Ultrahigh-pressure large-flow-rate supercharged hydraulically controlled stop valve and application thereof

An ultra-high pressure, globe valve technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve problems such as unfavorable system efficient utilization, lack of hydraulic control ultra-high pressure and large flow globe valve design, large energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

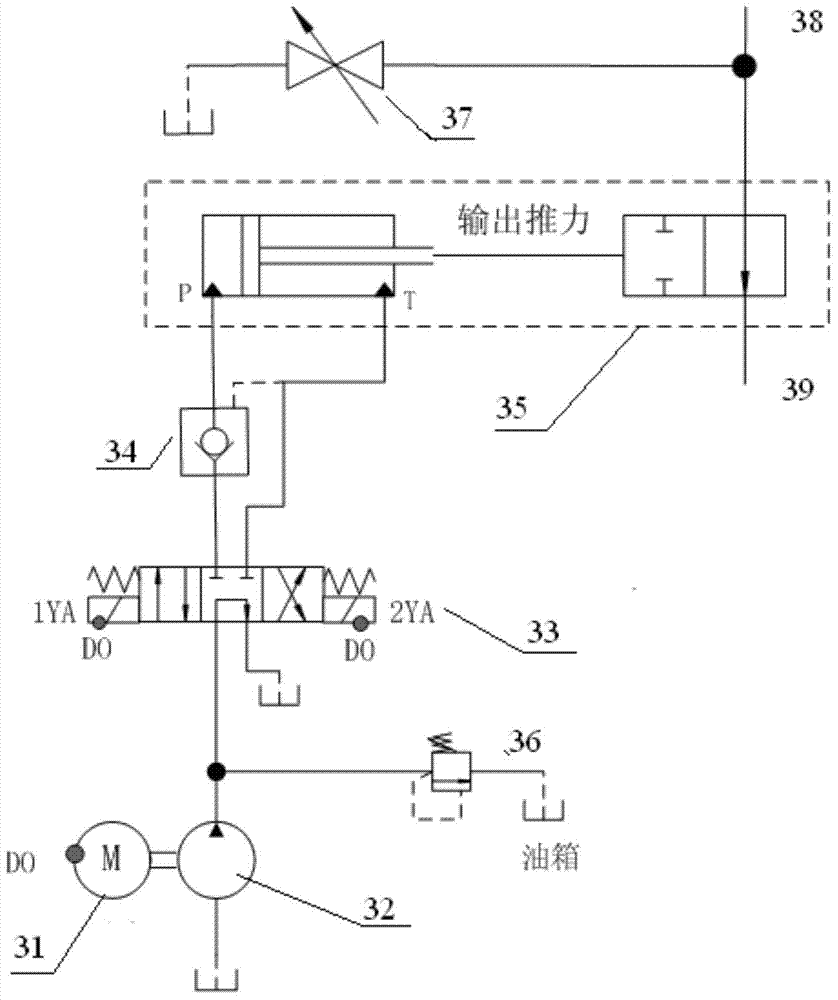

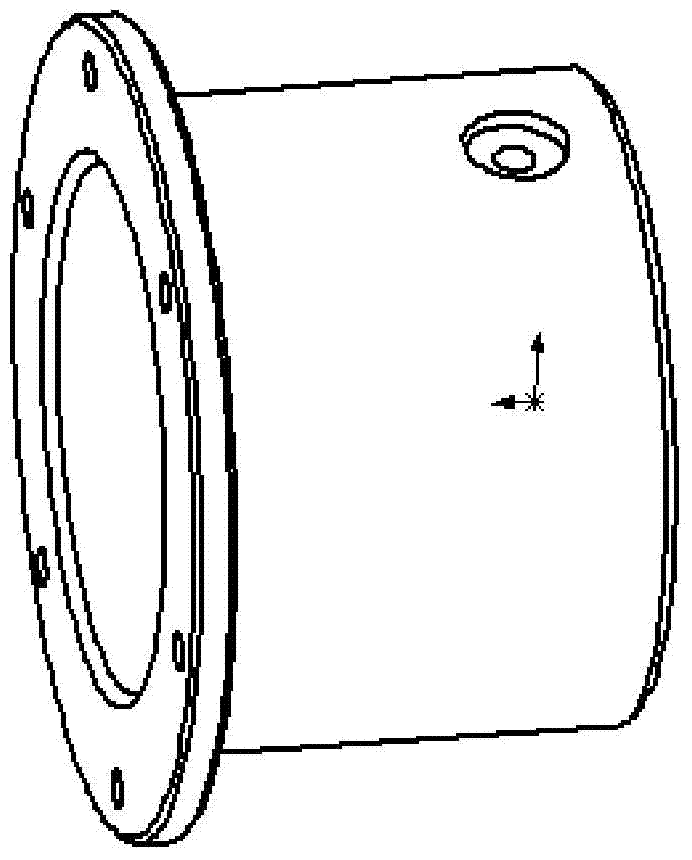

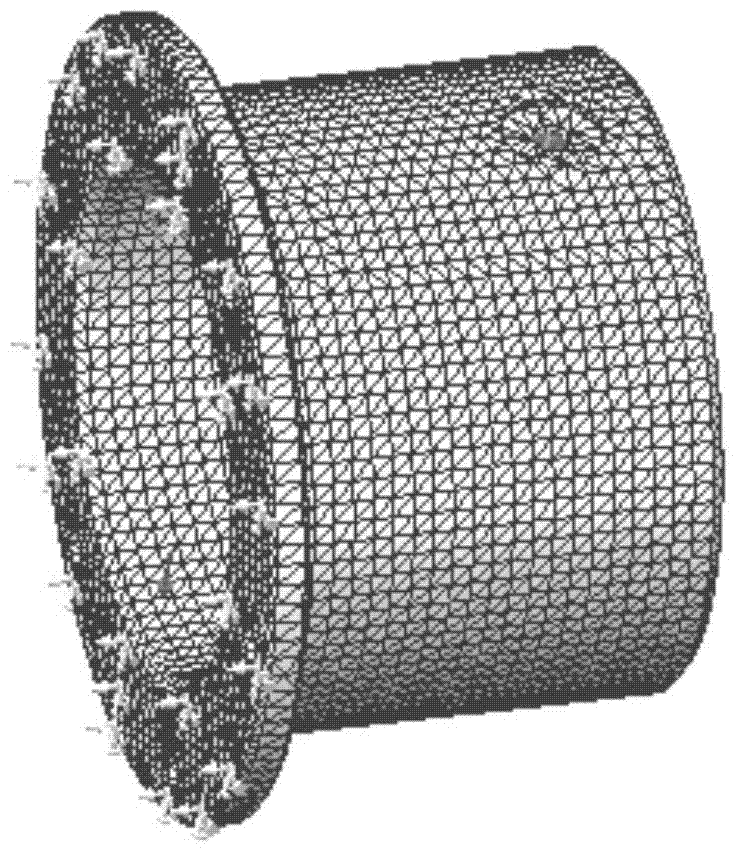

[0048] Such as Figure 1-5 shown.

[0049] An ultrahigh pressure and large flow pressurized hydraulic control shut-off valve, comprising a valve seat 1, a low pressure valve body 2 and an ultrahigh pressure valve body 8, the valve seat 1 is in sealing connection with one end of the low pressure valve body 2, the The other end of the low-pressure valve body 1 is connected to the ultrahigh-pressure valve body 8; a piston 5 is arranged through the valve seat 1 and the low-pressure valve body 2, and the valve seat 1 and the low-pressure valve body 2 are formed by the piston 5 The inner cavity of the valve is divided into I oil chamber and II oil chamber. A piston rod 11 connected to the piston 5 is arranged in the ultra-high pressure valve body 8, and an oil inlet 23 is arranged on the valve seat 1. The low-pressure valve body 2 is provided with an oil return port 24, the front end of the ultra-high pressure valve body 8 is provided with a III oil chamber, and the front portion o...

Embodiment 2

