Patents

Literature

186results about How to "Reasonable recycling" patented technology

Efficacy Topic

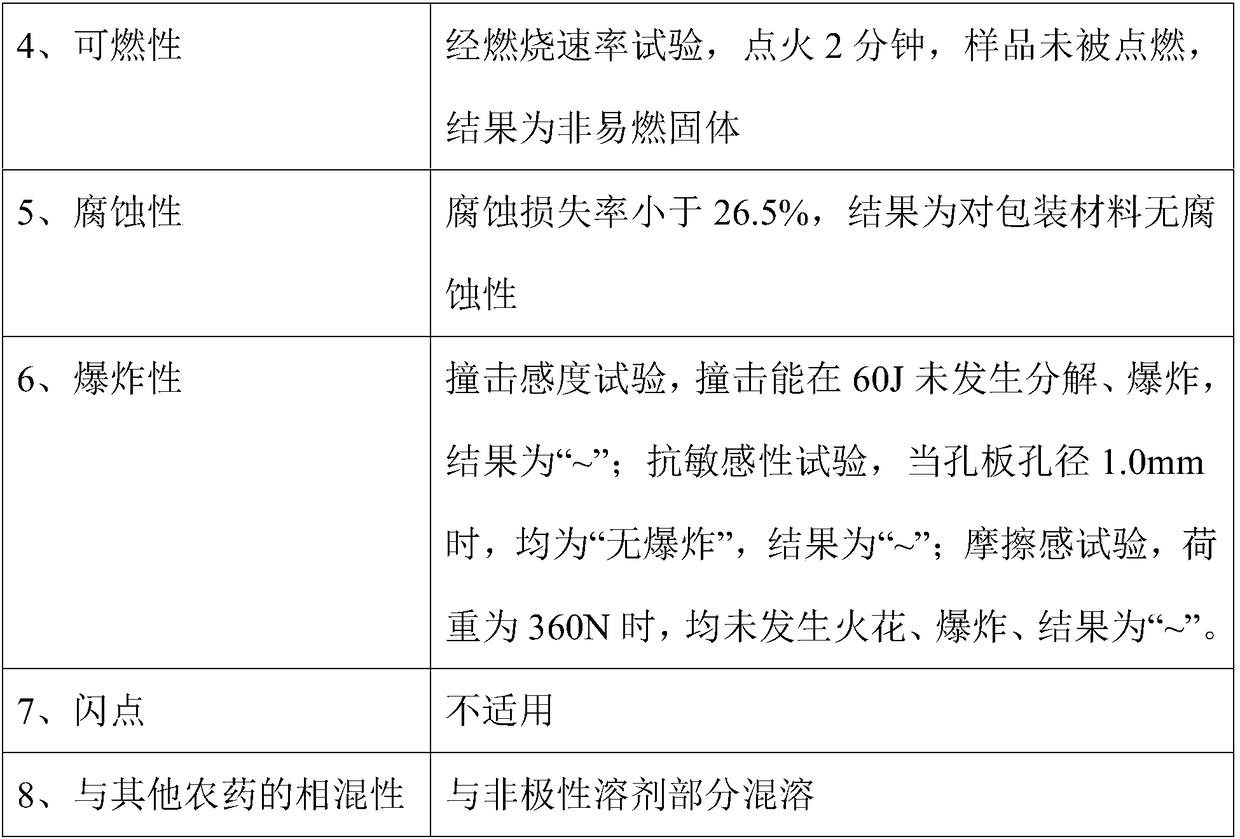

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

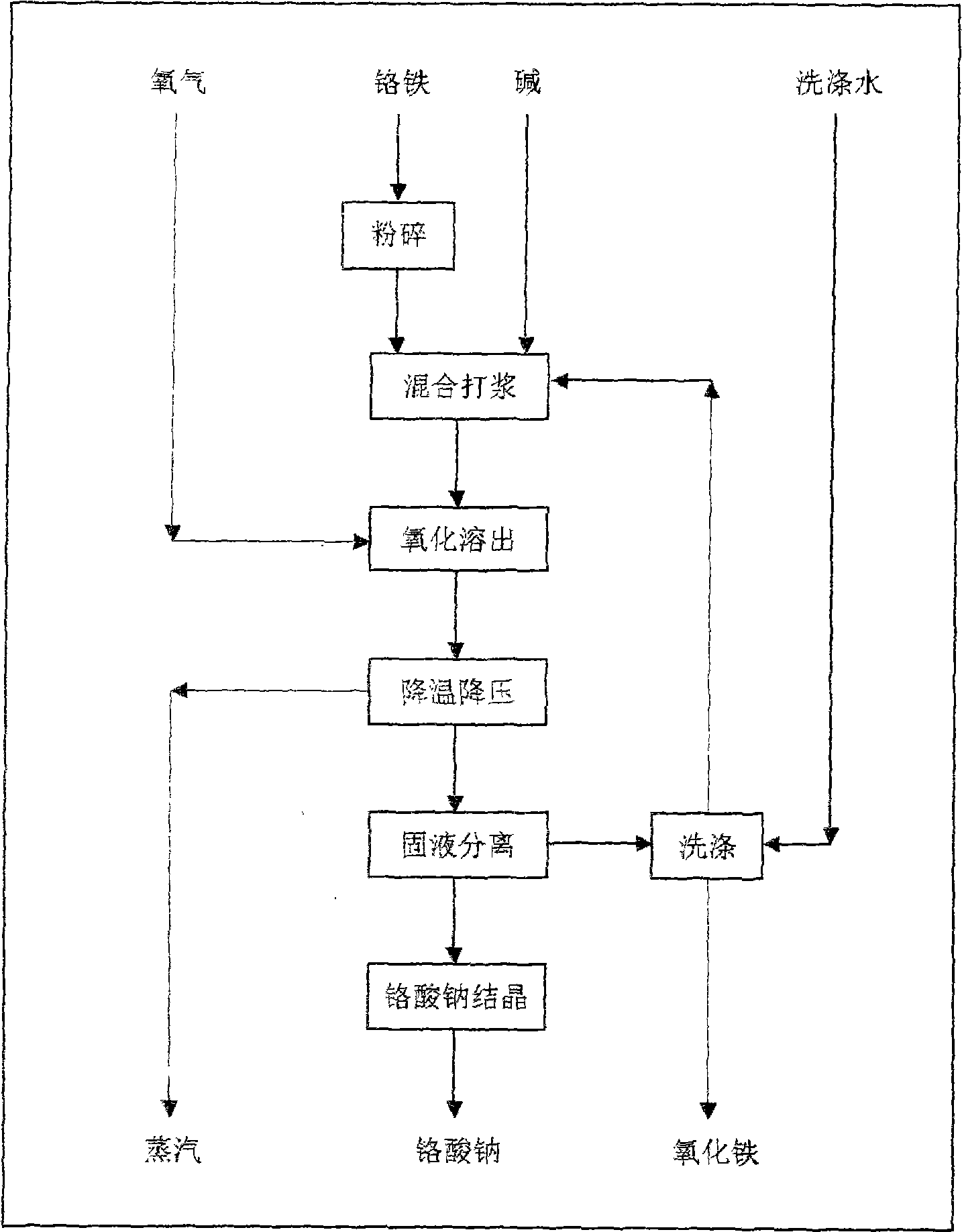

High-efficiency, energy-conservation and clean method for producing chromate

ActiveCN101508466ASolve pollutionAchieving the purpose of cleaner productionChromates/bichromatesWastewaterCleaning methods

The invention provides a method for producing chromate with high efficiency, energy conservation and cleanness. The method uses chromium iron as a raw material, and carries out oxidation dissolution in high-temperature high-pressure aqueous alkali to separate solid and liquid after temperature and pressure reduction so as to obtain a chromate solution, water and ferric oxide or mixture of the water, ferric oxide and chrome oxide. A high-temperature high-pressure reactor is used as the reactor of the method so as to greatly improve equipment efficiency and production efficiency. The method realizes autothermal reaction by system reaction heat to achieve the aim of energy conservation, and is an energy-saving process of chromate production. The method does not need external fuel to supply heating and does not generate waste gas, and the reaction precipitate is the water and the ferric oxide or the mixture of the water, the ferric oxide and the chrome oxide, wherein the water and the ferric oxide or the mixture of the water, the ferric oxide and the chrome oxide can be used for preparing chromium iron paint without generating waste residue; and washing of the precipitate adopts countercurrent washing, and washing water is used for preparing a reaction initial solution without generating waste water. The method does not generate the three wastes, and is a clean process for producing the chromate.

Owner:青海省博鸿化工科技股份有限公司

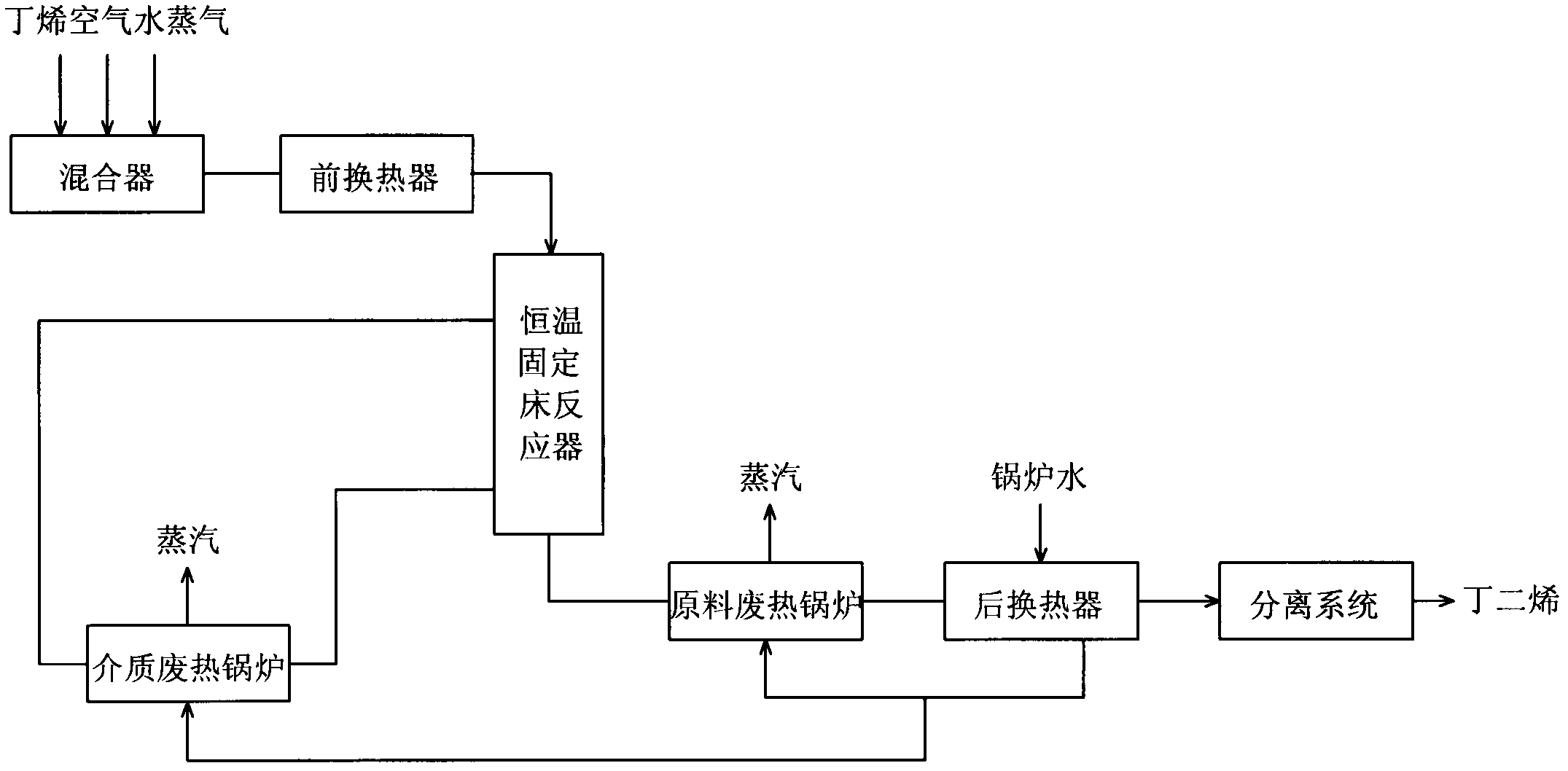

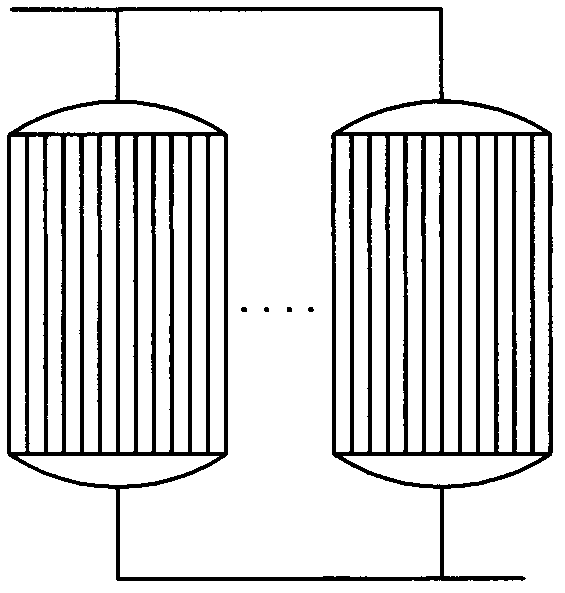

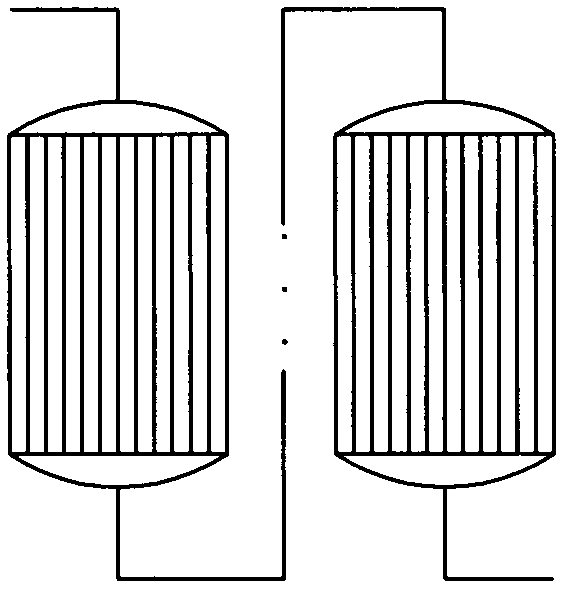

Method for preparing butadiene by oxidization and dehydrogenation of butane using constant-temperature static bed

InactiveCN102442874AHigh selectivityExtended service lifeHydrocarbonsHydrocarbon preparationButeneButadiene Dioxide

The invention provides a method for preparing butadiene by oxidization and dehydrogenation of butane using a constant-temperature static bed, which specifically comprises the steps that: the butane, air and water vapor are added into a static mixer according to proportions; mixed raw materials are heated to a certain temperature by a pre-heat exchanger, and then enter a constant-temperature static bed reactor for oxidization and dehydrogenation, wherein the static bed reactor is filled with catalyst, and the temperature of a catalyst bed layer of the reactor is controlled to be constant; after the mixed raw materials are oxidized and dehydrogenated, reaction products enter a post-heat exchanger for heat exchange through a raw material waste heat boiler, the products after heat exchange enter a separating system for separating the butadiene, so that butadiene product is obtained. In comparison with the prior art, the method for preparing butadiene by oxidization and dehydrogenation of butane using the constant-temperature static bed disclosed by the invention reaches a conversion per pass of the butadiene of 75%-85%, and the selectivity of the butadiene of at least 95%. The method can increase the conversion rate of the butane and the yield of the butadiene, reduce the butane and water consumed by the butadiene, greatly lower energy consumption, and decrease sewage discharge.

