High-temperature-resistant tab film and preparation method thereof

A technology of ear glue and high temperature resistance, which is applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problems of high equipment requirements and the diversification of color of ear glue for customers, and achieve the goal of preparation Simple method, excellent electrolyte resistance, and the effect of improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method for the above-mentioned high-temperature-resistant ear glue, comprising the following steps:

[0045] S1. Preparation of MPP membrane

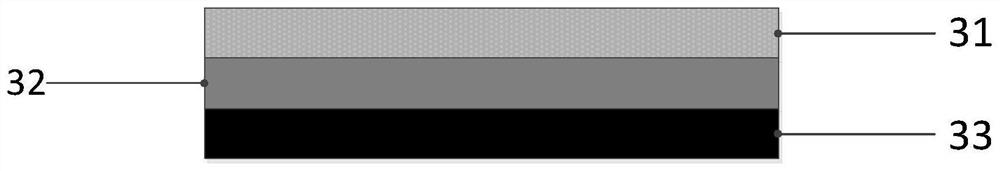

[0046] The raw materials are added into the hoppers of the extruder in the order of modified PP layer, homopolymerized PP layer and copolymerized PP layer by casting process, extruded and formed, and the outer side of the copolymerized PP layer is subjected to corona treatment to obtain MPP film , prepare 2 parts of MPP membrane for use;

[0047] Among them, the parameters of the casting process are: the melting temperature is 200-260° C., the cooling temperature is 10-40° C., and the traction ratio is (1-2):1.

[0048] Here, the blown film process can also be used instead of the tape casting process to prepare the MPP film. The parameters of the blown film process are: the melting temperature is 200-260°C, the cooling temperature is 10-40°C, and the inflation ratio is (1-3): 1....

Embodiment 1

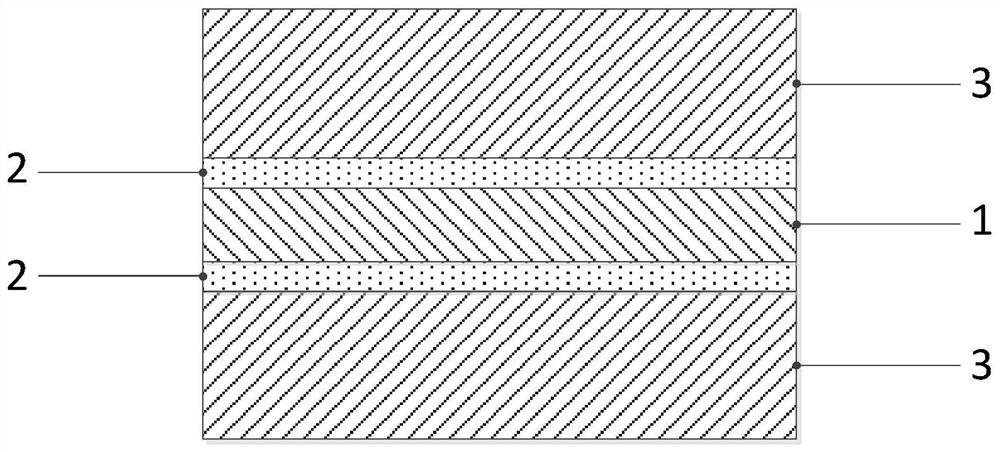

[0053] A kind of high temperature resistant ear glue, comprising PET layer, the glue layer that is arranged on both sides of PET layer, and the MPP layer that is arranged on the outside of glue layer, total thickness is 100um; Wherein, described PET layer, glue layer and MPP layer The thicknesses are 10um, 2um, and 43um respectively; the MPP layer is a three-layer structure, which is a modified PP layer, a homopolymerized PP layer and a corona-treated copolymerized PP layer from the outside to the inside, and the thickness ratio is 1:2: 1.

Embodiment 2

[0055] Compared with Example 1, the only difference is that the thicknesses of the PET layer, glue layer and MPP layer are 20um, 3.5um, and 36.5um respectively; the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com