Polymer retanning fatliquoring agent and preparation method thereof, polymer retanning fatliquoring agent emulsion, and preparation method and application for polymer retanning fatliquoring agent emulsion

A technology of retanning fatliquor and polymer, which is applied in the fields of polymer retanning fatliquor and its preparation, polymer retanning fatliquor emulsion and its preparation, and can solve the problem of poor acid and dielectric resistance, dimethylol Propionic acid is expensive and other problems, to achieve good resistance to oil extraction, excellent fatliquoring effect, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

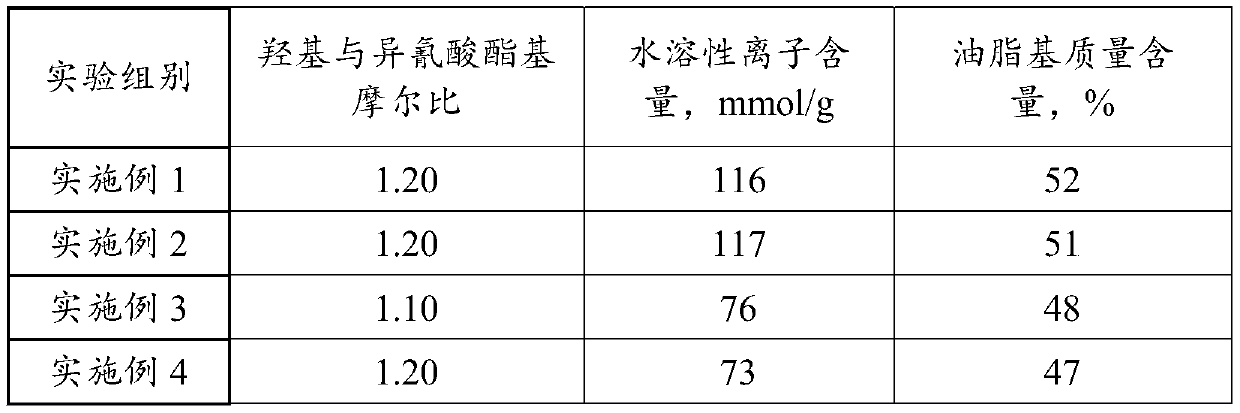

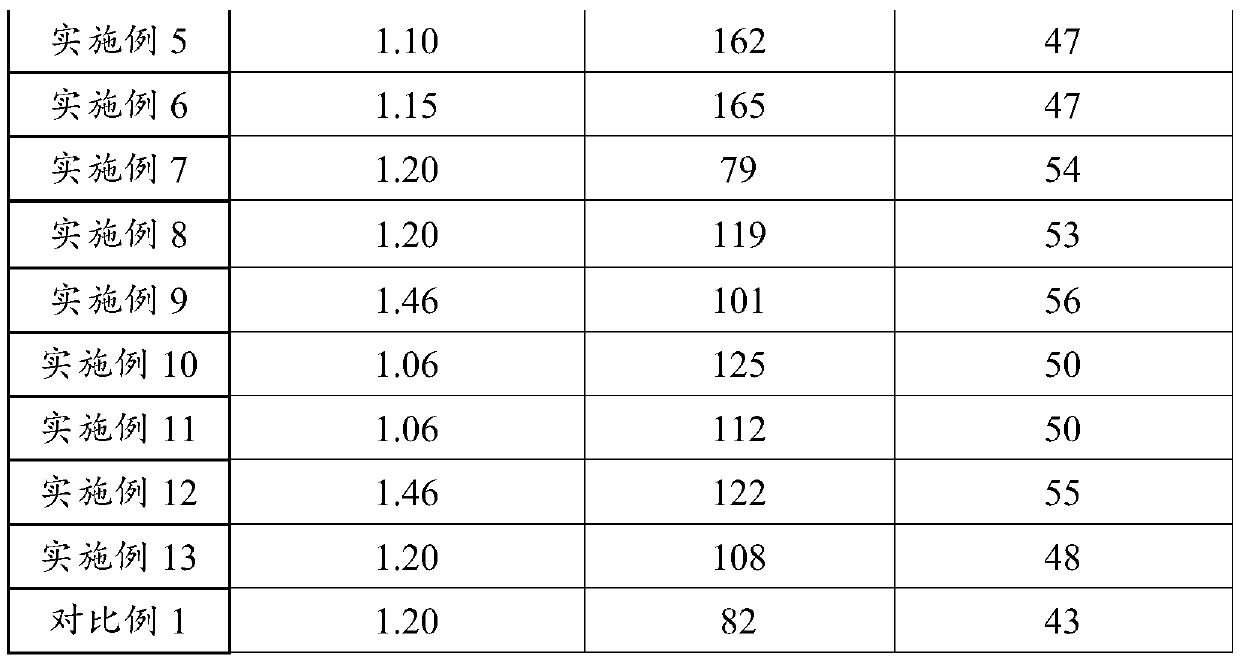

Examples

preparation example Construction

[0052] According to a first aspect of the present invention, a kind of preparation method of polymer retanning and fatliquoring agent is provided, comprising the following steps:

[0053] (a) providing an amphiphilic chain extender containing a sulfonic acid group and a hydroxyl group and having a long-chain alkane structure;

[0054] (b) reacting an amphiphilic chain extender, an isocyanate and optionally a hydroxyl compound to obtain a polymeric retanning fatliquor.

[0055] Specifically, the sulfonic acid group on the amphiphilic chain extender can be introduced into the polymer retanning fatliquoring agent as a hydrophilic group. It has good extractability and washability, and at the same time ensures that the polymer retanning and fatliquoring agent has excellent acid resistance and electrolyte resistance.

[0056] In the present invention, the long-chain alkane structure refers to a saturated or unsaturated carbon-alkane structure. The long-chain alkane structure of th...

Embodiment approach

[0063] As an optional embodiment of the present invention, in step (a), the preparation method of the amphiphilic chain extender comprises the following steps:

[0064] React the modified oil and alcohol amine compound under the action of a catalyst to obtain an amphiphilic chain extender;

[0065] Wherein, the modified oil includes any one or a combination of at least two of sulfonated vegetable oil, sulfonated vegetable oil fatty acid ester or sulfated castor oil.

[0066] To ensure that the amphiphilic chain extender contains a specific hydrophilic group sulfonic acid group and a lipophilic long-chain alkane structure, it is necessary to use specific reaction materials.

[0067] Sulfonated vegetable oil, sulfonated vegetable oil fatty acid ester or sulfated castor oil can be used as modified oil to introduce sulfonic acid groups to the amphiphilic chain extender.

[0068] In the preparation method of the amphiphilic chain extender, the amphiphilic chain extender not only h...

Embodiment 1

[0114] The present embodiment provides a kind of preparation method of polymer retanning and fatliquor, comprising the following steps:

[0115] (1) Put 1000g of sulfonated vegetable oil with a mass content of 75% into a 2000mL three-necked flask, then add 150g of diethanolamine, gradually raise the temperature to 90-100°C, keep it open for about 1 hour to remove water, and vacuumize for 30 minutes until the residual water is reduced to Below 0.1% (Karl Fischer method), gradually warm up to 135°C, add 5g of sodium methoxide catalyst, after 3 hours of heat preservation reaction, take a sample every 1h to detect the amine value, when the amine value is stable, cool down to end the reaction, cool down, and get Amphiphilic chain extender with sulfonic acid group and hydroxyl group and long-chain alkane structure;

[0116] (2) Add 50 g of monoglyceride oleate to 100 g of the amphiphilic chain extender, stir and heat up to 41° C. to obtain mixture A;

[0117] (3) Add 55 g of toluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com