Owner:SHANDONG HUAMAO NEW MATERIALS

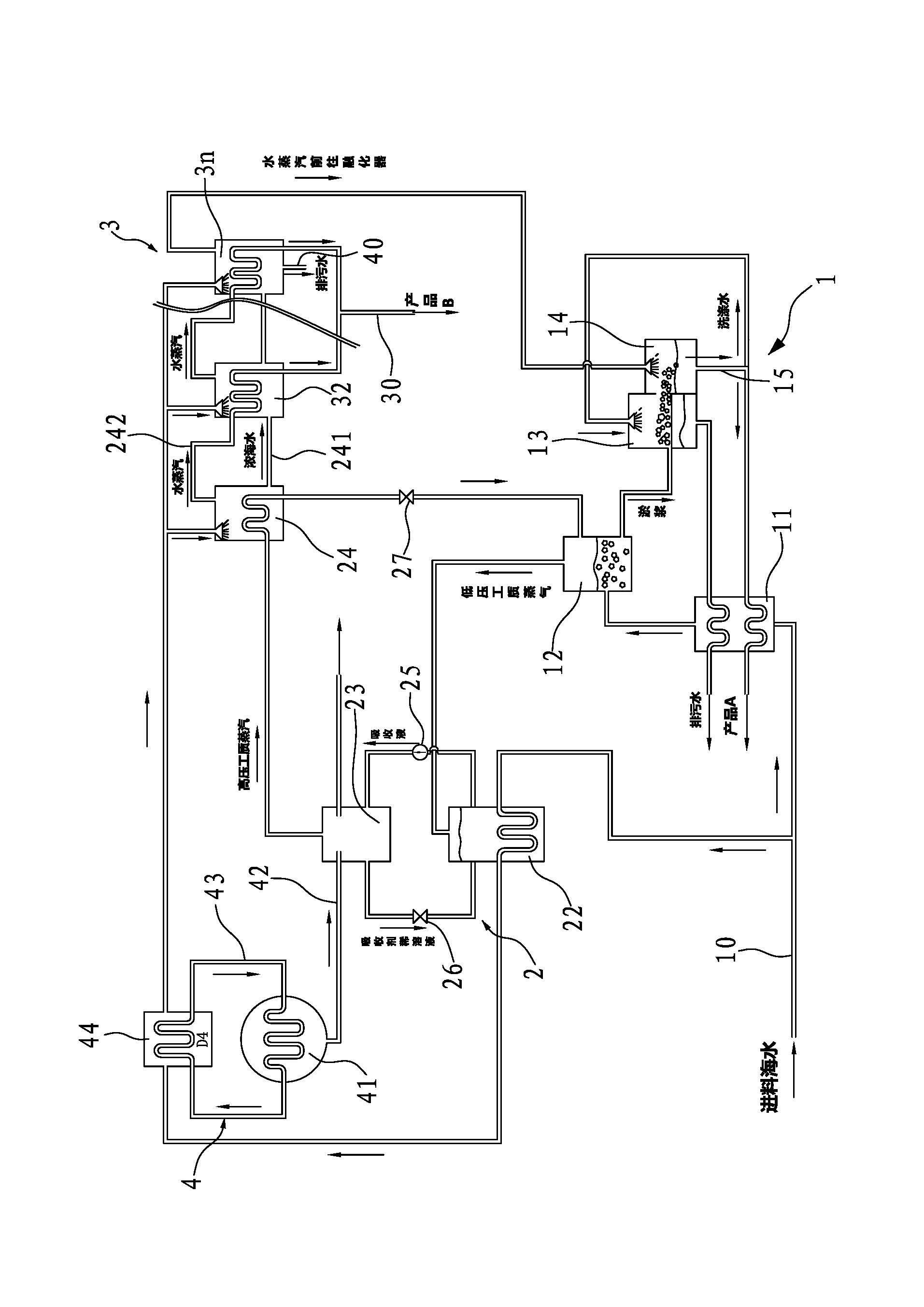

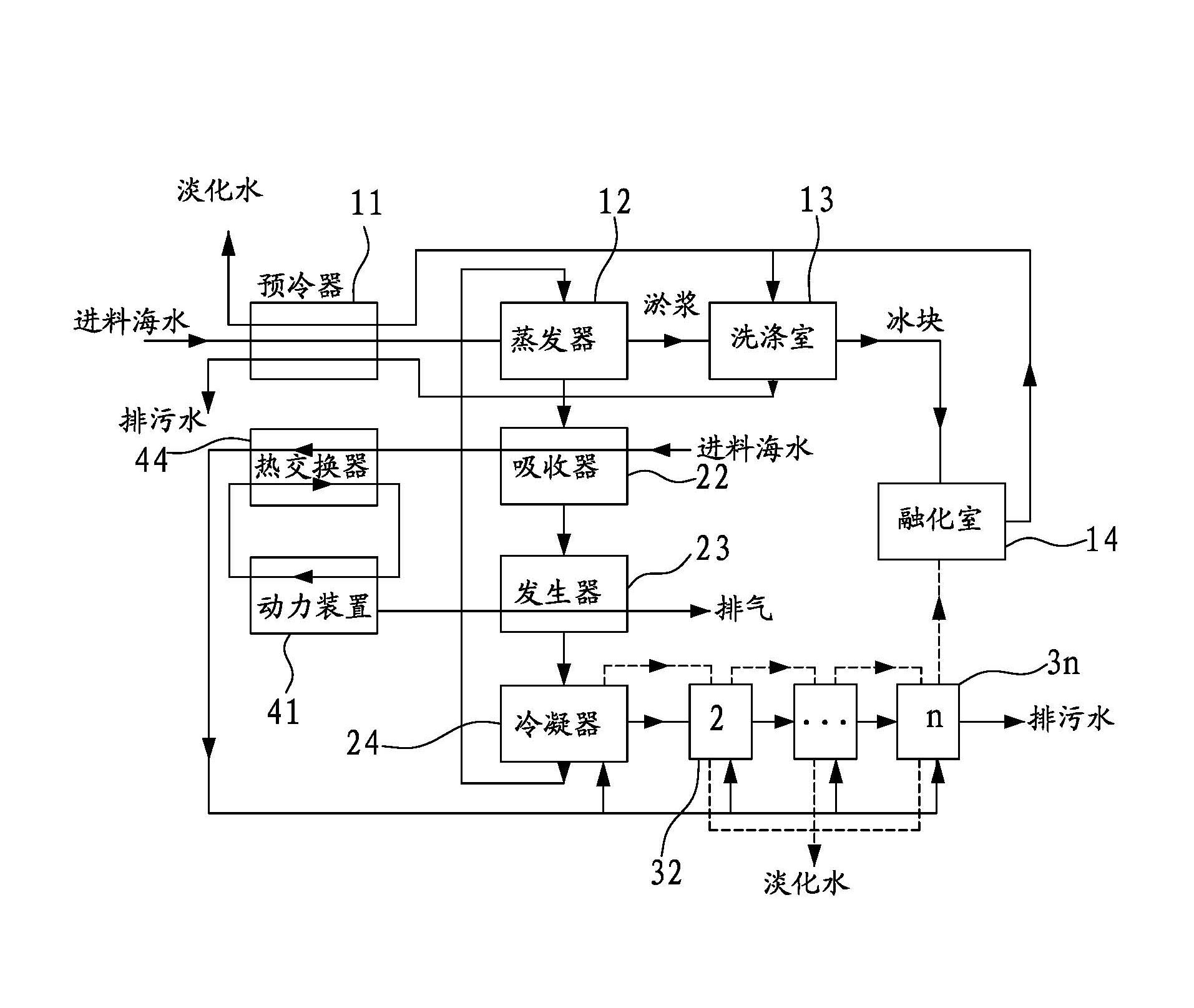

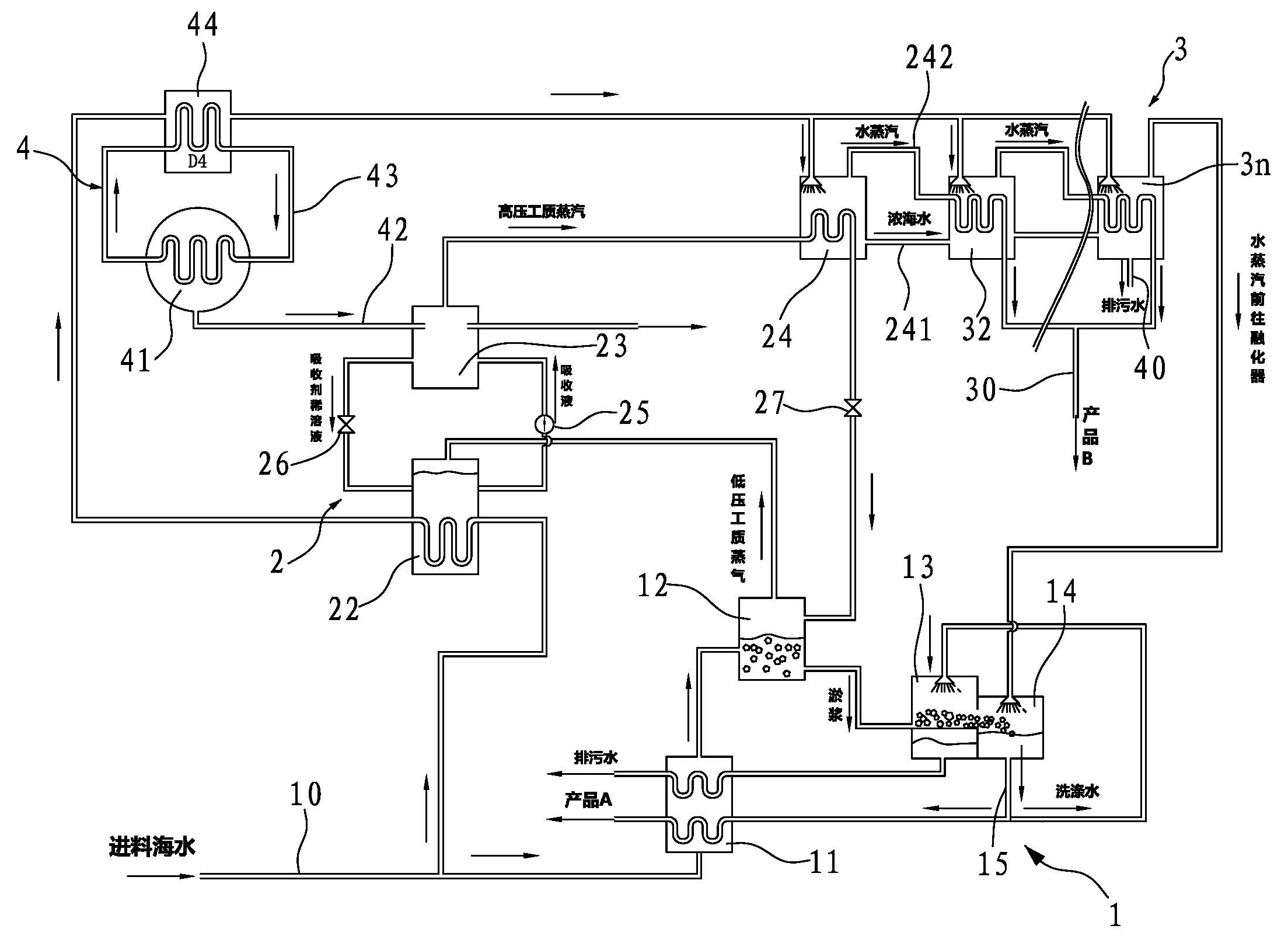

Marine cold and heat cogeneration seawater desalting method and equipment

InactiveCN102320674ASimple structureReduce power consumptionGeneral water supply conservationSeawater treatmentDesalinationCogeneration

The invention discloses marine seawater desalting method and equipment which couple a freezing method and a distilling method by utilizing an absorption type heat pump. The method comprises the steps of precooling-preheating, freezing-evaporating, washing-condensing, melting-condensing, and the like. According to the invention, because the novel cold and heat cogeneration seawater desalting method is realized by fully utilizing residual heat resources at different temperatures on a ship, the whole system is simple and feasible, is convenient for operation, can be used for optimally utilizing energy, has the characteristics of large desalted water output and high desalted water quality, is especially suitable for low-cost small-scale production on the ship and can be widely applied to the field of seawater desalting.

Owner:JIMEI UNIV

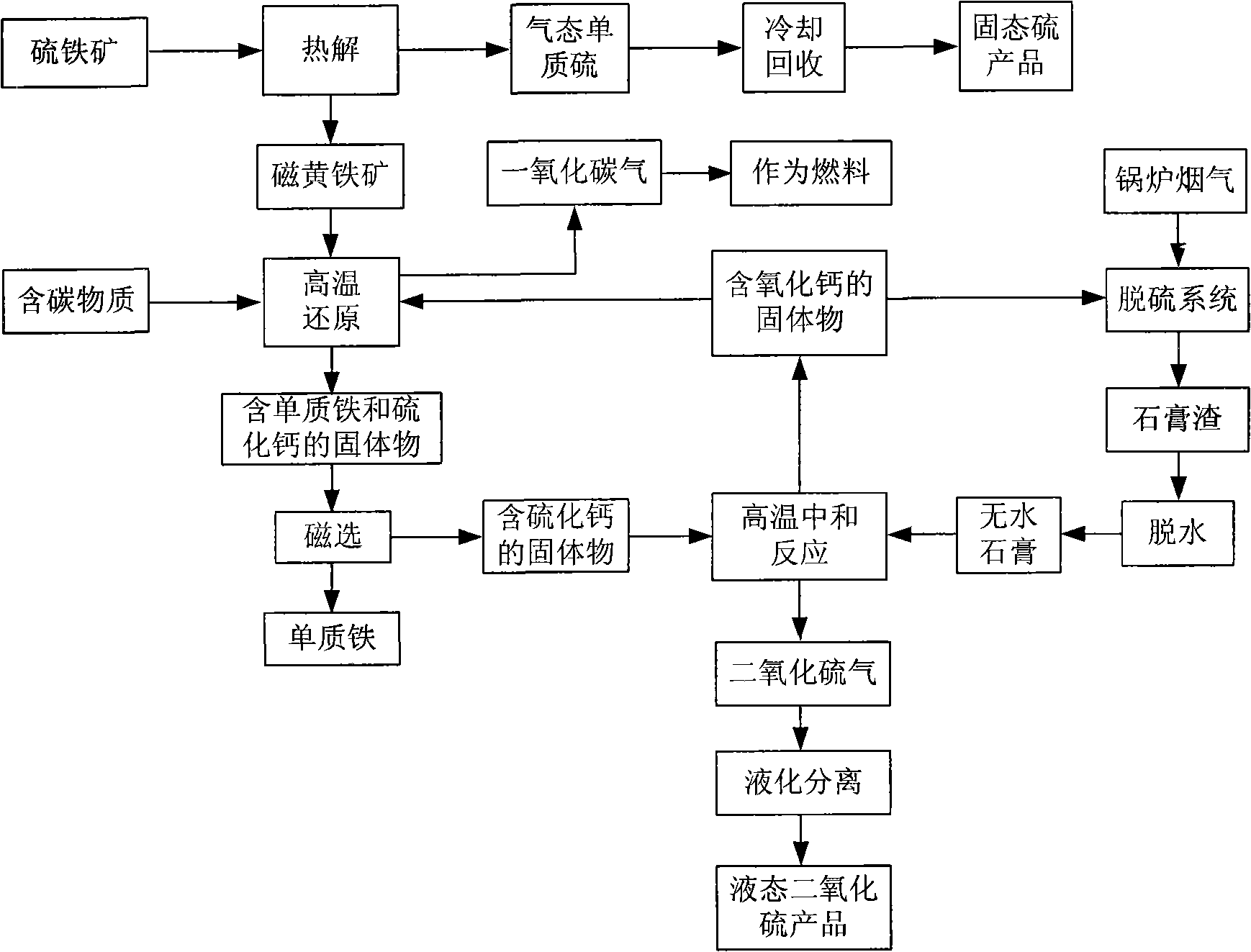

Method for utilizing comprehensive resource of sulfur-containing solid waste

InactiveCN101570341ATo promote metabolismSave resourcesDispersed particle separationSulfur compoundsSulfur containingPollution

The invention discloses a method for utilizing comprehensive resource of sulfur-containing solid waste, which comprises the following steps: (1) pyrolyzing sulfurous iron ore to obtain pyrrhotite and an elemental sulfur product; (2) mixing the pyrrhotite, a carbon-containing substance and a calcium-containing substance to carry out reduction reaction under a high temperature to obtain a solid mixture of elemental iron and calcium sulfide; (3) magnetically separating the solid mixture, and separating and recovering the solid mixture to obtain the elemental iron; (4) mixing and heating the solid containing the calcium sulfide and dehydrated gypsum to obtain tail gas containing SO2 and solid containing calcium oxide; and (5) separating the tail gas containing the SO2 through liquefying to obtain a liquid SO2 product, and using the solid containing the calcium oxide as the calcium-containing substance to participate in the reaction of the step (2) and as flue gas desulfurizing agent for cyclically utilization. The method solves the problems of occupied floor due to the stacking of desulfurization gypsum and coal washing sulfurous iron ore, environment pollution and potential safety hazard, makes full use of calcium, sulfur and iron resources rich in the wastes, and can realize recycling economy and clean production.

Owner:HUAZHONG UNIV OF SCI & TECH

1-polyolefin halogenation production method

InactiveCN101671412AMeet the needs of halogenation reactionIncreased macroscopic reaction ratePolyolefinProcess equipment

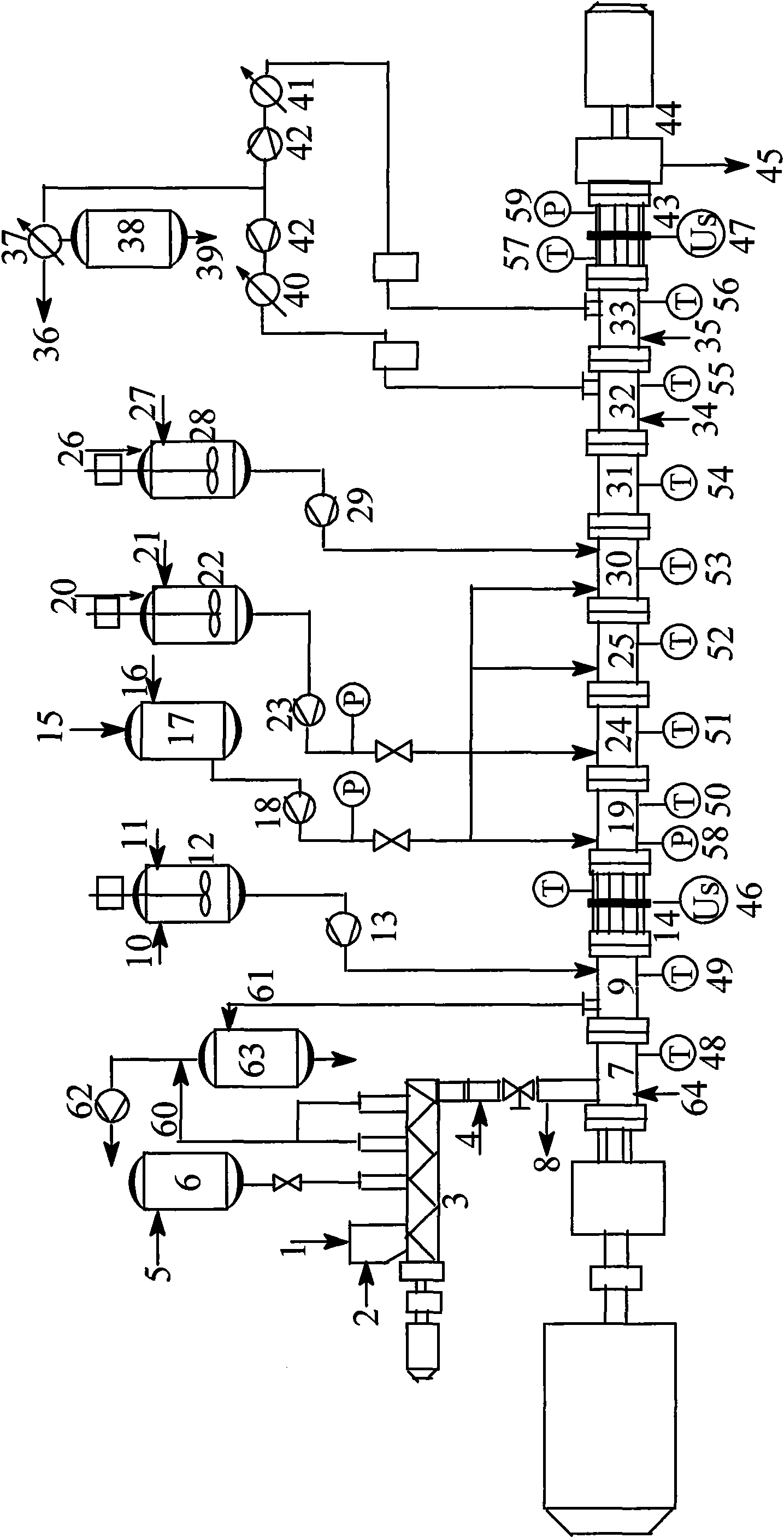

The invention relates to a 1-polyolefin halogenation production method which is characterized in that continuous plastication (mixing), degasification, ultrasonic wave visbreaking, softening, multistage halogenation, neutralization and stabilization, devolatilization, ultrasonic wave temperature reduction and stripping and slicing measurement are realized in a sealing drying system in a double-screw extruder reactor to produce the halogenated polyolefin. Compared with the traditional process, the process flow is shortened by three fourth, which saves investment and energy power consumption; the halogen content of the halogenated polyolefin can be controlled, and does not contain corrosive acid gas, so that the equipment can not be corroded severely, is the modern green engineering, and canwidely replace the process equipment of the current halogenated polyolefin.

