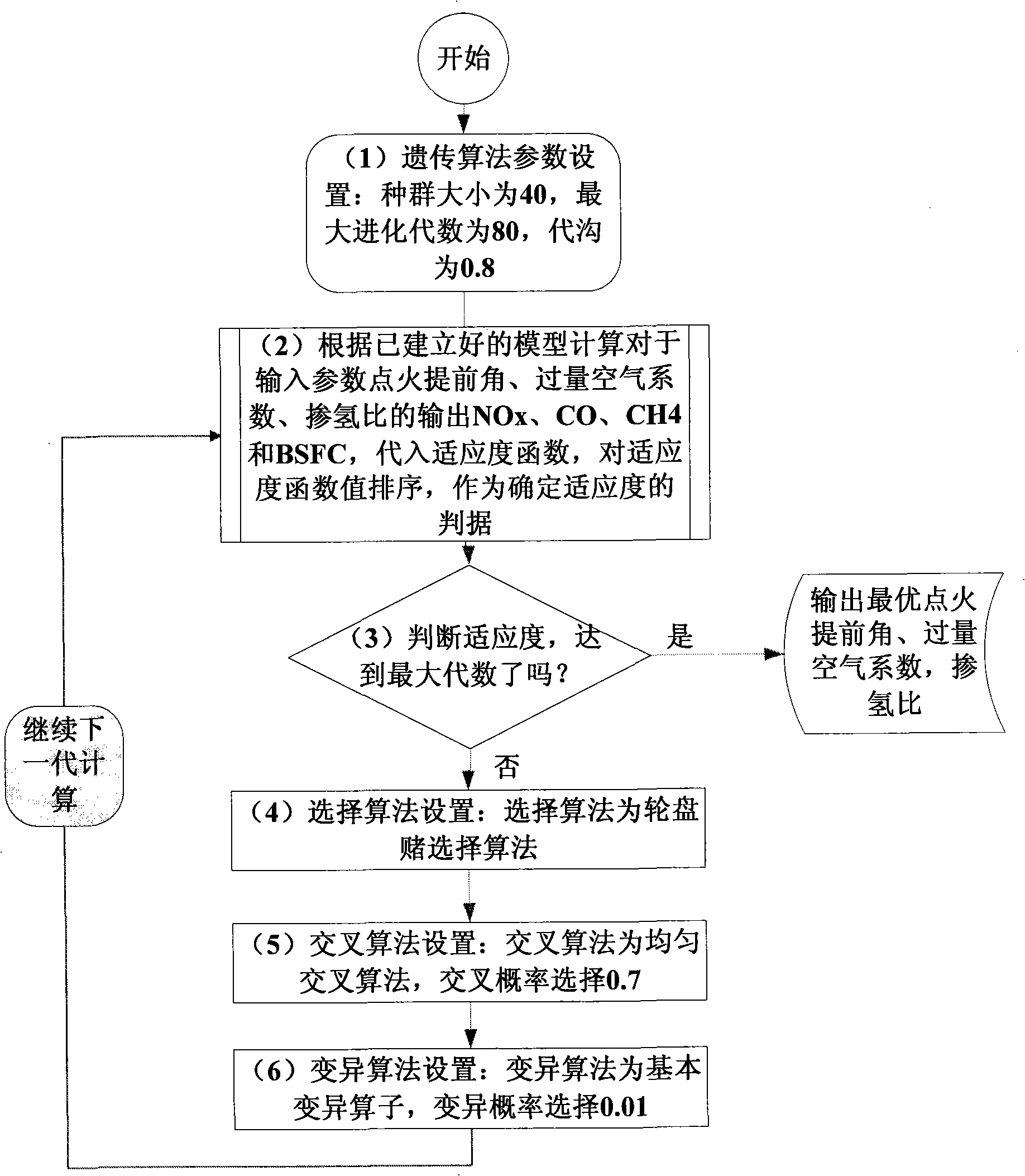

Hydrogen gas natural gas mixed fuel engine optimizing method

ActiveCN101333961AImprove economyImprove emission performanceElectrical controlInternal combustion piston enginesMixed fuelControl variable

Disclosed is an optimizing method for a hydrogen and natural gas mixed fuel engine, which belongs to the hydrogen and natural gas mixed fuel engine technical field. The invention aims to effectively discover three control variables, including the optimum hydrogen mixing ratio, ignition advance angle and the excess air factor under each operating condition and obtain the optimum comprehensive performance of the engine. The rotation speed and the torque are used for determining the operating condition point; the three-dimension state space of the hydrogen mixing ratio, the ignition advance angle and the excess air factor is determined under the operating condition point; based on the method of experimental design, the most representative point is selected for the experiment; the data is acquired after the experiment; the points in the data are used for establishing the engine error backward neural network model; namely, the relation of the control variables of the hydrogen mixing ratio, ignition advance angle and the excess air factor, and the economical exhaust is established; the model data is exported and the genetic algorithm is adopted to optimize the engine control parameters; finally, the control variables of optimum hydrogen mixing ratio, the ignition advance angle and the excess air factor of the engine are acquired under the operating condition so that the optimum engine performance is obtained.

Owner:TSINGHUA UNIV

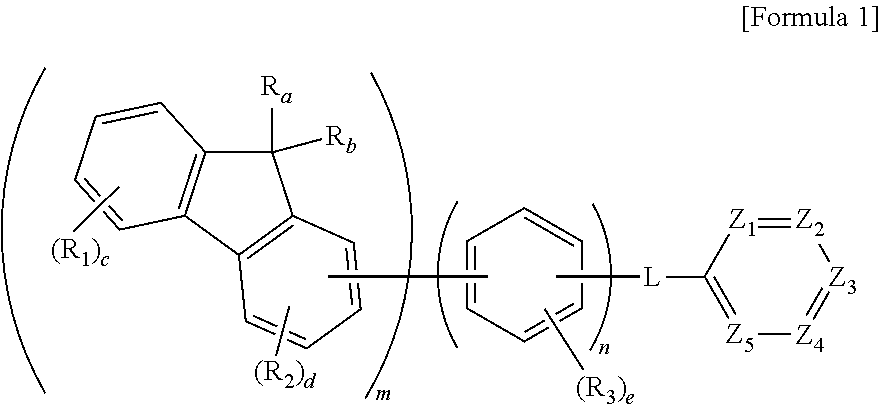

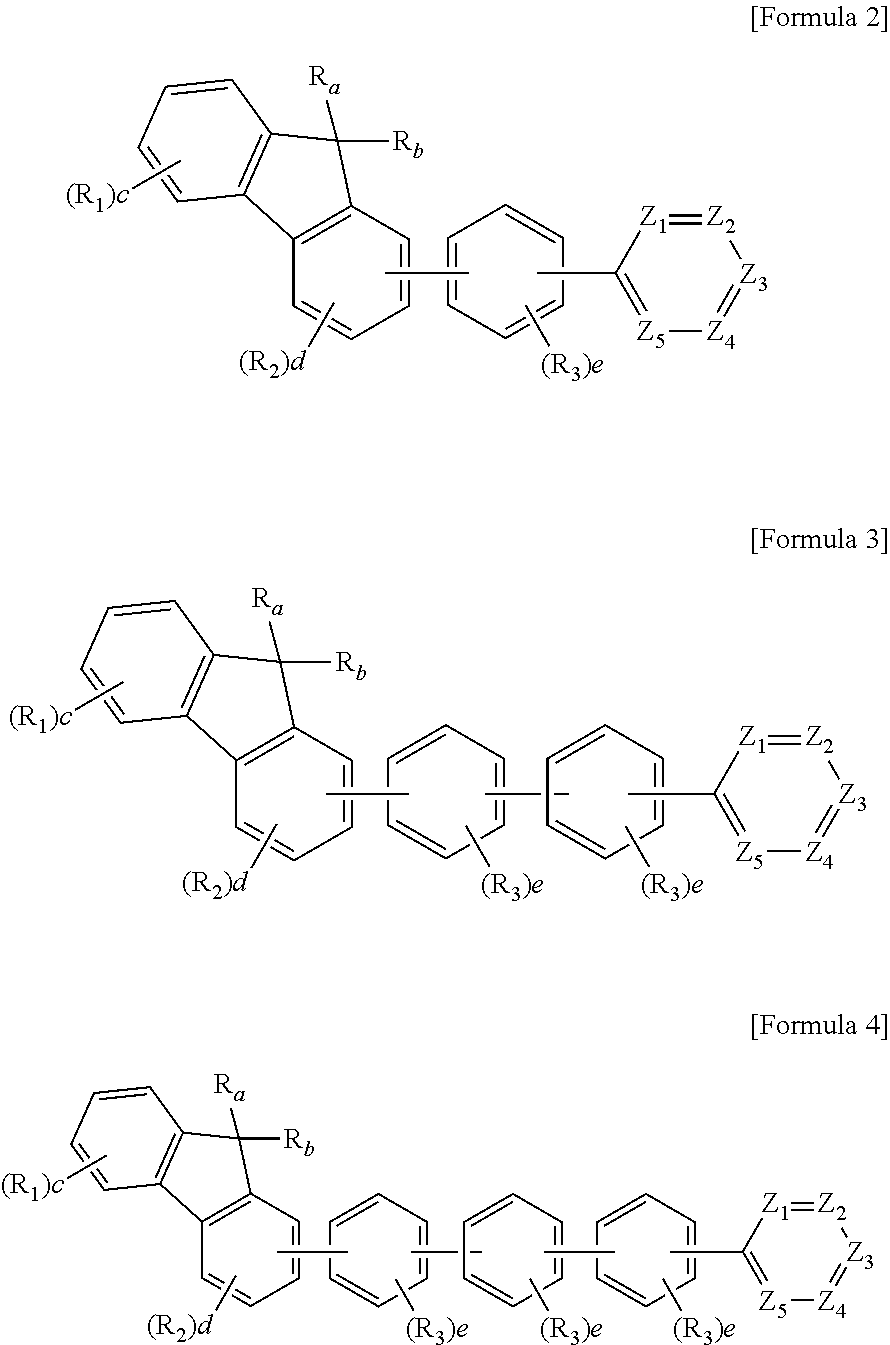

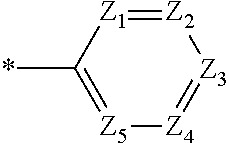

Organic compound and organic electroluminescent element comprising same

ActiveUS20180053900A1Improve emission performanceReduce the driving voltageOrganic chemistrySolid-state devicesOrganic electroluminescenceOrganic compound

