Control method of electric control petrol engine transient operating condition air/fuel ratio

A technology of transient working conditions and control methods, applied in electrical control, engine control, fuel injection control, etc., can solve problems such as large changes in response speed air-fuel ratio, engine emission level and poor economy, etc., to reduce calculation errors , fast response, make up for the effect of response lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

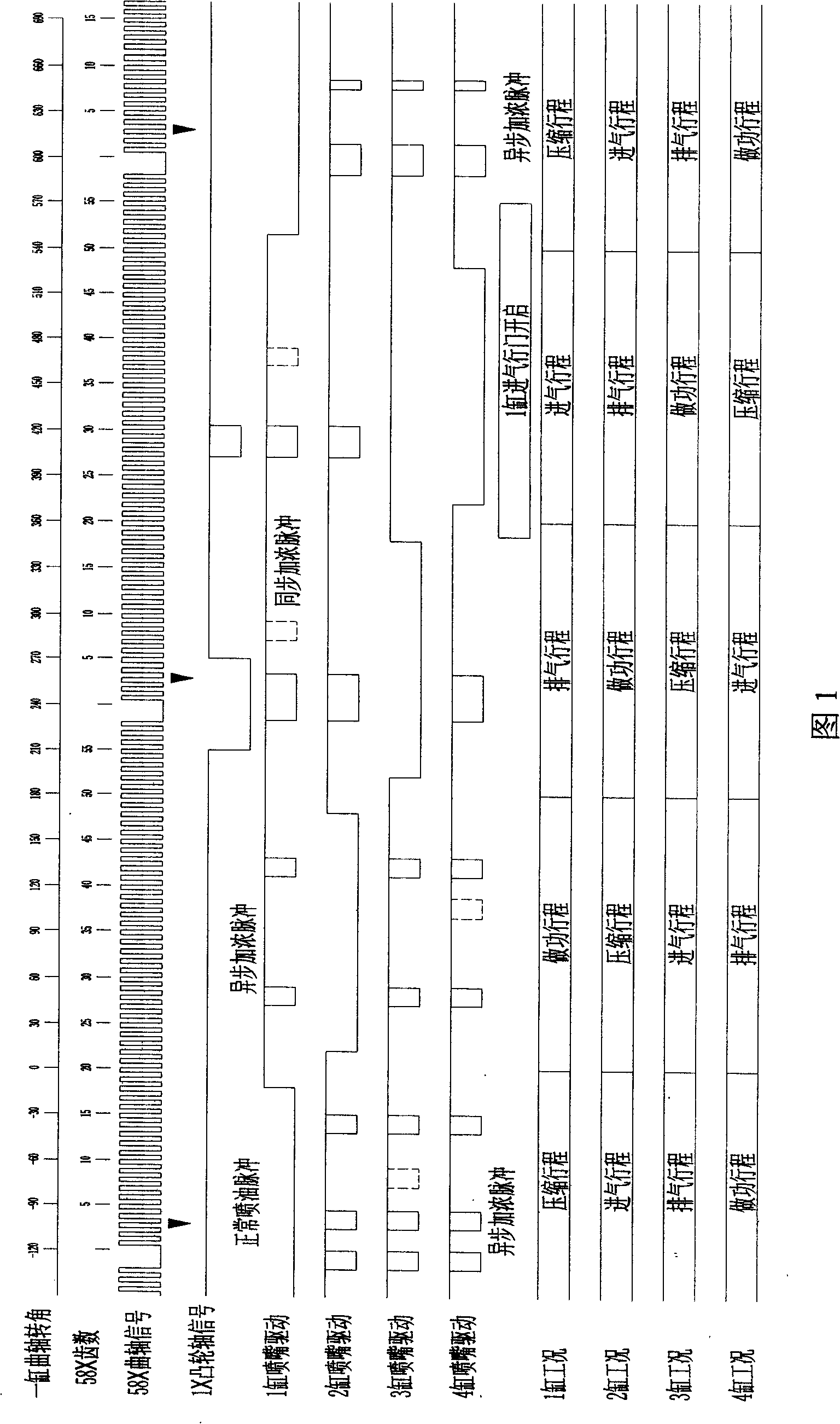

[0036] Please refer to Figure 1, which is an explanatory diagram of the timing sequence of synchronous enrichment and asynchronous enrichment of a four-cylinder gasoline engine; the small pulse width indicated by the dotted line in the figure is the synchronous enrichment pulse width of each cylinder, and the small pulse width indicated by the solid line is the pulse width of each cylinder. Cylinder asynchronous enrichment pulse width. It can be seen from the figure that the synchronous enrichment pulse width is output when the engine runs to a specific phase, while the asynchronous enrichment pulse width has nothing to do with the engine phase, it is determined by the main loop of the control program, and once the enrichment condition is met, Then the enrichment output is carried out to four cylinders at the same time.

