Service life evaluation method for bus electrolytic capacitor of motor driver

A technology of motor drivers and electrolytic capacitors, which is applied in the direction of instruments, measuring electronics, scientific instruments, etc., can solve the problems that cannot be used as engineering verification means, the accuracy of calculation results is poor, and the calculation results have large differences, so as to achieve accurate and effective evaluation results and calculation errors. Small, consider the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to specifically illustrate the technical solutions, technical effects and features of the present invention, the following will describe the present invention more clearly and in detail with specific examples in conjunction with the accompanying drawings of the embodiments of the present invention.

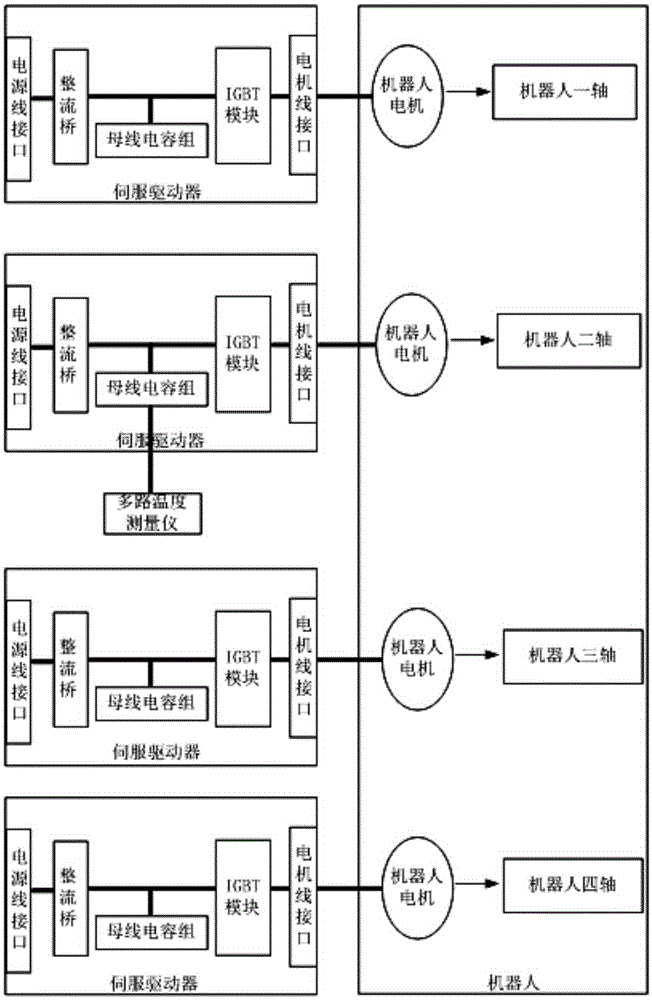

[0027] Embodiment: The test object is a servo driver in a 180Kg 4-axis robot system.

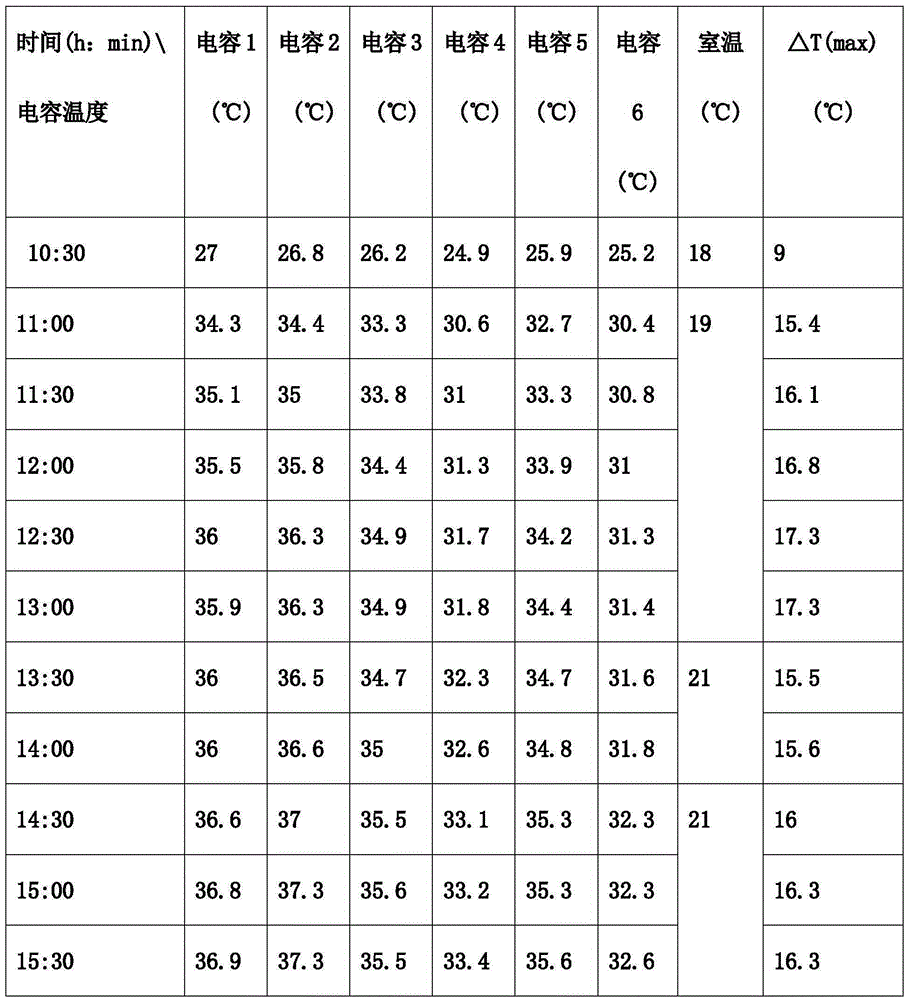

[0028] When the robot body simulates the actual working conditions, the 2-axis 7.5Kw servo driver drives the motor to perform fast forward and reverse motion at a speed of 3500rpm. Compared with other axes, the load inertia of the 2-axis is the largest, and the frequency of the forward and reverse rotation of the motor is the highest. The stroke is the longest, so the DC bus voltage fluctuation of the 2-axis servo driver is the largest, the ripple current of the bus electrolytic capacitor is the largest, and the life of the 2-axis servo driver is the shortest. Therefore, this spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com