Patents

Literature

67results about How to "Increase the degree of dissociation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of all-solid-state fluorine-containing polymer electrolyte membrane and lithium ion battery

ActiveCN109326822AImprove conductivityRetain flexibilitySolid electrolytesSecondary cellsPolymer sciencePolyethylene glycol

In order to obtain an electrolyte membrane with high electrochemical stability, the invention provides a preparation method of an all-solid-state fluorine-containing polymer electrolyte membrane, which belongs to the technical field of lithium ion batteries. The preparation method comprises the following steps: step I, adding 5 to 50 parts of fluorine-containing vinyl monomer, 40 to 80 parts of polyether monomer, and 0 to 3 parts of polyethylene glycol methyl acrylate monomer into 100 to 300 parts of solvent, continuously introducing nitrogen, stirring at a rotation speed of 100 to 800 r / min,adding 0.05 to 1.00 part of initiator, reacting for 5 to 48 hours at 60 to 110 DEG C, purifying to obtain a polymer A; step II, adding 30 to 80 parts of polymer A, 5 to 20 parts of lithium salt, and 0to 20 parts of filler and auxiliary into 100 to 300 parts of solvent, stirring at the rotation speed of 100 to 800 r / min in dry nitrogen atmosphere, stirring for 1 to 10 hours, adding 0 to 2.00 partsof hydroxyl cross-linking agent into a mixed system, uniformly smearing a mixed solution onto a special mold, and reacting for 6 to 24 hours at 60 to 100 DEG C in the nitrogen atmosphere of a vacuumdrying box; and step III, after the reaction is ended, drying for 30 to 60 hours at 90 to 98 DEG C in the nitrogen atmosphere, so as to obtain the all-solid-state fluorine-containing polymer electrolyte membrane.

Owner:ZHUHAI COSMX POWER CO LTD

Soldering flux and preparation method thereof

InactiveCN101983828AHigh activityGood welding effectWelding/cutting media/materialsSoldering mediaOrganic acidFilm-forming agent

The invention discloses a soldering flux, prepared by the following components by weight percent: 0.1-3% of organic acid activator, 0.01-2% of surfactant, 1-4% of wetting agent, 0.01-0.1% of corrosion inhibitor and 90.9-98.88% of film-forming agent. The preparation method thereof includes: (1) in weight percent, organic acid activator, surfactant, wetting agent, corrosion inhibitor and film-forming agent are accurately weighed; (2) the film-forming agent is added into a kettle with heating function and is heated to 110 DEG C, and mixing to be uniform is carried out; (3) slaw warming to 140 DEG C is carried out, the organic acid activator, surfactant, wetting agent and corrosion inhibitor are added once in ratio at 140 DEG C, and stirring is carried out for 0.5h; (4) cooling is carried out, thus obtaining the soldering flux finished product. The invention is mainly used in air conditioning and refrigeration industries, and the soldering flux can cause a welding ring to completely meet the welding requirement of the existing copper aluminium composite tube.