Owner:SOLUS ADVANCED MATERIALS CO LTD

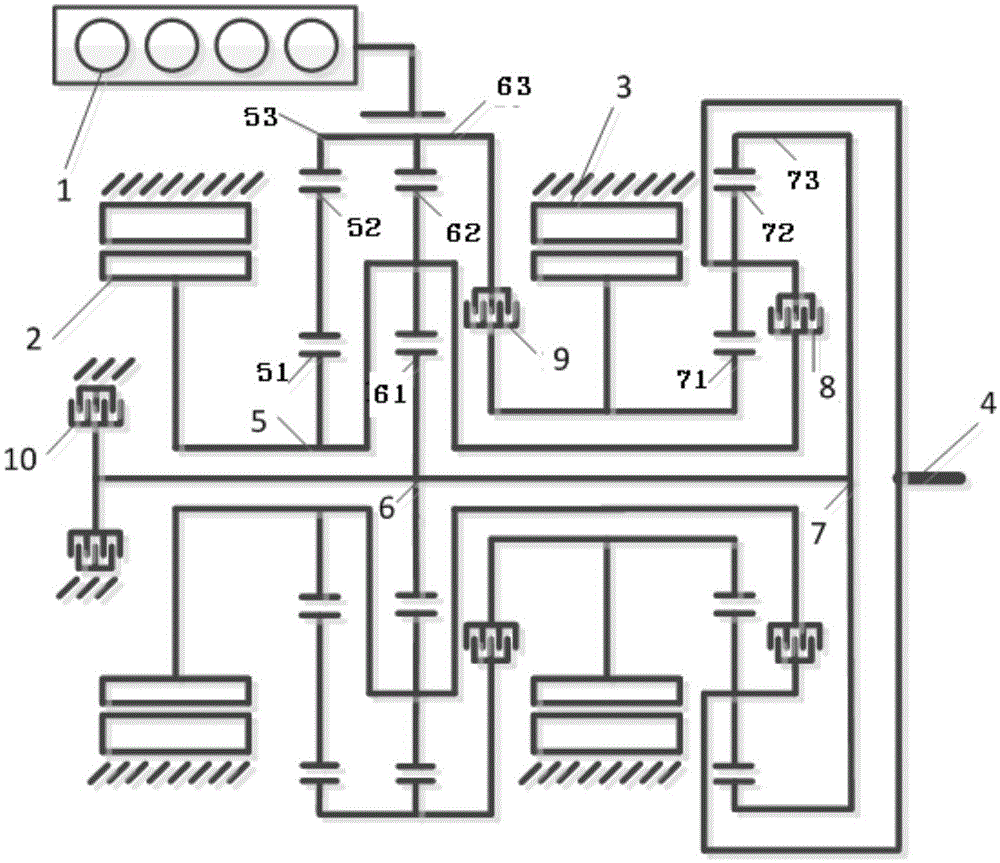

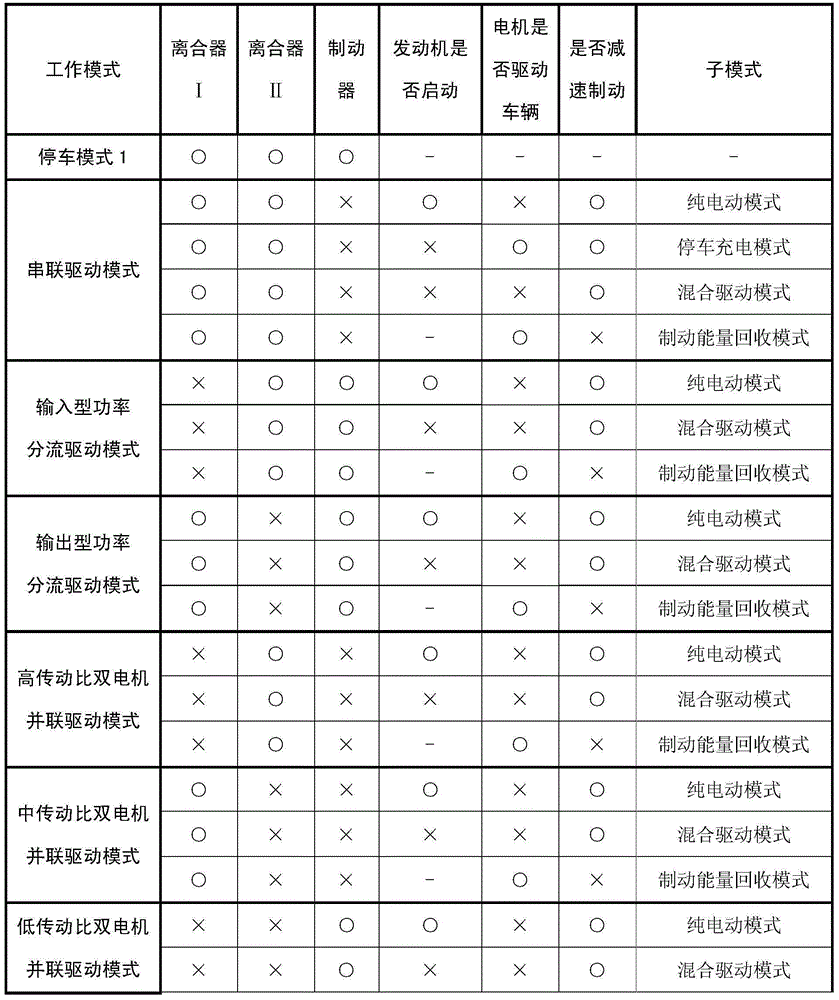

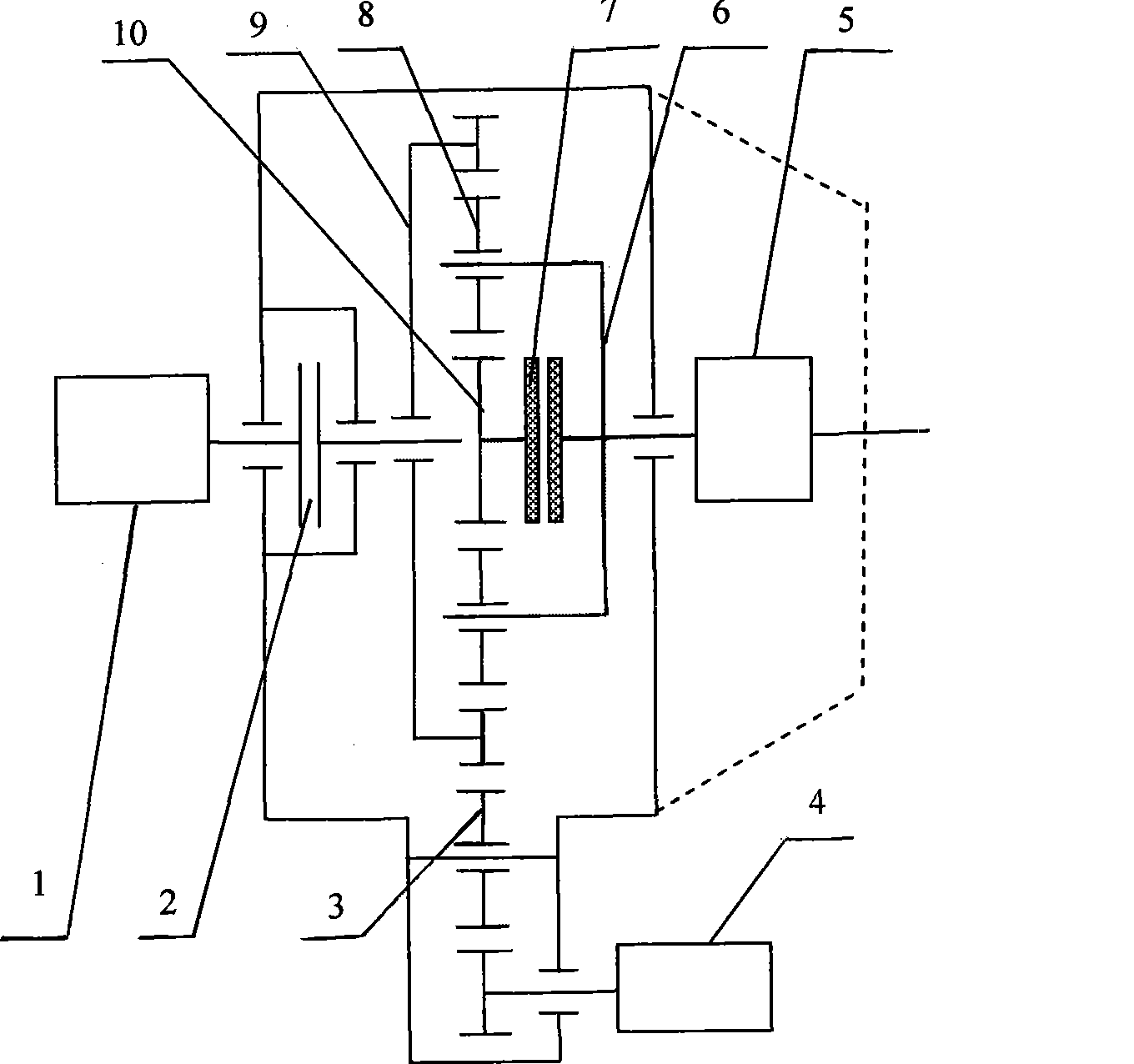

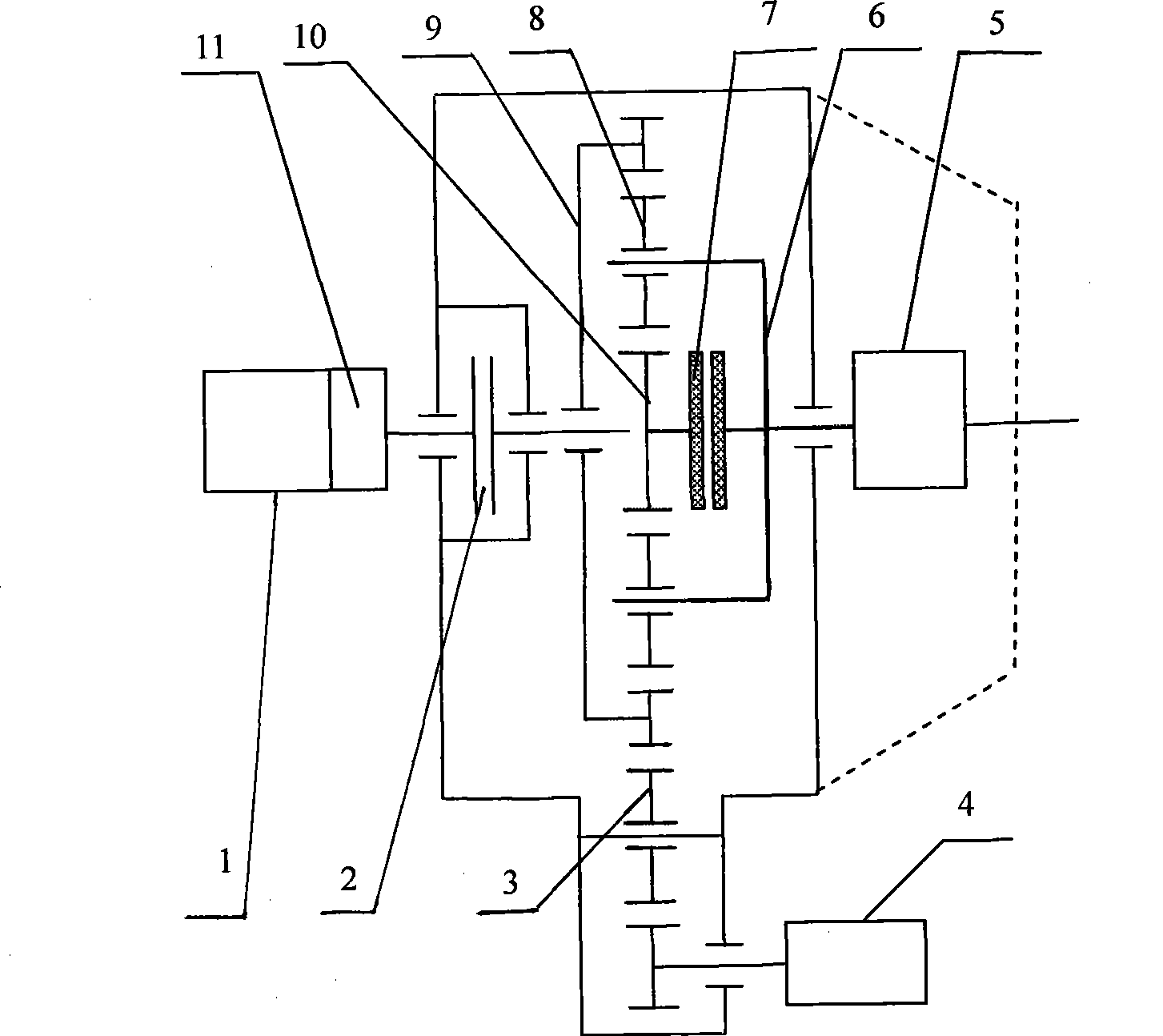

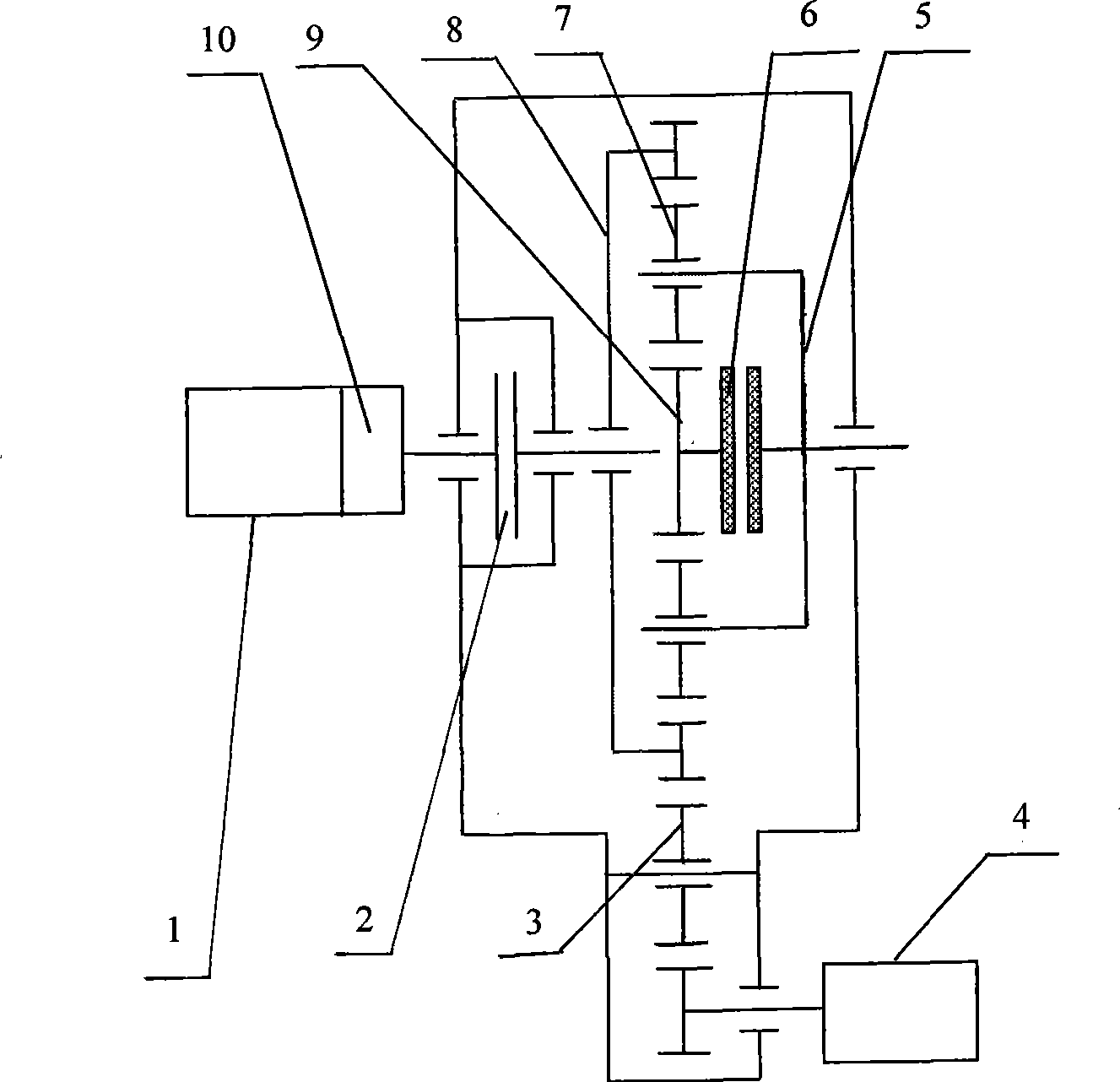

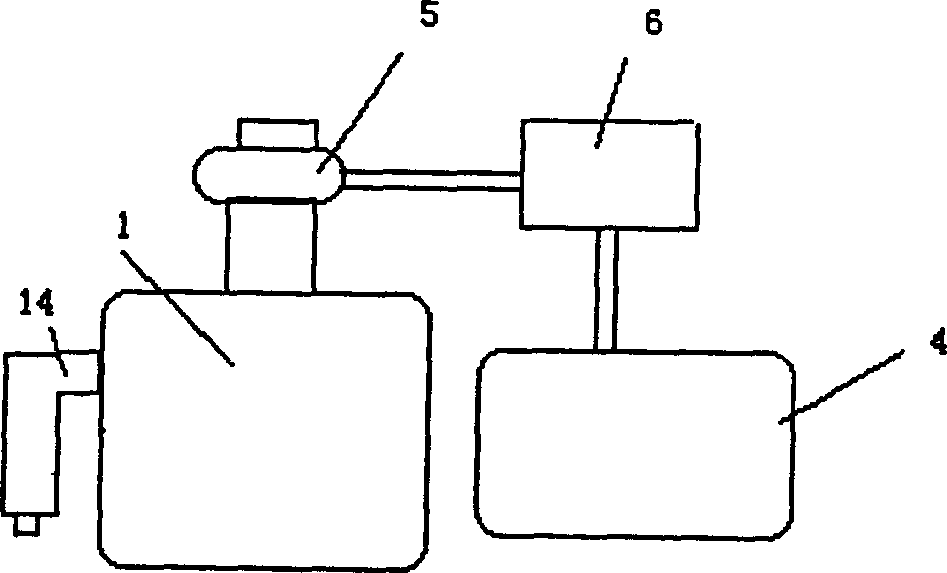

Multimode hybrid power transmission driving device

ActiveCN105128647AAchieving Series Drive ModeEnhance and improve dynamicsHybrid vehiclesGas pressure propulsion mountingGear wheelEngineering

The invention discloses a multimode hybrid power transmission driving device, comprising an internal combustion engine (1), a first motor / generator (2), a second motor / generator (3), an output shaft (4), a first planetary gear train (5), a second planetary gear train (6), a third planetary gear train (7), a first clutch (8), a second clutch (9), and a brake (10). The first planetary gear train (5) comprises a sun wheel (51), a first planet carrier (52), and a first gear ring (53). One end of the first planet carrier (52) is meshed with the sun wheel (51), and the other end is meshed with the first gear ring (53). The transmission driving device is simple in structure, and is provided with an engine start reverse gear mode, and after a vehicle battery runs down, a reverse function can still be realized.

Owner:NANJING UNIV OF SCI & TECH

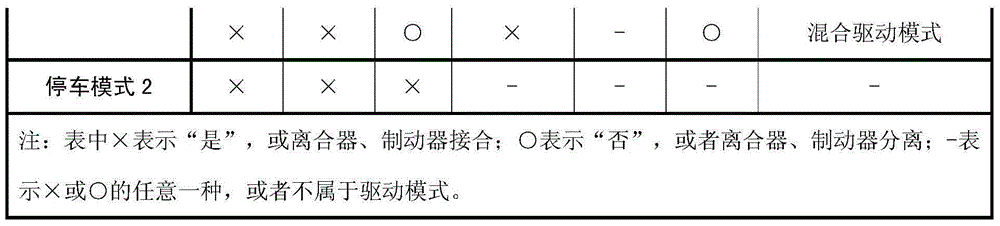

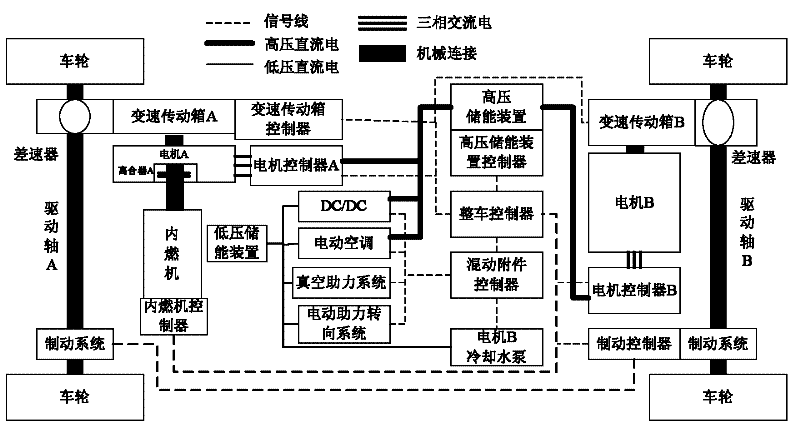

Plug-in hybrid power car system and energy control method thereof

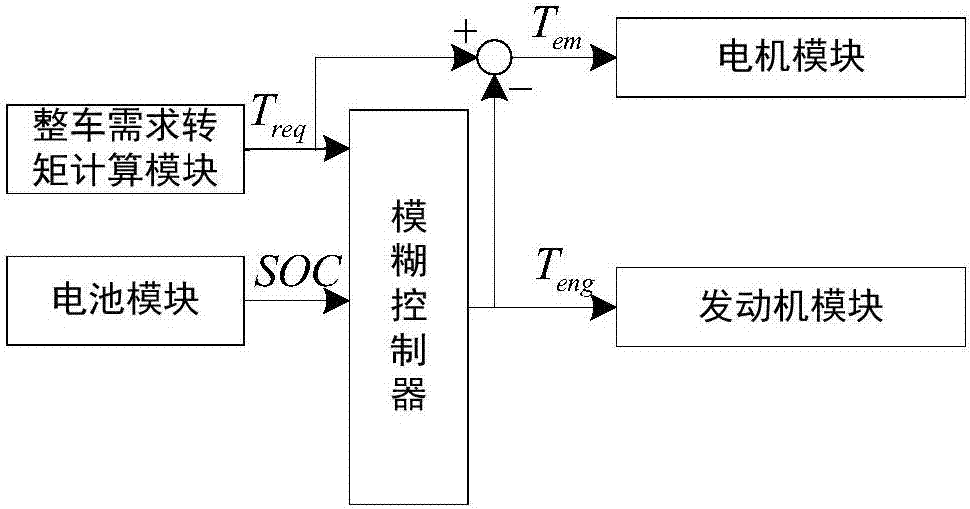

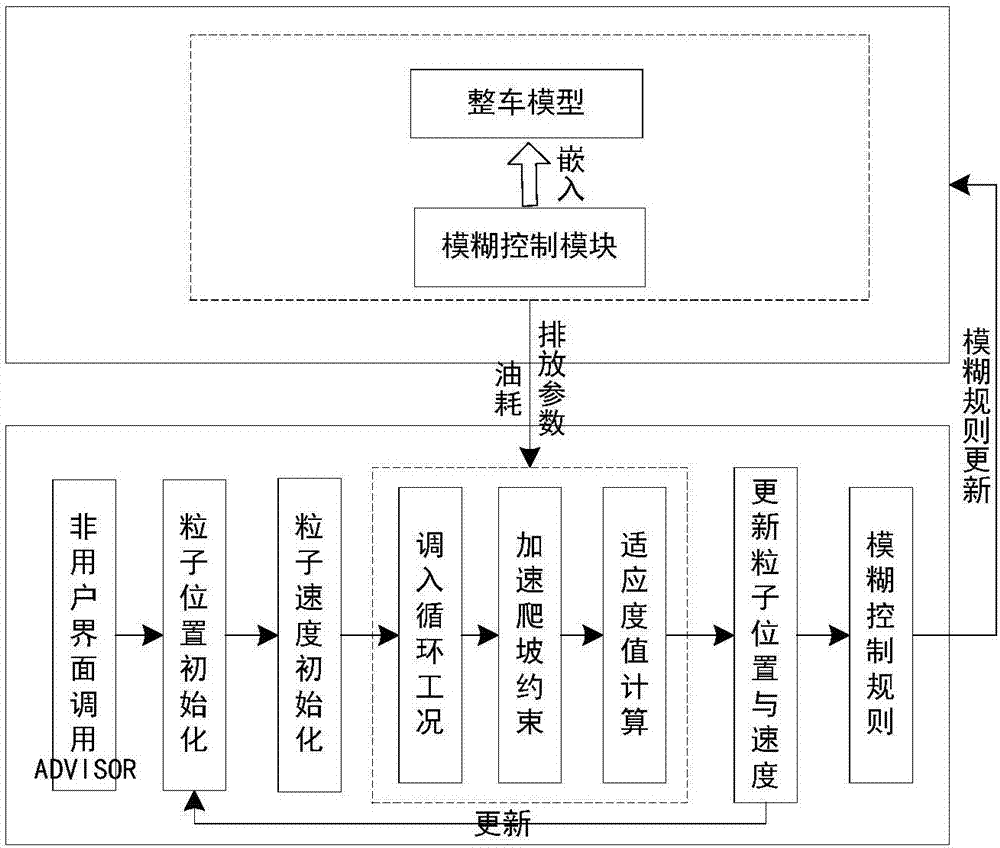

ActiveCN107161140AImprove fuel economyImprove emission performanceHybrid vehiclesInternal combustion piston enginesPower batteryEnergy control

The invention discloses a plug-in hybrid power car system and an energy control method thereof. The hybrid power car system comprises an engine, a first hub motor, a second hub motor, a power battery, an ISG starting and power generating integrated machine, a clutch, a transmission, an inverter, a front axle half shaft, a front shaft main reducer, a differential mechanism and a control module; the engine and the two hub motors serve as power sources, and the engine is placed in the front and conducts front drive; and the hub motors are placed on two rear wheels, mechanical connection between the two wheels is canceled, and a suitable space is provided for arrangement of a power battery. An optimized fuzzy control method is used for the energy control method; considering the situation that fuzzy control adopts fuzzy rules established through specialist experience, and thus the optimum effect cannot be achieved, the energy control method utilizes the particle swarm algorithm to optimize the fuzzy rules; and through the designed energy control method, the energy flow direction and magnitude between the engine and the electric motors are reasonably distributed so as to obtain the optimum fuel economy and emission performance of a vehicle.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

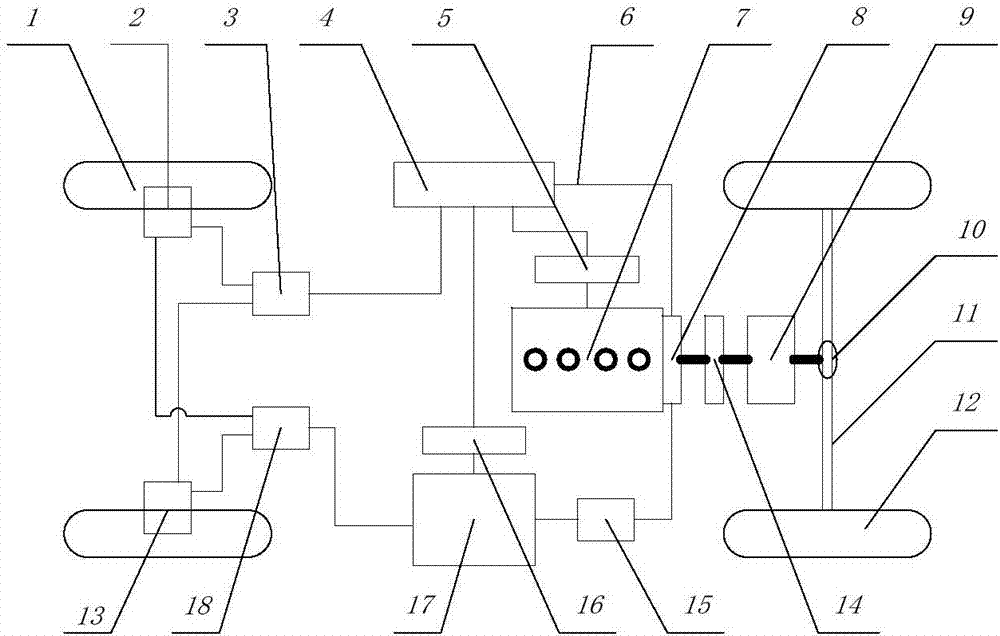

Mixed power electromechanical coupling power transmission device

InactiveCN101519035AImprove efficiencyImprove fuel economyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingPower couplingGear wheel

The invention relates to a power coupling transmission device, in particular to a mixed power electromechanical coupling power transmission device comprising a planet wheel mechanism, an arrester, a clutch, a first power source and a second power source, wherein the planet wheel mechanism comprises a planet wheel carrier, a planet wheel arranged on the planet wheel carrier, as well as a sun wheel and a gear ring which are meshed with the planet wheel; the arrester is connected between the sun wheel and the planet wheel carrier; the clutch is connected between the first power source and the sun wheel of the planet wheel mechanism; the gear ring of the planet wheel mechanism is connected with the second power source through a middle gear; and the planet wheel carrier of the planet wheel mechanism is the output end of coupling power. The invention has the advantages of simple structure, small volume and low cost and is suitable for various automobiles.