Owner:江苏圣杰实业有限公司

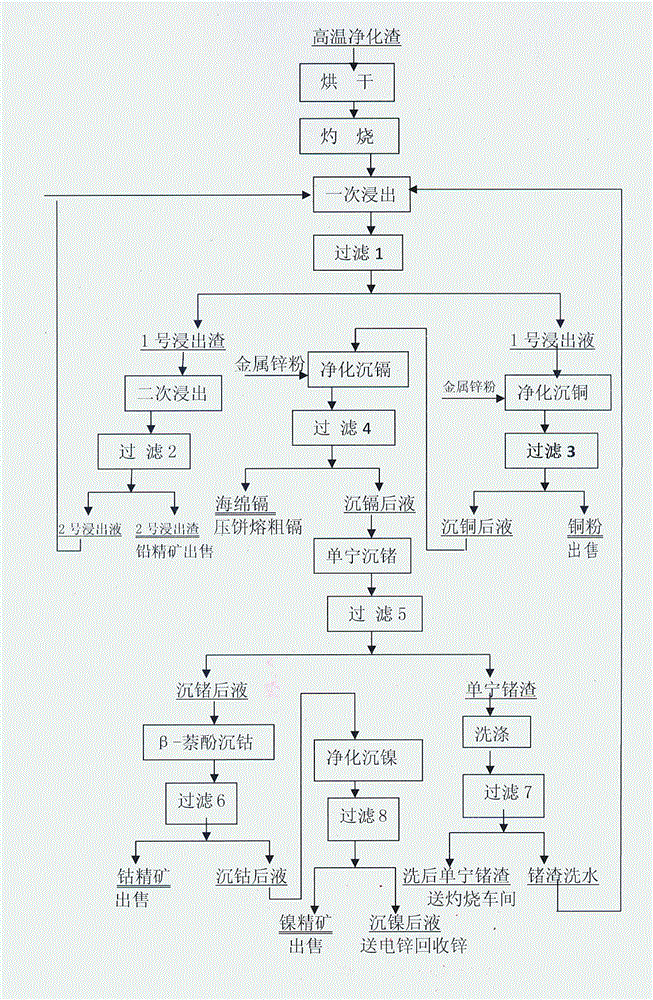

Method for comprehensively recovering valuable metals from zinc hydrometallurgy high-temperature purification slags

The invention discloses a method for comprehensively recovering valuable metals from zinc hydrometallurgy high-temperature purification slags. The method comprises the following steps: (1) drying and firing of the high-temperature purification slags; (2) first leaching; (3) second leaching; (4) purification and deposition of copper; (5) purification and deposition of cadmium; (6) deposition of tannin germanium; (7) deposition of cobalt; and (8) deposition of nickel and recovery of zinc by returning liquid obtained by deposition of nickel to a zinc hydrometallurgy system. The invention provides a method for leaching the zinc hydrometallurgy high-temperature purification slags twice after drying and firing to obtain the produced leaching slags, namely silver lead ore concentrate for sales, and comprehensively recovering copper, cadmium, germanium, cobalt, nickel and zinc from filtering liquid subjected to first leaching; the method is easy to carry out and simple in process; the recovery rate of the valuable metals is high, as the recovery rate of lead, silver, copper, cadmium, germanium, cobalt, nickel and zinc respectively reaches 98.50-99.50 percent, 99.10-99.70 percent, 94.40-97.80 percent, 95.10-96.90 percent, 93.50-96.70 percent, 94.70-95.70 percent, 94.80-96.80 percent, and 96.00-97.00 percent; moreover, the recovery of the valuable metals is more comprehensive, scientific and reasonable; waste water, waste gas and waste slags are avoided, and the requirement on national circular economy and sustainable development is met.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

Method for preparing porcelain granule from waste paper-making sludge

InactiveCN101386524ADifferent apertureDifferent porosityCeramic materials productionClaywaresSludgeCrushed stone

The invention provides a method for preparing porcelain granules by waste paper making sludge, which belongs to the technical field of solid waste treatment and disposal. The method comprises the following steps: mixing and milling, or mixing and granulating the waste paper making sludge, clay and pulverized fuel ash into spherical blank granules; and drying and sintering the spherical blank granules at a temperature of between 1,000 and 1,250 DEG C to produce a porcelain granule product. The method solves the problem of treating mass sludge produced by waste paper making, so that waste materials can be reasonably recycled, and the clay in fragmental stone chippings during the process of crushing construction aggregate can also be recycled, thereby solving the problems of occupying farmland, saving clay resource, and having certain significance for environmental protection. The method has the advantages of simple process and low cost, and is suitable for mass industrial production. The product produced by the method has high rate of finished products and wide application range. The light porcelain granules obtained by the porcelain granule preparation method have the advantages of standard dimension, easy graduation, and accord with national standard in pressure resistance and other indexes.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

MTP (methanol to propylene) device and novel separation process thereof

ActiveCN105503492AReduce lossLess solvent absorptionDistillation purification/separationHydrocarbon from oxygen organic compoundsGas phaseSolvent

The invention relates to an MTP (methanol to propylene) separation device and a novel separation process adopted by the MTP device. The novel separation process comprises the steps that quenched reaction gas is pressurized by a compressor and undergoes washing and alkali wash treatment on a third compression section, a gas phase at the outlet of a fourth compression section goes to a depropanizer and a liquid phase goes to a debutanizer, water phases of separating tanks among the sections of the compressor return to a quench tower, and a hydrocarbon phase is sent to a separating tank at the outlet of the fourth compression section after being pressurized; the materials ejected from the debutanizer go to the depropanizer and the materials discharged from tower reactors enter a dehexanizer; a deethanizer compressor is arranged between a deethanizer and an oil absorption tower, the oil absorption tower adopts recycle propane or C4 as an absorbing solvent, fuel gas excluding C2 is obtained at the tower tops, the materials discharged from the tower reactors go to a stripping tower to recover the propane or C4 solvent, and the materials ejected from the stripping tower go to an ethylene rectification tower, thus obtaining the byproduct ethylene. The novel separation process has the effects that the process flow can be effectively optimized; the energy consumption of systems, the pipeline corrosion and the cost of investment can be effectively reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

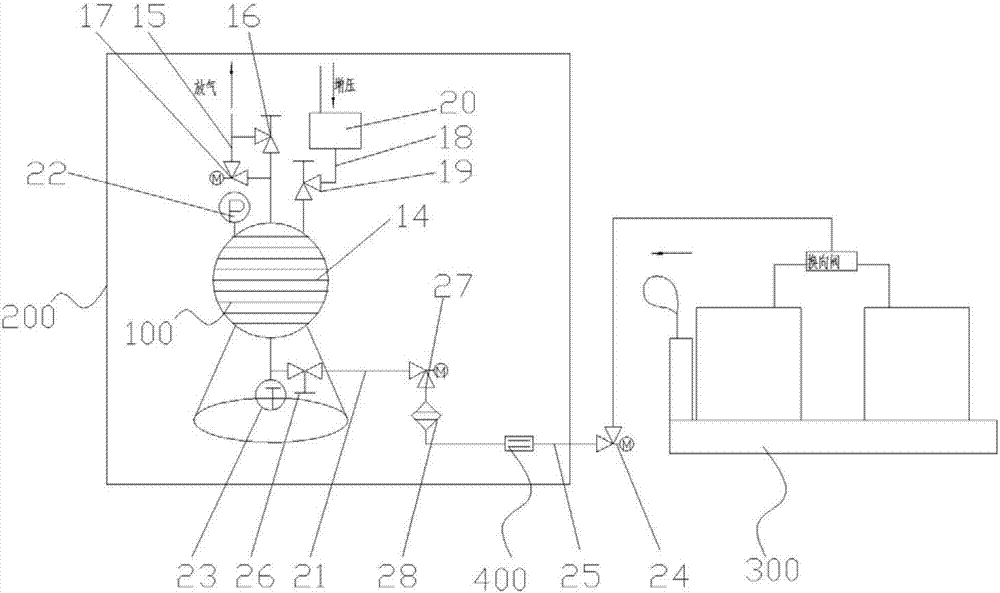

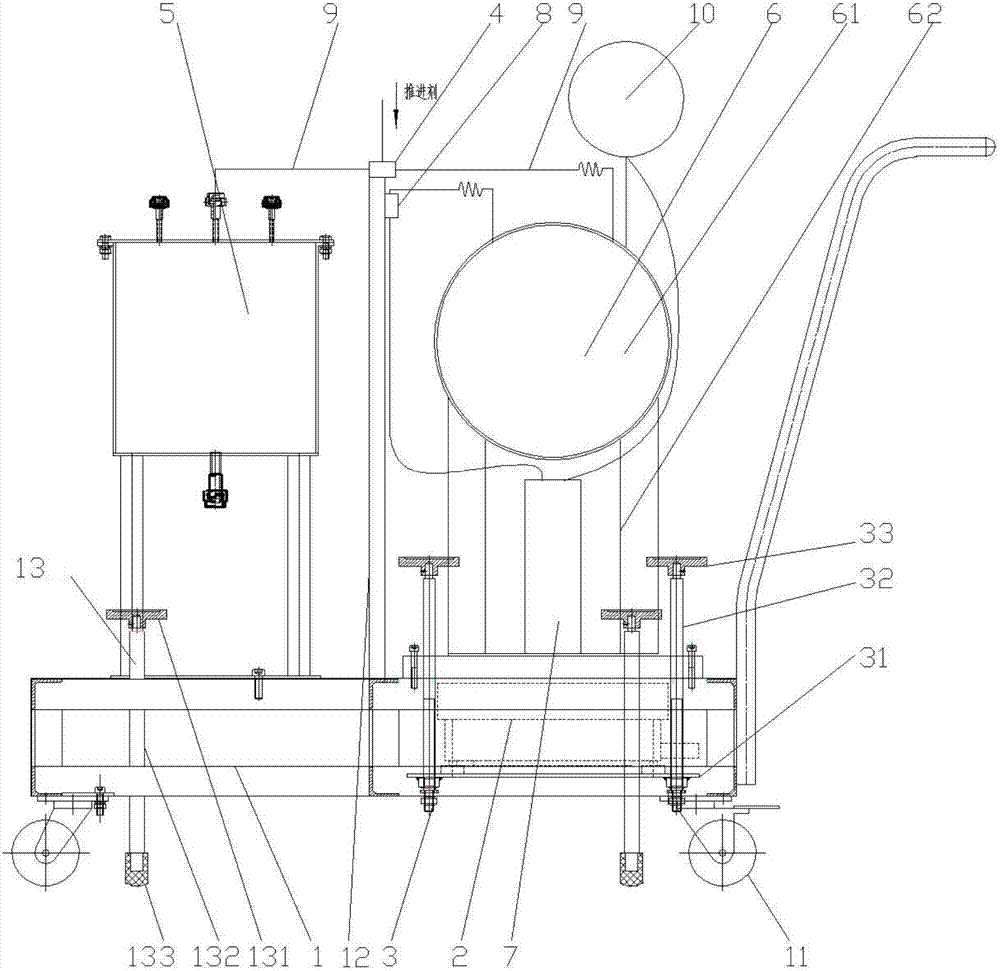

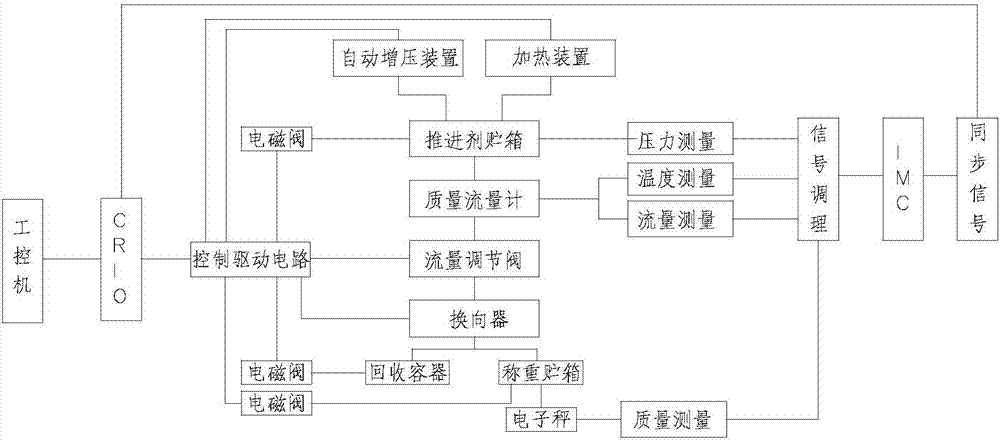

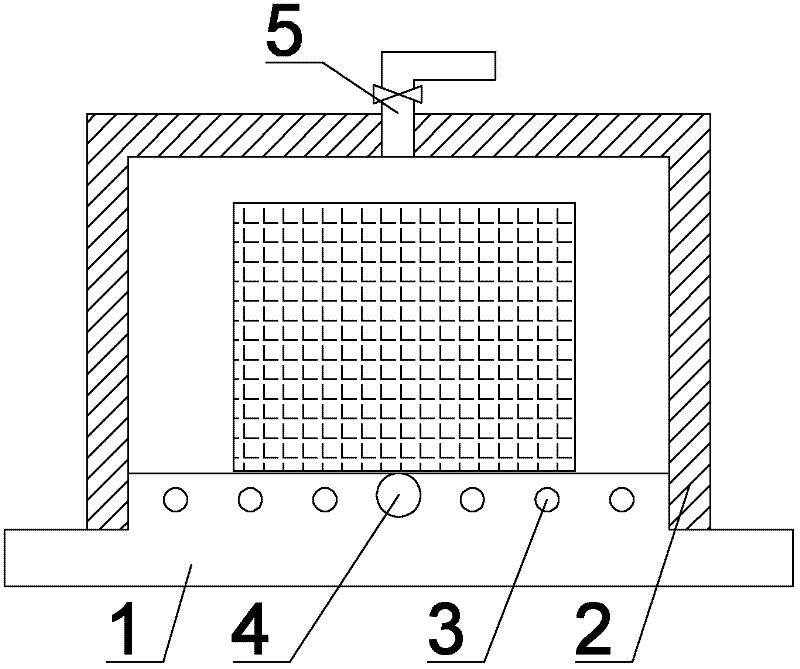

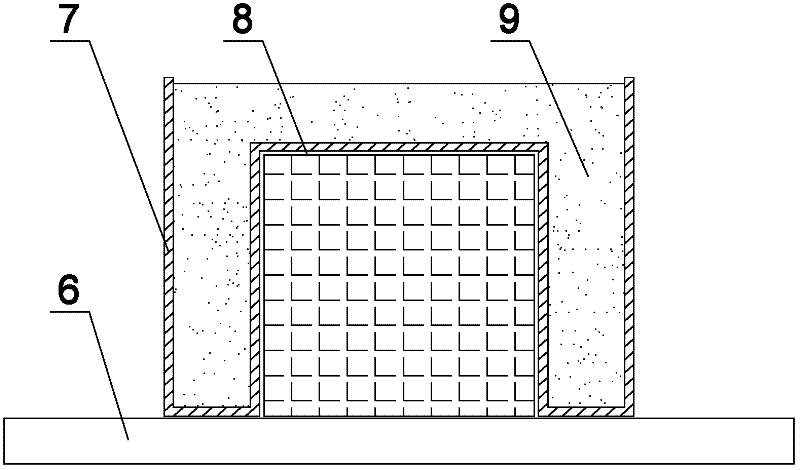

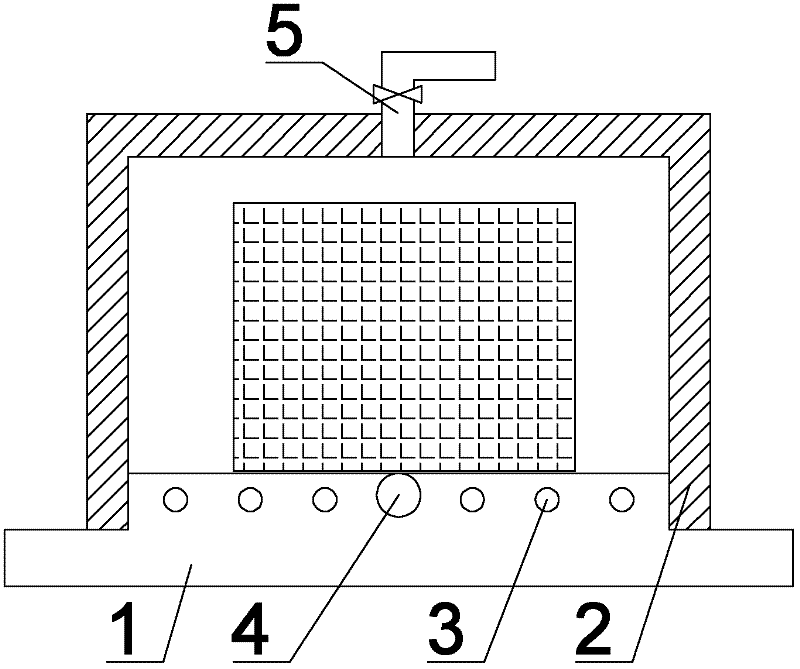

In-situ calibration device for steady state flow rate of high-temperature propellant of attitude control engine and calibration method

ActiveCN107131931AReduce the influence of flow measurementHigh measurement accuracyTesting/calibration apparatusAttitude controlControl system

The invention discloses an in-situ calibration device for the steady state flow rate of a high-temperature propellant of an attitude control engine and a calibration method. The calibration device comprises a propellant supplying device, a high-low temperature box, a weighing and recycling device, a control system and a measuring system; the propellant supplying device is used for supplying flow rate, pressure and propellant at stable temperature for a calibration system according to the flow rate requirement on a mass flow meter to be calibrated; the high-low temperature box is used for heating the propellant supplying device according to the calibration requirement of the mass flow meter to be calibrated; the weighing and recycling device is used for weighing and recycling the propellant which flows through the mass flow meter within the calibration setting time; the control system is used for controlling and regulating the propellant supplying device, the high-low temperature box and the weighing and recycling device; and the measuring system is used for collecting and treating data. By adopting the device, the influence of medium temperature, density and the like on the measuring result of the mass flow meter can be effectively reduced, and the flow rate measuring accuracy is improved.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

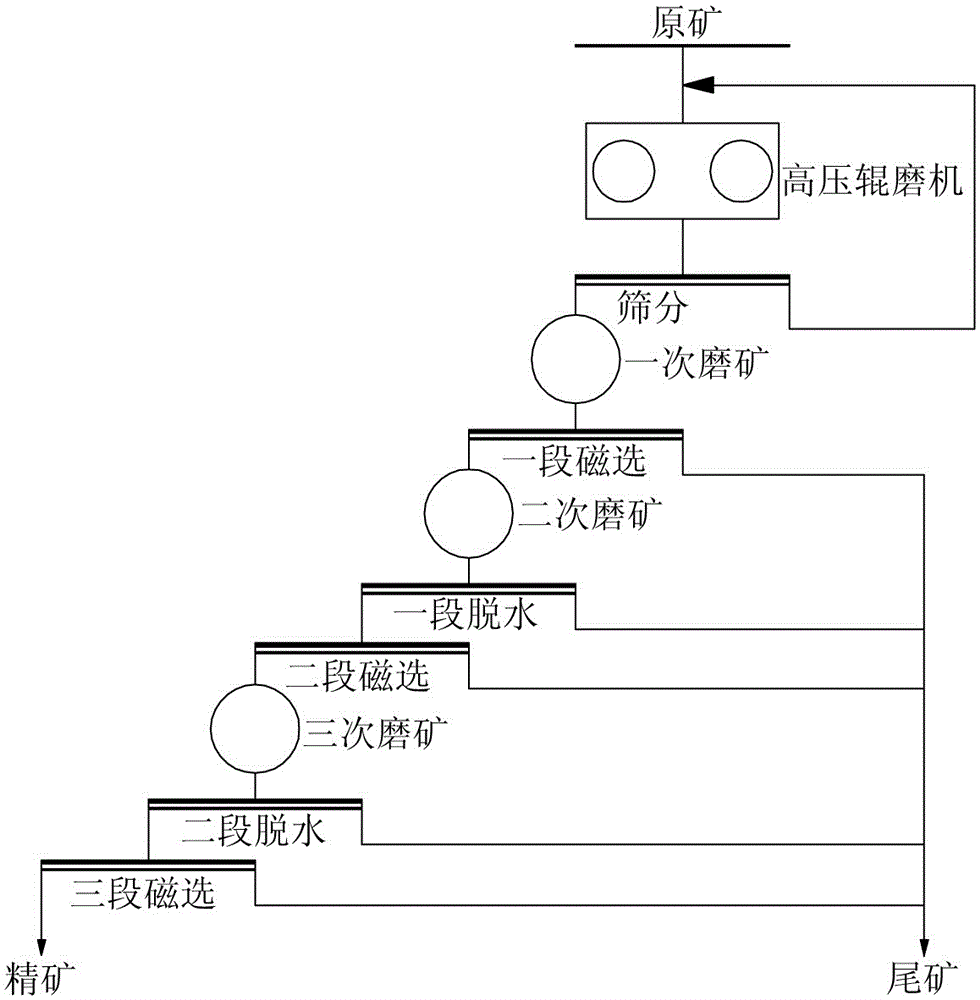

High-pressure roller selective comminuting and magnetic separating method for lean magnetite ore

The invention relates to a high-pressure roller selective comminuting and magnetic separating method for lean magnetite ore. According to the method, ultrafine crushing is conducted on raw magnetite with a grade of 28.59% by means of a high-pressure grinding roller, and three times of ore grinding, two-section dewatering and three-section magnetic separation are conducted on the crushed product to obtain concentrate with a grade of 68.23% and metal recovery rate of 82.35%. The method has the advantages that the recovery rate of the final concentrate can be increased, and efficient recovery and utilization of resources are achieved; the dissociation degree of the product is high, excessive grinding degree is low, follow-up magnetic separation effect is good, and the separation precision of equipment is improved; on the premise that the quality of the concentrate is guaranteed, concentrate recovery rate can be increased, iron ore resources can be recovered and utilized fully and reasonably, and resource waste is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Method for preparing isooctanoic acid

InactiveCN101125810AReasonable recyclingShort reaction timeOrganic compound preparationCarboxylic compound preparationIsooctyl alcoholHydrogen

The invention relates to an isooctyl acid preparation method: isooctyl alcohol and sodium hydroxide are positioned in an inert atmosphere for reaction, with zinc acetate being the catalyst and the temperature being 250-260 DEG C and the pressure being 2.8-3.2 MPa, until no hydrogen is produced, after which the reaction continues under the same pressure for 30-50min, then the reaction product is acidized at normal pressure and at a temperature of 65-80 DEG C, thereby acquiring the crude isooctyl acid which is finely distilled and purified to produce the fine isooctyl acid. The reaction time of the method is short, and the production cycle is essentially confined to 8-10 hours; the method has high purity, as much as 99.5 percent, high yield, fundamentally non-pollution and reasonably recyclable by-products.