Owner:LICHUANG TAISHAN ELECTRONICS TECH

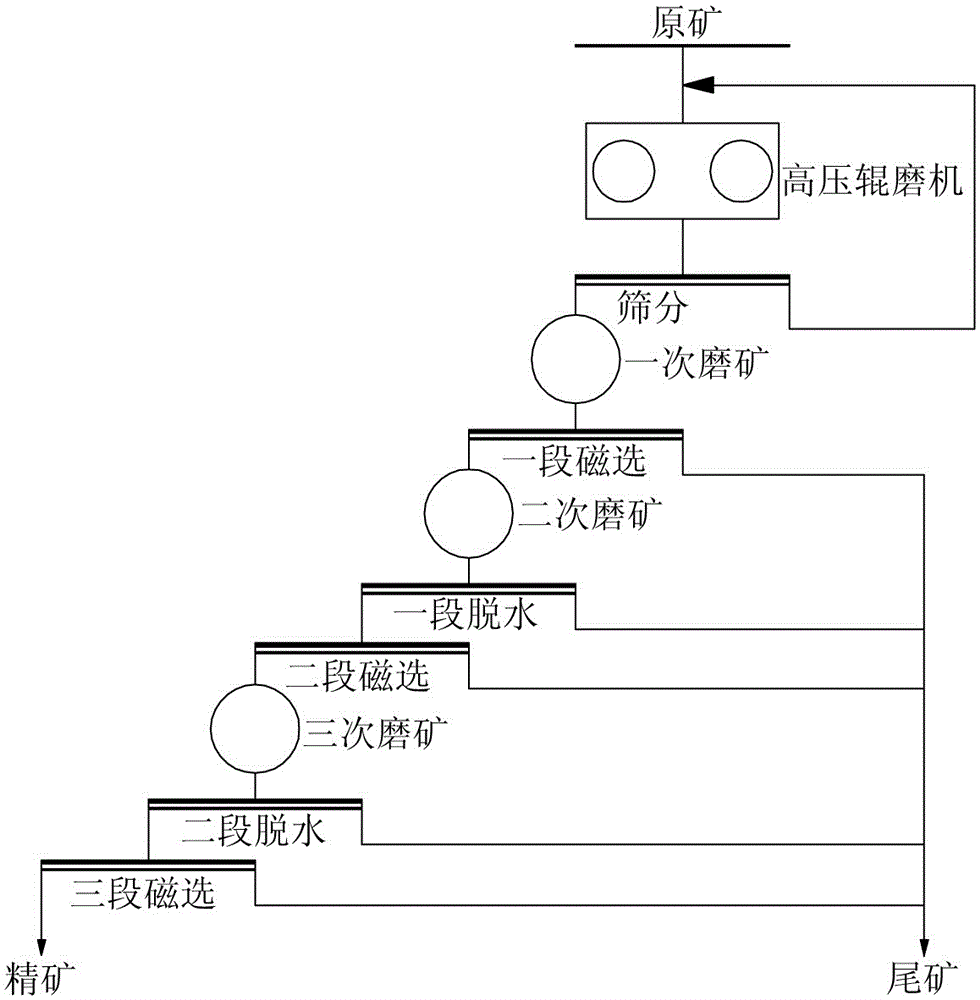

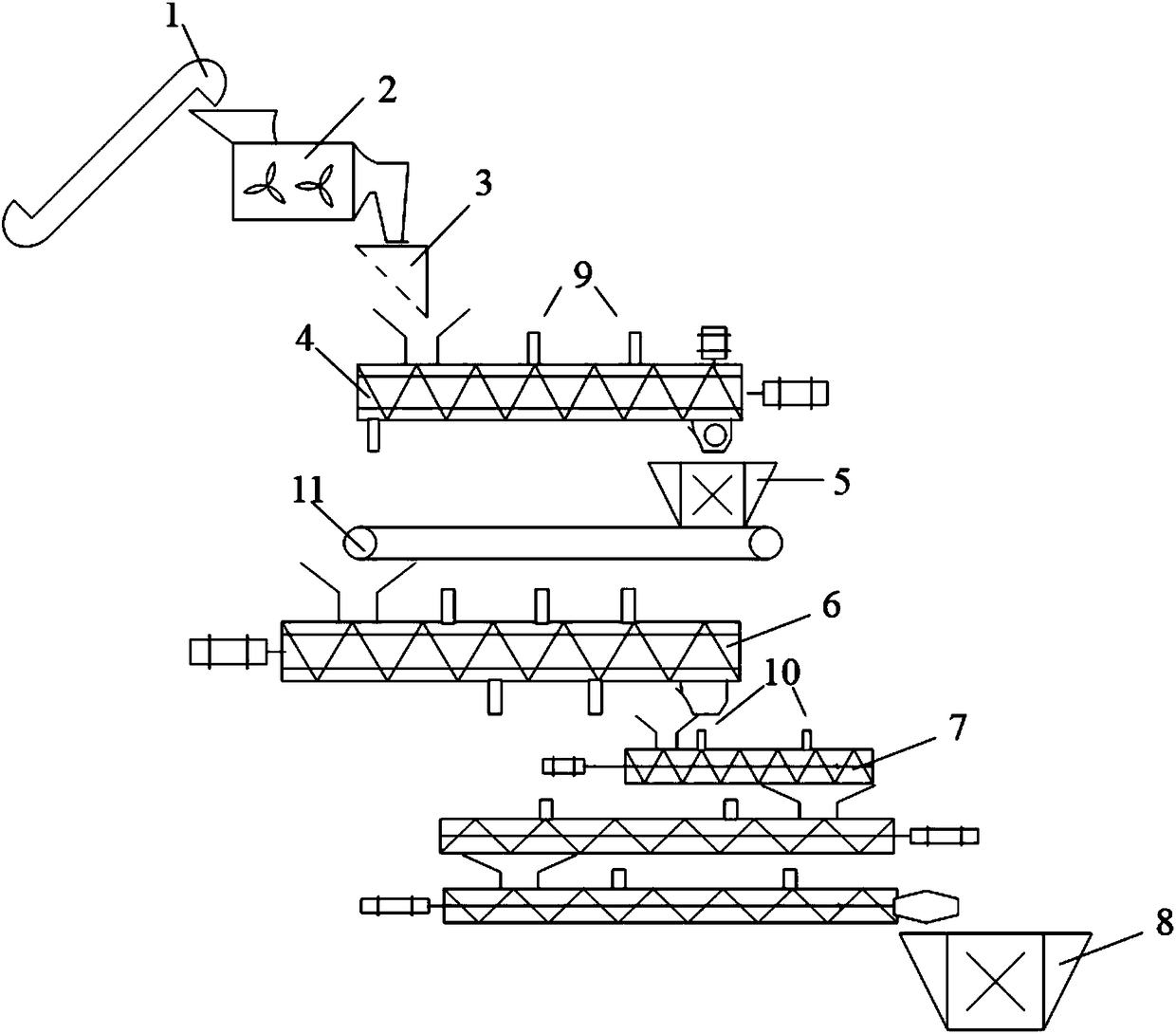

High-pressure roller selective comminuting and magnetic separating method for lean magnetite ore

The invention relates to a high-pressure roller selective comminuting and magnetic separating method for lean magnetite ore. According to the method, ultrafine crushing is conducted on raw magnetite with a grade of 28.59% by means of a high-pressure grinding roller, and three times of ore grinding, two-section dewatering and three-section magnetic separation are conducted on the crushed product to obtain concentrate with a grade of 68.23% and metal recovery rate of 82.35%. The method has the advantages that the recovery rate of the final concentrate can be increased, and efficient recovery and utilization of resources are achieved; the dissociation degree of the product is high, excessive grinding degree is low, follow-up magnetic separation effect is good, and the separation precision of equipment is improved; on the premise that the quality of the concentrate is guaranteed, concentrate recovery rate can be increased, iron ore resources can be recovered and utilized fully and reasonably, and resource waste is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Electrolyte for magnesium rechargeable battery and preparation method thereof