Owner:NANJING AUTOMOBILE GROUP CORP

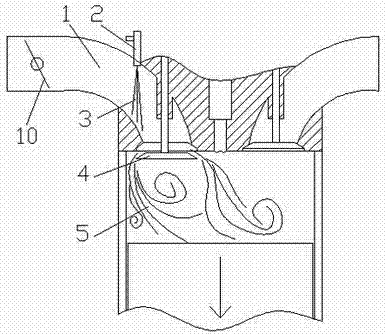

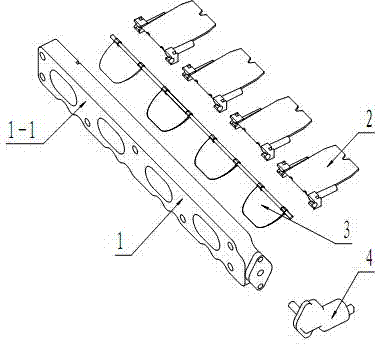

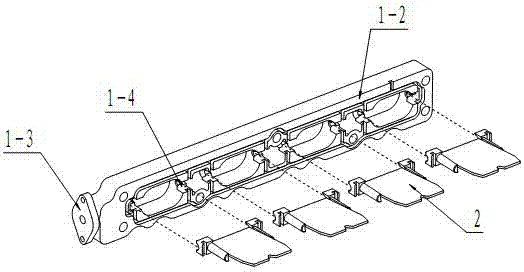

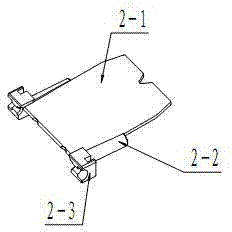

Variable intake tumble adjusting mechanism for gasoline engine

InactiveCN102953841AReduce resistanceSpeed up the flowInternal combustion piston enginesEngine controllersInlet channelGasoline

The invention provides a variable intake tumble adjusting mechanism for a gasoline engine, which is used for realizing the adjustment of intake tumble ratio and air input of the gasoline engine. The mechanism comprises a support body, a tumble adjusting valve assembly, a diversion plate assembly and an electric actuator; the support body is arranged between an intake manifold airway and an engine cylinder cover inlet channel; the tumble adjusting valve assembly is assembled with the support body in a matched way; the front end of the diversion plate assembly is assembled with the support body in a matched way; the rear end of the diversion plate assembly is extended to the engine cylinder cover inlet channel; and the electric actuator is arranged on the support body. The mechanism provided by the invention is simple in structure, compact in arrangement, convenient to install, and can be used for realizing continuous control for the intake tumble of the gasoline engine, thus, the requirement of the engine on the airflow states under different working conditions can be met; and the discharge performance, the economic performance and the power performance of the engine are improved.

Owner:GREAT WALL MOTOR CO LTD

Residual energy reclaiming type device for preparing biomass granular activated carbon

The invention belongs to the technical field of activated carbon preparation, and relates to a residual energy reclaiming type device for preparing activated carbon. A combined structure on one side of an air heating furnace of the device is provided with a gas burner and a combustion fan, the other side of the air heating furnace is communicated with a partition wall heating chamber, the center of the partition wall heating chamber is vertically provided with a charcoal chamber, the bottom of the charcoal chamber is provided with a charcoal chamber bottom connecting rod mechanism in an insertion mode, the periphery of the partition wall heating chamber is wrapped by an insulating material, one side of the charcoal chamber on the middle part of the partition wall heating chamber is reserved with a space up and down and provided with two thermoelectric couples, the top end of the partition wall heating chamber is provided with a top end cover used for sealing the partition wall heating chamber, and the top end of the partition wall heating chamber passing through the top end cover is provided with a charcoal chamber gas outlet pipe and a heating chamber smoke outlet pipe respectively in a communication mode; and the charcoal chamber gas outlet pipe is communicated with the top of a tube type condenser through a three-way valve, the bottom of the tube type condenser is communicated with the air heating furnace in a pipe mode, and the middle section of a communication passage is provided with a circulating fan in series. The device has the advantages of high efficiency, simple principle, flexible implementation, energy conservation, low pollution, high charcoal yield, and the like.

Owner:QINGDAO UNIV

Modified engine oil

A modified lubricating oil for engine is prepared by adding the super-dispersity carbon particles (3-6 nm in granularity) to the mineral lubricating oil. Said carbon particles contains diamond (10-98%). Its advantages are high antiwear and friction reducing effect, increasing engine power by 4-8%, saving fuel oil by 5-10% and lubricating oil by 1-4 times, and reducnig noise and HC and NOx exhaust.

Owner:张书达

Locking multi-mode lever-type variable valve driving system

InactiveCN106545380AMeet operational requirementsMeet the requirements of ventilationValve controlMachines/enginesMature technologyEngineering

The invention discloses a locking multi-mode lever-type variable valve driving system, belonging to the field of engine valve driving. The variable valve driving system mainly comprises a cam shaft, a mode input mechanism, a mode output mechanism, a mode switching mechanism, a valve regulating lever, a valve control mechanism and the like. By using the mode switching mechanism, the switching among multiple modes, including a two-stroke driving mode, a four-stroke driving mode, a two-stroke braking mode, a four-stroke braking mode and the like, of an engine is realized, further, by matching with the valve control mechanism for use, the optimum ventilation under different working conditions of the engine is finally realized, and the aims of comprehensively improving the engine dynamic property, fuel economy, emission performance and braking security are achieved. The invention is proposed by aiming at practical application, the reliability is high, the structure is compact, the requirements of a system on all the mechanisms are reduced, relatively mature technologies are adopted by all the mechanisms, the practical potential of the system in a short time is high, and the application prospect is good.

Owner:DALIAN UNIV OF TECH

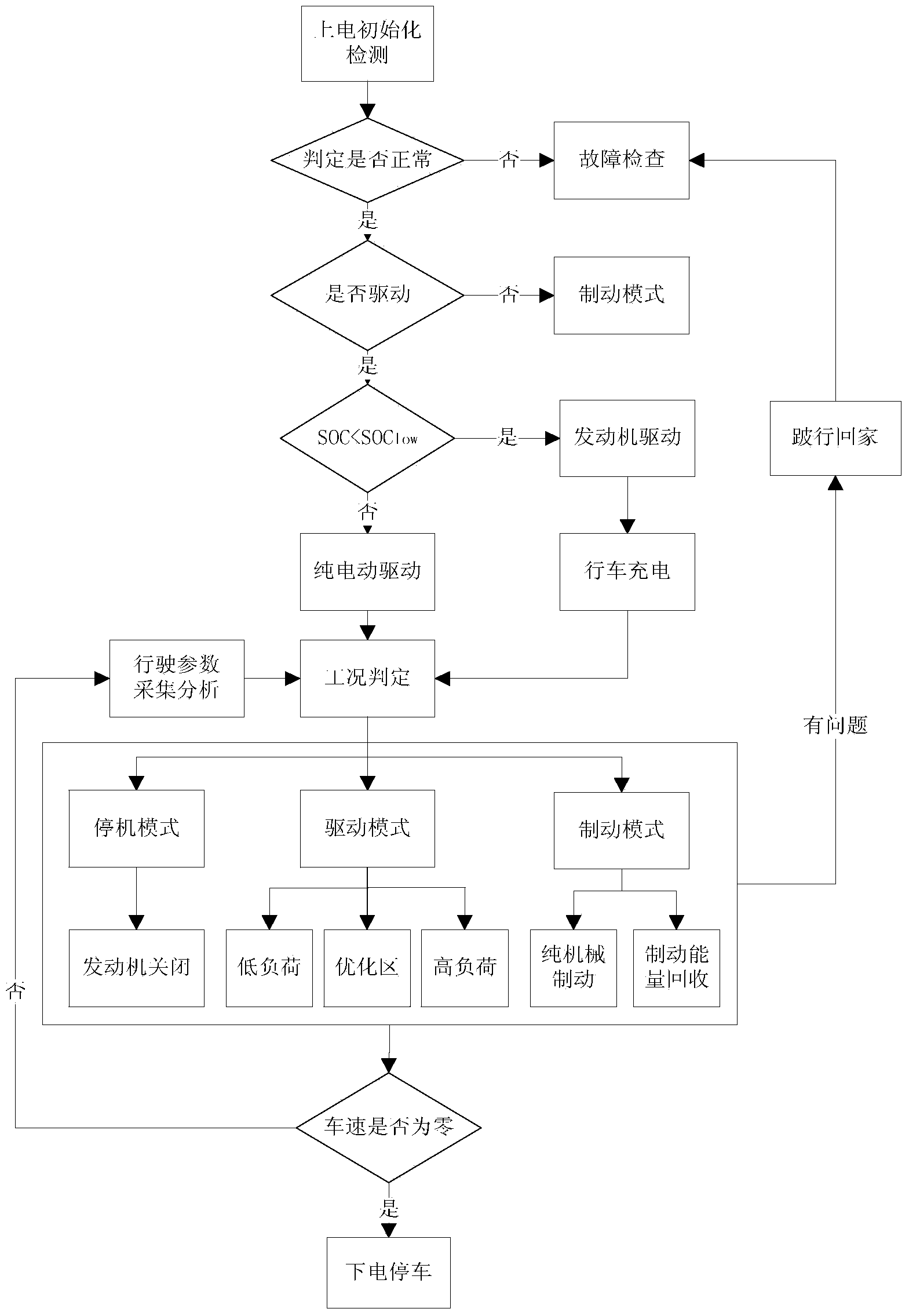

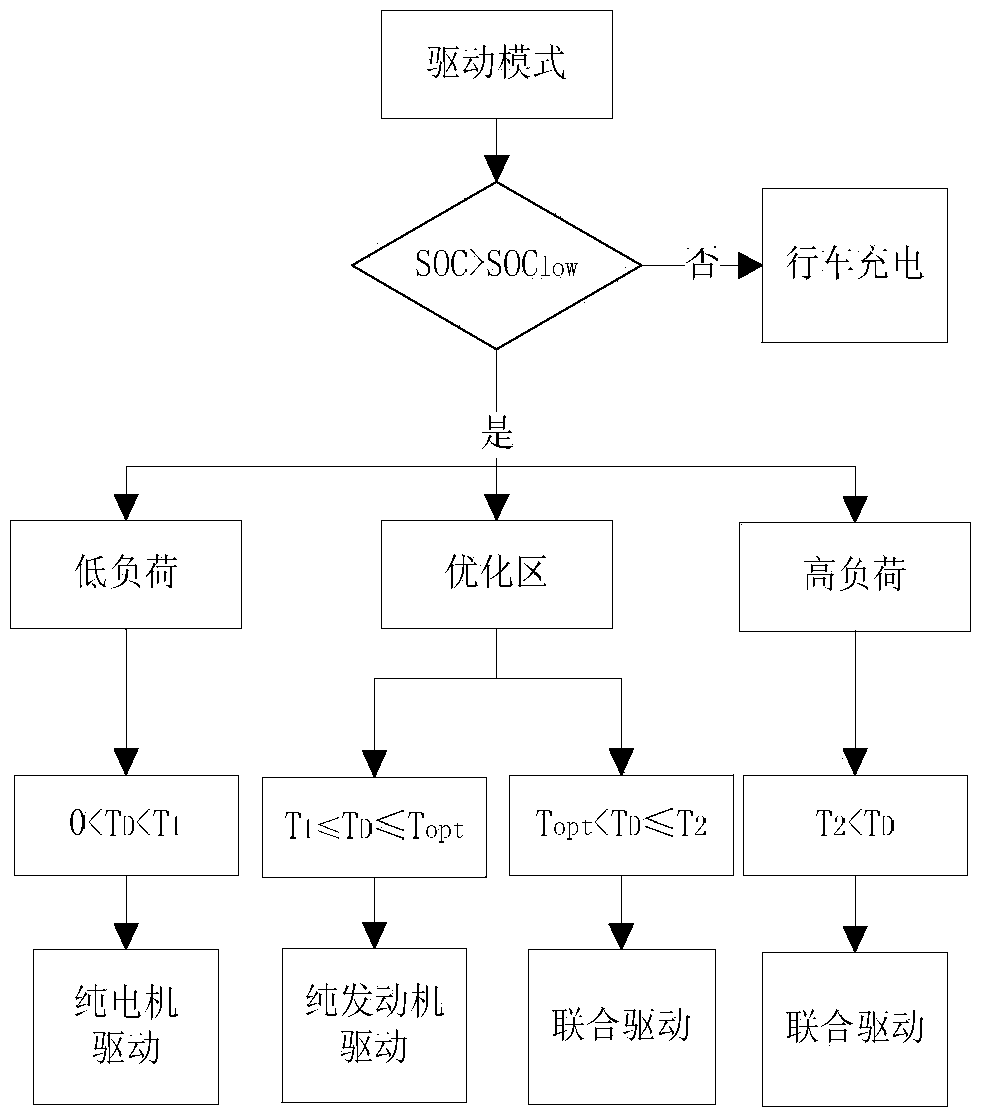

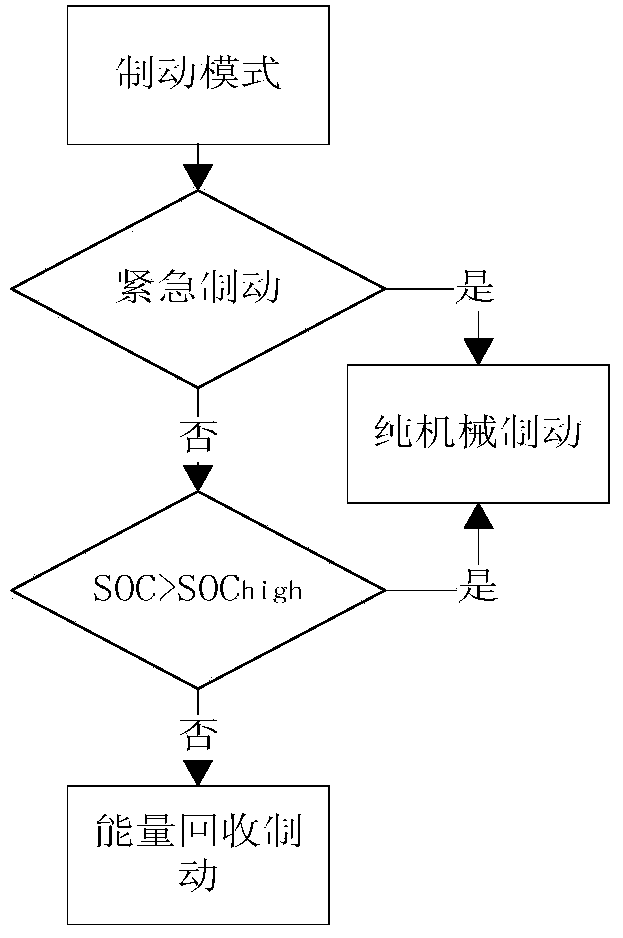

Energy distribution method for single-shaft parallel-connection hybrid electric bus

ActiveCN103660913AImproved adaptability to working conditionsImprove fuel economyHybrid vehiclesGas pressure propulsion mountingElectric machineryEnergy recovery

The invention discloses an energy distribution method for a single-shaft parallel-connection hybrid electric bus. A set of road conditions is set according to the bus speed-time historical statistics information of the city bus, and a corresponding set of optimization control parameters is set according to each road condition; driving parameters are collected automatically in the driving process of the bus, the corresponding road condition is judged, a whole bus controller takes the corresponding optimization control parameter and energy distribution mode, and torque output and energy recovery of a motor and an engine of the bus are optimized and adjusted. The energy resources of the single-shaft parallel-connection hybrid electric bus running in a city can be reasonably distributed, and under the condition that an AMT gearbox is carried, the power performance of the whole bus is satisfied. More importantly, fuel consumption and discharge of pollutants are effectively reduced, and fuel economy is improved.