Owner:河南庆安化工高科技股份有限公司

Method for processing coke by electrolytic aluminium waste and special device

ActiveCN102559225AReduce consumption costReduce manufacturing costEnergy inputCarbon preparation/purificationResource utilizationMarket competition

The invention discloses a method for processing coke by electrolytic aluminium waste and a special device. The method is characterized by comprising the following steps of: obtaining a carbon material from electrolytic aluminium waste via magnetic separation and flotation processes; drying the carbon material, and preheating to 100-120 DEG C; adding asphalt and tar, mixing via kneading equipment, and then moulding in hydraulic moulding equipment by pressing; curing the moulded raw materials in an electro-thermal dry distillation device; and drying and preheating the carbon material by the dry-distilled coke product via a waste heat utilization device. The invention discloses a new process and a new technology for resource utilization for the high-fluorine-content carbon-containing solid waste of electrolytic aluminium, which is used for deeply processing the carbon material obtained by the electrolytic aluminium waste, so as to further increase the additional value of the electrolytic aluminium waste. Compared with the prior art, the new process and the new technology have the advantages of being wide in application range, high in treatment and disposal amount, advanced in technology, low in treatment cost, and good for the implementation of industrialization. Simultaneously, the project is specific in the aimed target market, and obvious in market competition advantage.

Owner:周俊和 +1

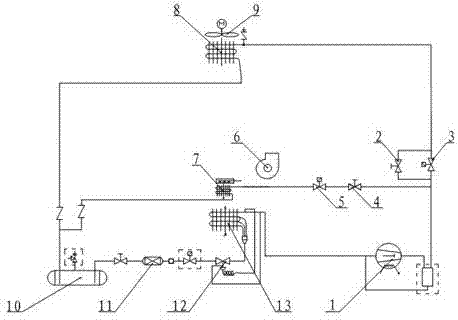

Energy-saving air conditioning unit having automatic heat recovery controlling function and control method thereof

InactiveCN102865651ATemperature and Humidity ControlSimple structureEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsAutomatic controlAir conditioning

The invention discloses an energy-saving air conditioning unit having an automatic heat recovery controlling function. The energy-saving air conditioning unit solves the problems that existing constant-temperature constant-humidity air conditioning units are high in usage cost and wasteful in energy after being used. The air conditioning unit comprises a refrigerating unit, the refrigerating unit is composed of a compressor, a condenser, a liquid storage pot, a drying and filtering device, an expansion valve and an evaporator which are connected through conveying pipelines sequentially, the evaporator is in back connection with the compressor, and simultaneously, the air conditioning unit is provided with a reheating unit which is in parallel connection with the pipeline between the compressor and the condenser. The air conditioning unit is simple in structure and convenient to use, the power of electrical heating is cancelled due to the application of the technology, the heat which is to be dissipated outdoors is directly led into a room, the requirements of the room for the temperature and the humidity are met, the electrical load is reduced, and energy conservation is achieved, so that the air conditioning unit has high practical values and promoting values.

Owner:YIMIKANG TECH GRP CO LTD

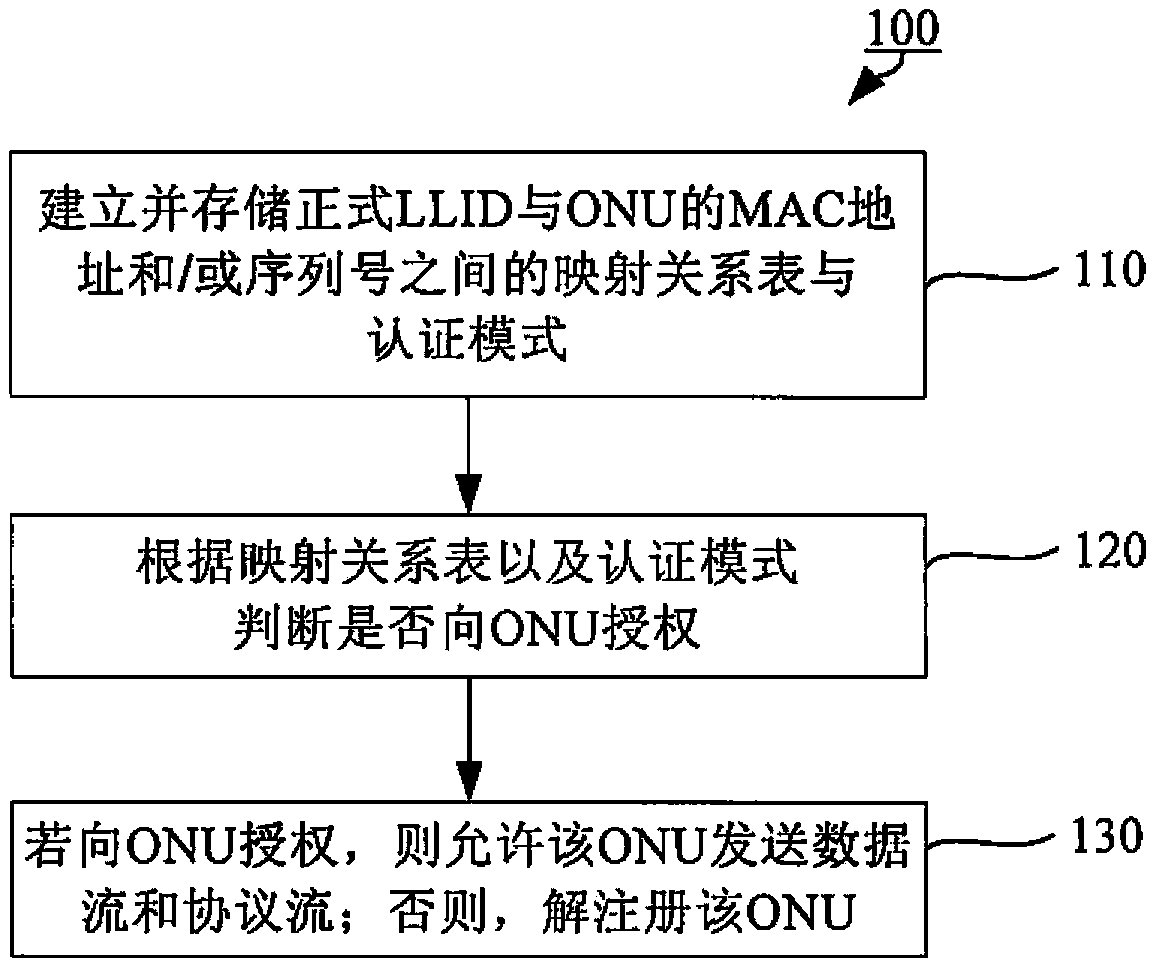

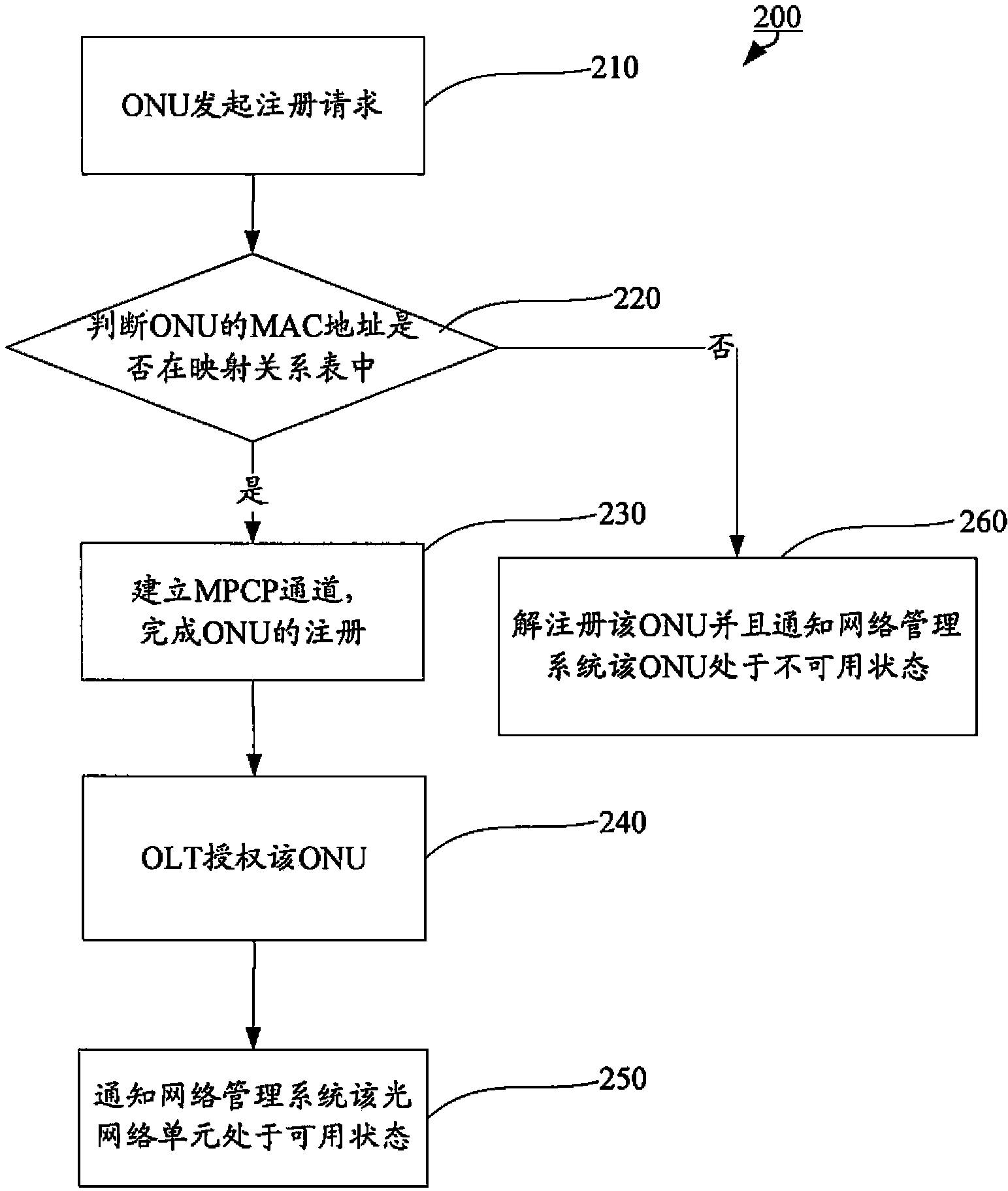

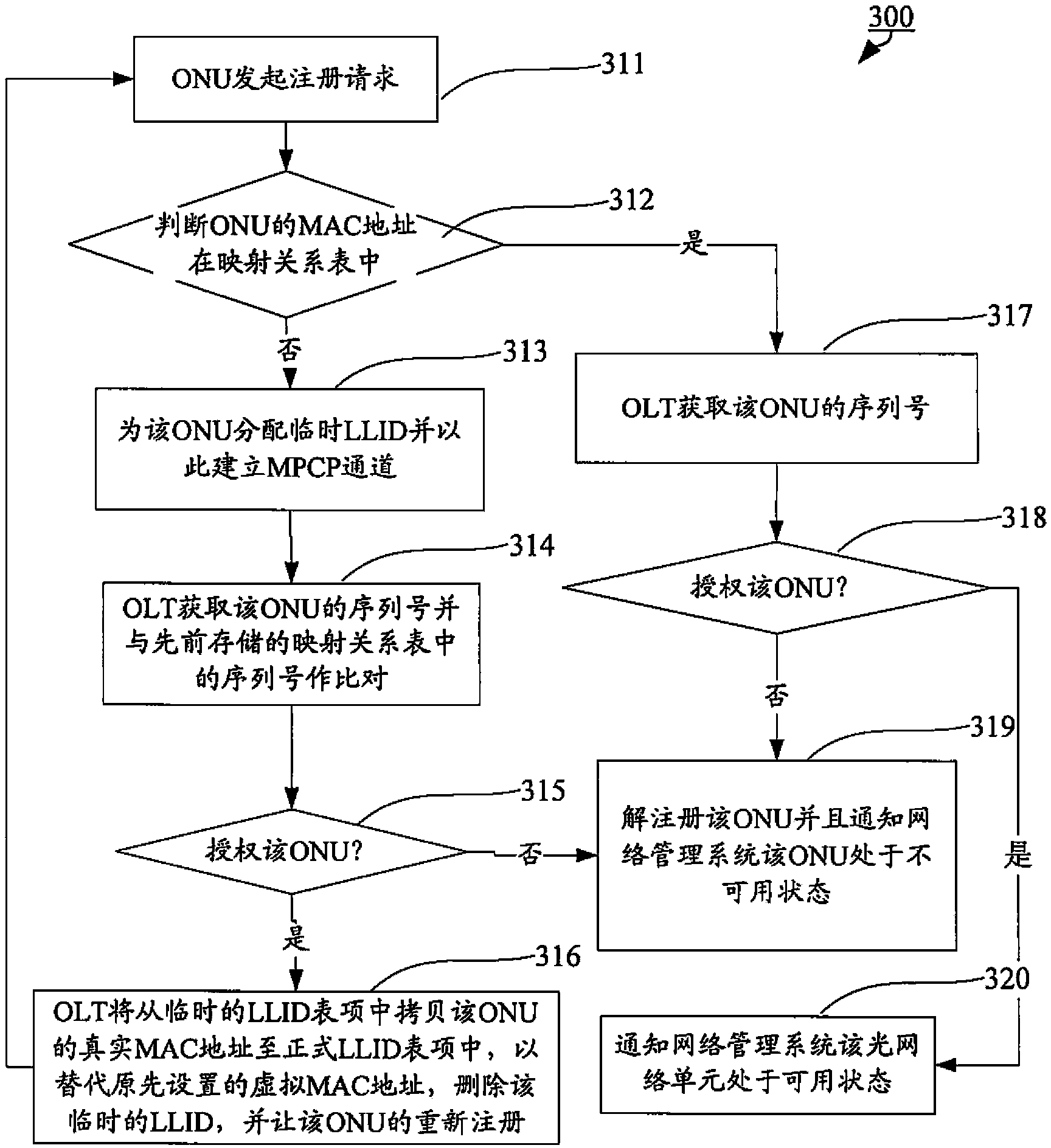

Method for configuring optical network unit in passive optical network

ActiveCN103905301ASolve association problemsSmooth and seamless associationMultiplex system selection arrangementsData switching networksData streamNetwork management

The invention relates to a method for configuring an ONU in a PON in an optical access communication network. The PON further comprises an OLT, and the method comprises the steps that a mapping relation table between formal LLIDs distributed by the an optical network management system and the MAC address and / or the serial number of the ONU and an authentication mode related to the ONU are built and stored in the OLT; when the ONU initiates a login request for having access to the PON, the OLT initiates an authentication request to the ONU, and whether the ONU is authorized or not is judged according to the mapping relation table and the authentication mode; if the ONU is authorized, the ONU is allowed to sent data flow and protocol flow; otherwise, the ONU is deregistered. All the other configuration in the OLT is based on the formal LLIDs, and the MAC address or the serial number of the ONU are not depended on any more. The method solves the correlation problem of the MAC address or the series number identifying the ONU and the formal LLIDs, all the configuration in the OLT is based on the formal LLIDs, and therefore the offline configuration of the ONU is achieved.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

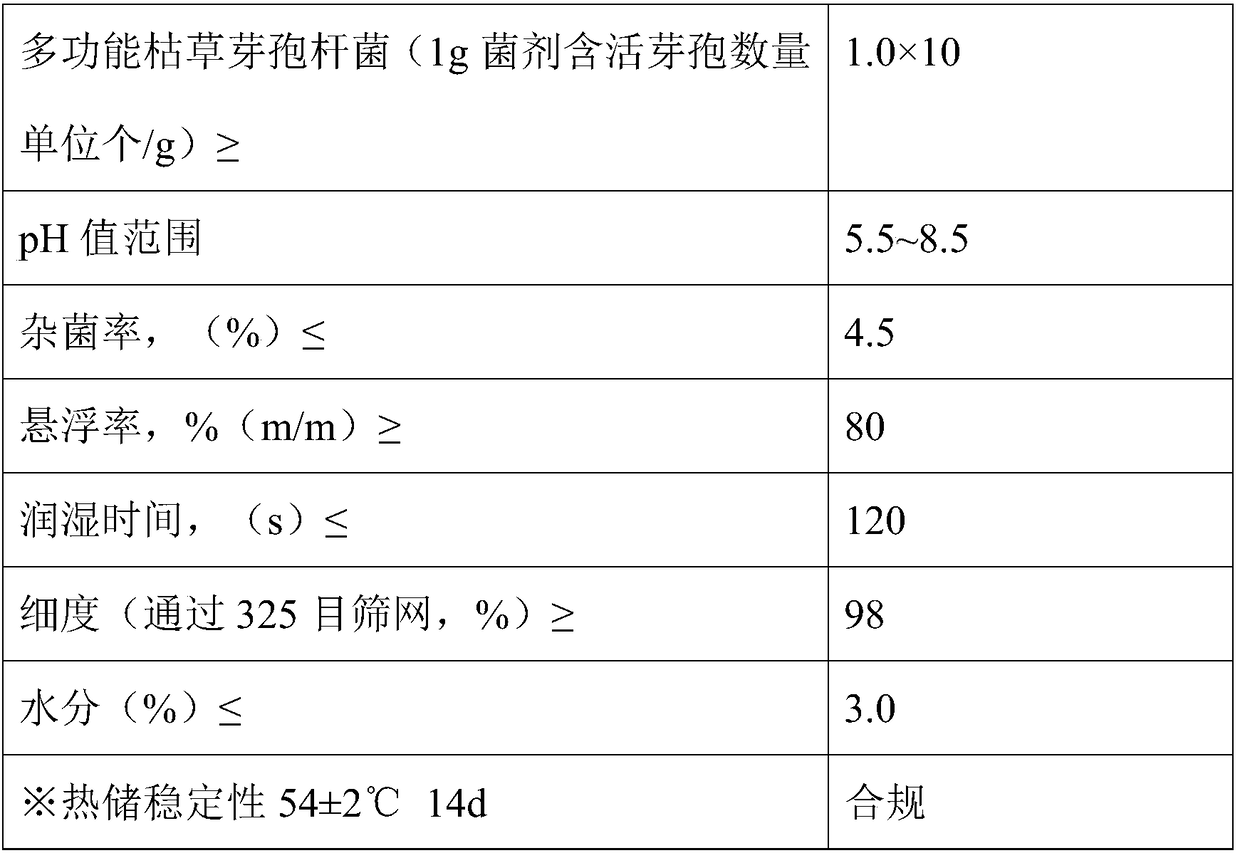

Biological organic fertilizer and preparation method thereof

InactiveCN108191480AReasonable recyclingImprove physicsBio-organic fraction processingExcrement fertilisersSporeFungicide

The invention relates to a biological organic fertilizer and a preparation method thereof. The biological organic fertilizer is mainly prepared from, by weight, 8-35 parts of gangue, 10-20 parts of animal dung, 55-180 parts of turfy soil, 20-50 parts of rice hull powder and / or straw, 8-35 parts of cake fertilizer, 1-5 parts of zeolite powder and 0.25-0.7 part of bacillus subtilis fungicide. The bacillus subtilis fungicide is solid fungicide, and in the solid fungicide, the number of viable organisms and / or viable spores is larger than or equal to 10,000,000,000 per g. The fertilizer can provide whole nutrition for crops and improve the fertilizer efficiency, and has good ecological benefits, energy can be reasonably recycled, the rural ecological environment is protected, and a good agricultural ecological system is created. In addition, due to the adoption of the bacillus subtilis strain screened by the applicant, the biological organic fertilizer further has the effect of preventingand controlling multiple fungal and bacterial diseases.

