Online measuring method of self clean glass contact angle

A technology of contact angle and glass, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of the influence of the accuracy of the measurement results, the absence of mathematical models, and the large range of relative errors, so as to improve the recognition ability and save energy. Time, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: On-line measurement for on-line production of self-cleaning glass:

[0043]The following is the test result of the same batch of production samples measured by the present invention and other existing methods:

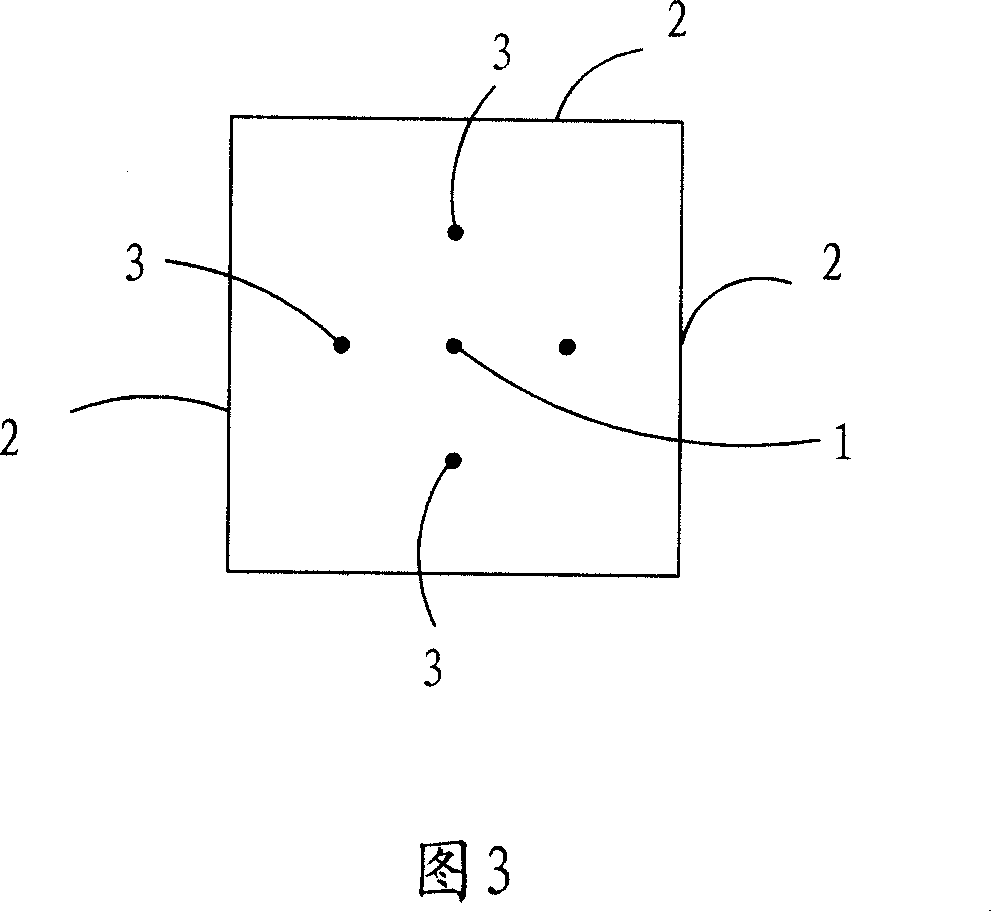

[0044] Three groups of 100mm×100mm samples were taken from the same original float glass sheet in the production line, and the number of each group was the same, for comparative experiments.

[0045] 1) the first group, adopt the method test of the present invention;