Owner:NANJING YUEBOO POWER SYST CO LTD

Hybrid system of four-wheel drive hybrid car with one-way clutch

InactiveCN102390249AImprove powerImprove economyHybrid vehiclesGas pressure propulsion mountingHybrid carInternal combustion engine

The invention relates to a hybrid system of a four-wheel drive hybrid car with a one-way clutch. The system comprises a plurality of power plants, which include an internal-combustion engine, a first motor, a second motor, the first transmission system, a second transmission system, a brake system, wherein the first motor is connected with a first drive shaft through the first transmission system; the second motor is connected with a second drive shaft through the second transmission system; the brake system is associated with the first drive shaft and the second drive shaft, a hybrid accessory, a hybrid control system, an energy storage device which provides energy to the hybrid control system and the hybrid accessory, and a one-way clutch, which is connected between a crank of the internal-combustion engine and the first motor. The hybrid control system controls the one-way clutch to build or cut off the connection between the crank of the internal-combustion engine and the first motor.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

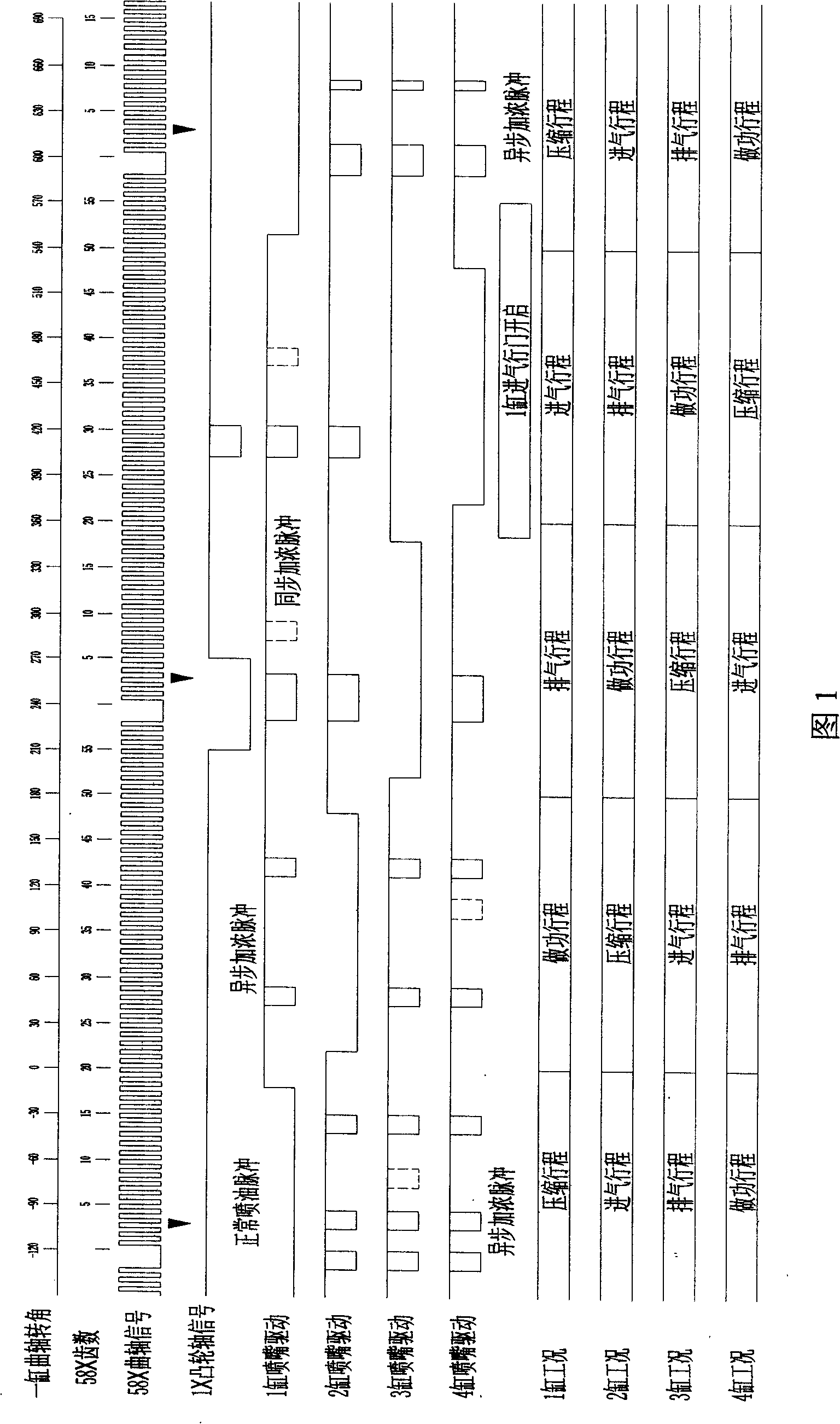

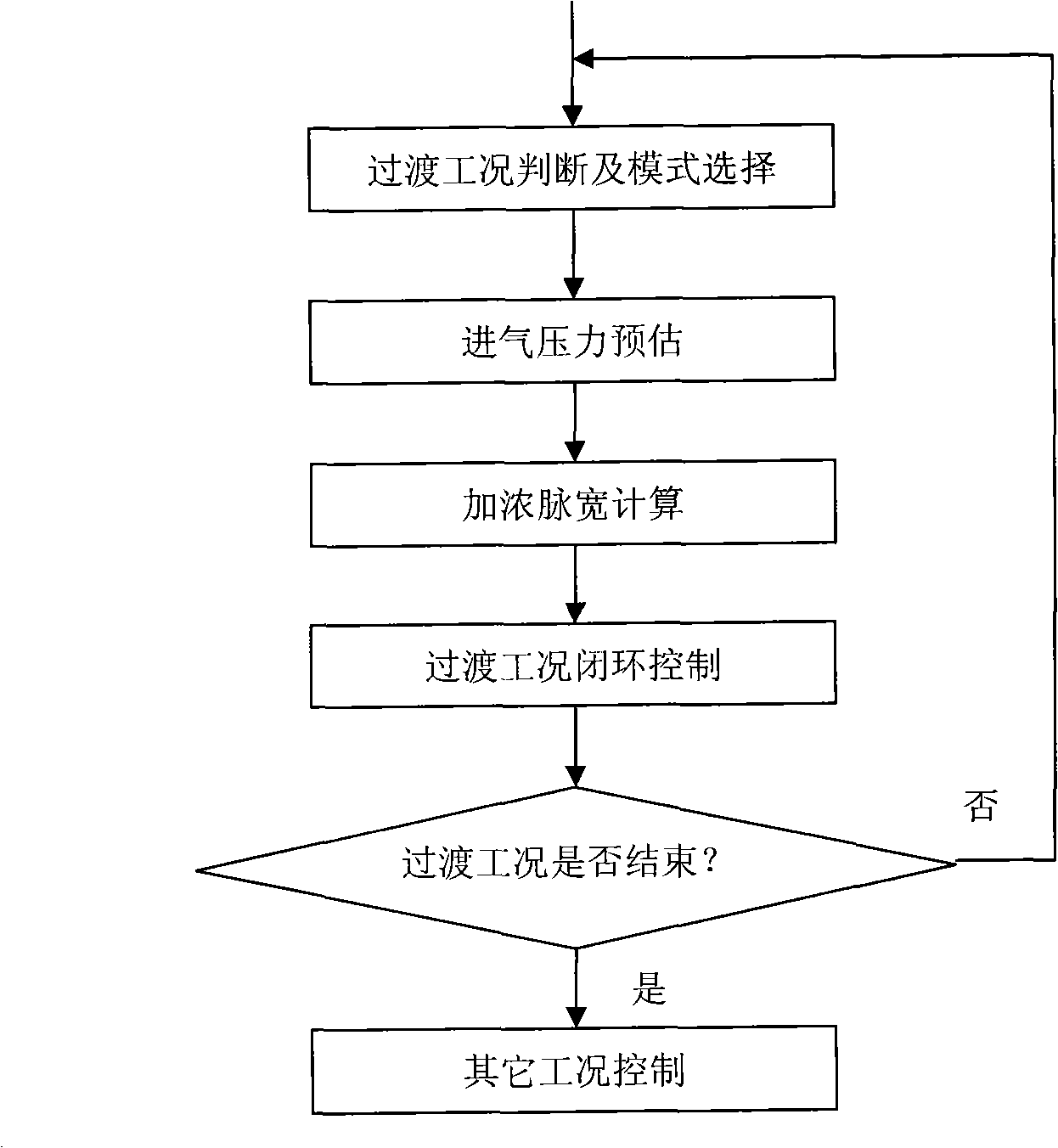

Control method of electric control petrol engine transient operating condition air/fuel ratio

InactiveCN101324208AMake up for the problem of response lagReduce calculation errorsElectrical controlMachines/enginesOxygen sensorGasoline

The invention discloses a method for controlling air-fuel ratio of instantaneous condition of an electric controlled gasoline engine; the method comprises the following steps of: controlling of synchronous and asynchronous enriching of transient working condition of the electric controlled gasoline engine, intake pressure prediction method and closed loop controlling of transient working condition; the transient working condition comprises the following steps of: controlling the step of synchronous and asynchronous enriching, intake pressure prediction step, and closed loop controlling step of transient working condition; the common characteristic of the three methods is that precise control of air-fuel ratio is realized in the control process of the whole transient working condition; according to different working conditions, the enriching mode is selected automatically, thus guaranteeing control precision of the response speed of the acceleration process and the air-fuel ratio of the acceleration process furthest; in the instantaneous transient working condition, an oxygen sensor signal is used fully so as to modify the error of enrichment or desaturation furthest, thus improving economy and emission of engines.

Owner:江苏汇动汽车电子有限公司

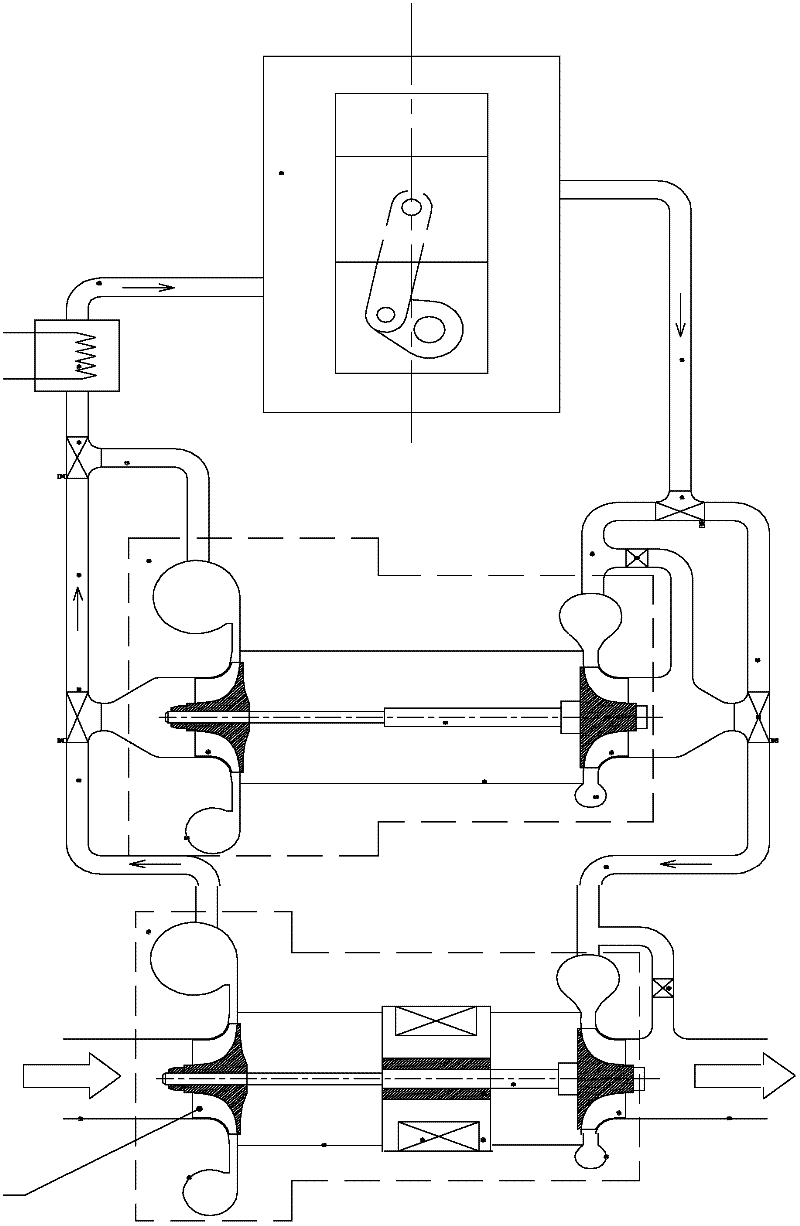

Electricity-auxiliary two-stage supercharging system capable of reusing exhaust gas

ActiveCN102230418AImprove acceleration performanceIncrease motivationInternal combustion piston enginesElectricityTurbocharger

The invention relates to an electricity-auxiliary two-stage supercharging system capable of reusing exhaust gas, belonging to the technical field of waste gas turbine supercharging. The electricity-auxiliary two-stage supercharging system specifically comprises the first-stage booster of an electricity-auxiliary turbine, the second-stage booster of a waste gas turbine, an electromagnetic three-way valve, an inlet and outlet pipeline system, a supercharging control circuit and an engine system. In the electricity-auxiliary two-stage supercharging system, the flexible control of opening and closing the three-way electromagnetic valve is used for further improving engine intake pressure by a second-stage supercharging system while solving the problem of waste gas turbine supercharging delaying, thereby realizing the high-pressure ratio of the engine supercharging, and improving the power and the emission performance of the engine under the whole working condition; the waste gas applying work in the second-stage booster of a waste gas turbine can be further utilized in the first-stage booster of an electricity-auxiliary turbine; and a storage battery is charged by power generation to fully utilize waste gas energy and effectively utilize fuel energy. Thus, the electricity-auxiliary two-stage supercharging system has an important energy-saving meaning.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

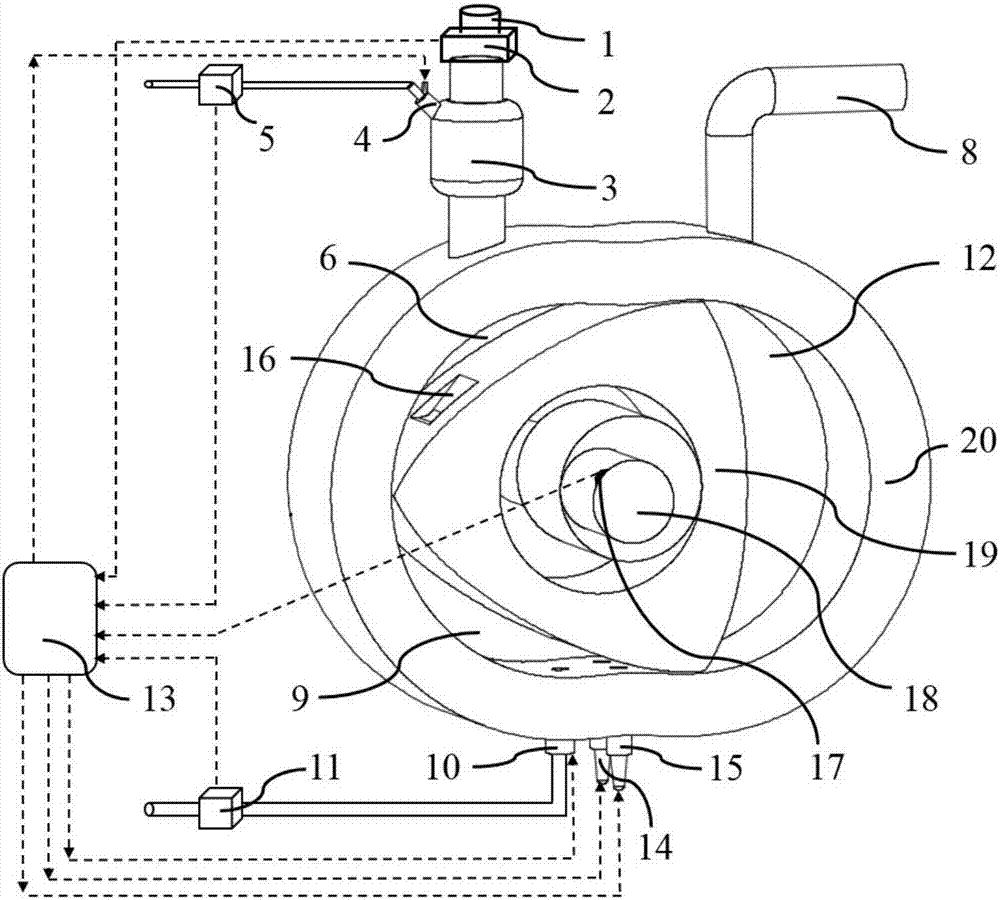

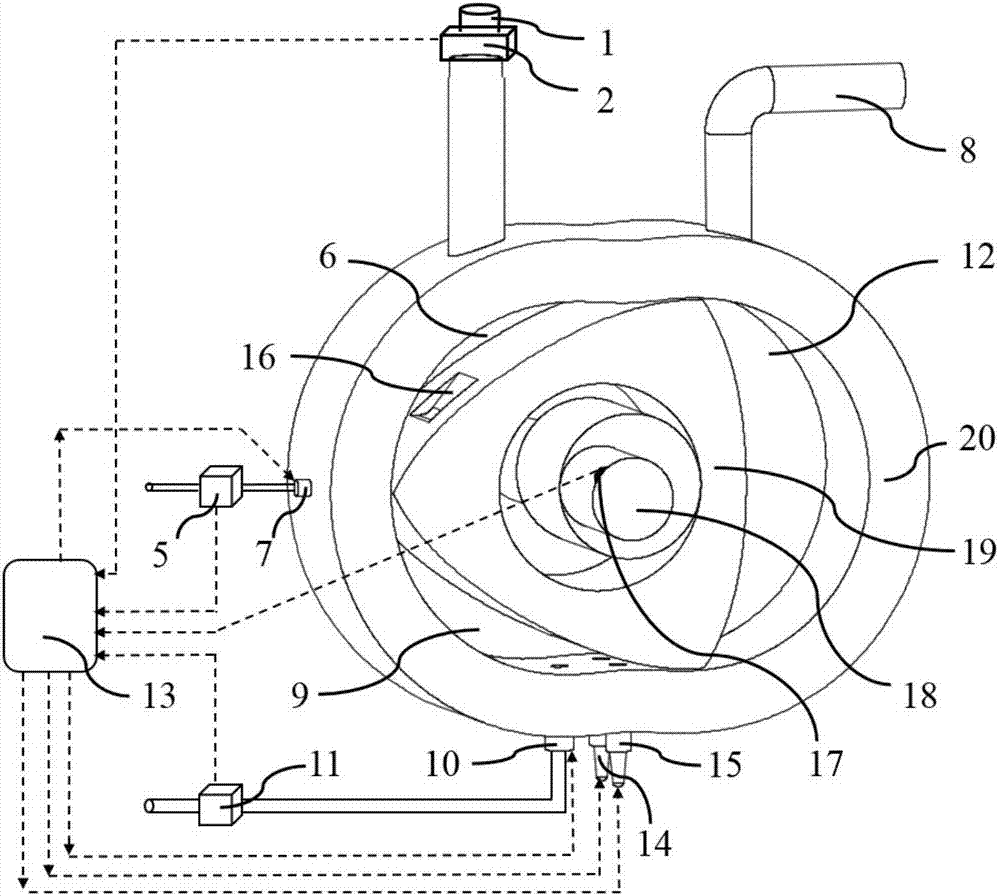

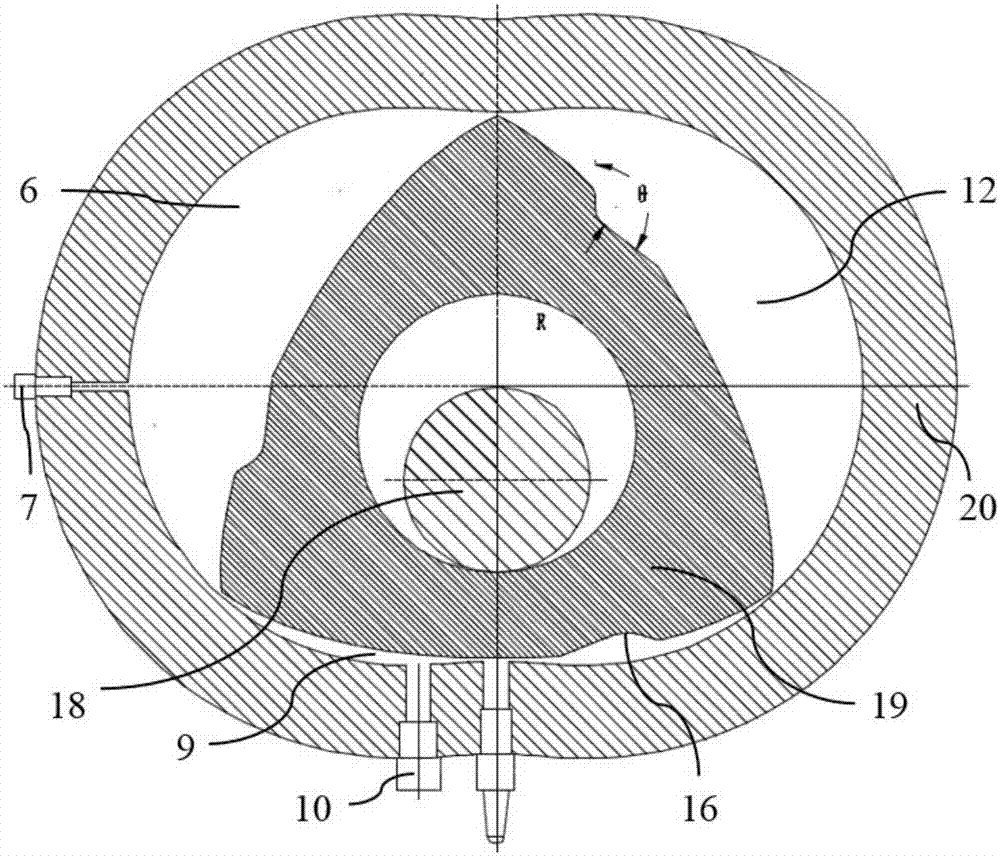

Direct injection type gas/liquid fuel supply system of rotary engine and control method of direct injection type gas/liquid fuel supply system