Owner:北京新正和农业科技有限公司

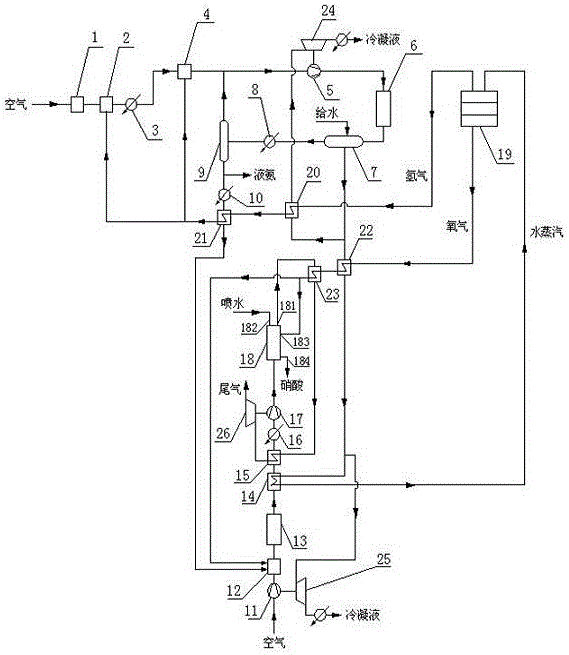

Water vapor electrolytic process based system for joint production of ammonia and nitric acid

ActiveCN106185984ARealize joint productionNot affected by market pricesElectrolysis componentsEnergy inputWater vaporEmission standard

The invention belongs to the technical field of chemical engineering and particularly relates to a water vapor electrolytic process based system for joint production of ammonia and nitric acid. The system comprises a nitrogen generation unit, an ammonia synthesis unit, a nitric acid generation unit, and a solid oxide electrolyzer. The ammonia synthesis unit is used to provide the material ammonia and process vapor for the nitric acid generation unit, no ammonia is externally purchased for the nitric acid generation unit, meanwhile, a heat recovery boiler is eliminated. The reaction heat of the ammonia synthesis unit and the nitric acid generation unit is used to produce high temperature vapor, the high temperature vapor is applied to the solid oxide electrolyzer, the solid oxide electrolyzer produces hydrogen and oxygen, the hydrogen and the oxygen are applied to the ammonia synthesis unit and the nitric acid generation unit, so that a mode of joint production of ammonia and nitric acid by taking air and water as raw materials is achieved, no materials or fuels are externally purchased, only electric energy is used, so that the system has the characteristics of high integration, low production cost, single and convenient energy consumption, reasonable recovery of energy, less environment pollution, conformity to the international emission standard and the like, and has an excellent economic benefit and an excellent application prospect.

Owner:陈志强

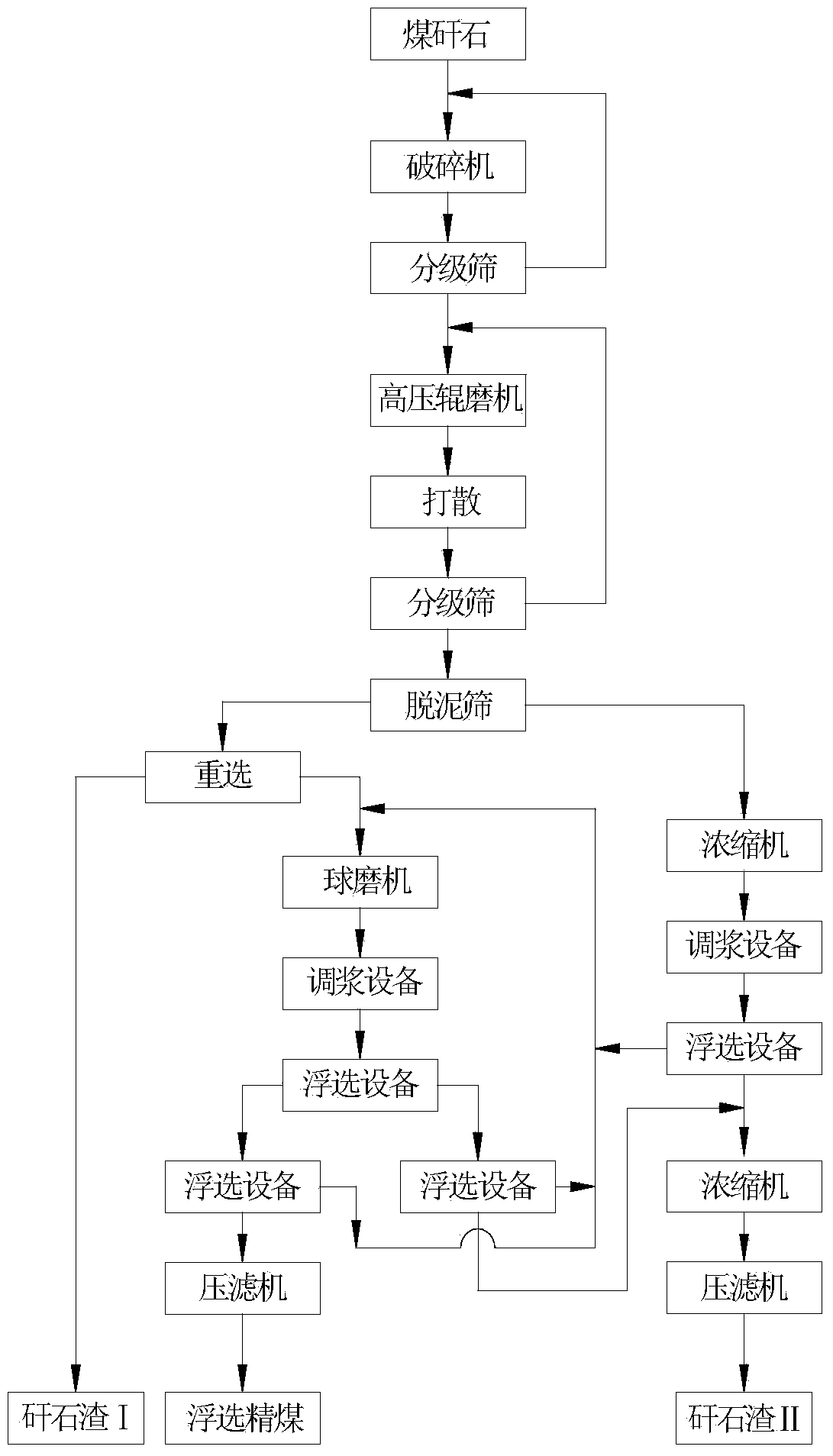

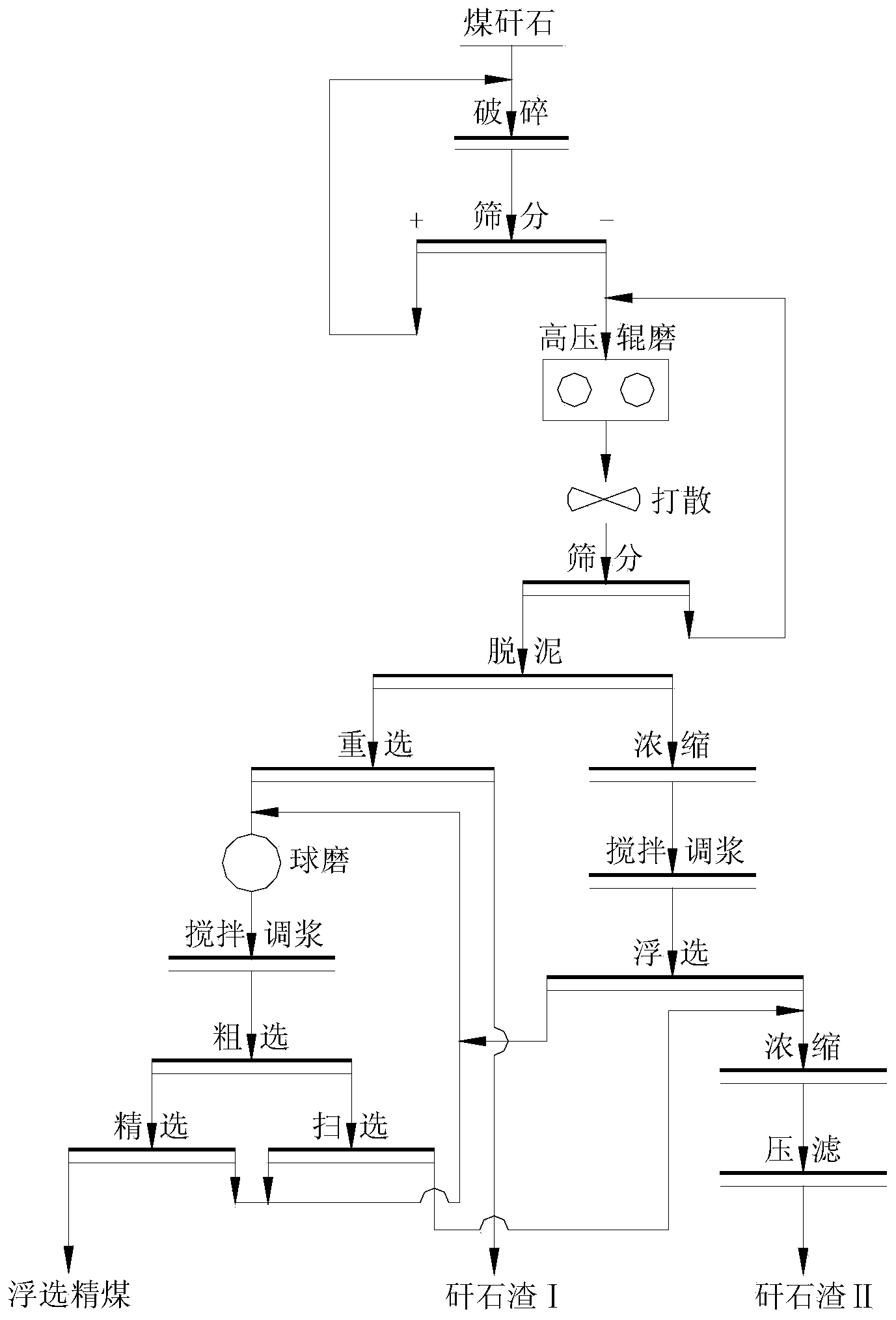

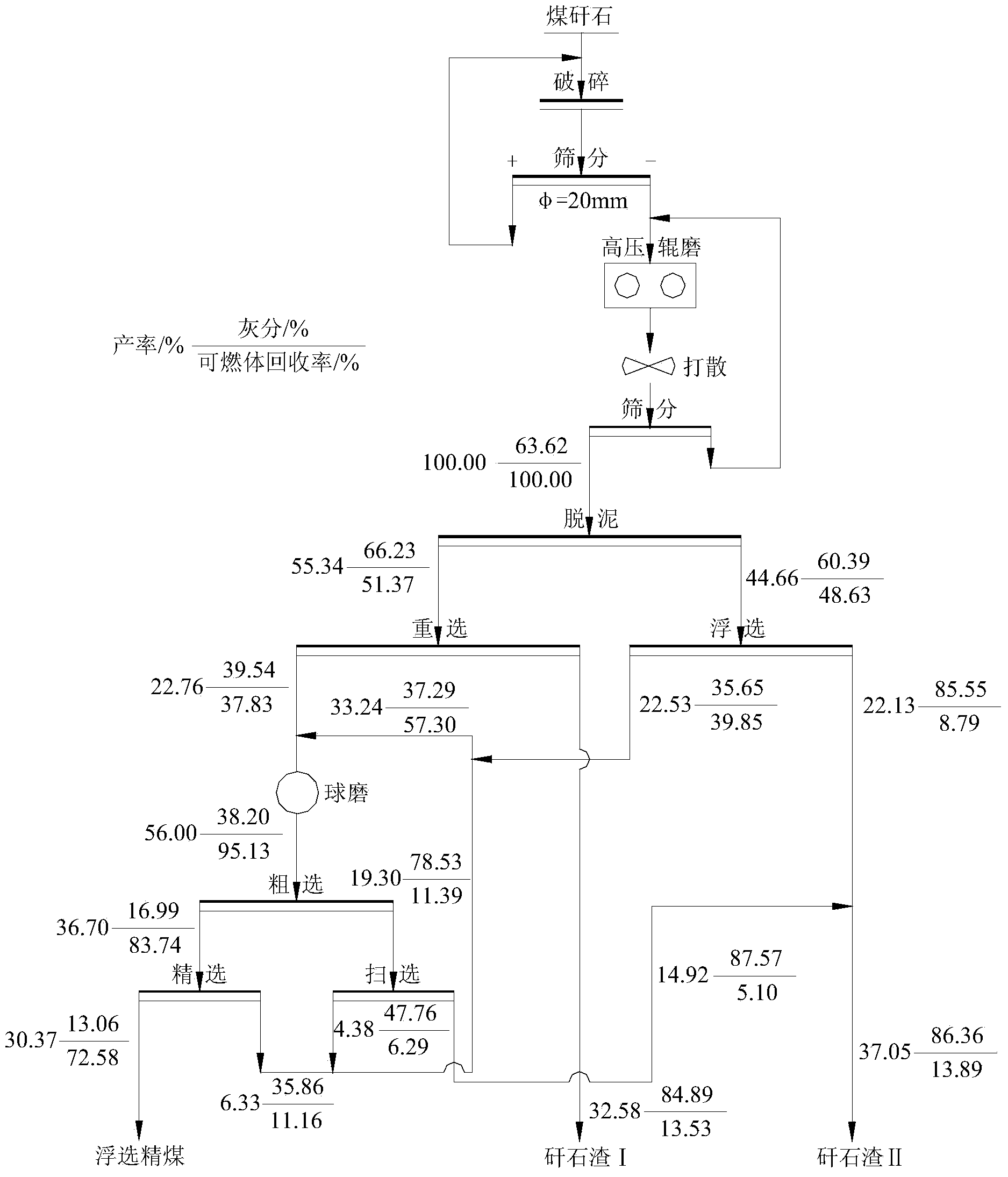

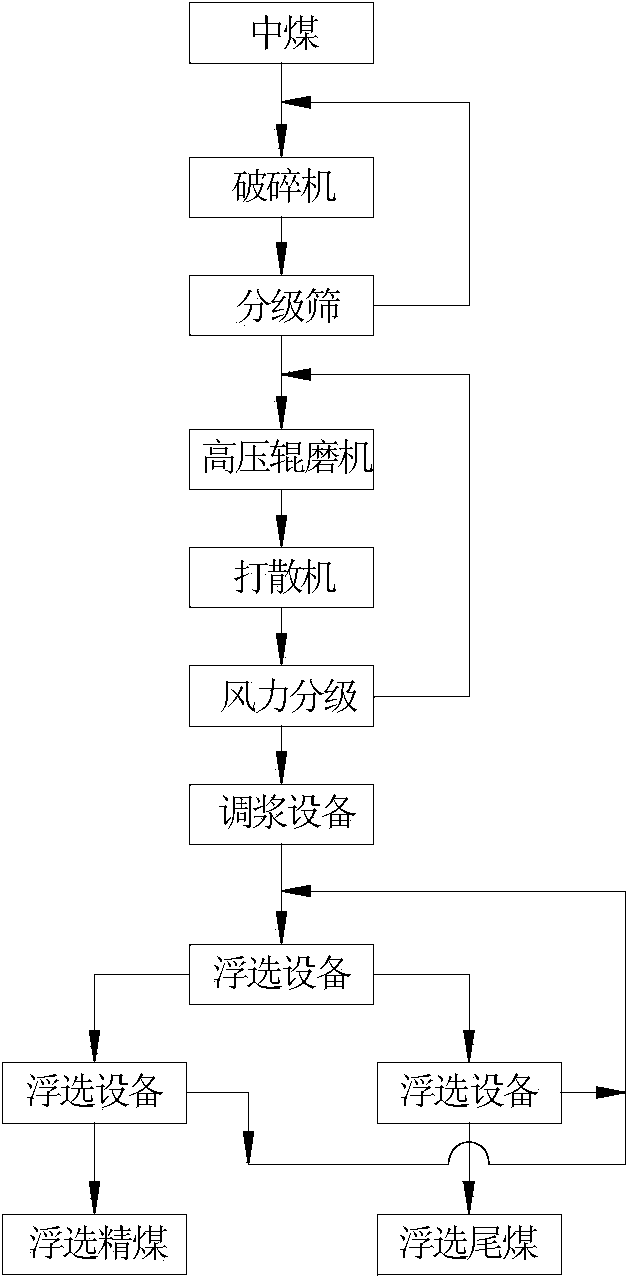

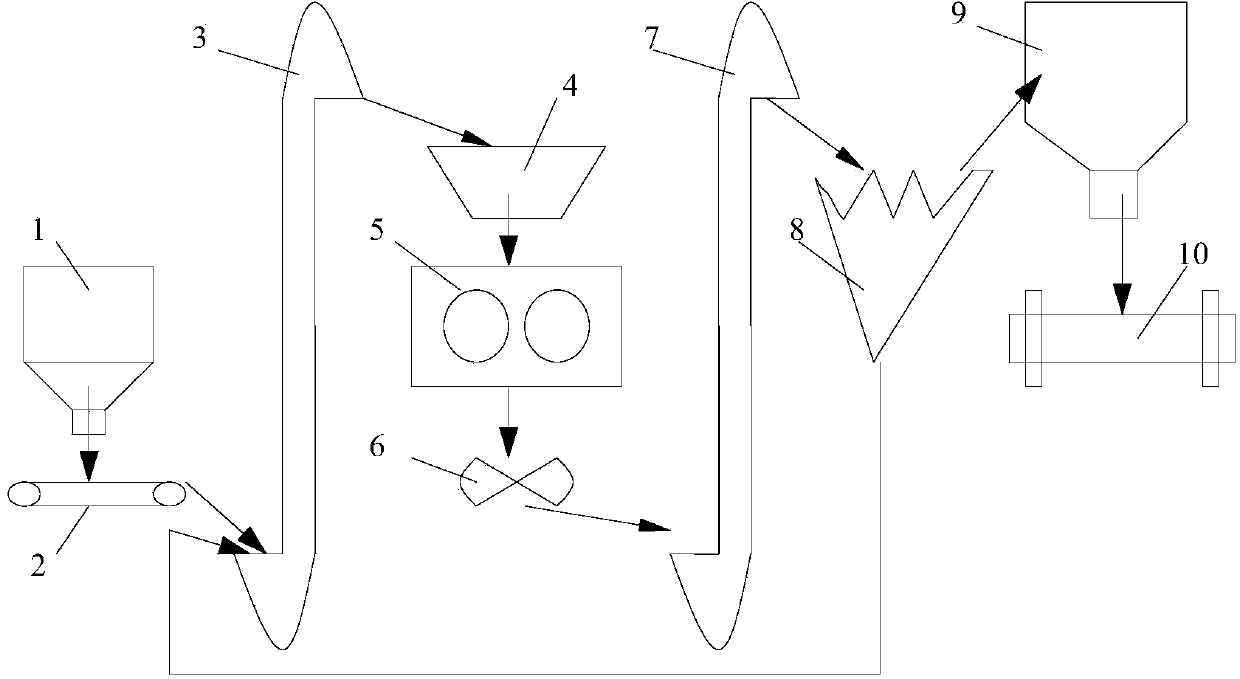

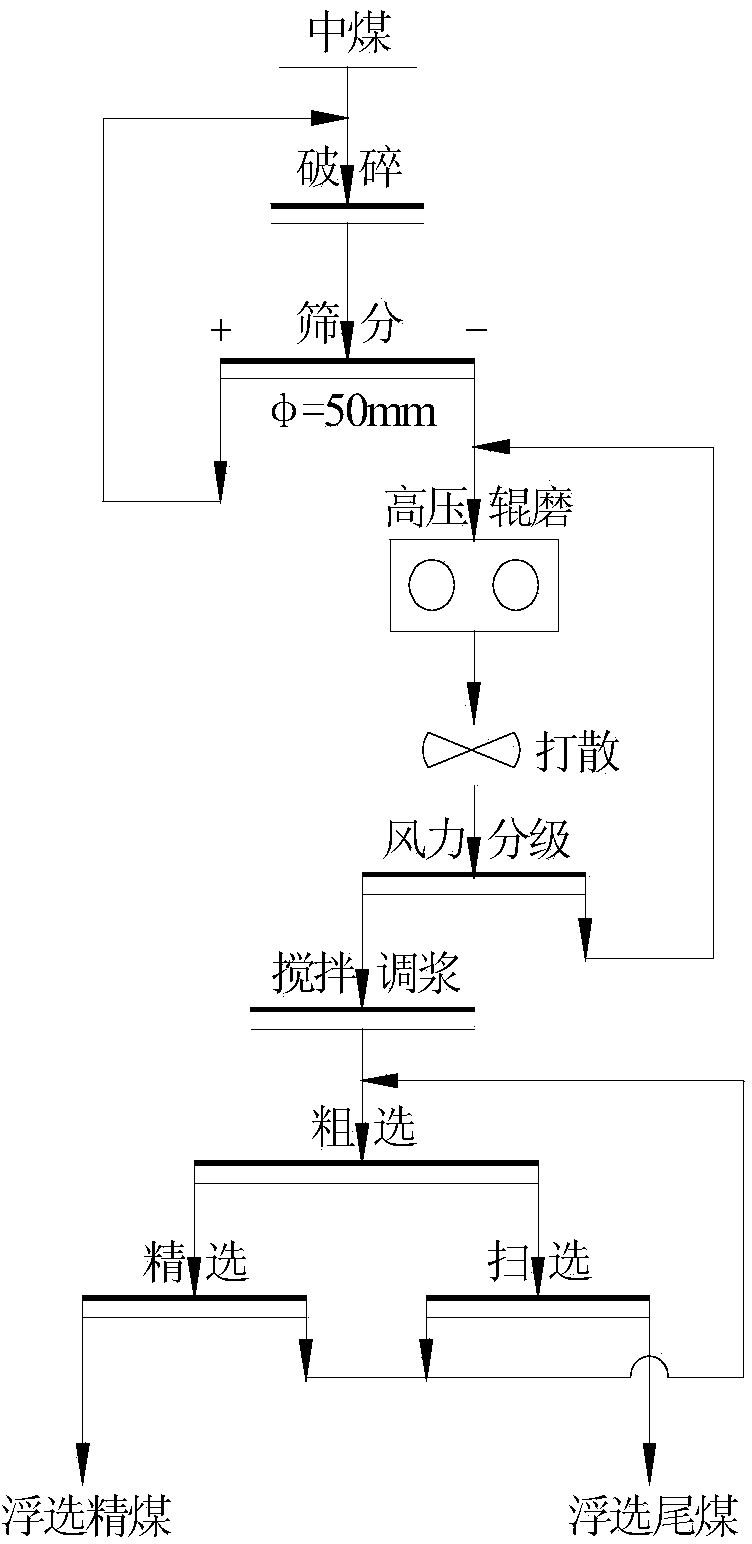

Method for smashing coal gangue through rollers at high pressure and recovering coal