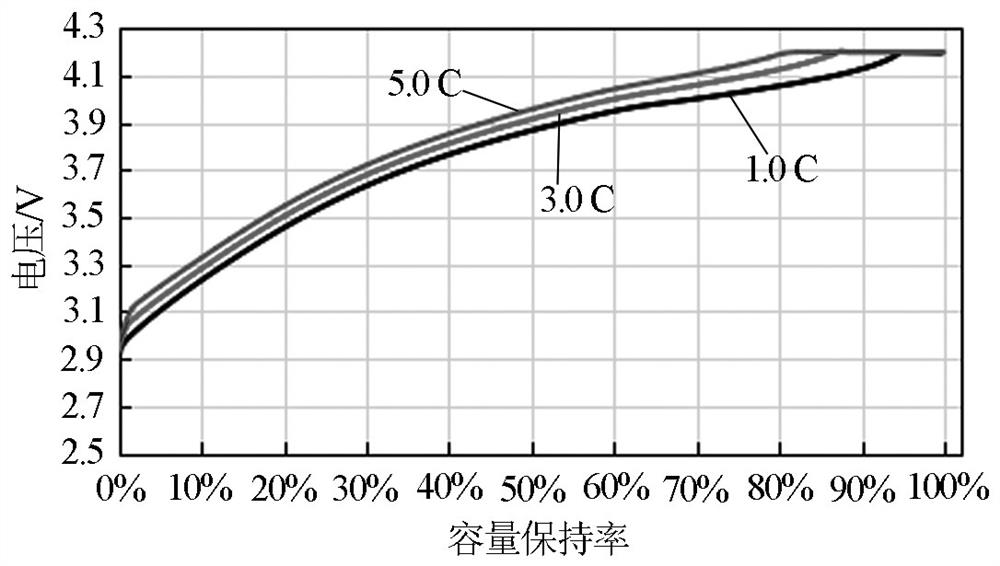

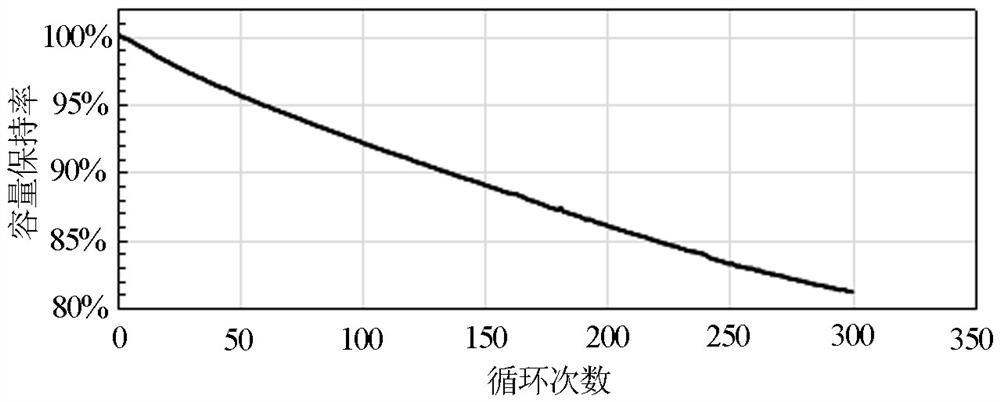

ActiveCN105322229AImprove discharge capacityImproved high-magnification performanceSecondary cellsOrganic electrolytesMetal chloridePhysical chemistry

Disclosed is an electrolyte solution for a magnesium rechargeable battery with a high ionic conductivity and a wide electrochemical window compared to the conventional electrolyte solution. The electrolyte solution is prepared by dissolving magnesium metal into the ethereal solution using combinations of metal chloride catalysts. The electrolyte solution can be applied to fabricate magnesium rechargeable batteries and magnesium hybrid batteries with a markedly increased reversible capacity, rate capability, and cycle life compared to those batteries employing the conventional electrolyte solution. Also disclosed is a method for preparing the electrolyte.

Owner:KOREA INST OF SCI & TECH

Extraction method for coconut oil

InactiveCN105238543AIncrease damageIncrease the degree of dissociationFatty-oils/fats productionEmulsionCOCONUT OIL BASE

The invention discloses an extraction method for coconut oil. The extraction method comprises the following steps: carrying out vacuum freezing and drying treatment on coconut meat; smashing the dried coconut meat; adding a compound enzyme into the mixed smashed coconut meat and water for enzymolysis treatment; carrying out centrifugalization after enzymolysis; taking upper layer grease; and carrying out vacuum drying on the upper layer grease to obtain natural coconut oil with a relatively good quality. By adopting the extraction method for coconut oil disclosed by the invention, the coconut meat obtained by adopting the vacuum freezing and drying technology is smooth and porous, and the destroy degree of coconut meat cells is improved, so that the dissociating degree of oil in the coconut meat is improved. Moreover, the water emulsion degree of the prepared coconut oil is greatly reduced, the extraction rate of the coconut oil is improved in a condition that the natural components of the coconut meat is not destroyed, the prepared coconut oil is excellent in quality, low in cost and pollution-free, and the prepared coconut oil product is harmless to human body and has a good application prospect.