InactiveCN107387234AImprove powerImprove economyElectrical controlInternal combustion piston enginesCombustion chamberCombustor

The invention provides a direct injection type gas / liquid fuel supply system of a rotary engine. The direct injection type gas / liquid fuel supply system comprises the rotary engine, a gas injection system, a liquid injection system and an electronic control unit (ECU). The rotary engine comprises a cylinder, combustors and a triangular rotor, wherein the combustors are located between the cylinder and the triangular rotor, and the cylinder is internally provided with an exhaust pipe which communicates with the third combustor. The liquid injection system comprises a liquid fuel nozzle and a sparking plug, the liquid fuel nozzle is arranged on the cylinder and communicates with the second combustor, and the second combustor is internally provided with the sparking plug. The gas injection system comprises a second gas fuel nozzle, and the second gas fuel nozzle is arranged on the cylinder and communicates with the first combustor. The ECU is connected with the sparking plug, the liquid fuel nozzle, a revolution speed transducer and the second gas fuel nozzle. The direct injection type gas / liquid fuel supply system can accurately control the injection strategy of gas fuel and liquid fuel and the ignition strategy of the sparking plug to reasonably recognize formation and reliable ignition of mixed gas.

Owner:JIANGSU UNIV

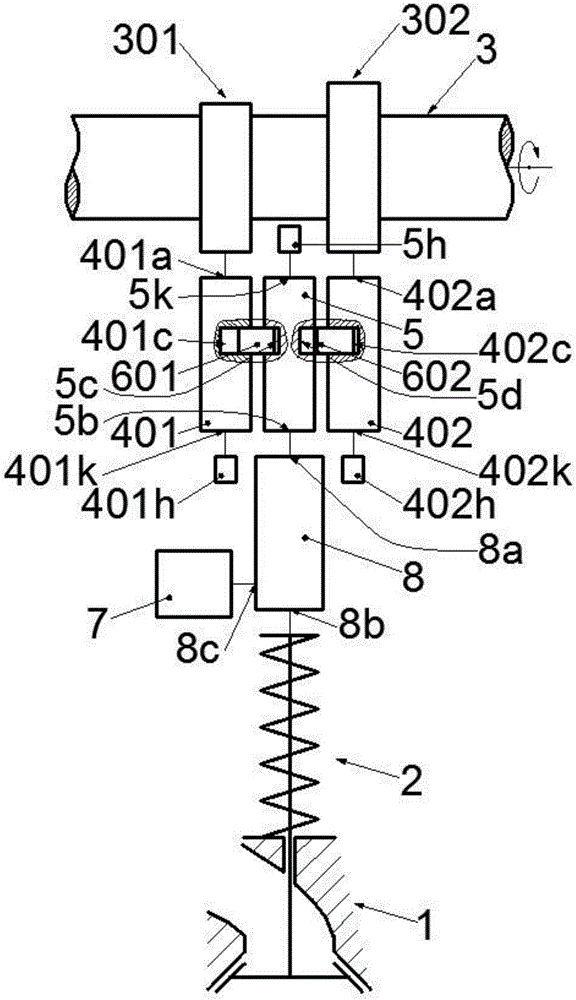

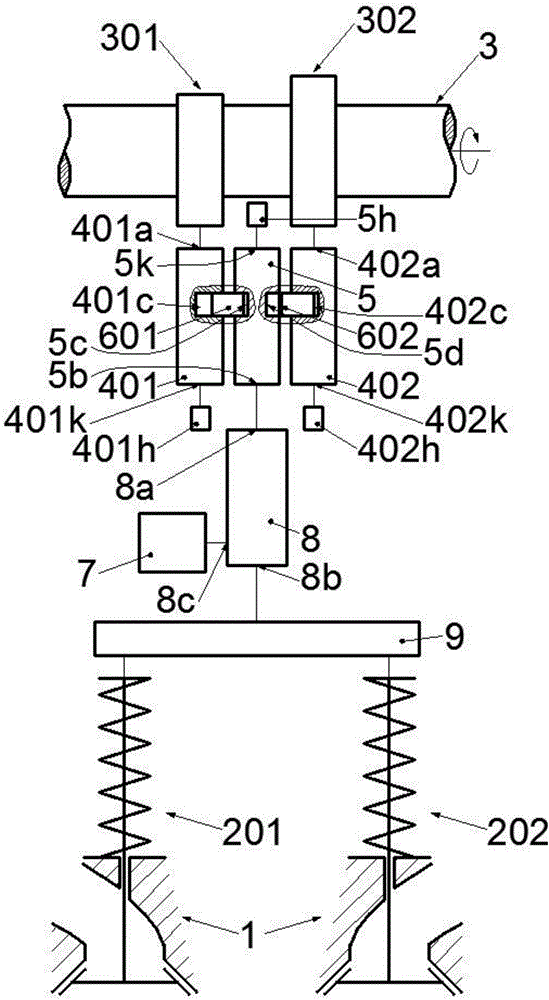

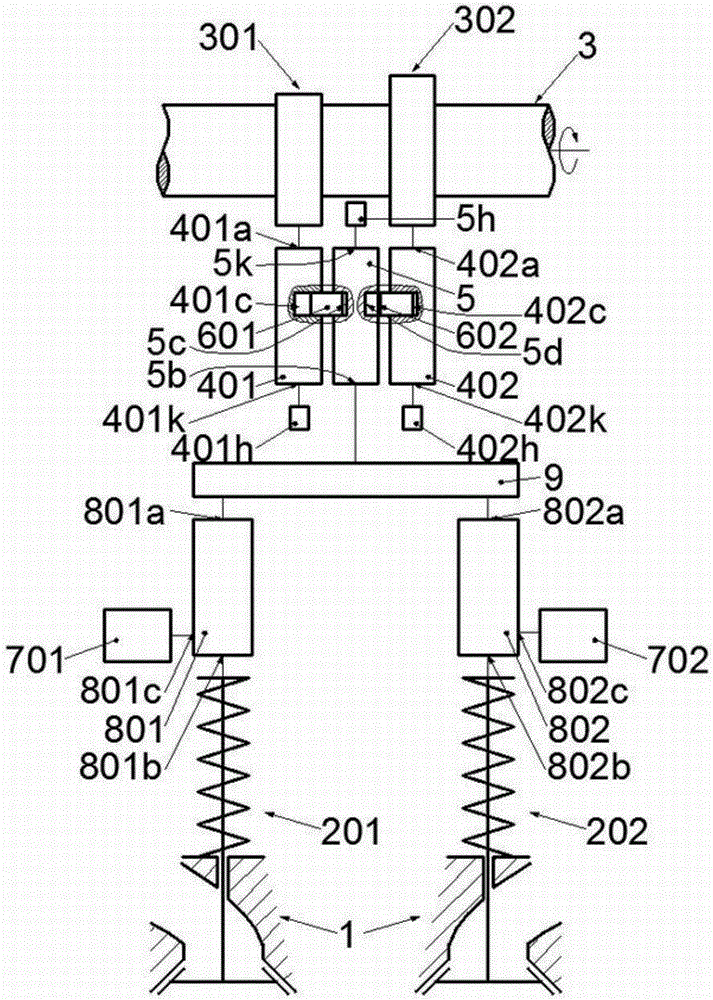

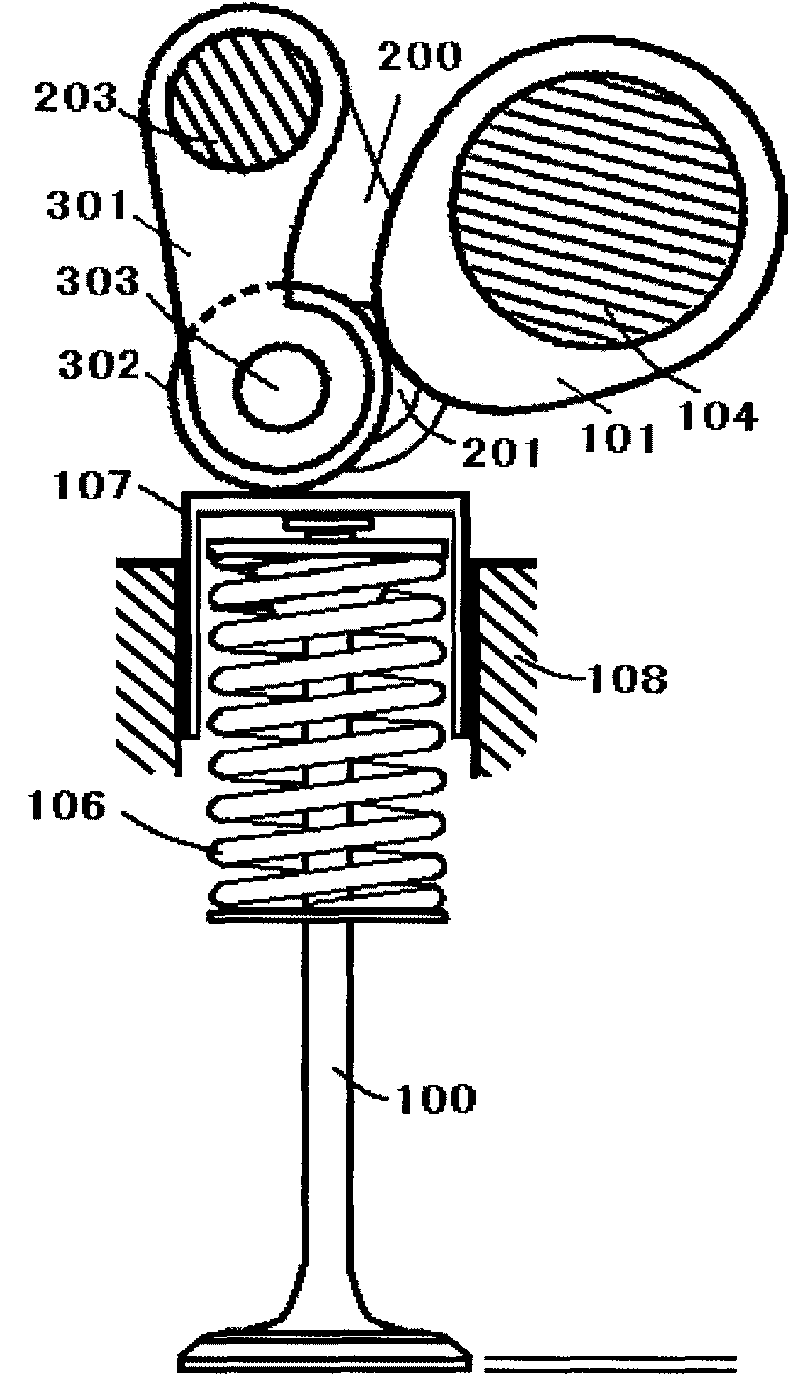

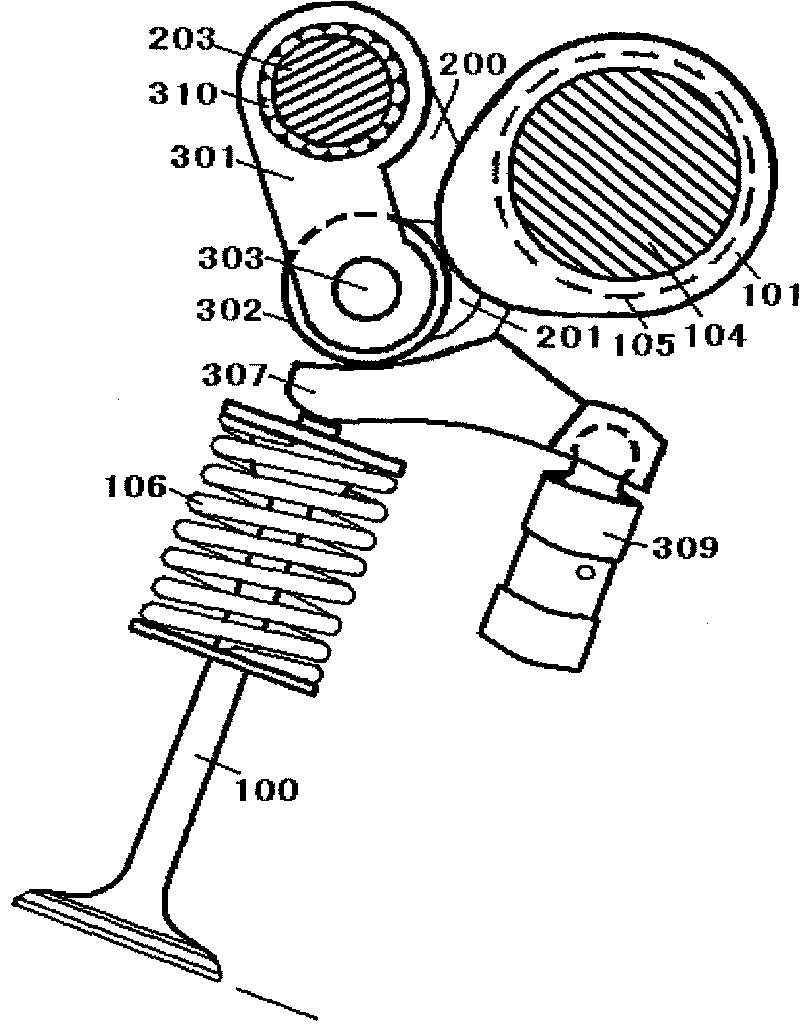

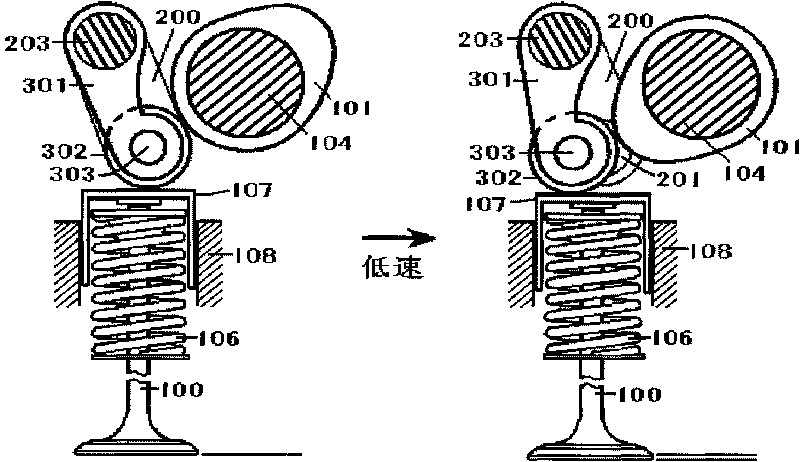

Mechanical continuous variable valve lift mechanism

InactiveCN101701540AImprove emission performanceImprove fuel economyValve arrangementsMachines/enginesLifting capacityEngine valve

The invention relates to a mechanical continuous variable valve lift mechanism which can lead the lift capacity of an engine valve to be changed into being closed all the way from the maximum according to the preset control value and ensure the valve timing not to be changed. The mechanism comprises a cam (101), an actuating mechanism (20) of a changeable rocker arm, the changeable rocker arm (301), a valve tappet (107), a tappet seat (108), a valve (100) and an auxiliary return spring (403); wherein the actuating mechanism (20) of the changeable rocker arm is provided with a changeable rocker arm shaft (203) which is connected with the changeable rocker arm (301), can control and change the space mechanical characteristics of the changeable rocker arm (301) and used for leading the lift capacity of the valve (100) to be continuously changed. The invention aims at thoroughly solving the problem of variable gas distribution of an internal-combustion engine puzzling the engine industry for dozens of years, omits a throttle valve of the engine, and leads continuous variable valve lift technology to be popularized to a minitype engine with less emission.