InactiveCN103962230AIncrease the degree of dissociationGood re-election and flotation effectsFlotationWet separationSlagCoal gangue

The invention discloses a method for smashing coal gangue through rollers at high pressure and recovering coal. The method comprises the following steps that the coal gangue is smashed into the size below the upper limit of the feeding particle size suitable for smashing conducted by a high-pressure roller mill; high-pressure roller grinding superfine smashing is conducted on the coal gangue, de-sliming is conducted on the smashed products, the de-slimed products are reselected, and coarse cleaned coal I and gangue slag I are obtained; floatation is conducted after slurry mixing and stirring are conducted on de-slimed slime water, and floatation cleaned coal II and floatation tailings II are obtained; the coarse cleaned coal I and the floatation cleaned coal II are combined and then ground, rougher flotation, concentration and scavenging are respectively conducted on the ground products once, floatation cleaned coal and floatation tailings III are obtained, and gangue slag II is obtained after the floatation tailings II and the floatation tailings III are combined and filter-pressed; the gangue slag I and the gangue slag II are conveyed to a brick factory to serve as raw materials for making bricks or be comprehensively used. According to the method, the dissociation degree of the smashed products is high, the follow-up reselection and floatation effects are good, and therefore coal resources in the coal gangue are recycled and used fully and reasonably.

Owner:UNIV OF SCI & TECH LIAONING

Method for preparing biological feed by using waste edible mushroom rods as raw material

InactiveCN103583809ARaw material composition formula is uniqueThe preparation method is simpleFood processingAnimal feeding stuffWeedCorn stover

A method for preparing biological feed by using waste edible mushroom rods as raw material comprises the following specific steps: selecting and mixing the waste edible mushroom rods and one or more of rich-resource and low-price rural crop straws such as rice straws, wheat straws, corn straws, peanut vines, sweet potato vines, soybean straws, non-toxic weeds and broadleaf leaves, as main raw materials; blending with a small amout of concentrate material; fermenting through high-quality probiotic, namely EM, to obtain the final low-cost biological feed. Through the implementation of the method, the main raw materials, namely the waste edible mushroom rods and the crop straws, are very wide in sources, easy to collect and low in cost; besides, the waste edible mushroom rods also contain plenty of mycelia, while the mycelia contain rich protein and various amino acids; through improvement and conversion, the waste edible mushroom rods and the crop straws are prepared into comprehensive-nutrition palatable low-cost feed which can be directly absorbed by animals.

Owner:何寒

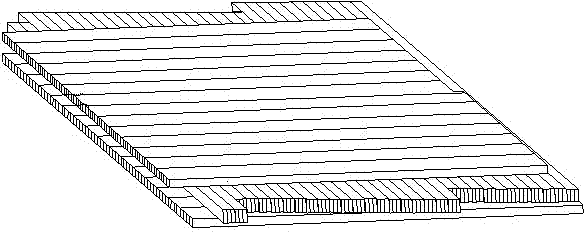

Vertical recombined hot-pressed plywood and its production method

InactiveCN102294713ANot easily deformedNot easy to delaminate and degummingWood veneer joiningWood layered productsEngineeringHot press

Vertical recombined hot-pressed plywood and its production method, the core layer of the plywood is a plurality of single layers superimposed and pasted together, and the single layers are all composed of side-by-side long strips pasted together, and the long strips are cut along the longitudinal direction. Formed by plywood, the veneer layers of the long strips in a single layer are all perpendicular to the surface layer and the bottom layer, and the angles between the strips in adjacent single layers are α, 0°

Owner:陈琳

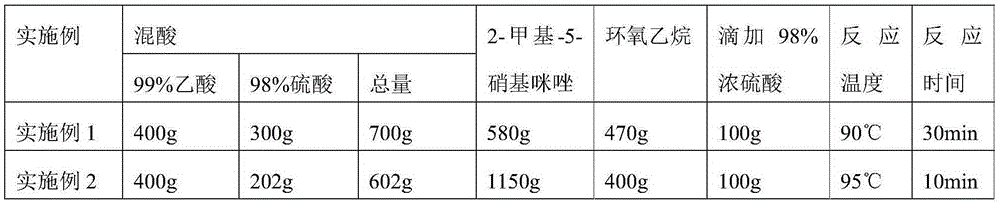

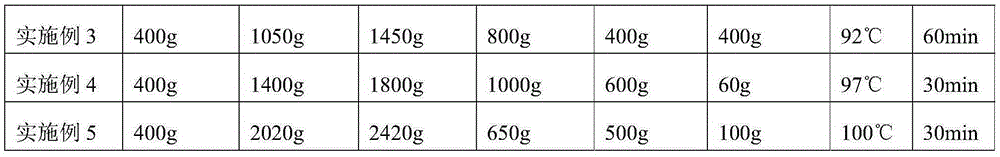

Environment-friendly method for metronidazole synthesis

The invention discloses an environment-friendly method for metronidazole synthesis. Formic acid is replaced with acetic acid, alcohol is added for esterification, neutralization is performed for three times, sodium sulfate and ethylene glycol are recovered, a nitration product is effectively recovered from a metronidazole mother solution, derivatives such as acetic ester, anhydrous sodium sulfate and the like are obtained, by-products such as ethylene glycol and the like are chemical raw materials with wide applications, resources are recycled, the raw materials are greatly saved, the production cost is reduced, and the whole novel process adopts simple steps and is convenient to operate.

Owner:WUHAN WUYAO PHARMA

Flotation activating agent of marmatite and blende and preparation method thereof

InactiveCN101816979AImprove hydrophobicitySolve the problem of activation efficiency in flotation processFlotationHigh activationSulphate Ion

The invention provides a flotation activating agent of marmatite and blende, which is a coordination compound of copper and ammonia and is characterized in that the molecular formula of the coordination compound is [Cu(NH3)x]2+, wherein X=1-8. The activating agent of the invention solves the problem of selected activation and inhibition of marmatite, overcomes the problems of low activation selection, low zinc concentrate grade, serious metal mutual containing and the like of common activating agent copper sulphate and solves the problems of high-efficiency enrichment and comprehensive recovery of concomitant rare and noble metal. The activating agent is activated under the condition that pH value is as low as 7-11, provides necessary guarantee for reducing lime dosage in production, reasonably and effectively recovers other sulfide minerals and comprehensively recovers rare metal, and has the advantages of high activation efficiency, low production cost and the like. The invention also applies a preparation method for the flotation activating agent.

Owner:KUNMING UNIV OF SCI & TECH

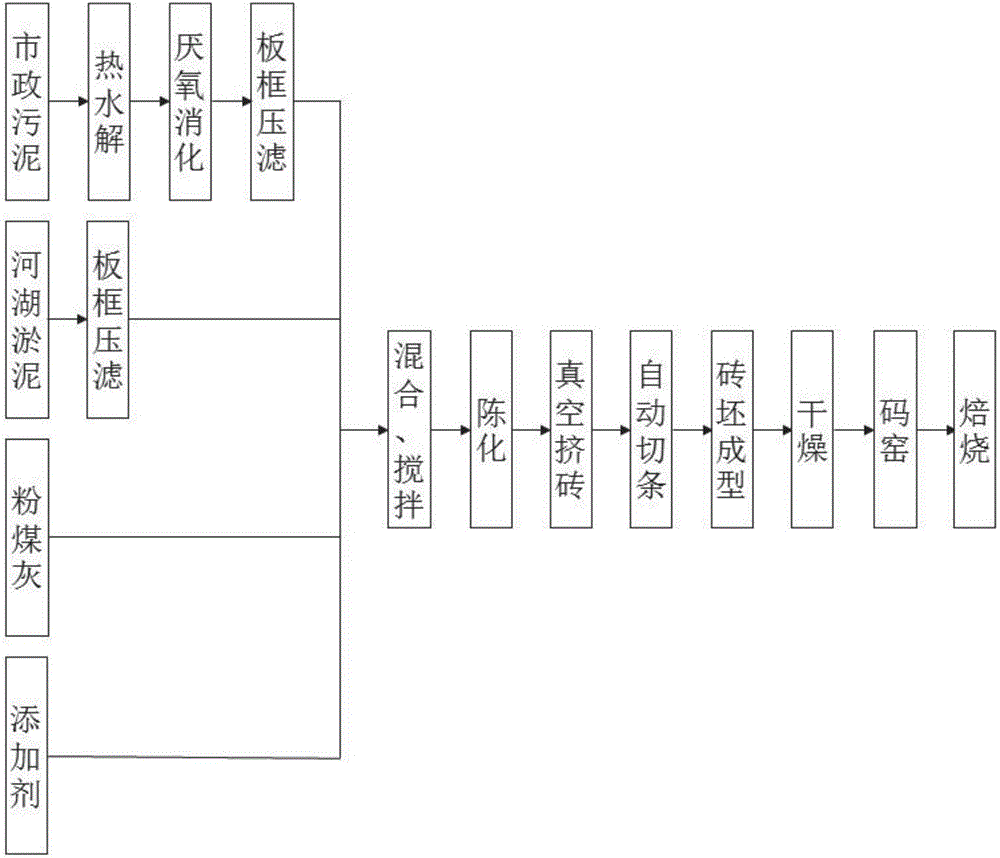

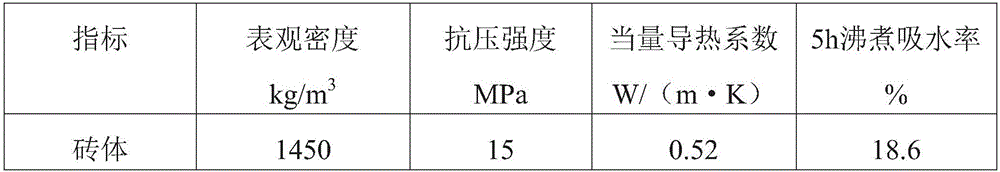

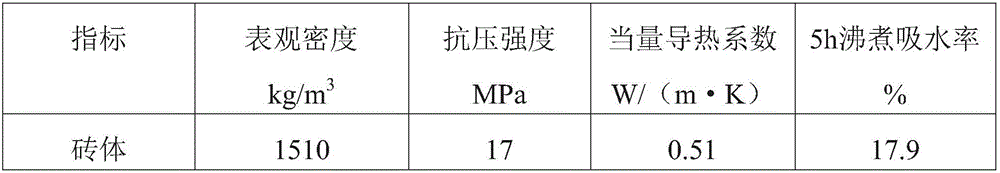

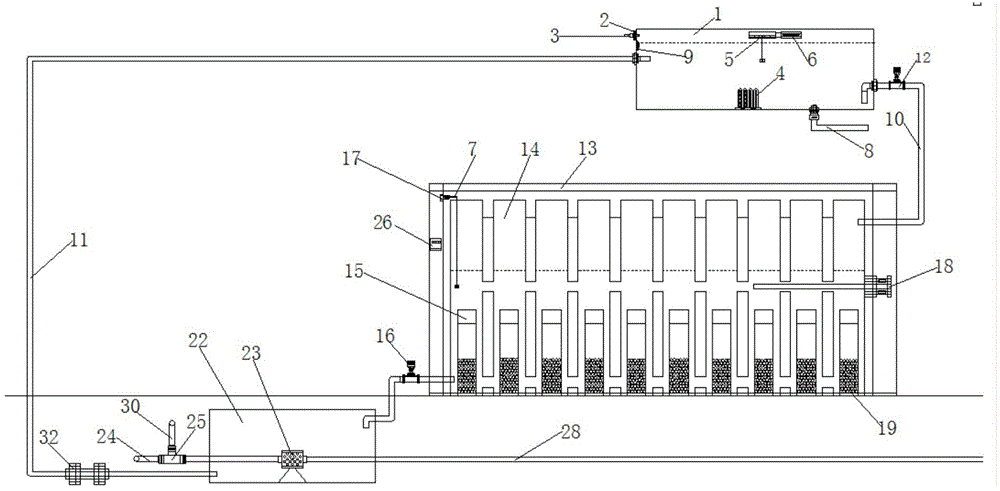

Mud and sludge sintered brick and preparation method thereof

InactiveCN106747314ASolve the way outRealize resource utilizationSludge treatment by pyrolysisWaste based fuelBrickResource utilization

The invention discloses a mud and sludge sintered brick, which is prepared from the following sintering raw materials in mass fraction according to the oven dry weight: 30 percent to 45 percent of municipal mud sequentially subjected to pyrohydrolysis pretreatment and anaerobic digestion treatment, 35 percent to 60 percent of river sludge with the solid content being 60 to 70 percent, 5 percent to 10 percent of pulverized fuel ash and 5 percent and 10 percent of additive. The invention also discloses a preparation method of the mud and sludge sintered brick. The preparation method comprises the steps of pretreating the municipal mud, pretreating the river sludge, preparing a mixture, forming a green brick, drying, roasting to obtain a finished product, and the like. According to the mud and sludge sintered brick and the preparation method thereof provided by the invention, the digested mud and the dried river sludge are mixed to prepare the sintered brick, so that not only are the problems of the two kinds of sludge solved, but also the secondary pollution problem produced by stacking of the two kinds of sludge is solved, and the resource utilization of the mud and the sludge is realized. The sintered brick prepared through the invention has no crack, no unfilled corner and no pressing marks on the appearance, and has better physical and mechanical properties.

Owner:上海同济普兰德生物质能股份有限公司

Method for preparing iodized salt from iodine-contained absorption solution

ActiveCN102502504AEasy to makeReasonable recyclingIodide preparationLithium halidesHydroiodic acidMother liquor

The invention discloses a method for preparing iodized salt from iodine-contained absorption solution, which comprises the following operation steps of: reducing a free iodine elementary substance in the iodine-contained absorption solution into an iodide ion with a reducing agent, adding an appropriate amount of barium carbonate to convert a sulfate ion in a solution system into barium sulfate and adding alkali or salt being capable of reacting with hydroiodic acid into a filtrate after filtration to obtain required iodized salt solution; and obtaining the corresponding iodized salt in concentration and crystallization manners. The method has the beneficial effects that the complicated process of preparing the iodized salt by utilizing iodine is avoided, the process flow is shortened, and meanwhile, a large quantity of energy sources can be saved; intermediate body hydroiodic acid is taken as a raw material to prepare the iodized salt by utilizing an iodine recovery process, the raw material is easily obtained, and obtained mother liquid after concentration and crystallization can be directly returned to an iodine recovery device, so that the sources are reasonably recycled; and the preparation process of the iodized salt is simple, and products after concentration and crystallization have good quality and high product yield.

Owner:WENGFU (GRP) CO LTD

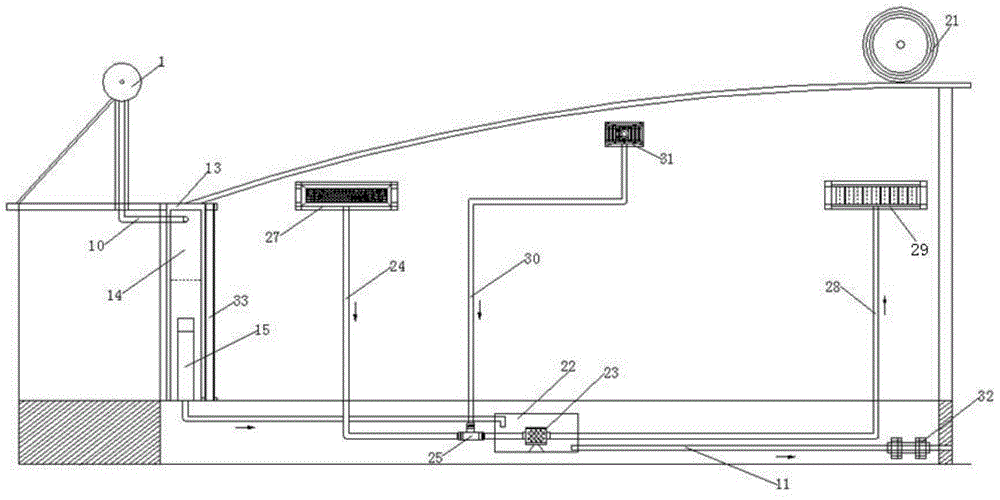

Solar water heater system capable of providing sunlight greenhouse heat-storage and ventilation functions

InactiveCN104089416AExcellent performanceStable heat storage and heat collection temperatureSolar heat devicesClimate change adaptationSolar waterEngineering

The invention discloses a solar water heater system capable of providing the sunlight greenhouse heat-storage and ventilation functions. The solar water heater system comprises a solar heat collecting water tank, a phase change heat storage wall and a heat preservation box. The water outlet end of the solar heat collecting water tank is communicated with the phase change heat storage wall, the phase change heat storage wall is communicated with the heat preservation box, the heat preservation box is communicated with the solar heat collecting water tank, and a heat source circulation loop is formed. The heat preservation box is respectively connected with an air inlet pipe and an air outlet pipe, the air inlet pipe is connected with an air inlet fan on the inner side of a sunlight greenhouse, and the air outlet pipe is connected with an air outlet fan on the inner side of the sunlight greenhouse. The solar water heater system has the advantages of being excellent in performance, safe, reliable, stable in heat storage and heat collecting temperature, high in intelligent degree, low in manufacturing cost, small in power consumption, free of pollution and the like, and heat energy can be effectively and reasonably used and recycled.

