Molding equipment for controlling cross-section deformation of glass guide groove of automobile

A forming equipment and automobile glass technology, applied in the field of stamping sheet metal, can solve the problems of unfavorable installation of glass sealing strips, affecting the sealing effect of the car body, etc., and achieve the effect of reducing deformation and dents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

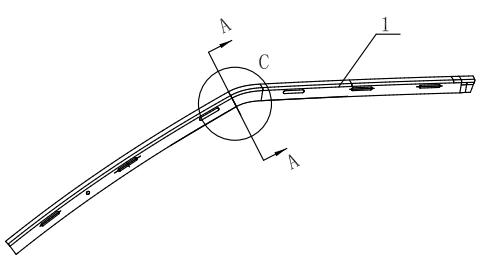

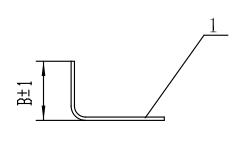

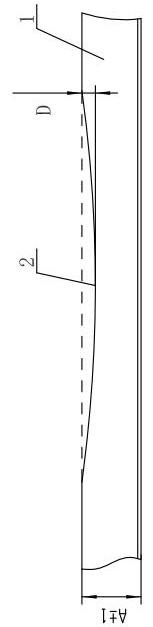

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0015] like Figure 4 , Figure 5 As shown, the forming equipment for controlling the cross-sectional deformation of the automobile glass run channel of the present invention adds a conformal pressing device on the outer peripheral side of the fixed former lower mold 3 and upper mold 4 of the existing mold, and the rotary plate 8 rotating shaft Driven by the rack 10, the central gear 9 can deflect around the axis of the fixed cam; the outer side of the rotary plate 8 is fixed with an oil cylinder 7, and the front end of the piston rod 6 of the oil cylinder 7 is fixed with a movable cam 5, and the movable cam 5 Can slide back and forth on the revolving plate 8.

[0016] During actual work, the first step: manually limit one side of the section of the straight profile in the gap between the lower mold 3 and the upper mold 4 of the fixed fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com