Insulating fluororubber material for sealing lithium battery and preparation method thereof

An insulating material and fluororubber technology, which is applied in the field of insulating fluororubber materials for sealing lithium batteries and their preparation fields, can solve the problem that the requirements of electrolyte resistance cannot be met, the silicone rubber has poor dielectric resistance, and the volume resistance cannot meet the requirements of lithium battery seals. and other problems, to achieve the effect of excellent electrolyte resistance, high insulation performance and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the insulating fluororubber material used for lithium battery sealing comprises:

[0030] (1) Put the fluororubber into the internal mixer for mastication, and then add reinforcing fillers, vulcanization aids, and some processing aids in turn for mixing; after degluing at no higher than 120 ° C, make triangular bags and turn over on the open mixer The rubber is re-mixed, parked for 20-30 hours, and the mixed rubber is obtained;

[0031] (2) Put the mixed rubber into the internal mixer again, add the remaining vulcanizing agent and processing aids for mixing; after the rubber is not higher than 90°C, make triangular bags and turn the rubber on the open mixer for additional mixing. Refining is to keep turning the mixed rubber on the open mill and the rubber turning machine to make the rubber mix more evenly.

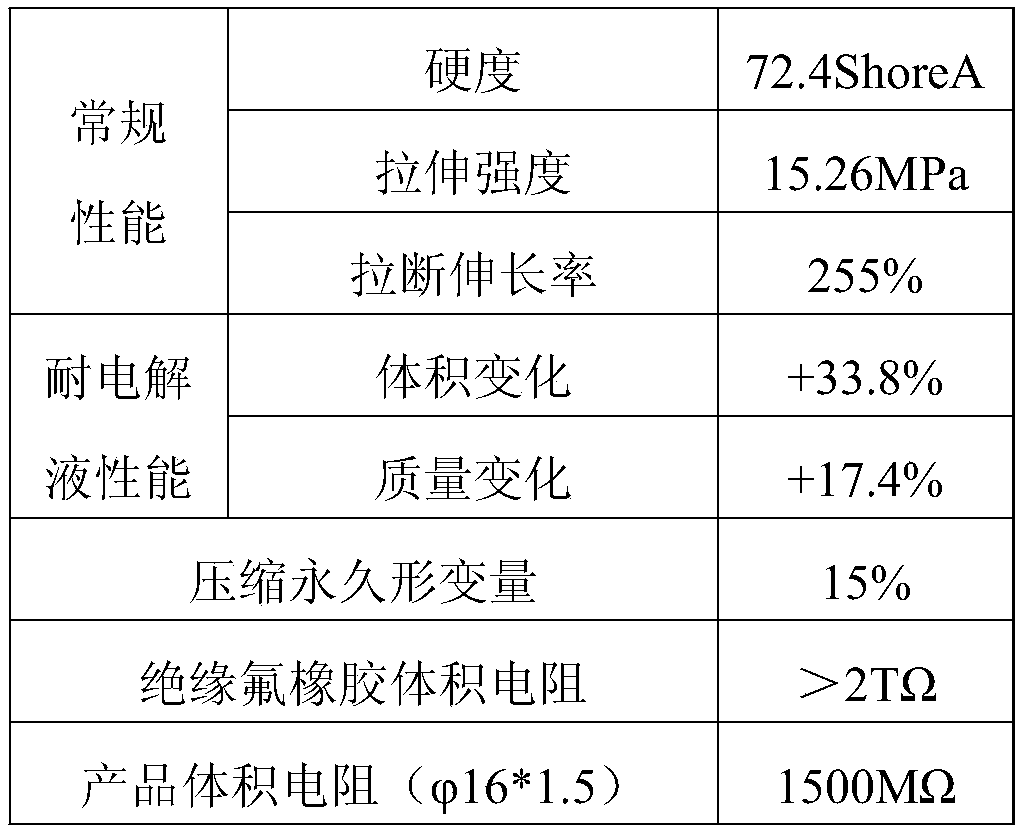

Embodiment 1

[0033] The insulating fluororubber material used for lithium battery sealing of the present embodiment includes the following components by mass: 100 parts of fluororubber, 4.5 parts of insulating filler barium sulfate, 22.5 parts of reinforcing filler carbon black, processing aids fatty acid derivatives and silicone 2.5 parts of the condensation product, 1 part of palm wax as a processing aid, 1.5 parts of peroxide curing agent 2,5-dimethyl-2,5-bis(tert-butyl peroxy)hexane, 0.3 parts of dicumyl peroxide and 2.7 parts of triallyl isocyanurate as a vulcanization aid.