Owner:SOUTHEAST UNIV

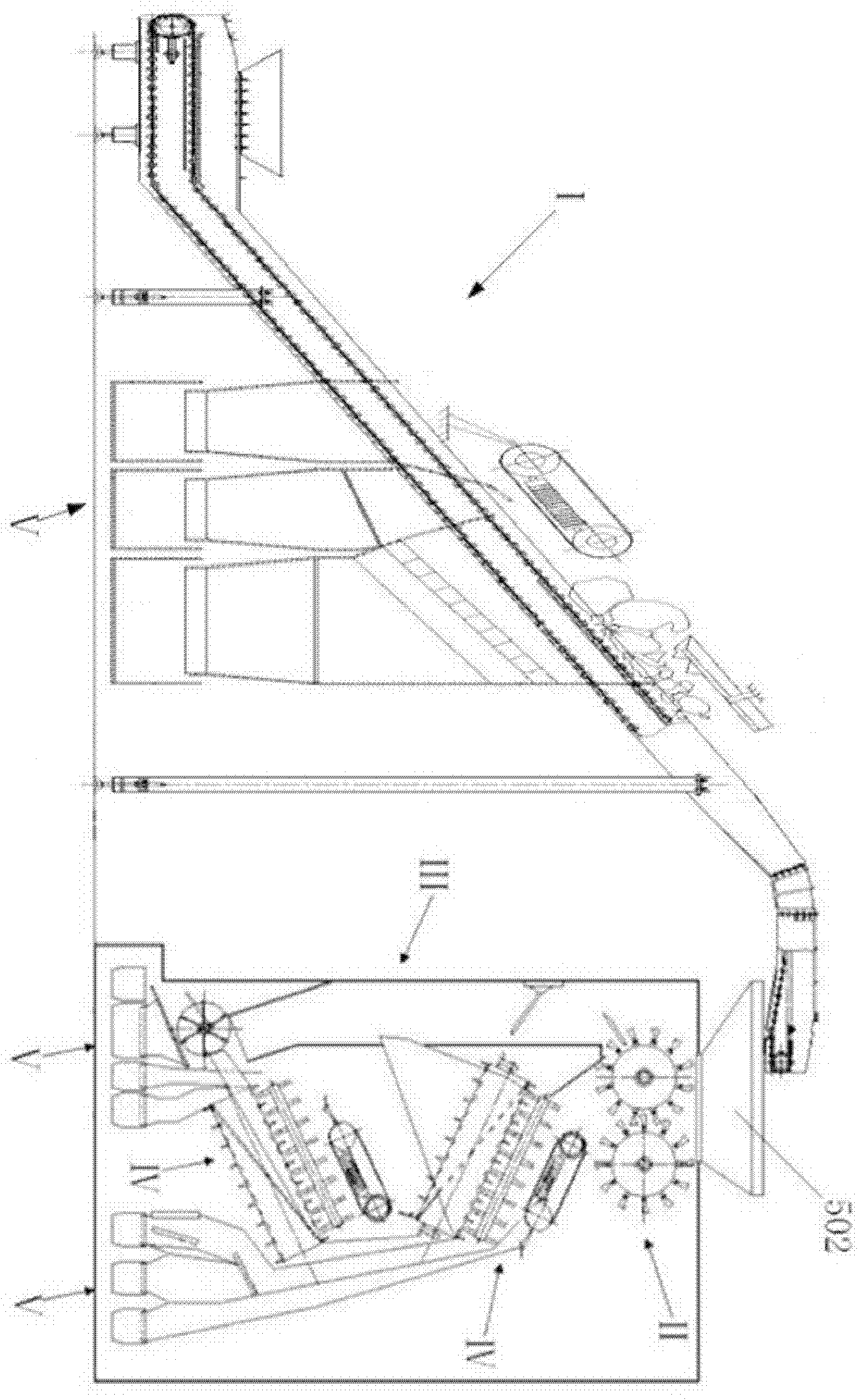

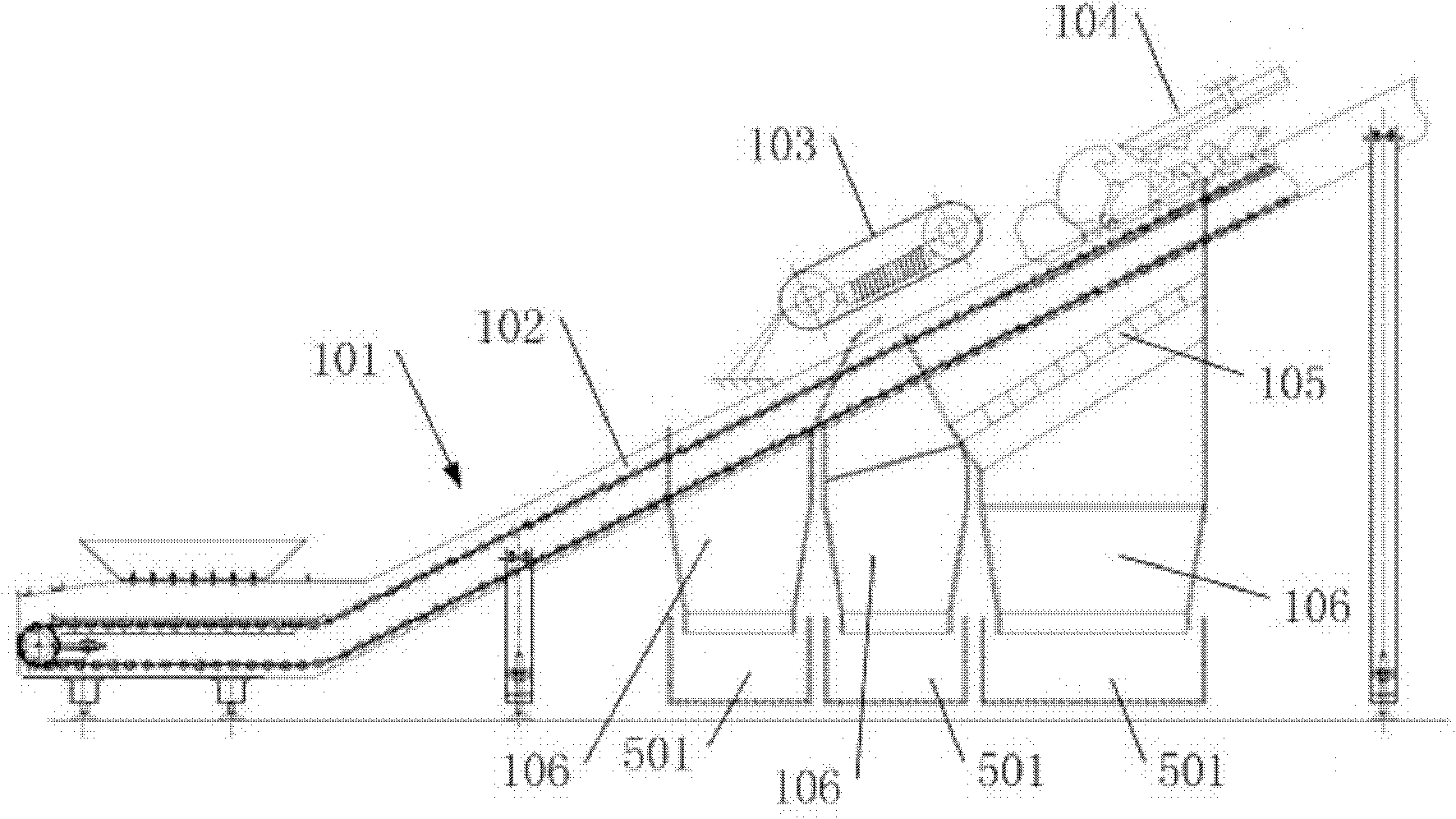

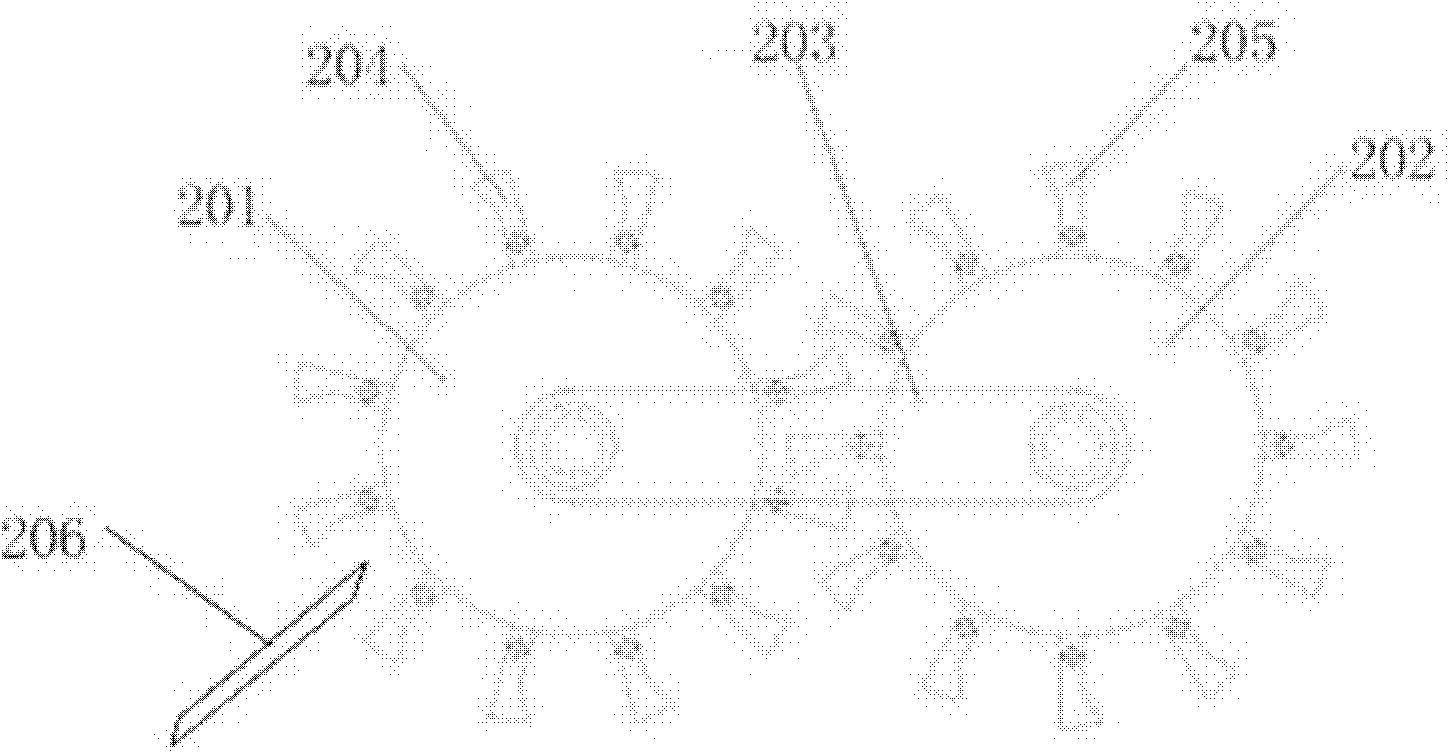

Multi-stage quick energy-saving garbage sorting system

ActiveCN102836825AReasonable recyclingLarge amount of processingGradingProcess engineeringRefuse Disposals

The invention belongs to the field of a garbage processing machine, and in particular relates to a multi-stage quick energy-saving garbage sorting system. The invention aims at providing the multi-stage quick energy-saving garbage sorting system. The technical proposal is that the multi-stage quick energy-saving garbage sorting system comprises a feeding mechanism, a roller bag breaking mechanism, a screening and classifying mechanism, a material collecting mechanism and the like, wherein a discharging end of the feeding mechanism is arranged above the roller bag breaking mechanism; the screening and classifying mechanism is arranged on the lower lateral side and / or the lower side of the roller bag breaking mechanism; the material collecting mechanism is respectively arranged on the lower side and / or the lower lateral side of the feeding mechanism, the roller bag breaking mechanism and the screening and classifying mechanism. The multi-stage quick energy-saving garbage sorting system sufficiently uses the weight of the garbage, the structure characteristic, weight characteristic, shape characteristic and material characteristic, and the like of various materials in the garbage to carryout multi-stage sorting on the garbage, thereby rationally recycling and using the garbage.

Owner:刘素华

High-pressure roller final grinding and screening method of middling coal

InactiveCN103623932ARemarkable effect of energy saving and consumption reductionIncrease the degree of dissociationFlotationWet separationChemistryEngineering

The invention discloses a high-pressure roller final grinding and screening method of middling coal, and belongs to the technical field of mineral processing. The method comprises the following steps that (1) the middling coal is crushed to be below the upper limit of the grinding particle size of a final grinding system; (2) the work parameters of a high-pressure roller mill are set, after the high-pressure roller mill idles normally, the rotating speed of a feeding belt, the rotating speed of a V type powder concentrator rotor and the rotating speed of a dust collector are set, then a spiral conveyer is started and materials are fed into a high-pressure roller mill hopper in sequence, a roller press flap valve is opened, and a high-pressure roller final grinding experiment is carried out; (3) water is added to high-pressure roller final grinding products for size mixing and stirring, the high-pressure roller final grinding products with the water are fed into flotation equipment, collecting agents and foaming agents are added in sequence to carry out roughing, fine selection and scavenging once, and flotation clean coal and flotation tailing are obtained. Compared with a traditional method that flotation is carried out after the middling coal is crushed and ball-milled, the dissociation degree of the products is high, the follow-up flotation effect is good, and coal resources are fully and reasonably recycled and used.

Owner:UNIV OF SCI & TECH LIAONING

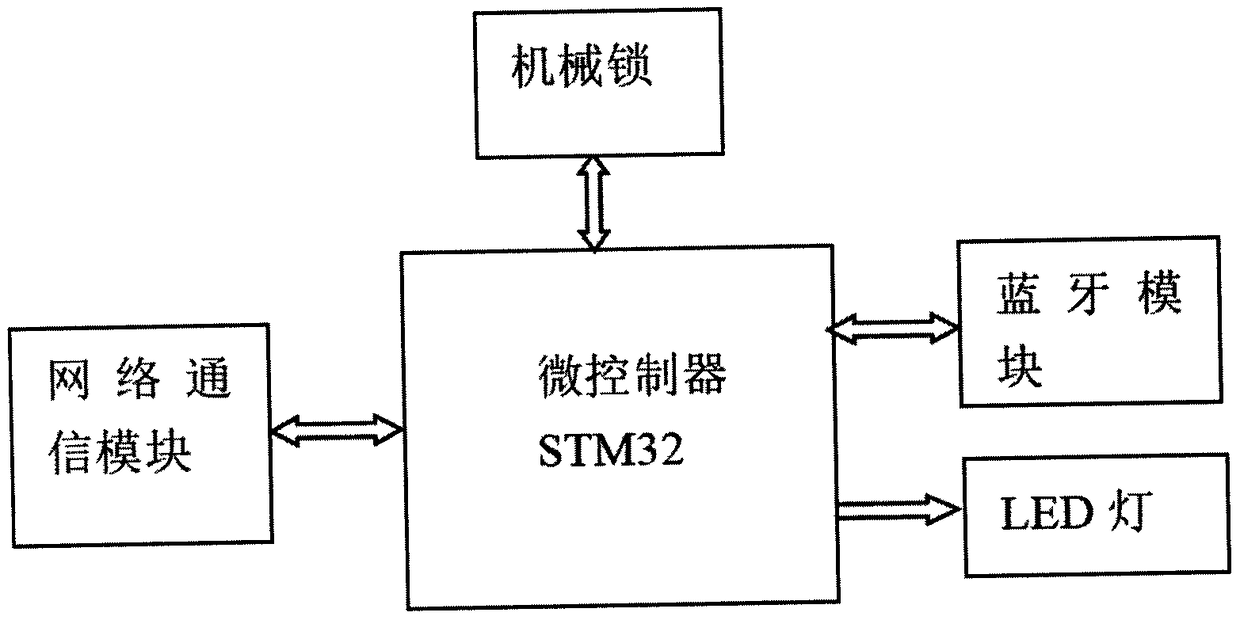

Shared bicycle temporary parking system

InactiveCN108282758AConvenience to workImprove the ride experienceTicket-issuing apparatusParticular environment based servicesMicrocontrollerSTM32

The invention relates to the filed of shared bicycles, particularly relates to a shared bicycle temporary parking system, and the system comprises a microcontroller STM32, a Bluetooth module, a network communication module and a mechanical lock. The microcontroller, the Bluetooth module and the network communication module can realize data interaction of a cloud server, a mobile phone and a sharedbicycle lock. The microcontroller also can perform real-time monitoring for vehicle information. The temporary parking system supports entering temporary parking by a key of the mechanical lock, alsosupports entering a temporary parking stage by clicking a button on a mobile phone APP, also supports canceling a temporary parking state by the mobile phone APP and simultaneously supports automatically removing and setting the temporary parking state by a control system. By the technical scheme above, better bicycling experience is provided for users, convenience is provided for city bicyclingsharing management staffs, meanwhile, legitimate interest of consumers is guaranteed, product safety of providers is also guaranteed, and bicycles are not liable to lose. So, the shared bicycle temporary parking system confirms to a life idea of cyclic utilization and green travel of sharing economy.

Owner:成都思为交互科技有限公司

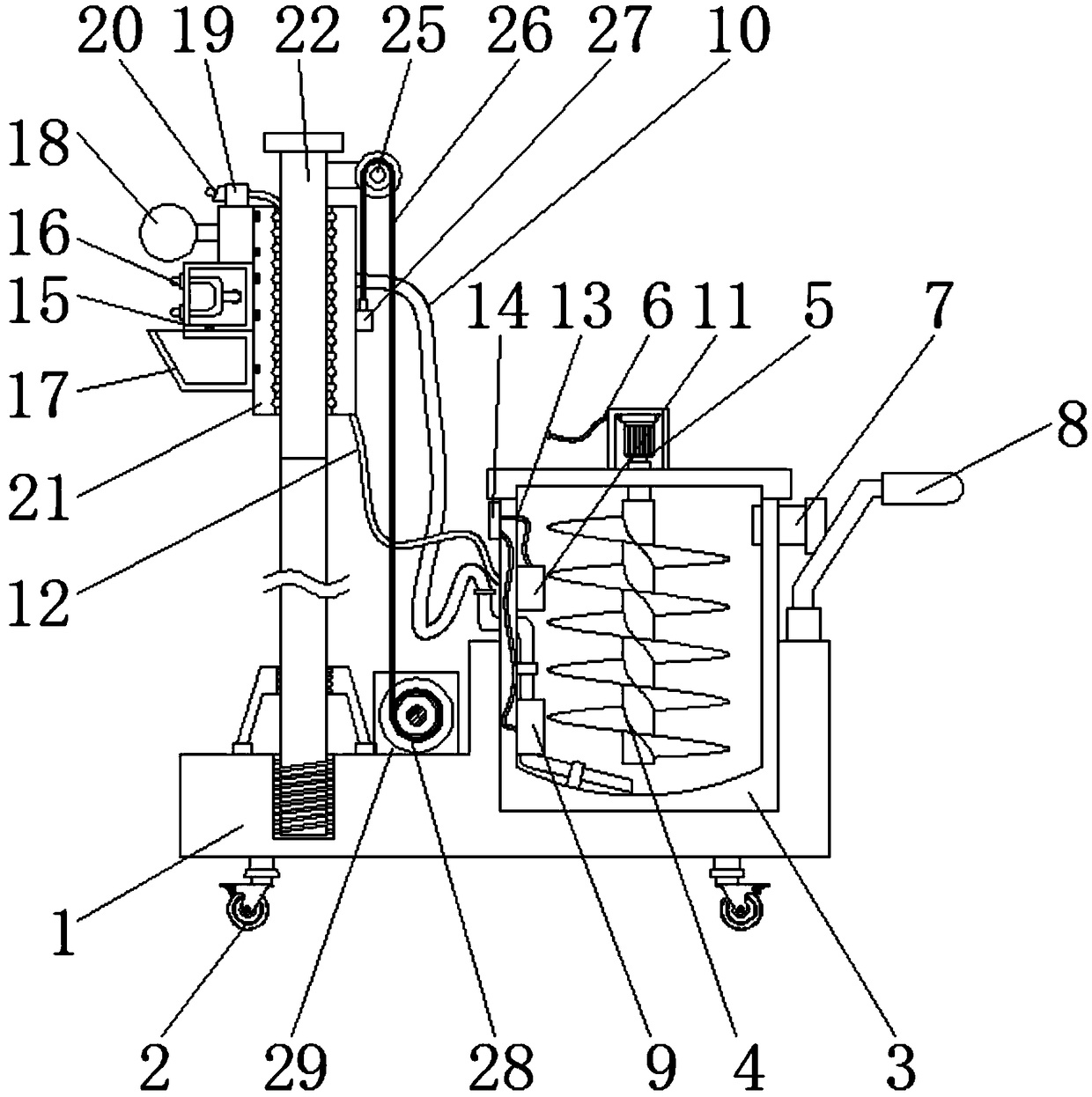

Indoor wall surface water-based environment-friendly coating spraying device facilitating high-place operation

The invention discloses an indoor wall surface water-based environment-friendly coating spraying device facilitating high-place operation. The indoor wall surface water-based environment-friendly coating spraying device comprises a base, a feeding inlet and a supporting rod; universal wheels are connected to the lower surface of the base in a welded mode, a vertical rod is arranged at the center in a storage box, the feeding inlet is located in the right side of the upper end of the storage box, a push rod is connected to the upper end of the right side of the base in a welded mode, a first booster pump is fixedly mounted on the left side surface inside the storage box, the supporting rod is in threaded connection with the interior of the left end of the base, and the outer side of the upper end of the supporting rod is in nested connection with a fixing cylinder; and the head end of a traction rope is fixedly connected to a second fixing block, the tail end of the traction rope is coiled on the outer side of a winding reel, and a storage battery is fixedly mounted at the right end of a second motor. The indoor wall surface water-based environment-friendly coating spraying device facilitating high-place operation sprays the wall surface at the high place conveniently, waste of coating is avoided, and spraying is uniform enough.