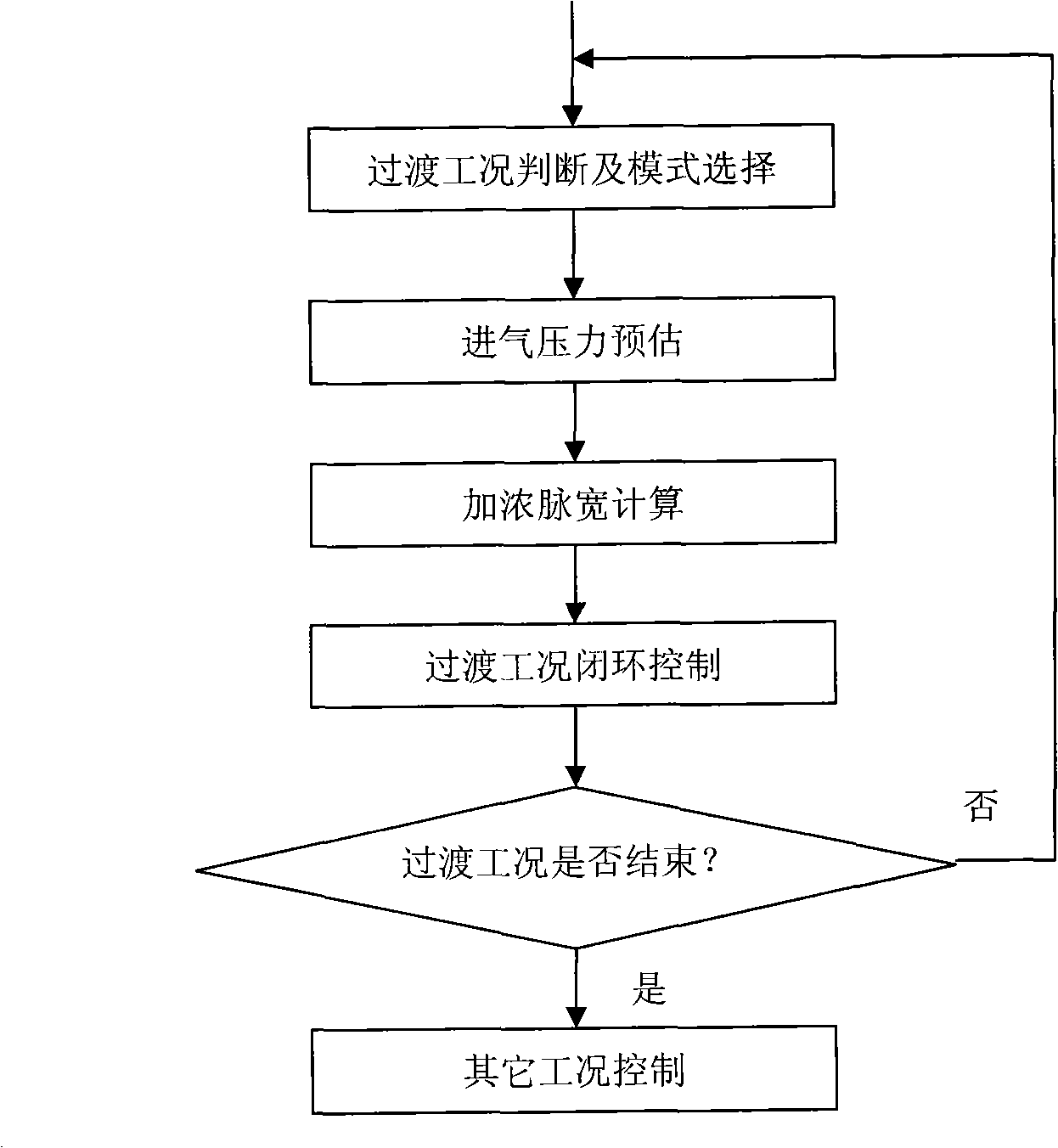

[0037] figure 2 It is a flow chart of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com