Movable suction box

A technology of box body and annular suction nozzle, which is applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., which can solve the problems of failure to meet the normal use of equipment, fatigue aging of telescopic hoses, cracking and leakage, etc. , to achieve the effect of thorough dust collection, simple structure and small ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

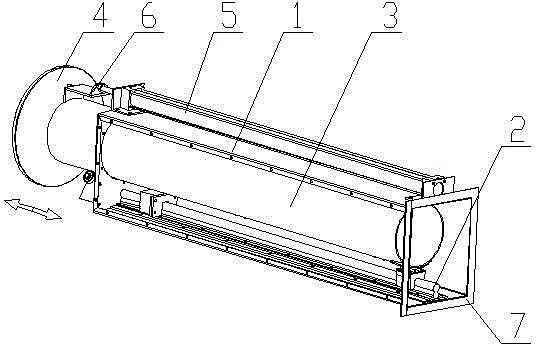

[0037] see figure 1 , figure 2 , a movable suction box of the present invention, which includes a box body 1, the front end of the box body 1 is sealed, and the rear end is provided with a connection port 7, and a linear guide rail 2 is provided along the horizontal direction in the box body 1, and the linear guide rail 2 is provided with a sliding air duct 3, the front end of the sliding air duct 3 extends out of the box body 1 and the end is provided with an annular suction nozzle 4, the top of the box body 1 is provided with a cylinder 5, and one end of the cylinder 5 is connected to the box body 1 is fixedly connected, and the other end of the cylinder 1 is fixedly connected with the sliding air duct 3 or the annular suction nozzle 4 through the connecting piece 6.

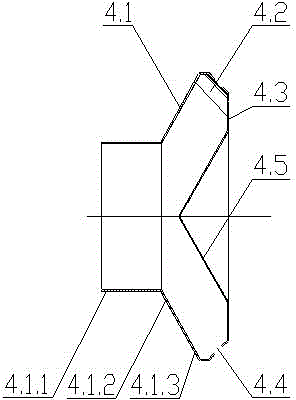

[0038] The annular suction nozzle 4 includes a support cylinder 4.1 and a front plate 4.3, the front plate 4.3 is fixedly arranged on the front side of the support cylinder 4.1, and an annular slit suction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com