Owner:魏涛

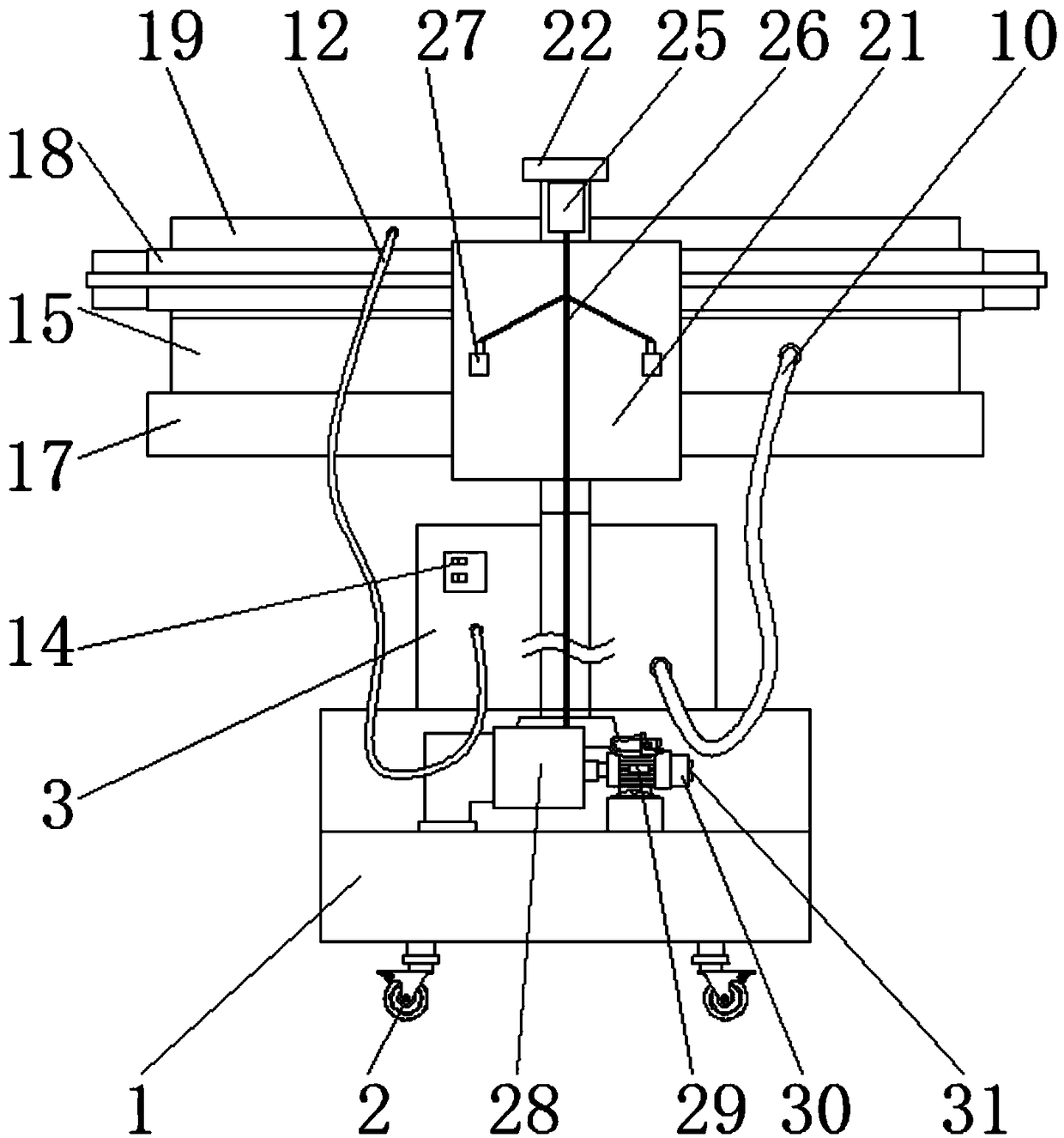

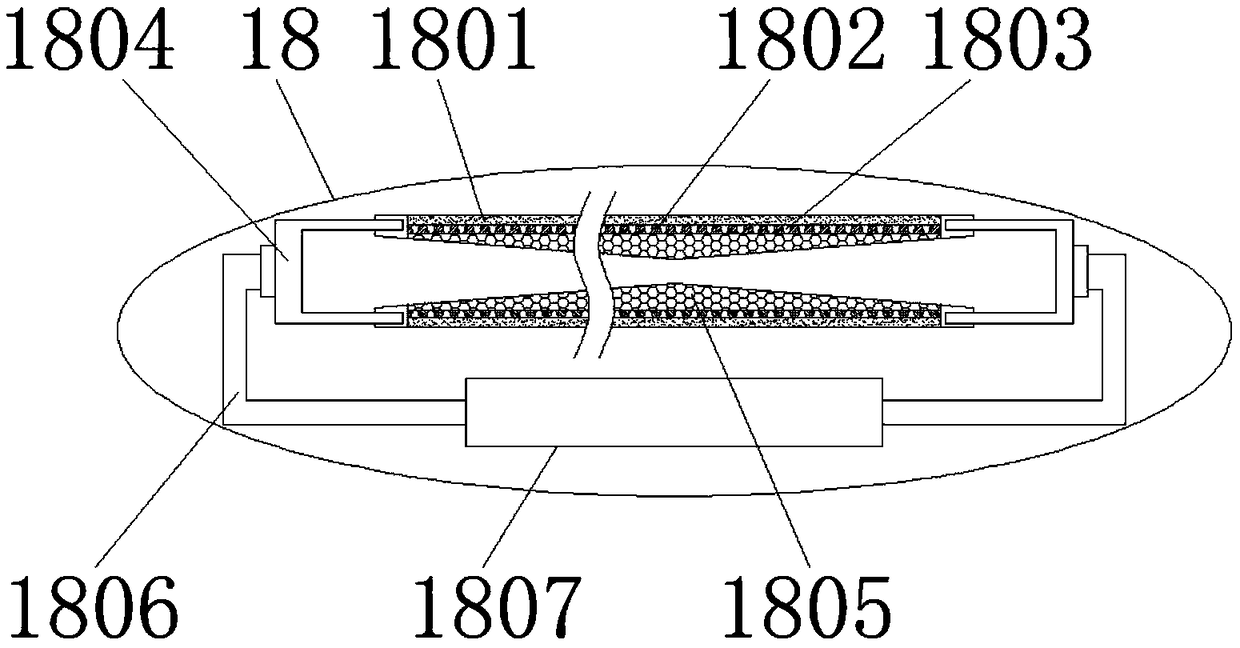

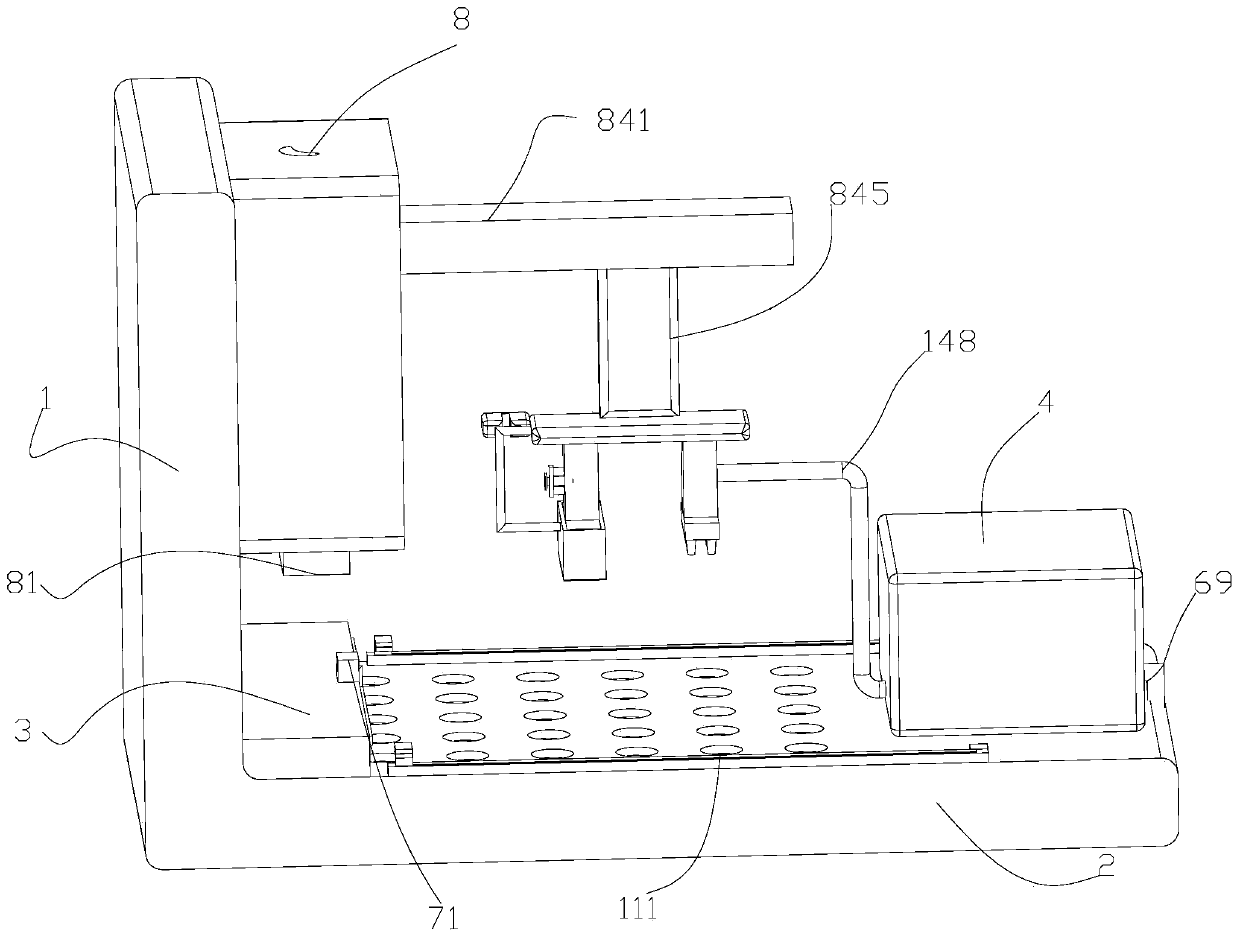

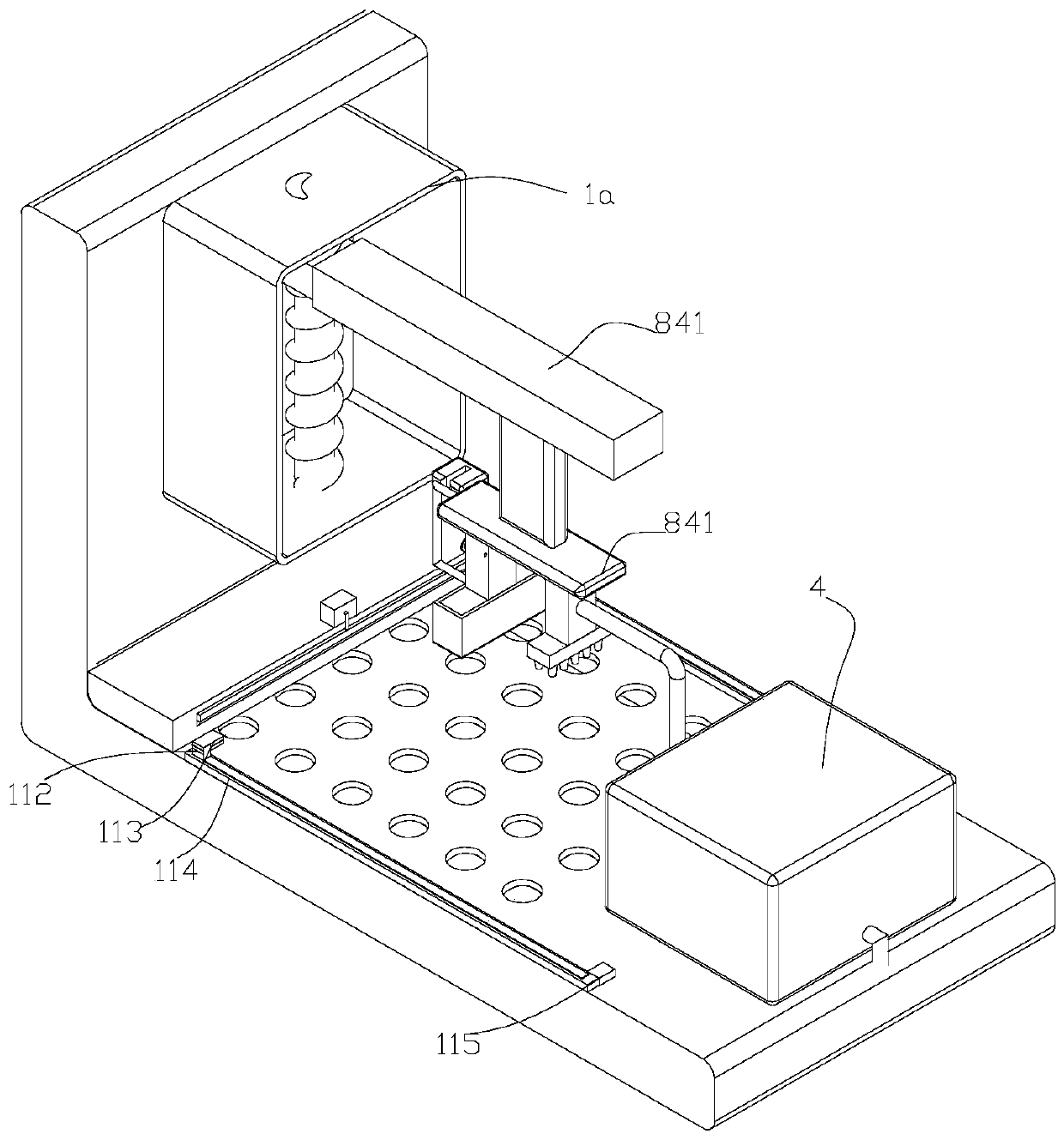

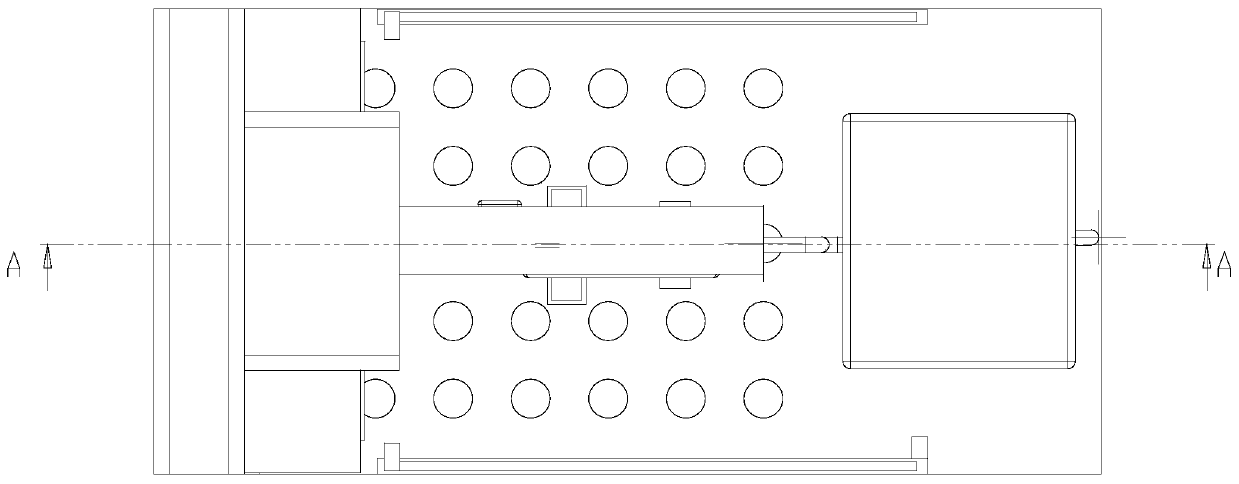

Automatic coating device

ActiveCN111515075APrecise positioningRise steadilyLiquid surface applicatorsSpraying apparatusElectric machineryEngineering

The invention discloses an automatic coating device. The automatic coating device comprises a vertical plate, a transverse plate arranged at the lower portion of the vertical plate, a material distribution box arranged on the left side of the upper portion of the transverse plate, a coating box arranged on the right side of the upper portion of the transverse plate, a coating recycling box arranged in the transverse plate, a moving box arranged on the right side of the vertical plate, a moving mechanism arranged in the moving box, a coating mechanism arranged in the coating box, and a cutting-off mechanism arranged on the material distribution box. The automatic coating device is characterized in that the moving mechanism comprises a first motor, a first screw rod arranged at the upper portion of the first motor, a first nut arranged at the outer portion of the first screw rod in a sleeving manner, and a lifting part arranged on the right side of the first nut, wherein the first nut can move vertically on the first screw rod.

Owner:吴璐纯

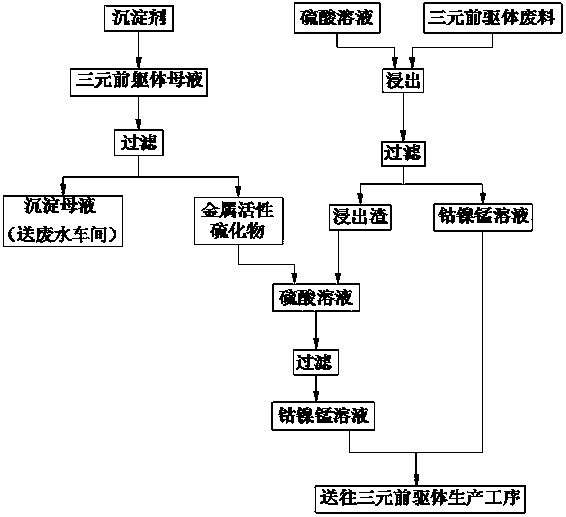

Waste recovery process in production process of nickel-cobalt-manganese ternary precursor

ActiveCN108199106AReasonable recyclingEfficient recyclingWaste accumulators reclaimingNickel compoundsManganeseCobalt

The invention discloses a waste recovery process in a production process of a nickel-cobalt-manganese ternary precursor used for recovering valuable metals, such as unqualified wastes which are not upto the product standard and ground recovered materials produced in the production process. Acid solution reaction is firstly carried out on a nickel-cobalt-manganese ternary precursor waste by usinga sulfuric acid solution to leach out acid-decomposable components in the waste; oxidation-reduction reaction is carried out on one part of acid-insoluble oxides in the nickel-cobalt-manganese ternaryprecursor waste by using the reductibility of valuable metal active sulfide recovered from precipitated mother liquor of the nickel-cobalt-manganese ternary precursor; and the waste is decomposed byfully utilizing the oxidation-reduction properties of two materials, so that the recovery target is achieved. The treatment process of combining waste residues with waste water in the production process is fully considered in the whole process reaction, so that the recovery rate of the valuable metals is improved while the production cost is reduced; the whole process is simple and control pointsare few; and other impurities are not introduced into the reaction process, so that the impurity removal process is reduced and the impurity removal cost is reduced.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com