[0061] As described in Example 1, the difference is that the piston rod 11 is quenched and tempered to a hardness of 229-285HB after being processed, and then undergoes high-frequency quenching to reach a hardness of 45HB. ~55HRC; the roundness tolerance value is selected according to the 9th grade precision; the end face verticality tolerance value is selected according to the 7th grade precision; the thread on the piston rod is processed according to the 6th grade precision;

Embodiment 3

[0063] An ultra-high pressure and large flow pressurized hydraulic control shut-off valve as described in Example 1, the difference is that the cross-sectional diameter of the low-pressure valve body is 5 times the cross-sectional diameter of the ultra-high pressure valve body.

[0064] The valve seat, low-pressure valve body, piston and piston rod are all made of No. 45 steel, the heat treatment temperature is 740-760°C, the holding time is 4-6h, and the cooling rate is 50-100°C / h. Temperature ≤ 600 ℃, air cooling out of the oven, hardness ≤ 197HBS before treatment, hardness ≤ 156HBS after treatment.

[0065] The material of the ultra-high pressure valve body is 40Cr alloy steel, quenched and tempered, the quenching temperature is 850°C±10°C, oil-cooled and tempered, and the hardness is between HRC32-36.

[0066] The tolerance value of the verticality between the end surface of the valve seat and the axis is selected according to the 7th grade precision; the surface roughness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com