Residual energy reclaiming type device for preparing biomass granular activated carbon

A biomass particle and residual energy recovery technology, applied in the field of activated carbon preparation, can solve the problems of poor activated carbon quality, complex production process, low relative density, etc., and achieve high energy utilization efficiency, simple working principle, and high carbon yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

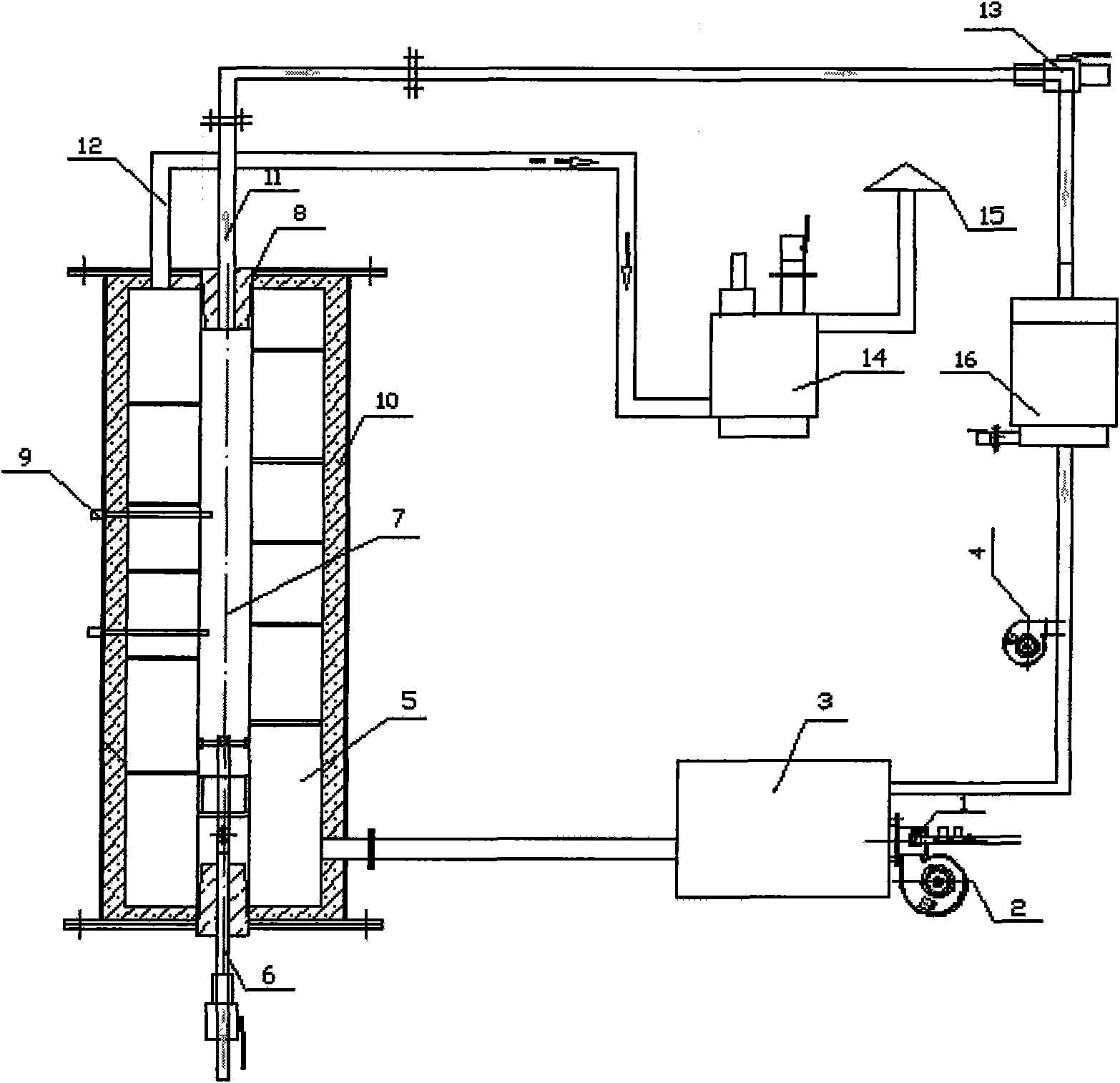

[0011] The main structure of this embodiment includes a gas burner 1, a combustion-supporting fan 2, a hot blast stove 3, a circulating fan 4, a partition heating chamber 5, a connecting rod mechanism at the bottom of the charcoal chamber 6, a charcoal chamber 7, a top end cover 8, and a thermocouple 9. Insulation material 10, carbon chamber gas outlet pipe 11, heating chamber flue gas outlet pipe 12, three-way valve 13, waste heat boiler 14, chimney 15 and tubular condenser 16. The combined structure of the hot blast stove 3 of the device system in this embodiment is provided with a gas burner 1 and a combustion-supporting fan 2, and the other side of the hot blast stove 3 communicates with the partition heating chamber 5, and the center of the partition heating chamber 5 is vertically provided with a carbon material chamber 7. The bottom of the carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com