Method for evaluating electrolyte resistance of aluminum-plastic composite film

A technology of aluminum-plastic composite film and evaluation method, which is applied in the field of evaluation of electrolyte resistance of aluminum-plastic composite film, can solve the problems of inability to determine sealing and insulation properties, decline in battery performance, thinning of corrosion-resistant layer, etc. The effect of good electrolyte performance, real test results and good encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for evaluating the electrolyte resistance performance of an aluminum-plastic composite film, the steps comprising:

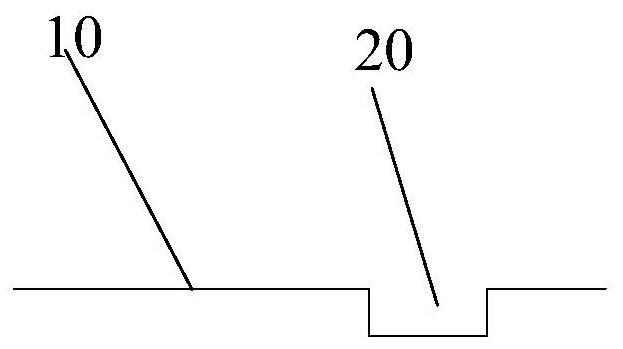

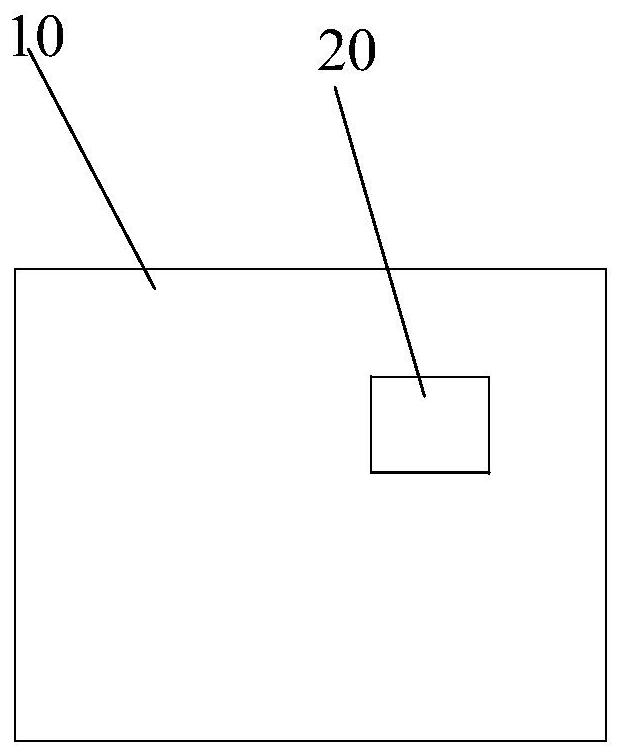

[0038] (1) Provide a 120×150mm aluminum-plastic composite film from Company A as sample 1. The thickness of the aluminum-plastic composite film is 113 μm, and a certain position of the aluminum-plastic composite film is drawn deep by a drawing machine (also called a punching machine) Form the accommodation space, put the drawn aluminum-plastic composite film into the trimming mold, and use the trimming machine to remove the excess aluminum-plastic composite film outside the trimming mold;

[0039] (2) Fold the undrawn aluminum-plastic composite film area toward the accommodation space to form a bag;

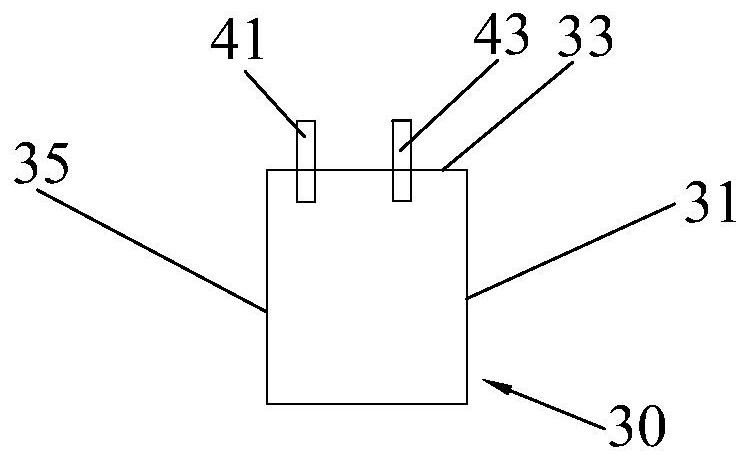

[0040] (3) Use a heat sealing machine to seal the first side of the bag body, use the tab glue to position the positive and negative tabs on the top side of the bag body, use a heat sealing machine to seal the top side, and select the positive tab ...

Embodiment 2-4

[0044] Embodiment 2-4 is basically the same as Embodiment 1, the difference is:

[0045] Examples 2-4 respectively use aluminum-plastic composite films from different companies as samples 2-4, and use the same method as in Example 1 to prepare corresponding test products 2-4, and the rest are the same as in Example 1, and will not be described here .

[0046] Using the edge resistance test of test products 1-4 in the evaluation method of the aluminum-plastic composite film resistance to electrolyte of the present application, the specific results are shown in Table 1.

[0047] At the same time, samples 1-4 in Examples 1-4 were tested for electrolyte resistance by immersion, the conditions were 150 ppm free acid, baked at 85 degrees, and the specific results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com