Reassembled double-row full-complement tapered roller bearing

A tapered roller and roller bearing technology, applied in the direction of bearings, bearing assembly, bearing components, etc., can solve the problems of no hardness transition zone, increased heat treatment cost, and sudden hardness change, and achieves good lubrication effect, compact structure and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

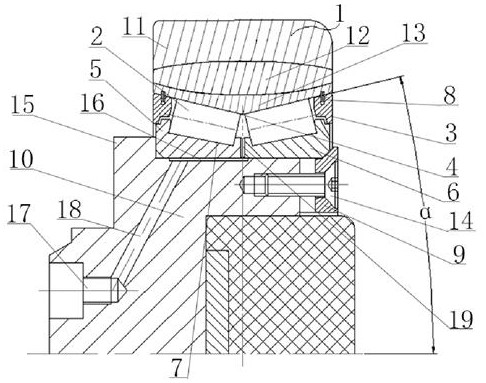

[0037] Refer to attached figure 1 , a heavy-duty double-row full complement tapered roller bearing, which includes an outer ring 1, two inner rings, tapered rollers 2, and a metal sealing retaining ring 3, and the inner side of the outer ring 1 is designed with an annular convex cone 4. The two inner rings are the left inner ring 5 and the right inner ring 6 respectively. The outer sides of the left inner ring 5 and the right inner ring 6 are respectively designed with an inwardly inclined annular raceway 7. The left inner ring 5 and the right inner ring The ring 6 is designed on the inner side of the outer ring 1 at the same time, and the outer ring 1, the left inner ring 5 and the right inner ring 6 are respectively filled with tapered rollers 2, forming two sets of full-filled tapered rollers 2 that are symmetrical to each other. Between the outer ring 1 and the left inner ring 5 and the right inner ring 6, there are metal sealing retaining rings 3 installed respectively; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com