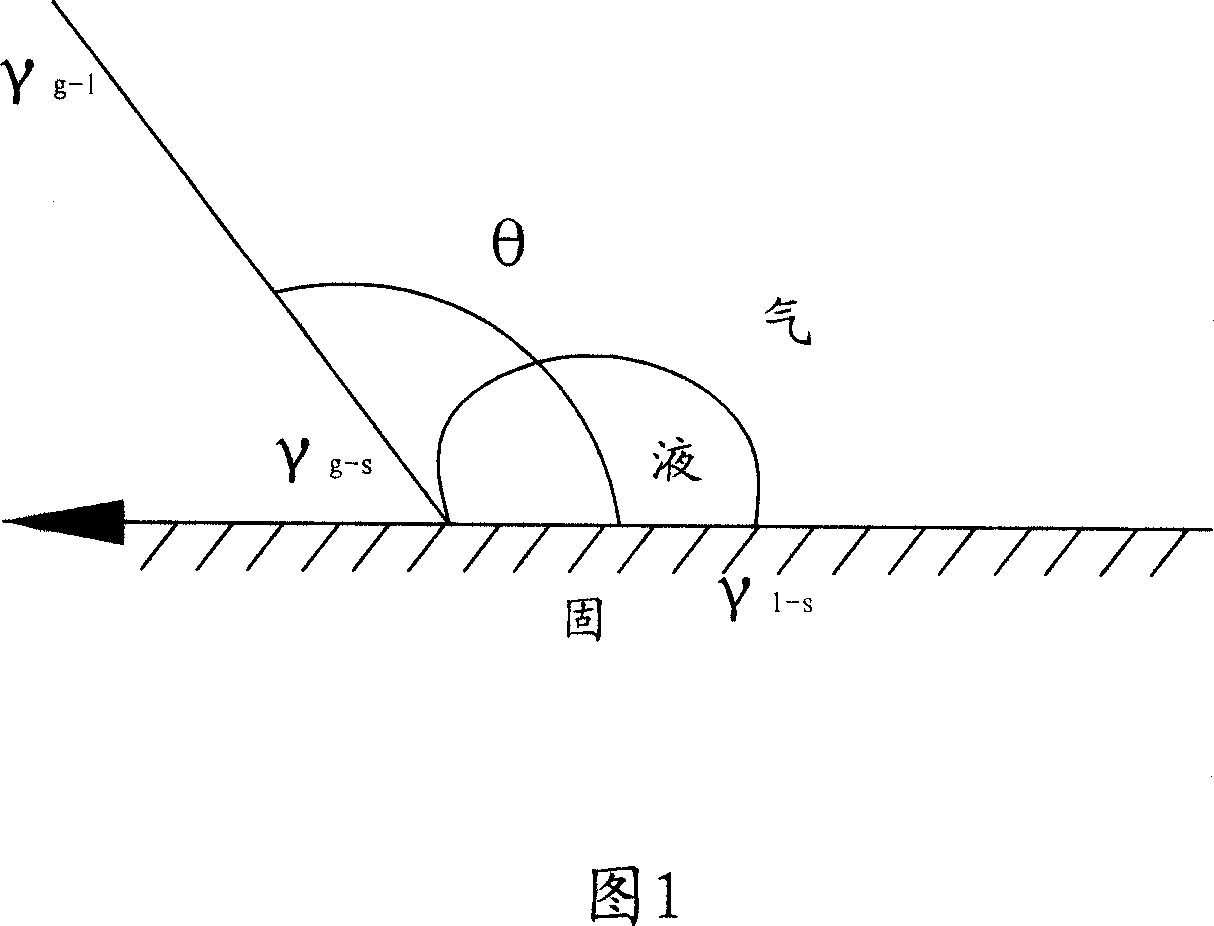

[0046] The relative humidity in the test room is 50%±5%, the humidity variation range is ±2%, and the temperature is 23±1°C. The test method adopts the pendant drop method, and the calculation method adopts the θ / 2 method. This group uses the SL series contact angle tester to measure. The analysis system of the SL series contact angle tester is the CAST software system. The software system is installed in the computer, and then the contact angle tester is connected to the computer....

