Method for comprehensively recovering valuable metals from zinc hydrometallurgy high-temperature purification slags

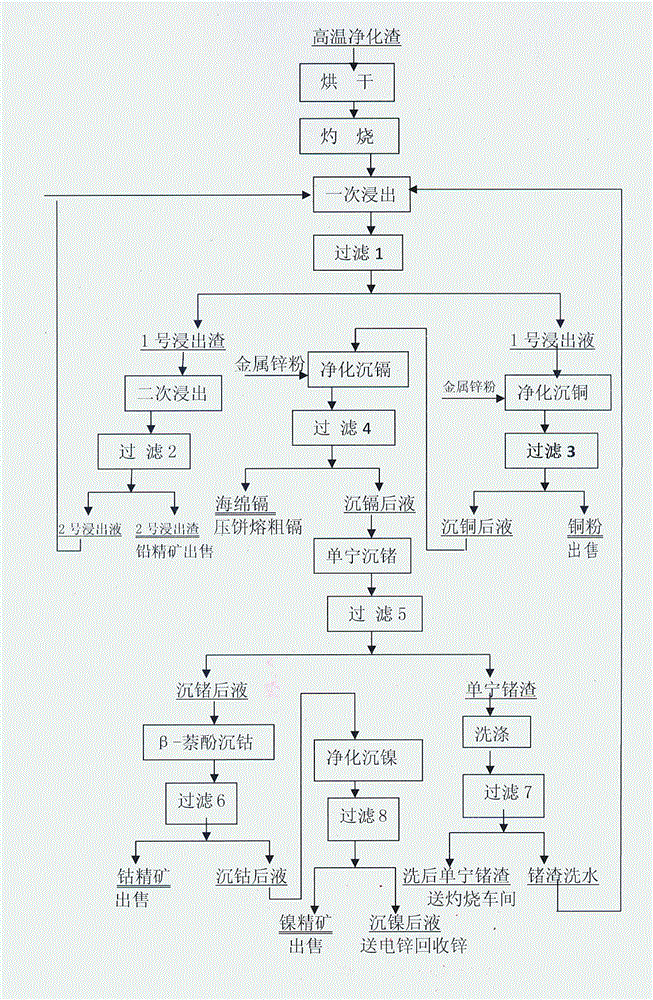

A valuable metal, hydrometallurgical zinc smelting technology, applied in silver, comprehensive recovery of valuable metals, cobalt, nickel, copper, comprehensive recovery of zinc, germanium, cadmium, lead fields, can solve the problem of low comprehensive recovery rate of valuable metals, The industry chain is not long and has not been recycled, so as to achieve the effect of comprehensive recovery of valuable metals, easy operation and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 : Use the high-temperature purified slag of wet-process zinc from Yunnan Luoping Zinc Electric Co., Ltd. as raw material, after drying, 20,000.00 grams of samples are shrunk and divided for use. The ingredients are: zinc 31.15wt%, copper 1.47wt%, cadmium 1.05wt% , cobalt 0.06wt%, nickel 0.04wt%, germanium 0.04wt%, lead 3.41wt%, silver 0.0119wt%.

[0034] (1) Burning of high-temperature purification slag: take 15000.00 grams of high-temperature purification slag after drying, and burn it for 2.5 hours under natural ventilation at 350°C to obtain 32.63wt% zinc, 1.54wt% copper, and 1.10wt% cadmium , cobalt 0.063wt%, nickel 0.042wt%, germanium 0.042wt%, lead 3.56wt%, silver 0.0125wt% high temperature purification slag 14250.00 grams.

[0035] (2) Primary leaching: Use industrial water as the pre-liquid, take 72 liters, add 13000.00 grams of burned high-temperature purification residue for slurry; then use concentrated sulfuric acid to adjust the initial acid 90g...

Embodiment 2

[0049] The high-temperature purified slag from hydrometallurgy of Yunnan Luoping Zinc Electric Co., Ltd. was used as the raw material. After drying, 18,000.00 grams of samples were prepared by shrinking and fractionating. The components were: zinc 39.08wt%, copper 3.49wt%, cadmium 1.98wt%, Cobalt 0.076wt%, nickel 0.088wt%, germanium 0.076wt%, lead 3.96wt%, silver 0.0180wt%.

[0050] (1) Burning of high-temperature purification slag: take 14000.00 grams of high-temperature purification slag after drying, and burn for 3.5 hours under natural ventilation at 450°C to obtain 41.76wt% zinc, 3.74wt% copper, and 2.11wt% cadmium , cobalt 0.081wt%, nickel 0.094wt%, germanium 0.081wt%, lead 4.23wt%, silver 0.0192wt% high temperature purification slag 13020.00 grams.

[0051] (2) Primary leaching: Use industrial water as the pre-liquid, take 66 liters, add 11000.00 grams of burned high-temperature purification slag for slurry; use concentrated sulfuric acid to adjust the initial acid 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com