Owner:HAINAN UNIVERSITY

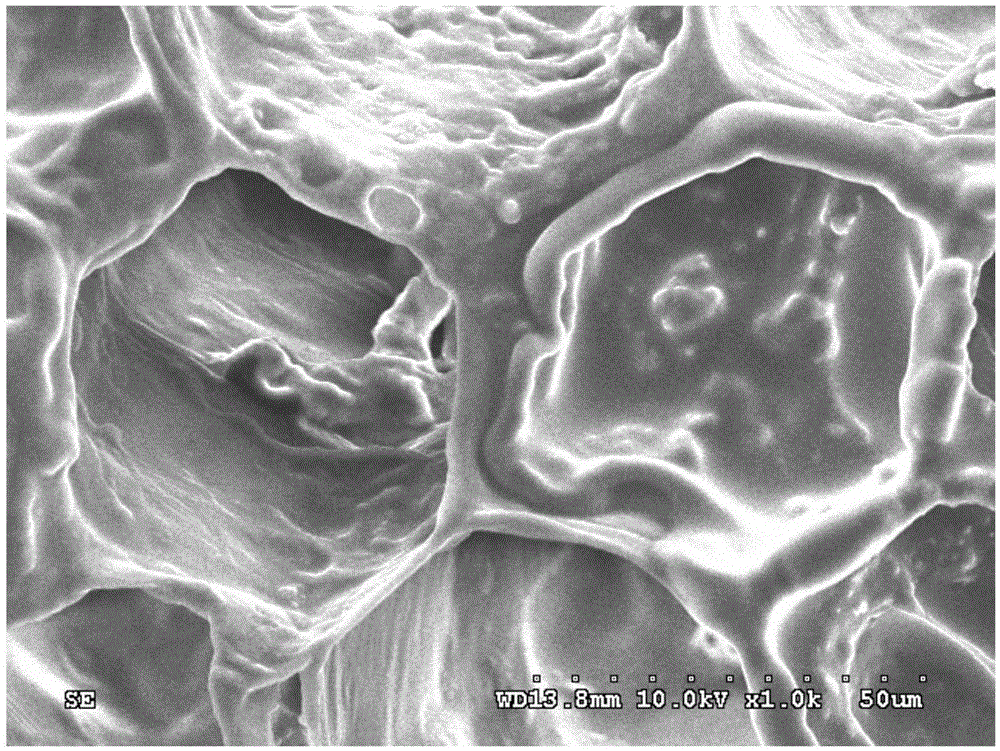

