High-pressure roller selective comminuting and magnetic separating method for lean magnetite ore

A technology of lean magnetite, magnetic separation, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of wasting manpower and financial resources, not fully excavated, lack of guiding role, etc., to save The construction cost, the magnetic separation effect is good, and the effect of shortening the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

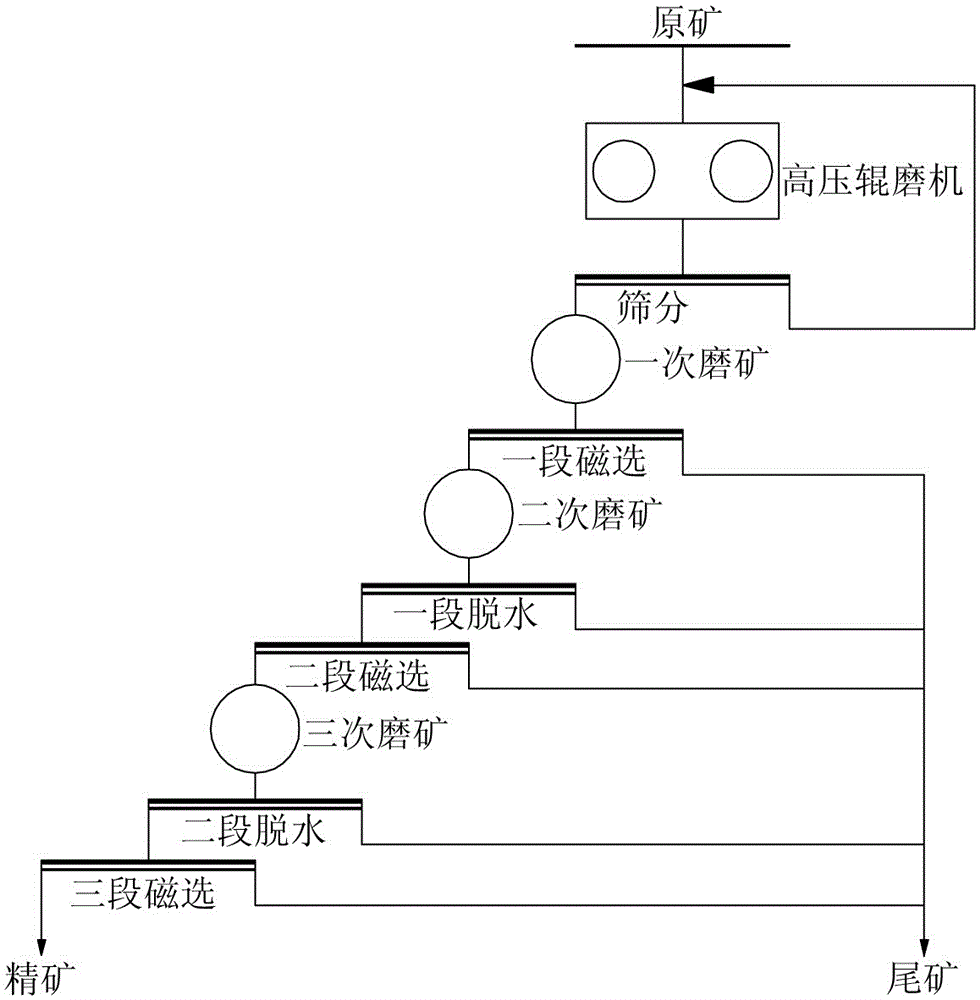

[0030] Such as figure 1 As shown, the high-pressure roller selective crushing and magnetic separation separation method of lean magnetite of the present invention is characterized in that the lean magnetite is pulverized by a high-pressure roller mill, and the pulverized product is ground, and the ground product is Carry out magnetic separation, concrete steps are as follows:

[0031] (1) Crush the raw ore to less than 20mm, and feed it into the high-pressure roller mill for ultra-fine crushing. When the high-pressure roller mill is working, the pressure between the rollers is 5MPa, the roller speed is 1.6m / min, the roller gap is 3mm, The ultra-fine crushed product is screened by a vibrating sieve with a sieve hole of 3mm, and the material on the screen is returned to the high-pressure roller mill to be combined with the new feed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com