[0034] The preparation method of the insulating fluororubber material used for lithium battery sealing of the present embodiment comprises the following steps:

[0035] (1) Put the fluororubber into the internal mixer for mastication to 60°C, then add reinforcing filler carbon black, banbury for 120 seconds, add insulating filler barium sulfate and vulcanization aid triallyl isocyanurate, dense After refining for ...

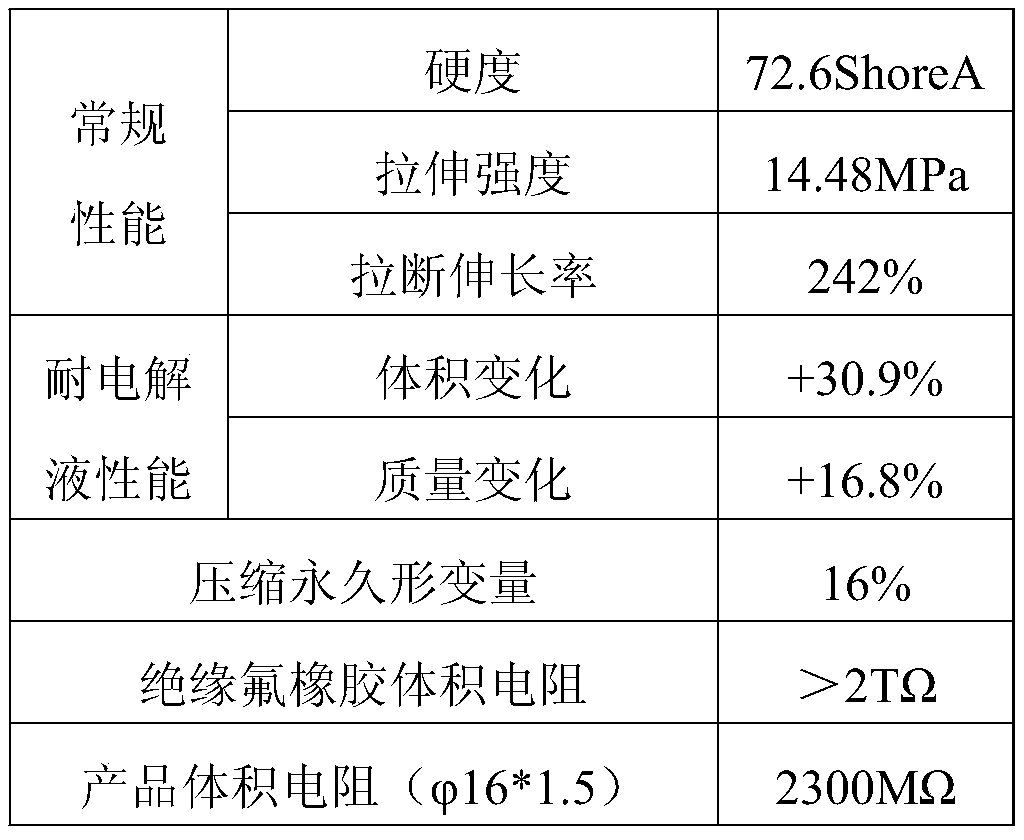

Embodiment 2

[0041] The insulating fluororubber material used for lithium battery sealing in this embodiment includes the following components in parts by mass: 100 parts of fluororubber, 8.7 parts of insulating filler white carbon black, 20.3 parts of reinforcing filler carbon black, and 1 part of processing aid stearic acid 1.6 parts of condensation products of fatty acid derivatives and silicone processing aids, 0.5 parts of palm wax as processing aids, 2,5-dimethyl-2,5-bis(tert-butyl peroxy) peroxide vulcanizing agent 1.4 parts of hexane, 2 parts of triallyl isocyanurate and 0.3 parts of N,N'-m-phenylene bismaleimide as vulcanization aid.

[0042] The preparation method of the insulating fluororubber material used for lithium battery sealing of the present embodiment comprises the following steps:

[0043] (1) Put the fluororubber into the internal mixer for mastication to 50°C, then add reinforcing filler carbon black and vulcanization aid triallyl isocyanurate, banbury to 75°C, add i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com