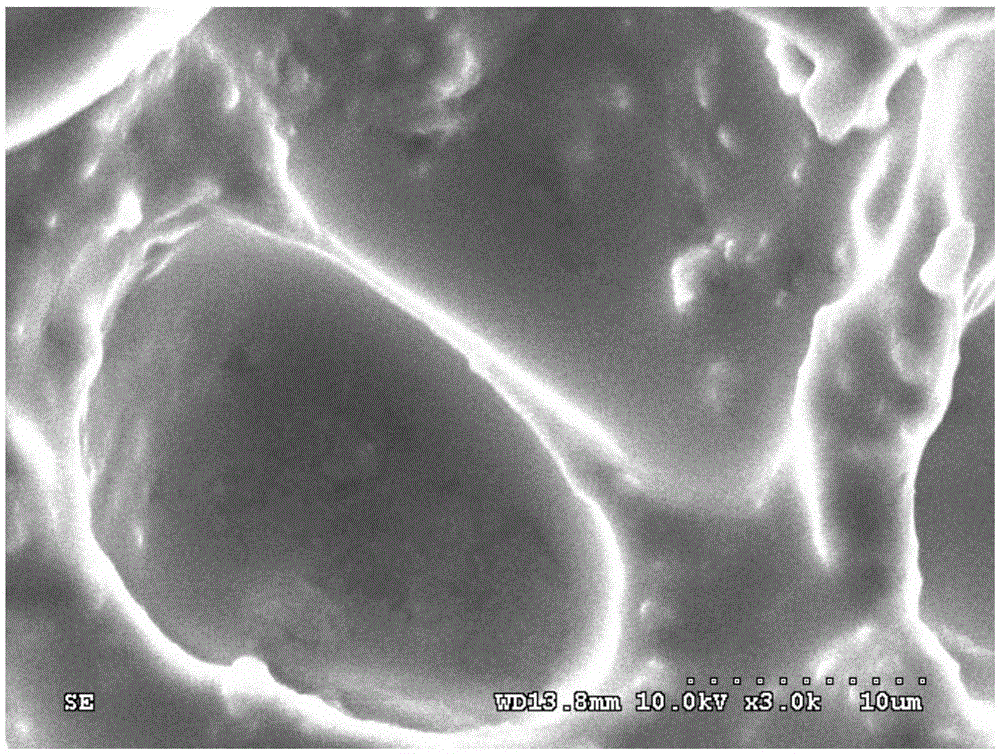

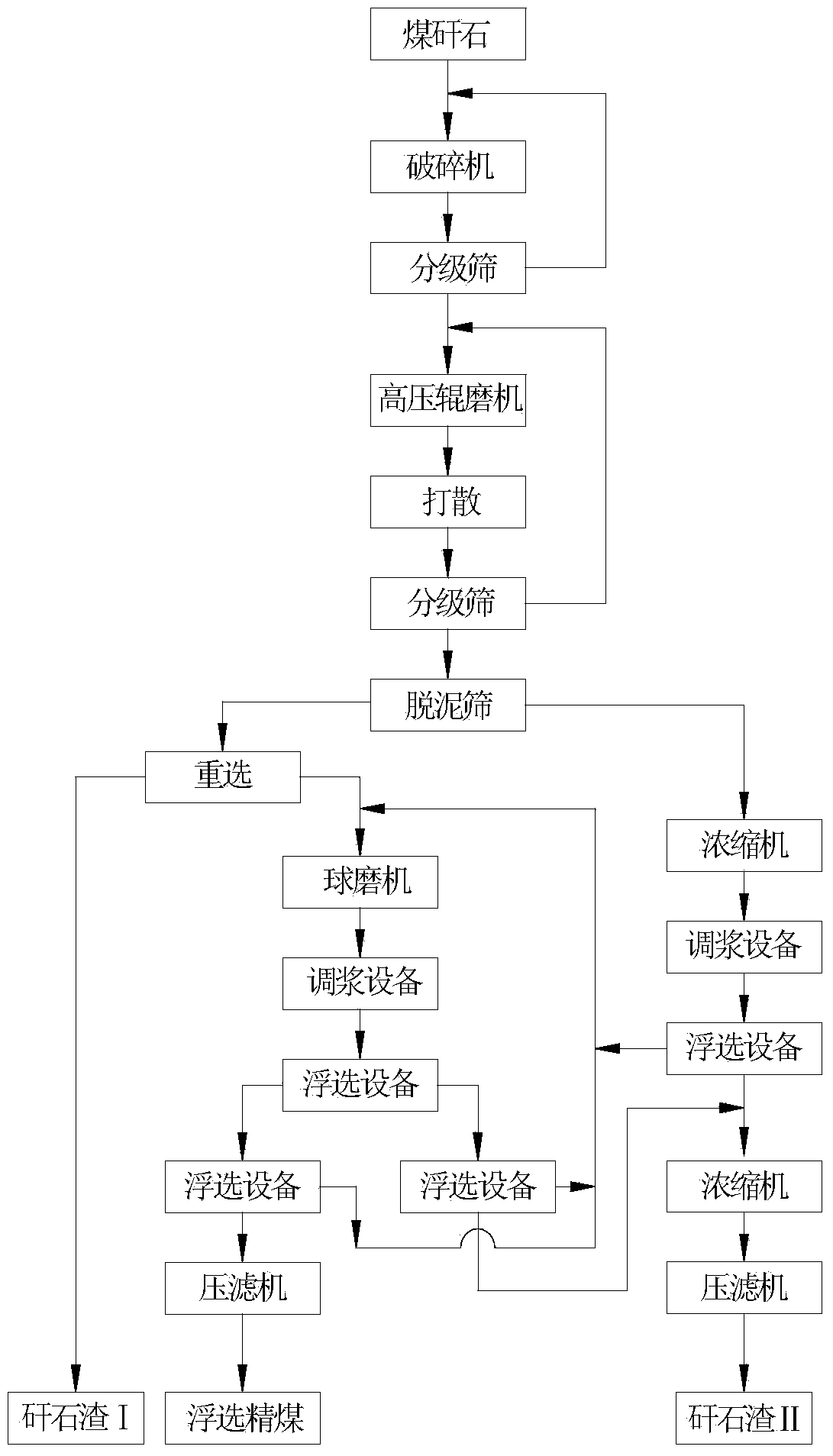