Owner:丛培伟

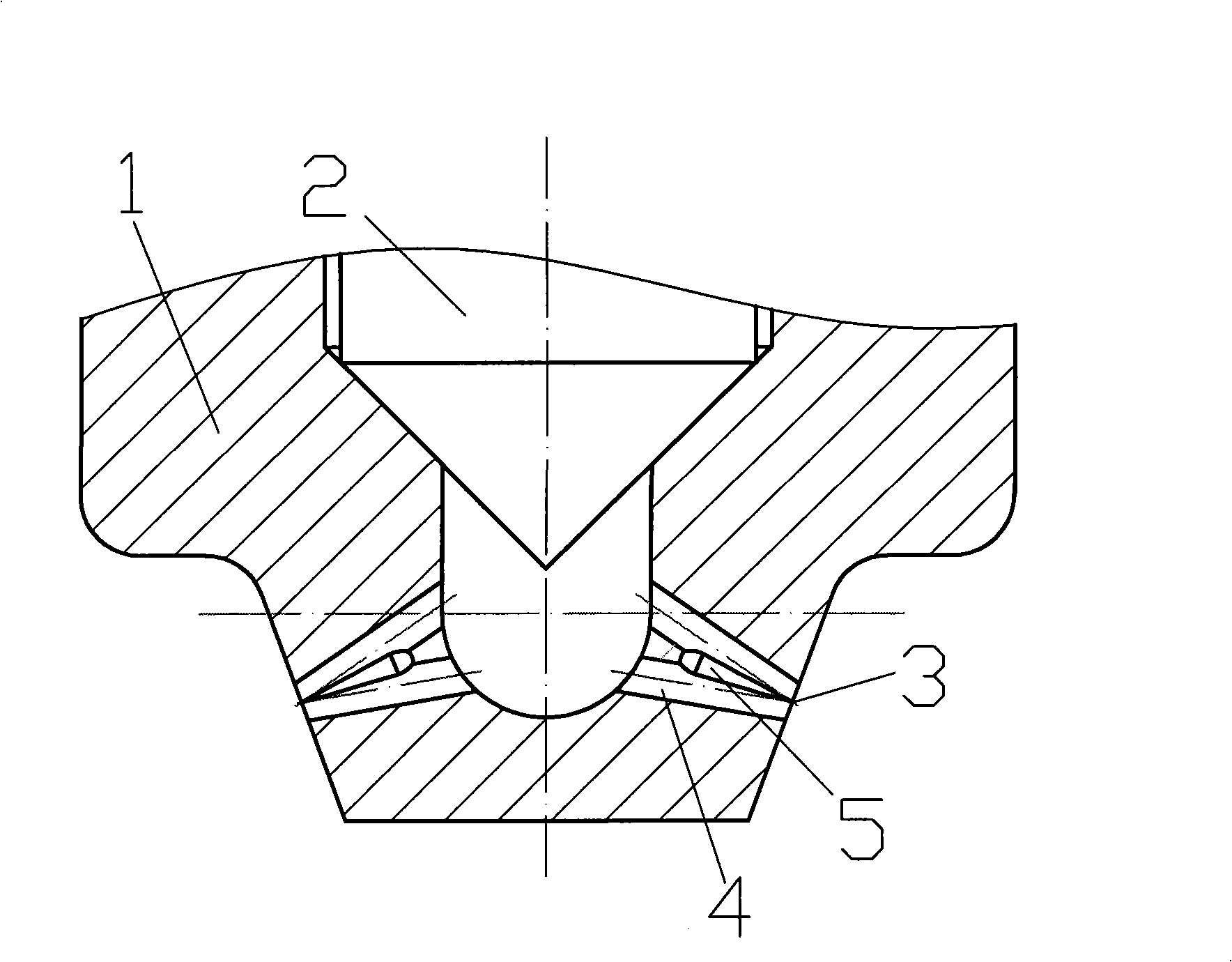

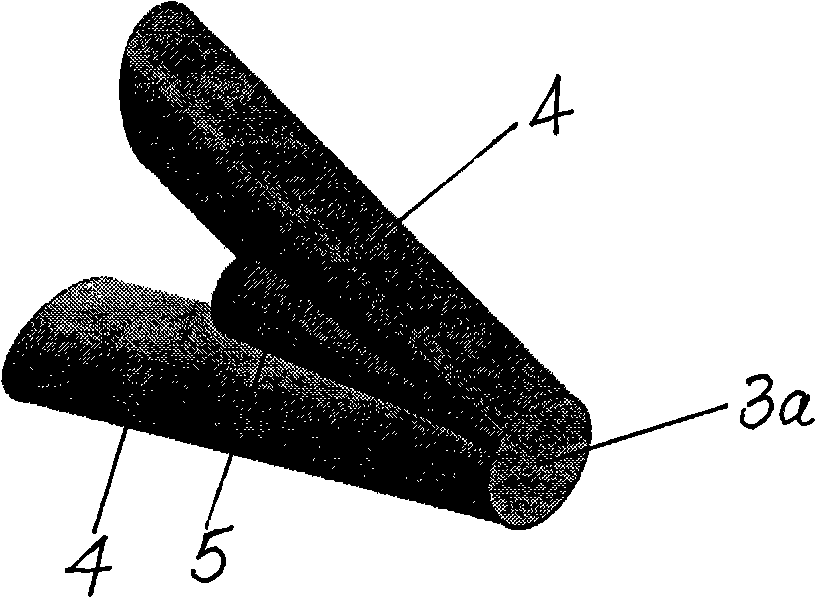

Internal-combustion engine alternating spray hole type nozzle with perturbing zone

ActiveCN101333993APromotes fuel atomizationEnhanced mixing processFuel injection apparatusMachines/enginesPower performanceNeedle valve

Disclosed is a cross jet-hole injection nozzle with a disturbance area of an internal combustion engine, which belongs to the oil injection device of the internal-combustion fuel-oil system. The cross jet-hole injection nozzle with the disturbance area of the internal combustion comprises a precise matching part composed of a needle valve body and a needle valve; at least a cross jet-hole injection hole with the disturbance area is arranged on the head part of the needle valve body. The turbulence flow of the internal fuel oil intensity of the injection nozzle, based on the turbulence flow disturbance generated on the cross position of the sub nozzle is further improved; thereby, the fuel-oil pulverization of the injection nozzle outlet is improved; the quality of the mixed gas is improved; the combustion is enabled to be more rapid, sufficient and complete; the engine is ensured to obtain better economy, exhaust and power performance under the same injection pressure.

Owner:DALIAN UNIV OF TECH

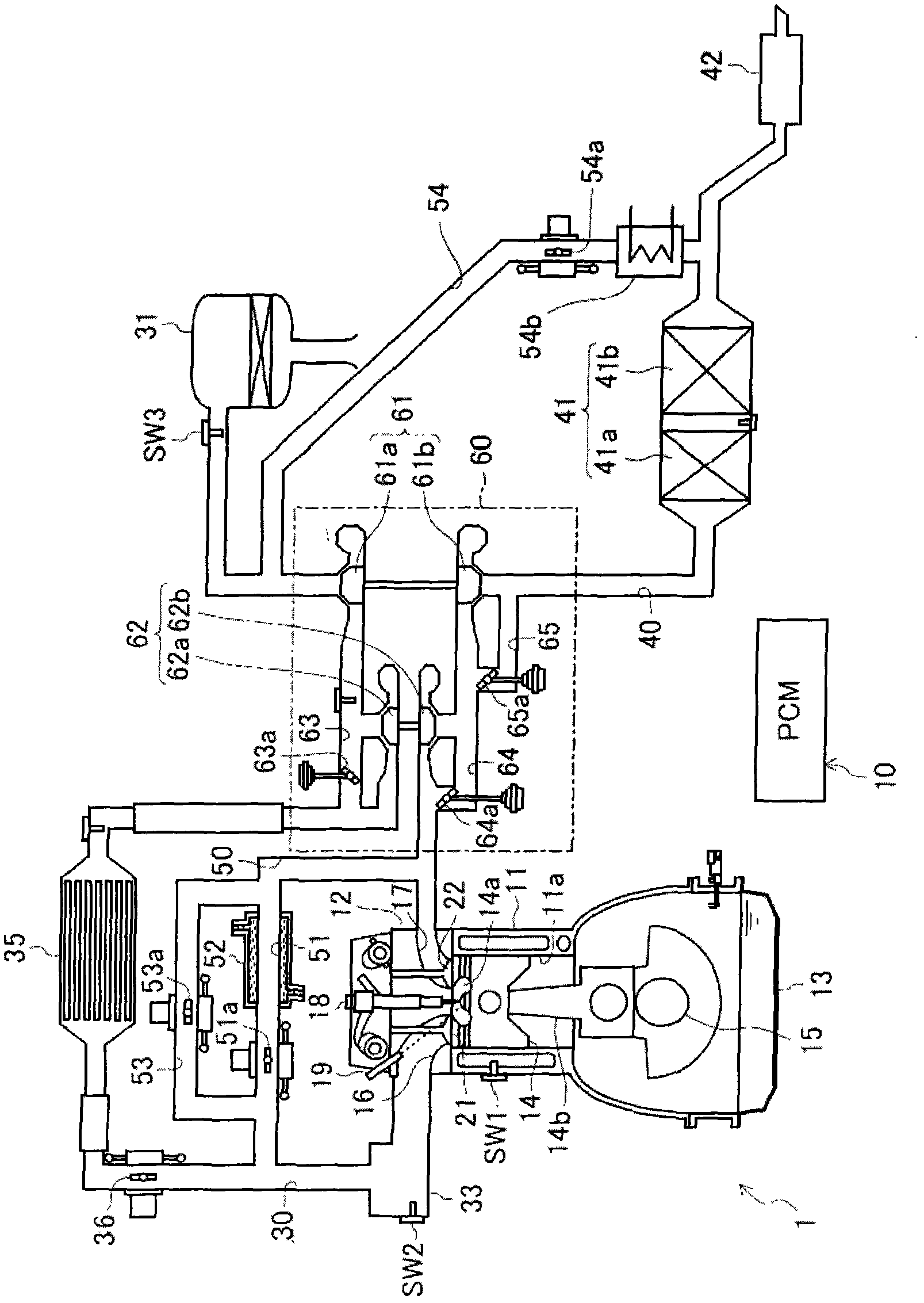

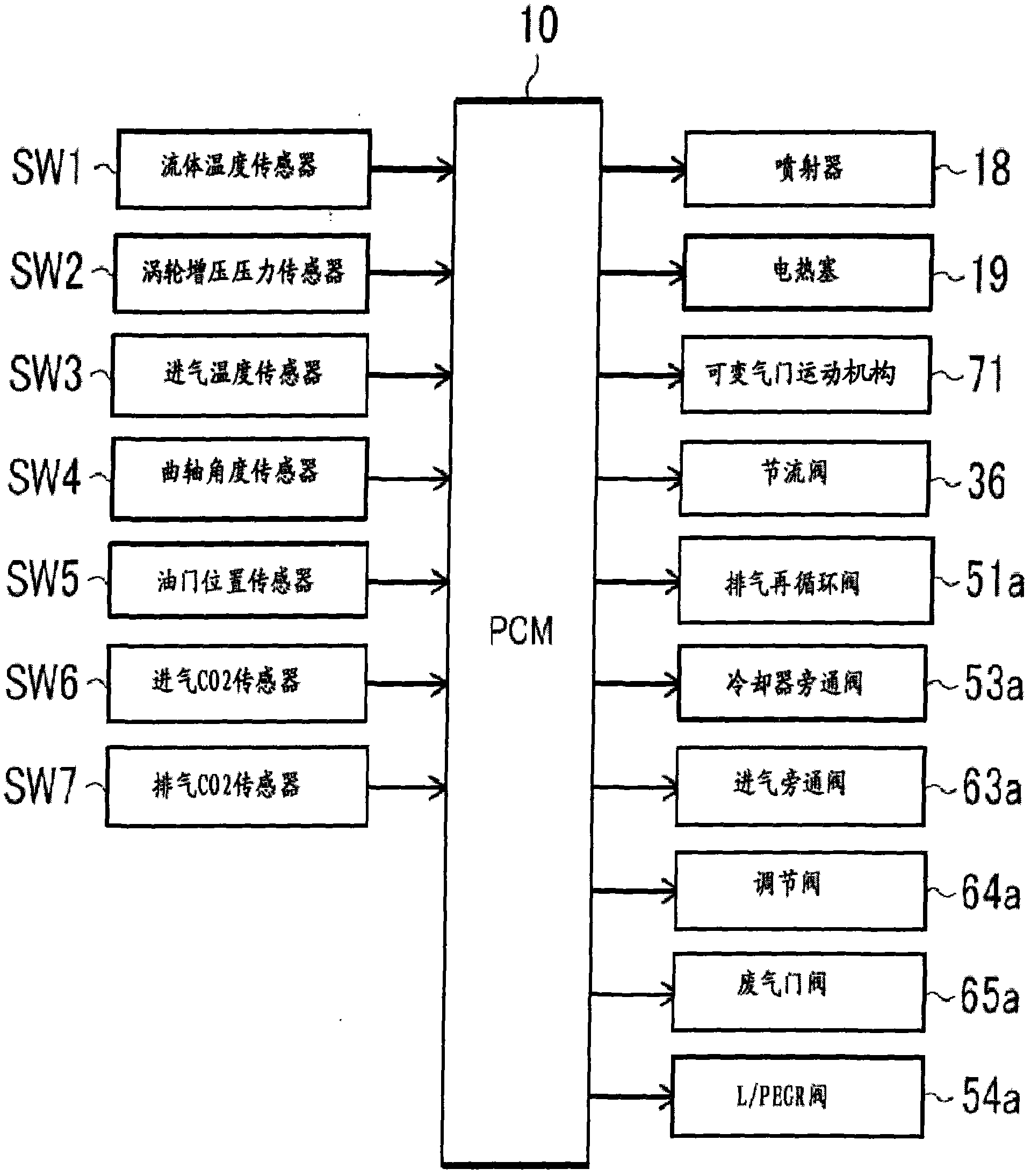

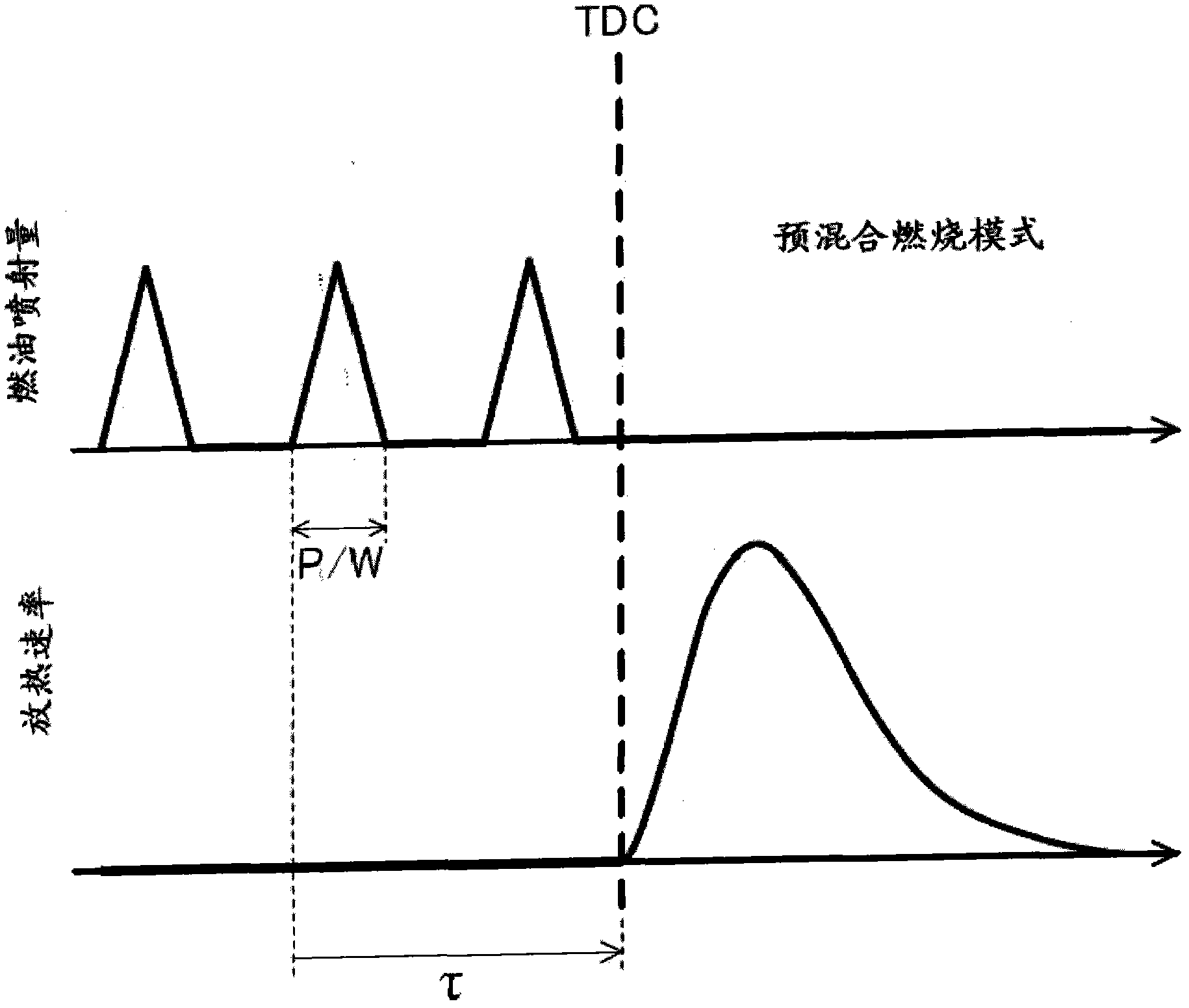

Method and device for controlling diesel engine

InactiveCN102374059AImprove emission performanceElectrical controlInternal combustion piston enginesCombustionTop dead center

This disclosure provides a method of controlling a diesel engine. The method includes adjusting an EGR ratio according to an engine load so that a cylinder O2 concentration decreases gradually to a predetermined load with an increase in the load of the engine, while the O2 concentration increases gradually above the predetermined load, operating the engine in a premix combustion mode where the fuel injection is terminated before a top dead center of a compression stroke in a low load operating range including the predetermined load where the O2 concentration is lowest and, after that, the fuel ignites and combusts, and operating in a diffusion combustion mode where the fuel injection is executed in parallel to the ignition and combustion of the fuel in an operating range where the load is higher than that of the operating range in the premix combustion mode and the O2 concentration is relatively high.