Embodiment 2

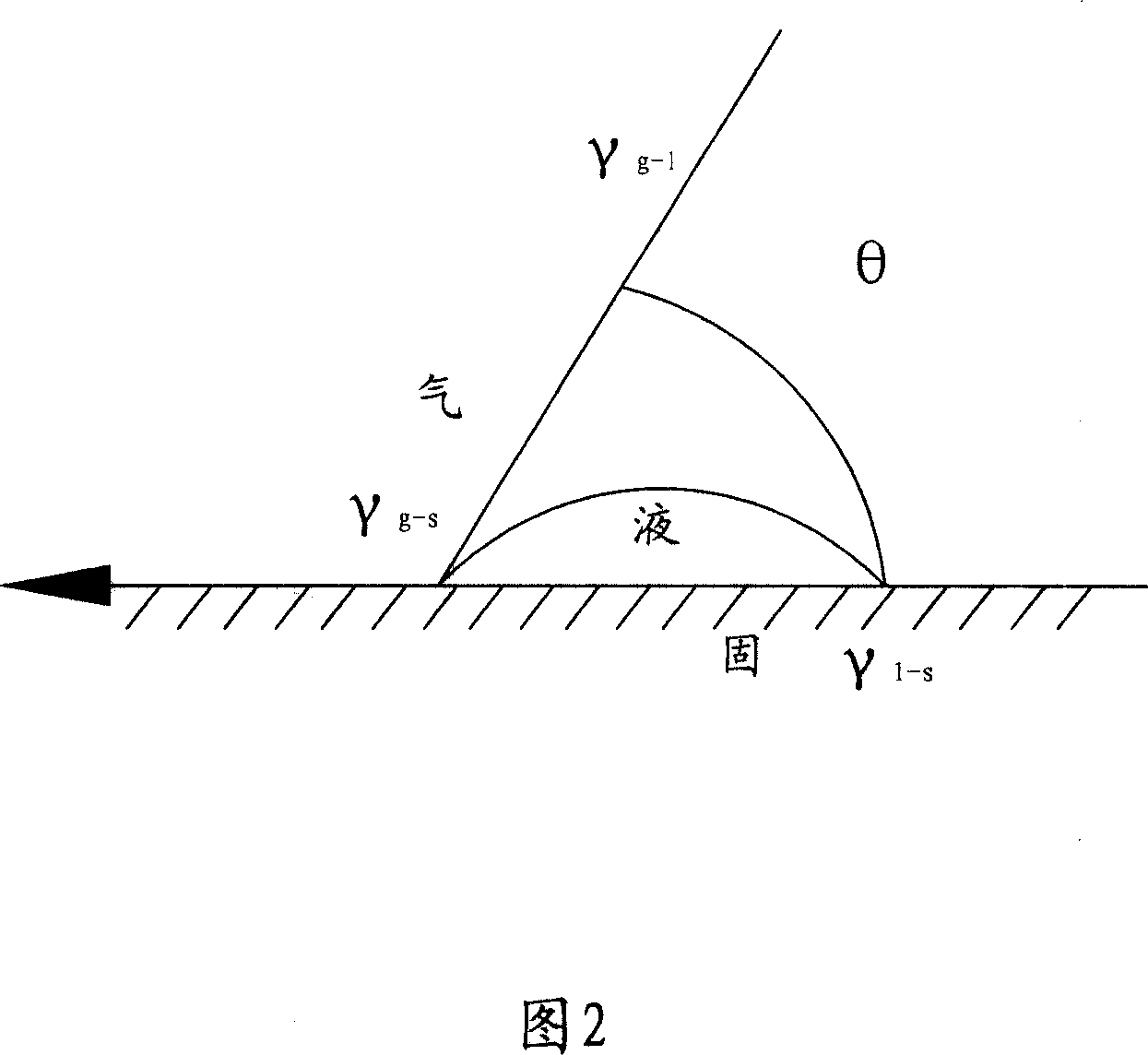

[0067] Embodiment 2: The method of the present invention is used to test the contact angle of super-hydrophilic self-cleaning glass.

[0068] The contact angle of super-hydrophilic self-cleaning glass is very small, also called hydrophilic angle, generally less than or equal to 3°. When the contact angle measured by the general contact angle tester is less than or equal to 3°, it is difficult to use the general test method. Accurate measurement; and the measuring result of the measuring method of the present invention is also more accurate to this situation, and error is below 1 °. The following is the application of the present invention in testing the hydrophilic angle of superhydrophilic self-cleaning glass:

[0069] In the test of the hydrophilic angle of the superhydrophilic film layer, there is no need to make any adjustments in operation, and the measurement results are shown in Table 2, and Table 2 records the two measurement results.

[0070] Preface

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com