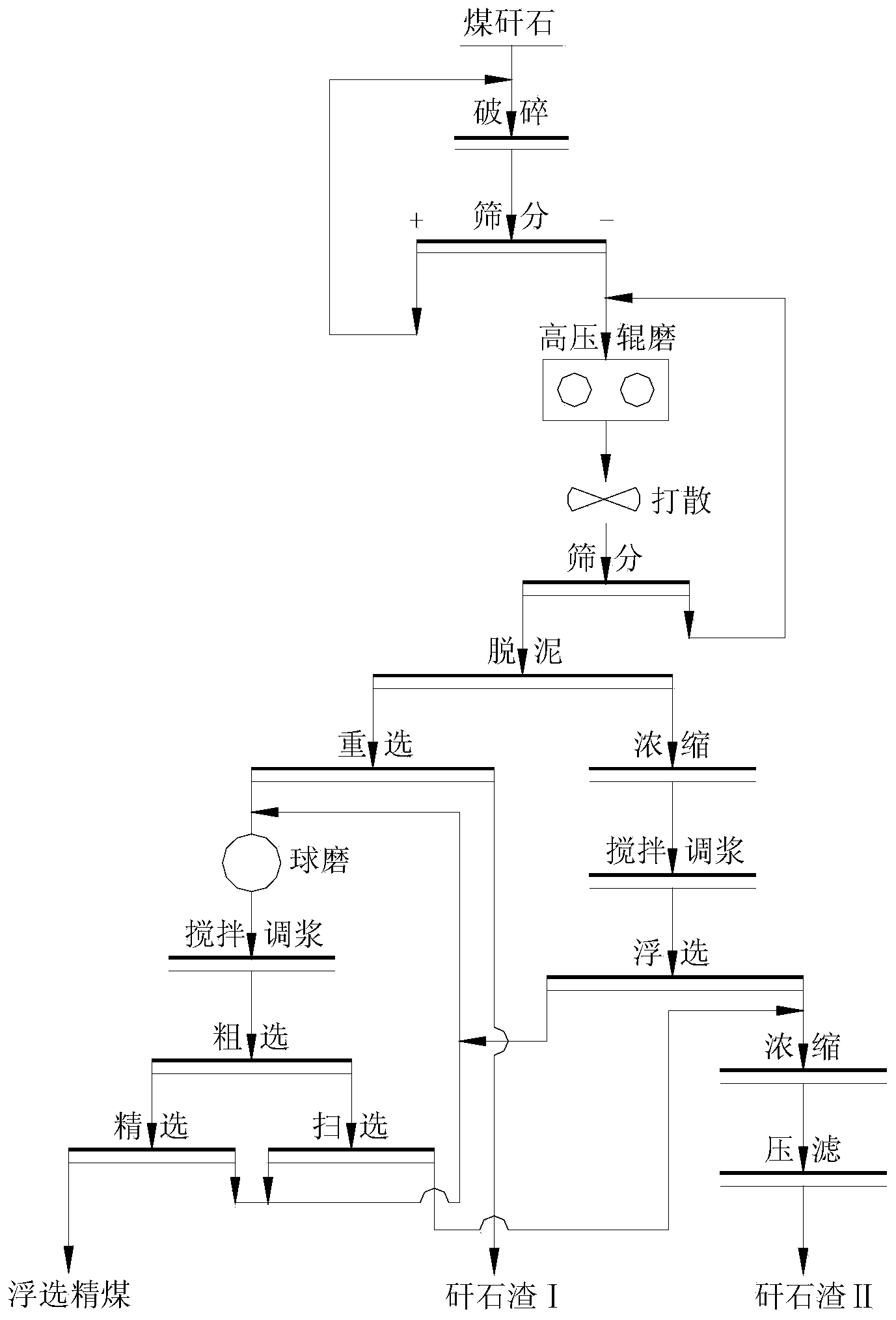

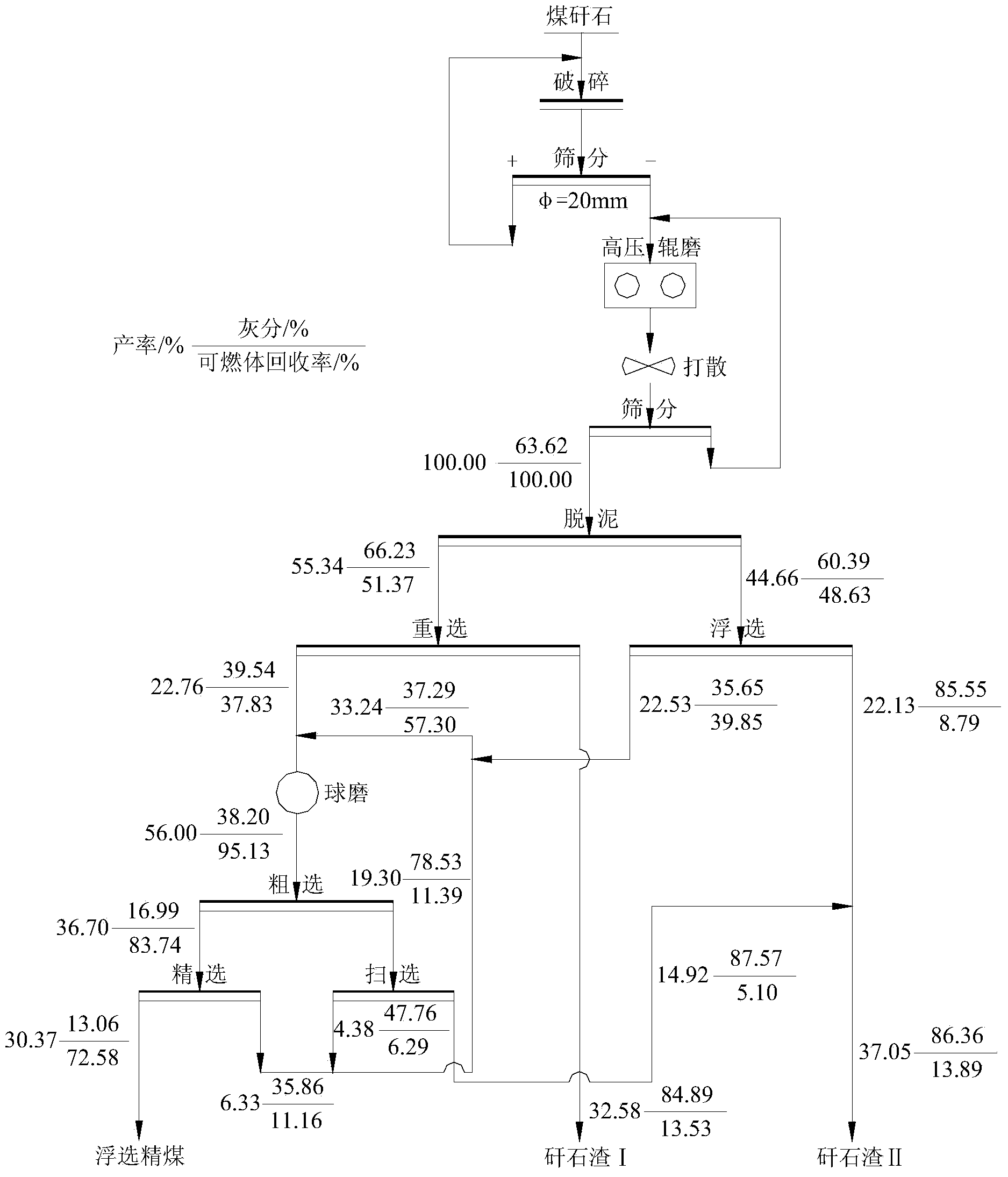