Owner:MAZDA MOTOR CORP

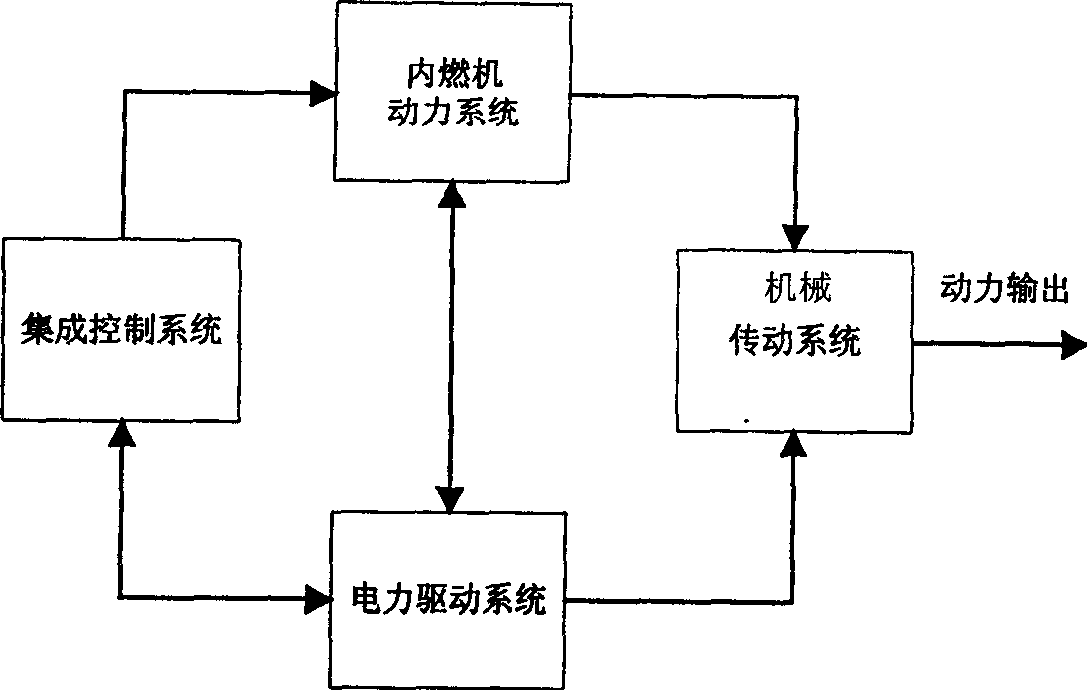

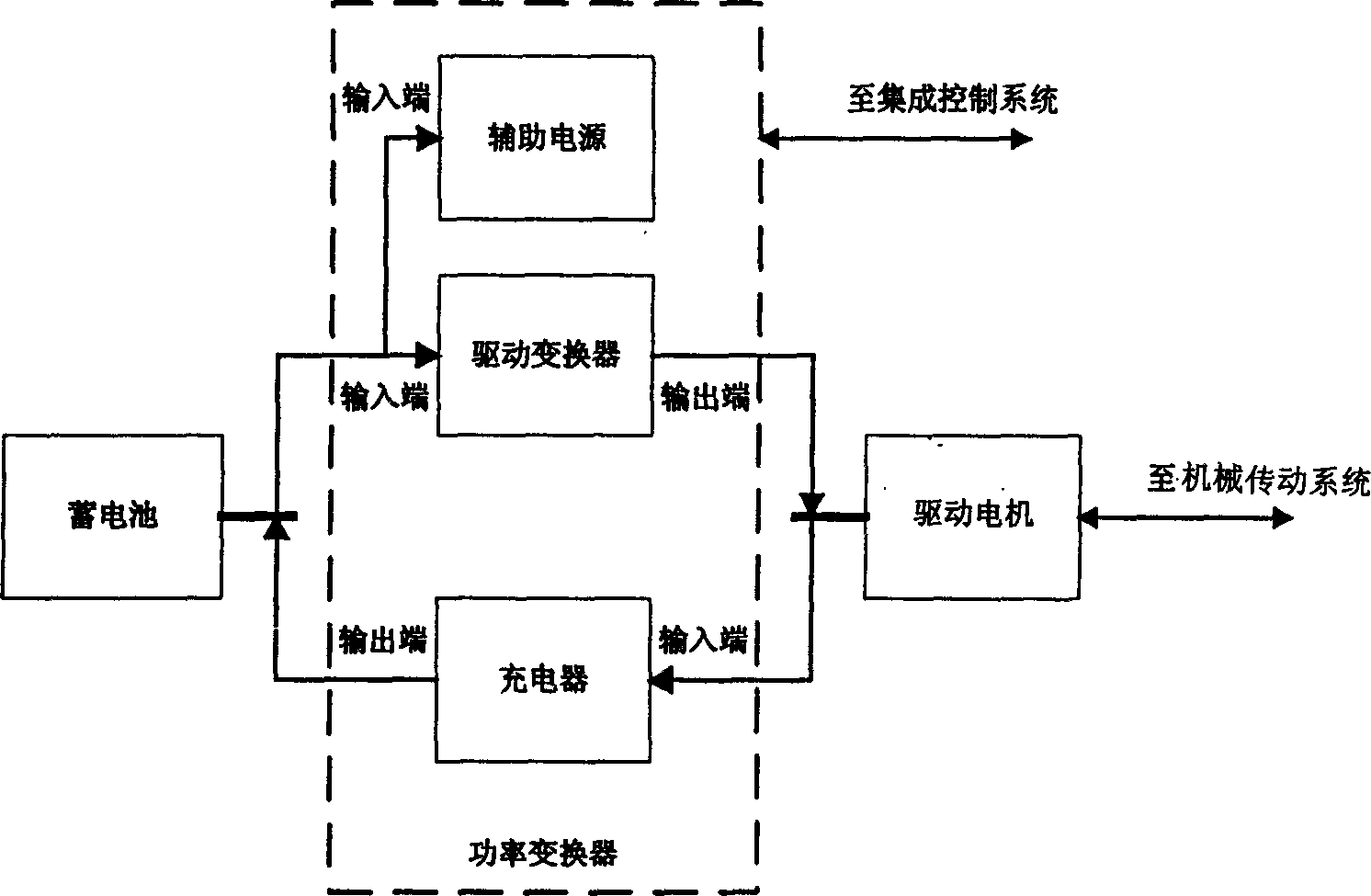

Gas and electric mixed power system of light traffic tool

InactiveCN1583459ALong distanceAvoid more emissionsHybrid vehiclesSpeed controllerLow speedEngineering

A gas-electric power integrated power system for light communication means is composed of integrating control system, electric drive system for low speed, IC engine system for high speed, and mechanical transmission system.

Owner:杭州迪源电气科技有限公司

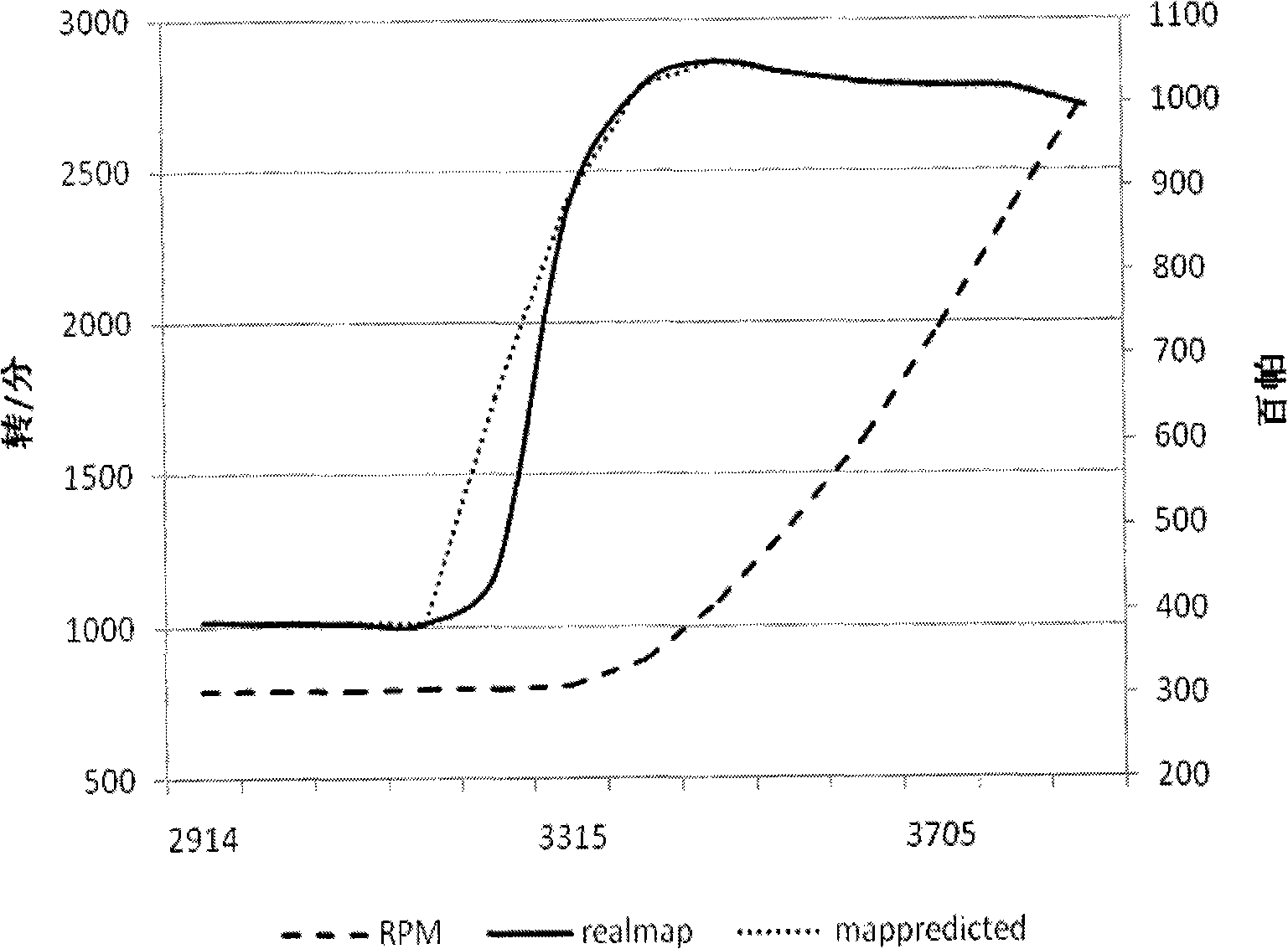

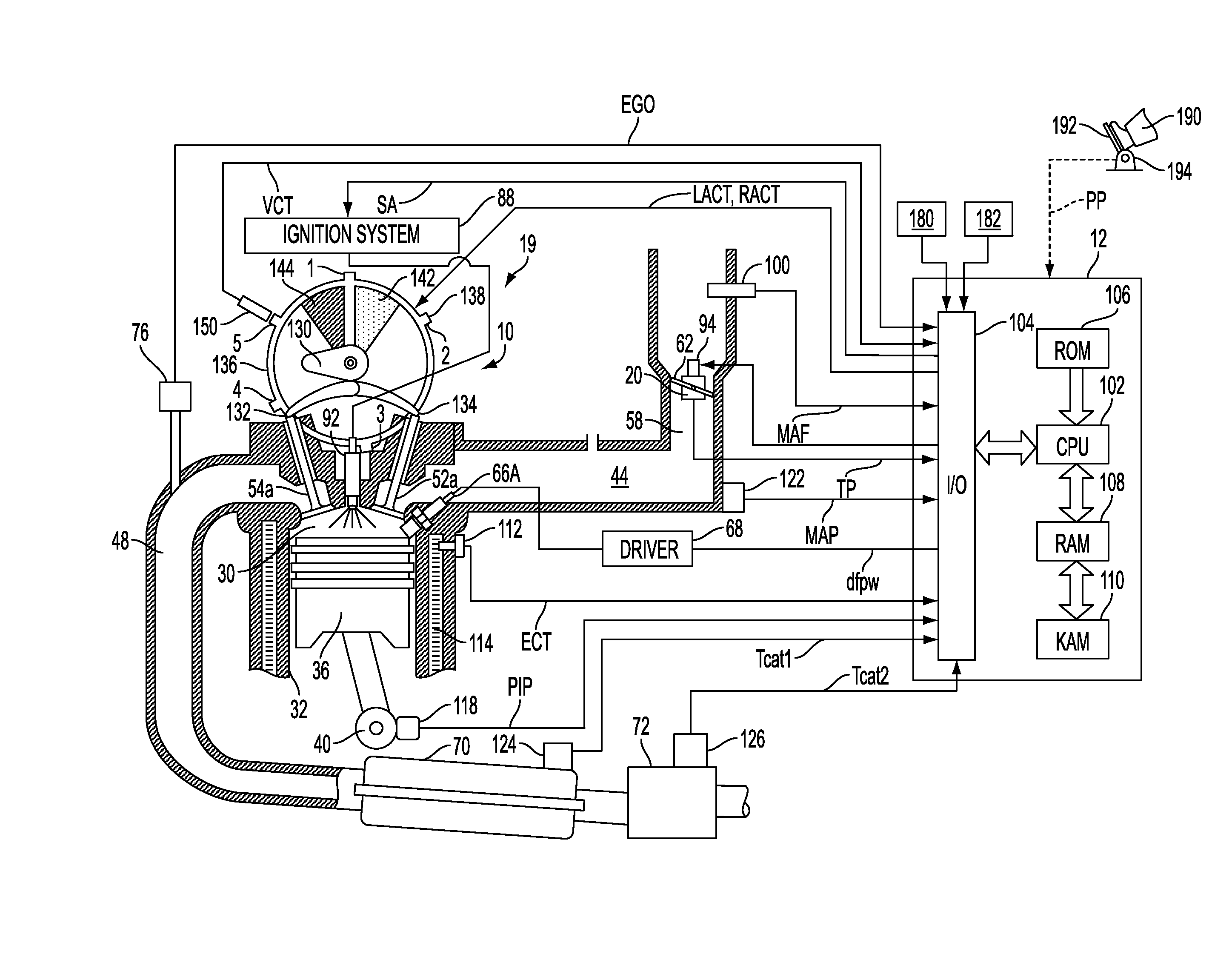

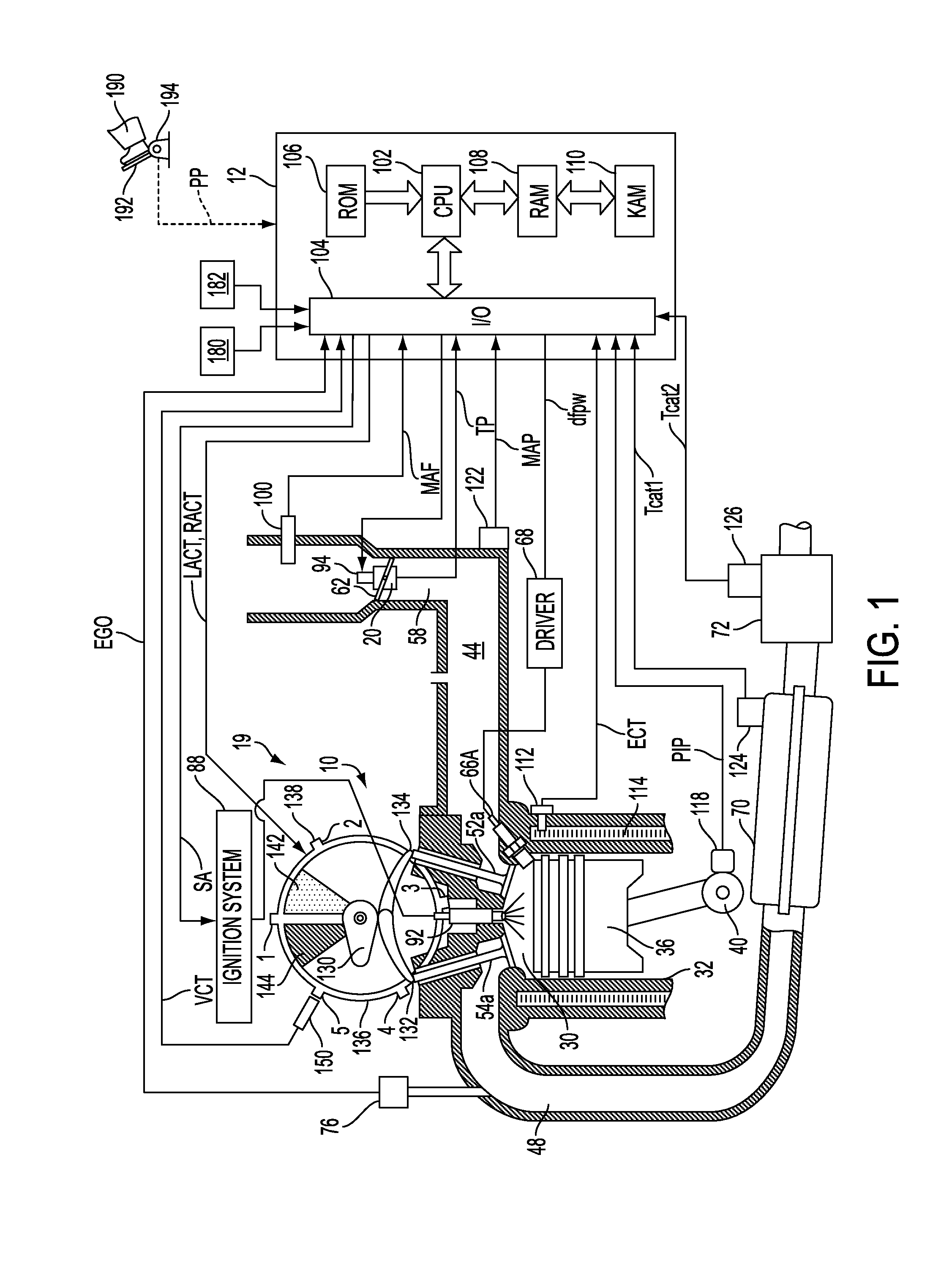

Method and system for variable cam timing device

ActiveUS20160108774A1Improve emission performanceImprove fuel economy performanceValve arrangementsMachines/enginesSpool valveEngineering

Methods and systems are described for an engine with a cam torque actuated variable cam timing phaser. Phaser positioning control is improved by reducing inaccuracies resulting from inadvertent spool valve and / or phaser movement when the spool valve is commanded between regions. In addition, improved spool valve mapping is used to render phaser commands more consistent and robust.

