Method for multi-roadway layout of long wall working face of thick coal seam

A layout method and working face technology, which is applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of large loss of section coal pillars, long maintenance time, difficult maintenance, etc., and achieve the reduction of comprehensive coal pillar loss , high safety and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings. However, those skilled in the art should realize that the present invention is not limited thereby.

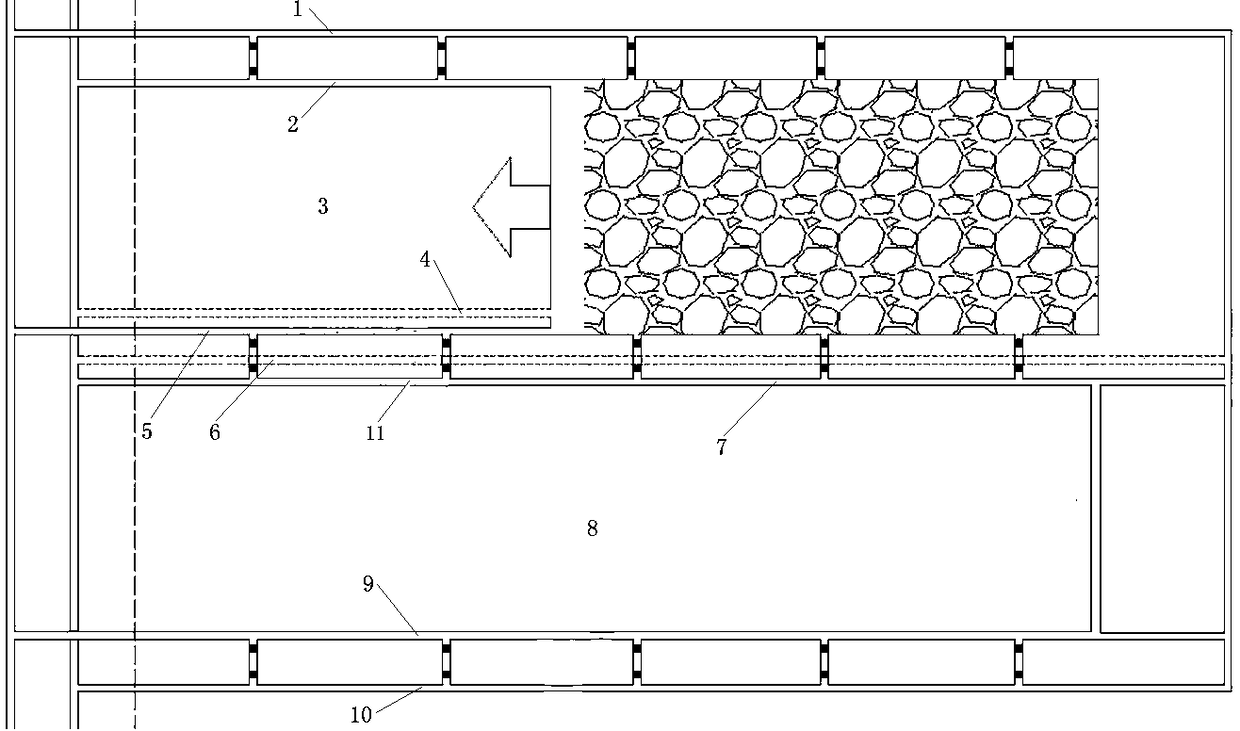

[0019] A multi-lane layout method for longwall working faces in thick coal seams, comprising the following steps:

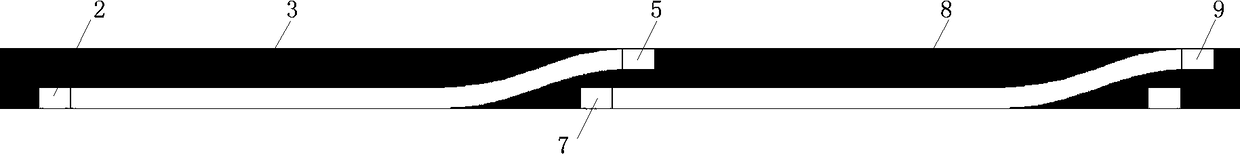

[0020] Step 1: Excavate the four entryways of the first working face in parallel, among which, the first auxiliary transportation entryway and the first main transportation entryway are arranged along the floor, and the first main return air entry entry and the first auxiliary return air entry entry are arranged along the floor. The roof layout is located at the higher level of the coal seam, and the working face at the right end gradually completes the slope by adjusting the chute of each section of the scraper conveyor, hydraulic support and other equipment, forming the mining system of the first working face;

[0021] The second step: Mining the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com