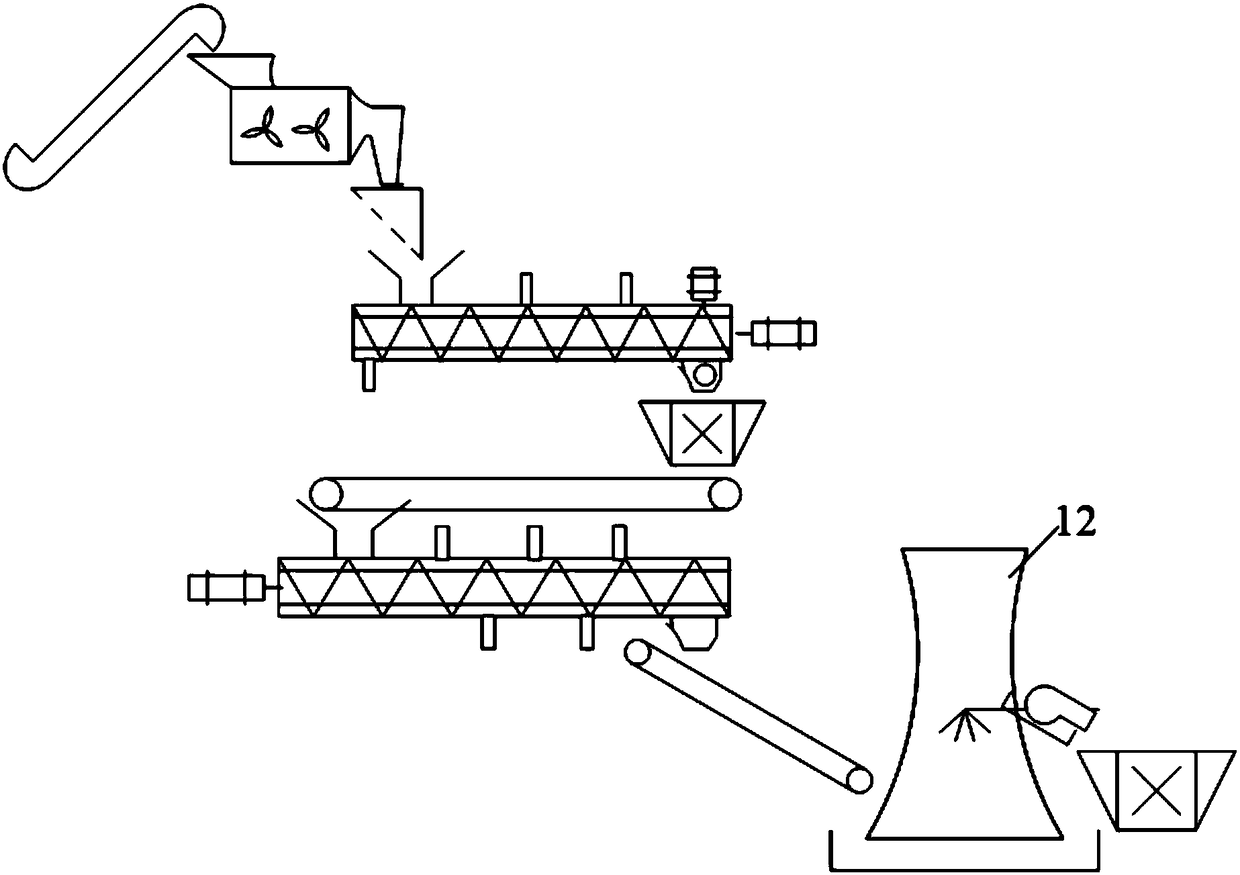

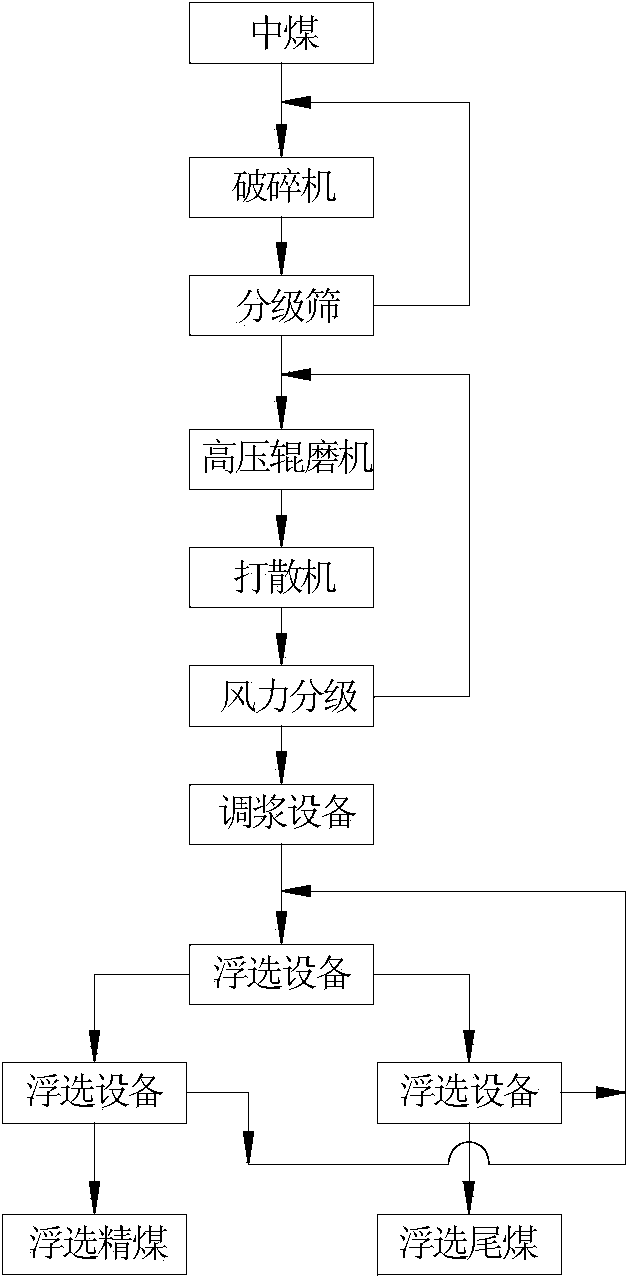