Owner:FORD GLOBAL TECH LLC

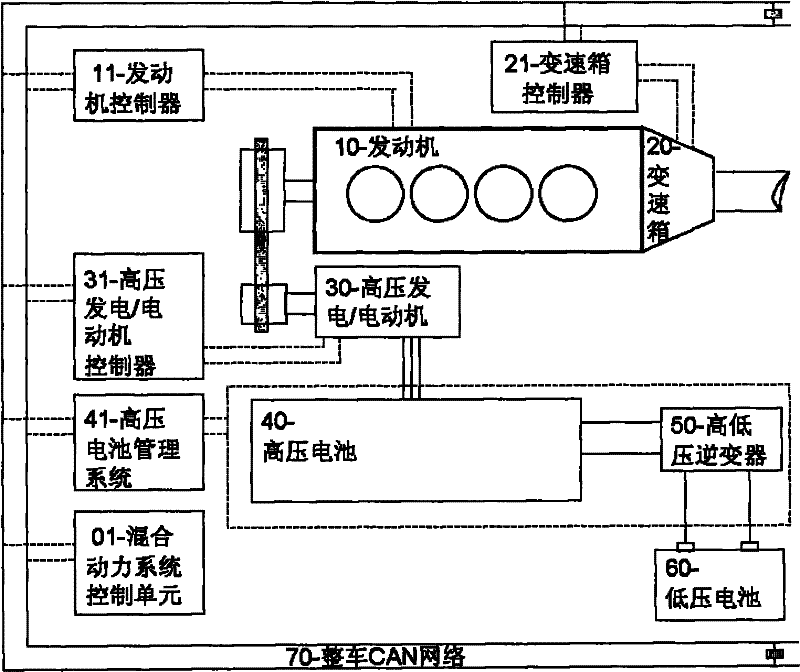

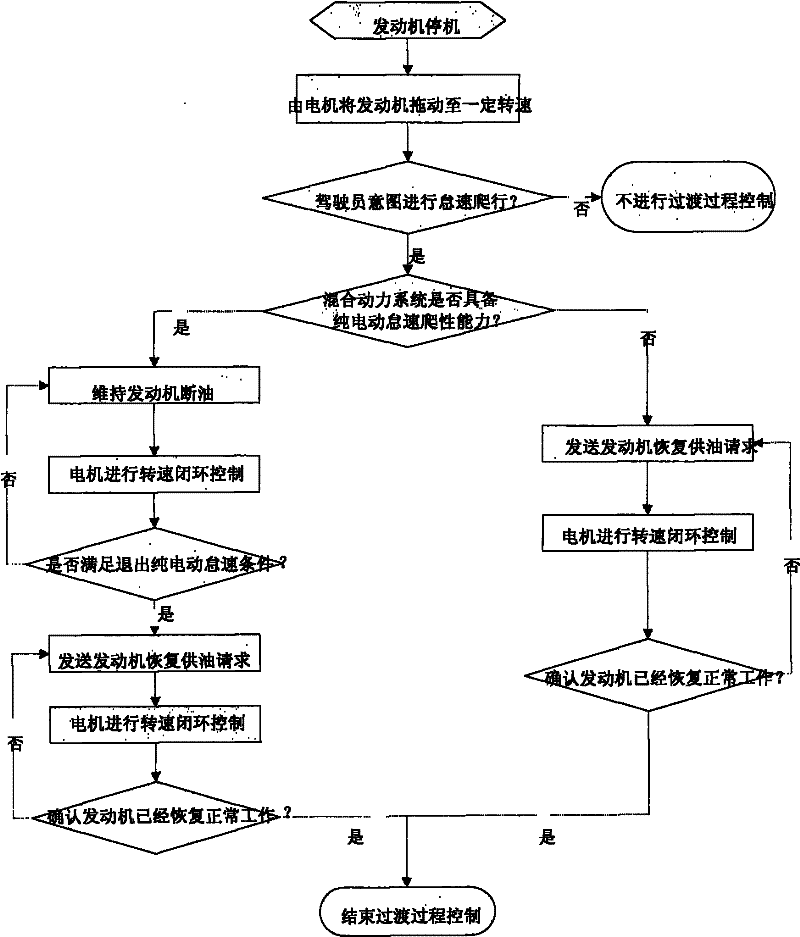

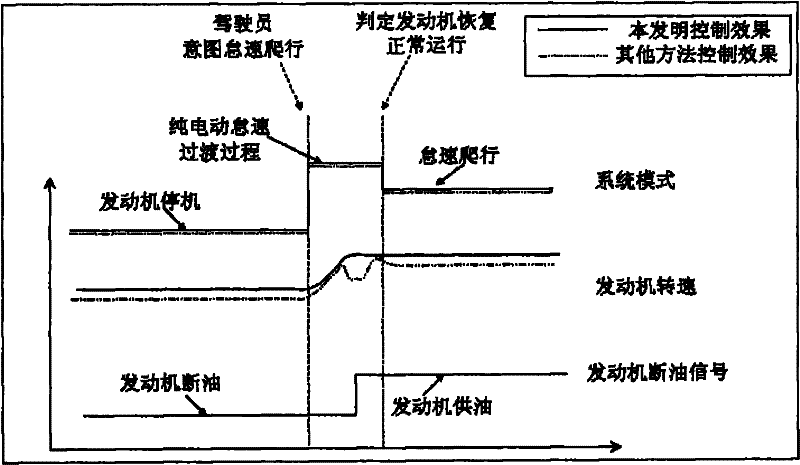

Control method for hybrid system

The invention relates to a control method for a hybrid system, in particular to a control method for enabling the hybrid system to enter an engine drive mode from an engine shut-down mode. The control method comprises a step of closed-loop control of a hybrid motor. With the adoption of the control method, control is smooth during a process from turning on an engine to the process of enabling the automobile to crawl at an idle speed, the engine is turned on stably, the driving comfortableness is improved, and the economic property and the emission property of the entire automobile are improved.

Owner:SAIC MOTOR

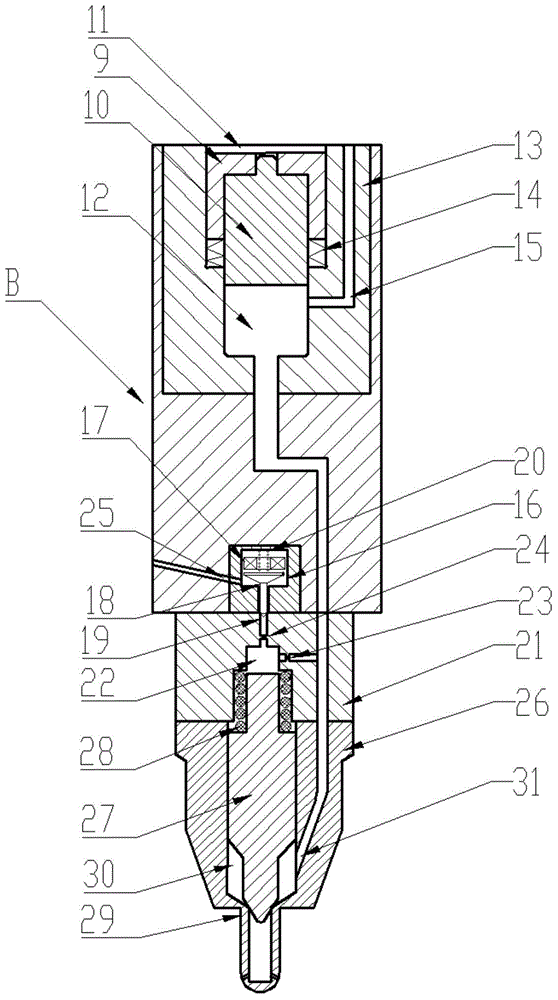

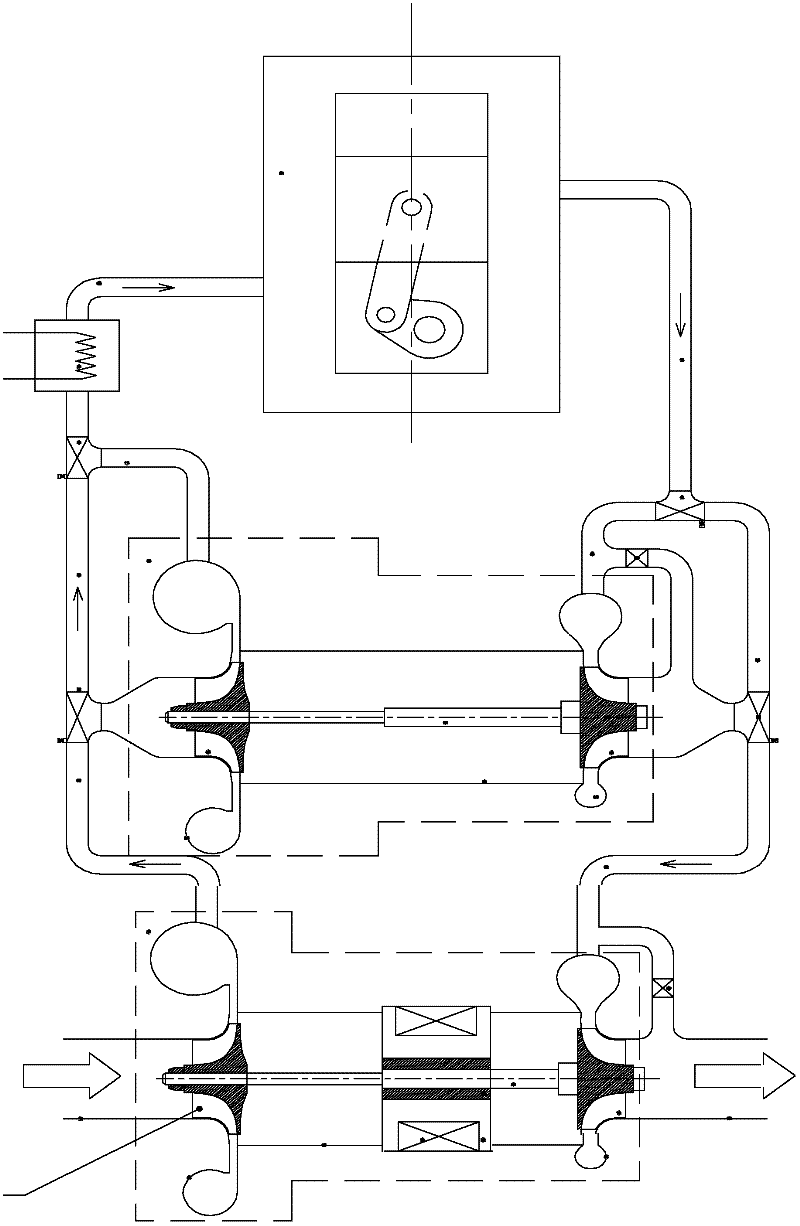

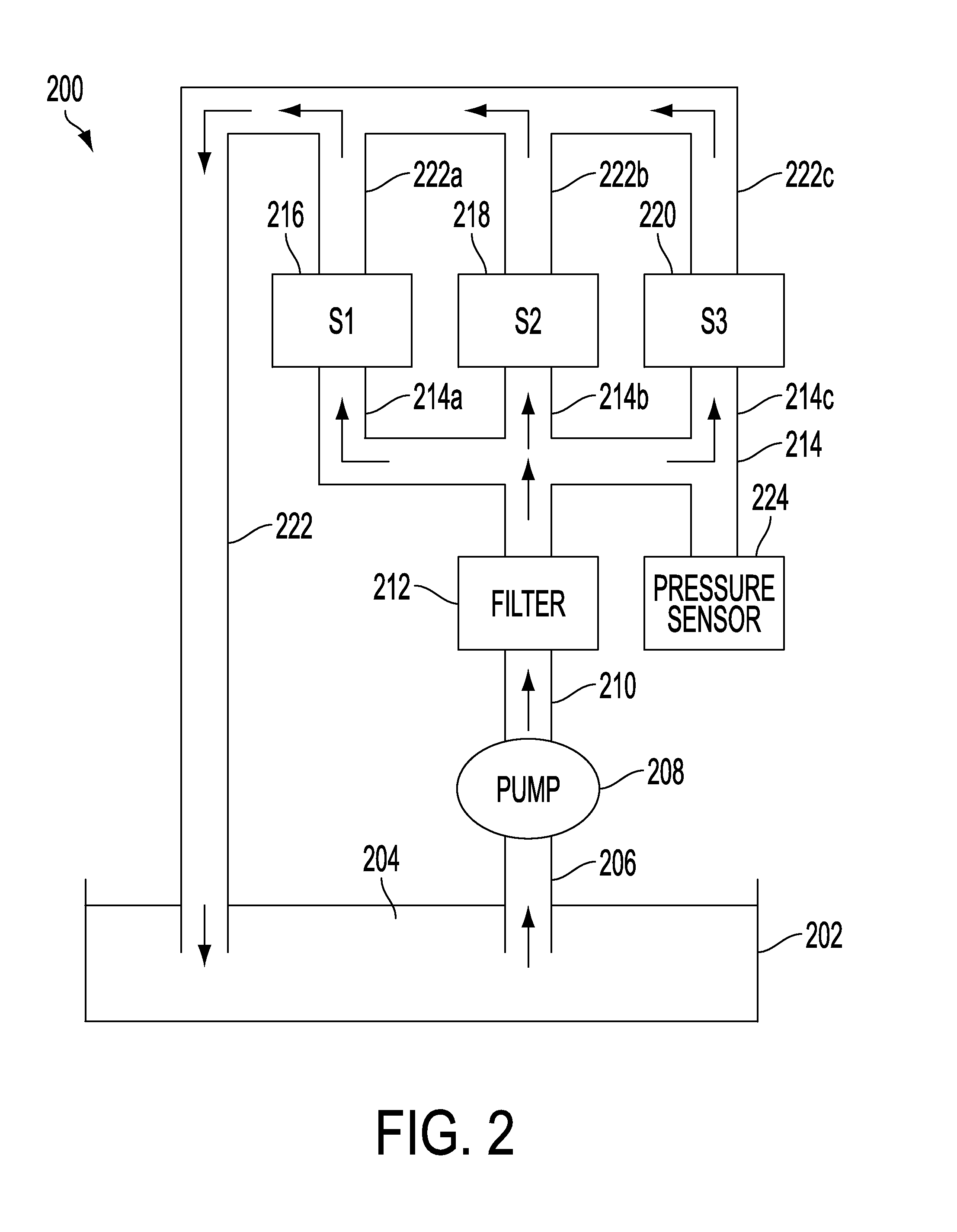

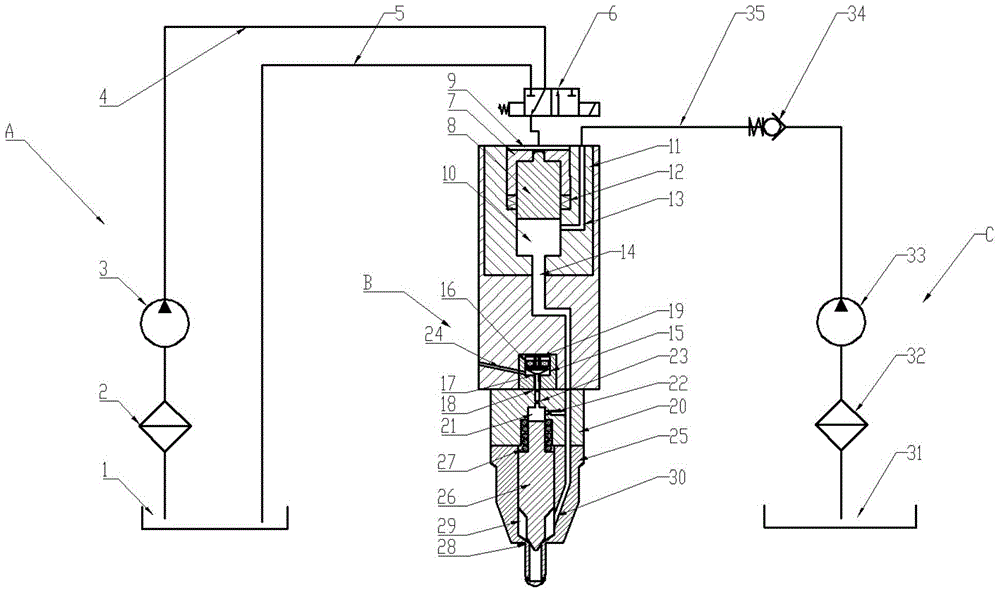

Supercharged common rail fuel injection system of marine low-speed diesel engine

InactiveCN104564460AAdjust the injection pressureImprove reliabilityFuel injection apparatusMachines/enginesMultiple injectionLow speed

A supercharged common rail fuel injection system of a marine low-speed diesel engine comprises a servo fuel supplying part, a common rail fuel injector and a fuel supplying part, wherein the servo fuel supplying part and the fuel supplying part respectively supply servo fuel and fuel to the common rail fuel injector; in the common rail fuel injector, an upper supercharged piston chamber and a lower supercharged piston chamber are formed between a supercharging piston and a supercharging piston body; a supercharging piston control valve controls whether the servo fuel supplying part and the upper supercharged piston chamber are communicated or cut off, so that the supercharging or suction of the fuel is realized; supercharged high-pressure fuel in the lower supercharged piston chamber is divided into two paths: one enters a control chamber and the other enters a fuel holding tank; a fuel injection control electromagnetic valve performs precise and flexible control under all working conditions to the fuel injection timing and the cyclic fuel injection quantity of the common rail fuel injector. According to the supercharged common rail fuel injection system of the marine low-speed diesel engine, the fuel supercharging process and the fuel injection process are completely separated; multiple injections in one circulation is allowed, and the fuel economy and the emission performance of the diesel engine are improved.

Owner:HUDONG HEAVY MACHINERY +1

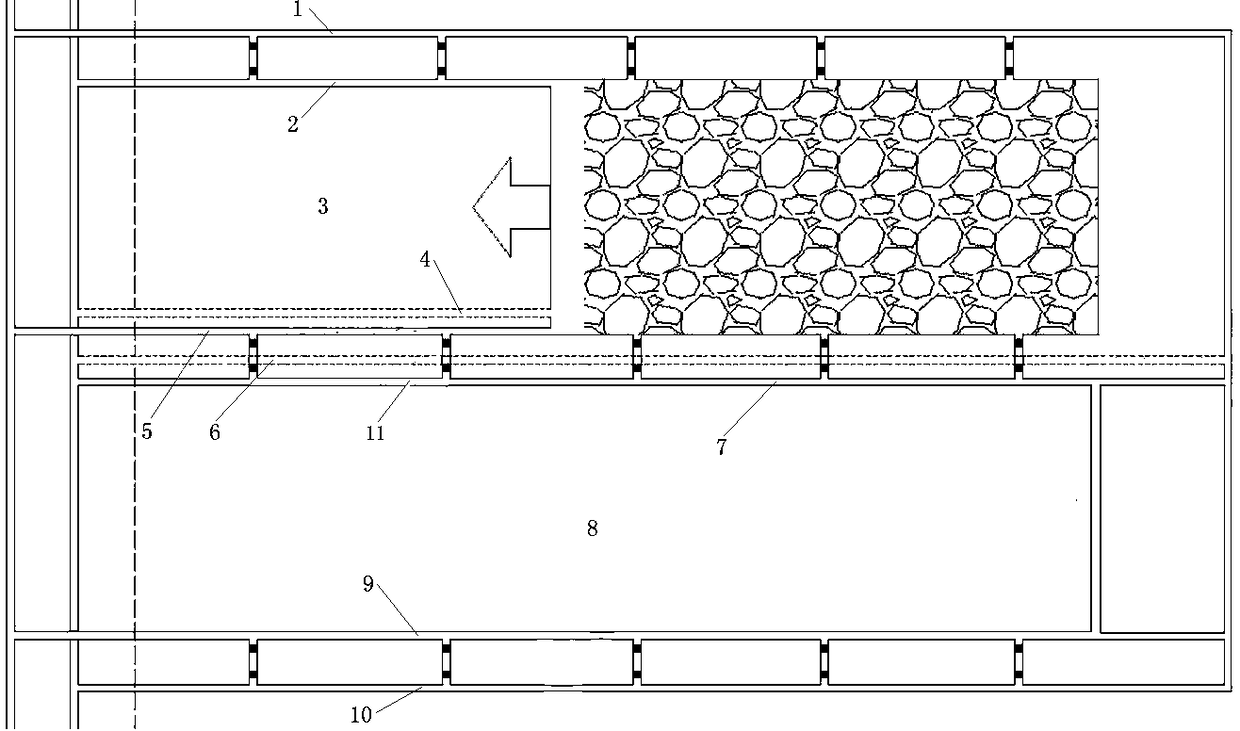

Method for multi-roadway layout of long wall working face of thick coal seam

ActiveCN108952716AReduce lossesImprove fraudulentUnderground miningSurface miningEngineeringHigh security

The invention relates to the field of coal mining, in particular to a method for multi-roadway layout of a long wall working face of a thick coal seam. The method for the multi-roadway layout of the long wall working face of the thick coal seam solves the problem that roadways of the multi-roadway layout system of a conventional long wall working face are all tunneled along a floor, a lower section air roadway is affected by repeated mining, the maintenance time is long, and the maintenance is difficult. The method for the multi-roadway layout of the long wall working face of the thick coal seam comprises the following steps that step 1, four roadways of a first working face are parallelly tunneled, a first auxiliary transport roadway and a first main transport roadway are arranged along the floor, and a first main return air roadway and a first auxiliary return air roadway are arranged along a roof; step 2, the first working face is mined; step 3, after mining of the first working face is completed for more than half a year, a second auxiliary transport roadway of a second working face parallelly tunnels four roadways of the second working face in a goaf of the first working face;step 4, coal of the second working face is mined; and step 5, in the way, subsequent working faces are arranged in sequence for mining, a layout mode the same as that of the front working face is adopted, and stoping is carried out in sequence. The method for the multi-roadway layout of the long wall working face of the thick coal seam has better economy and higher security.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com