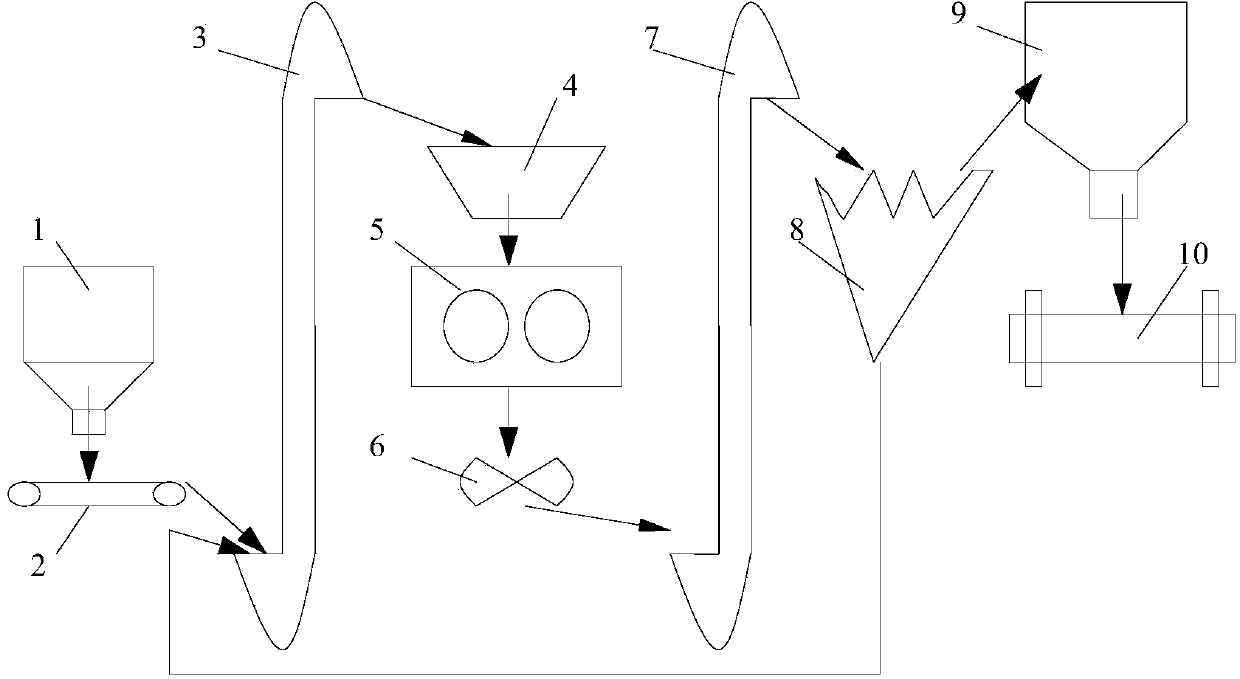

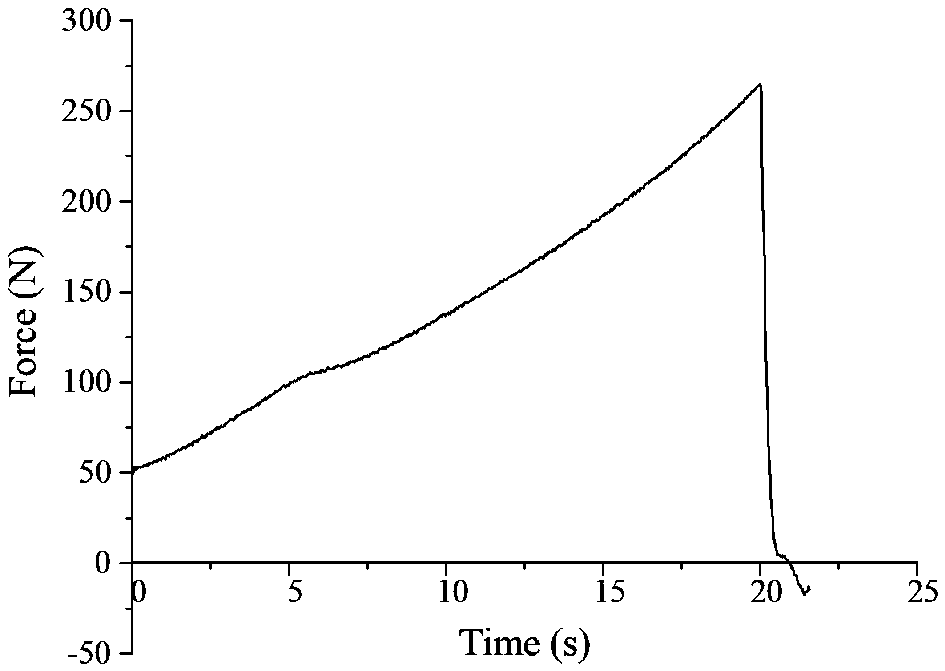

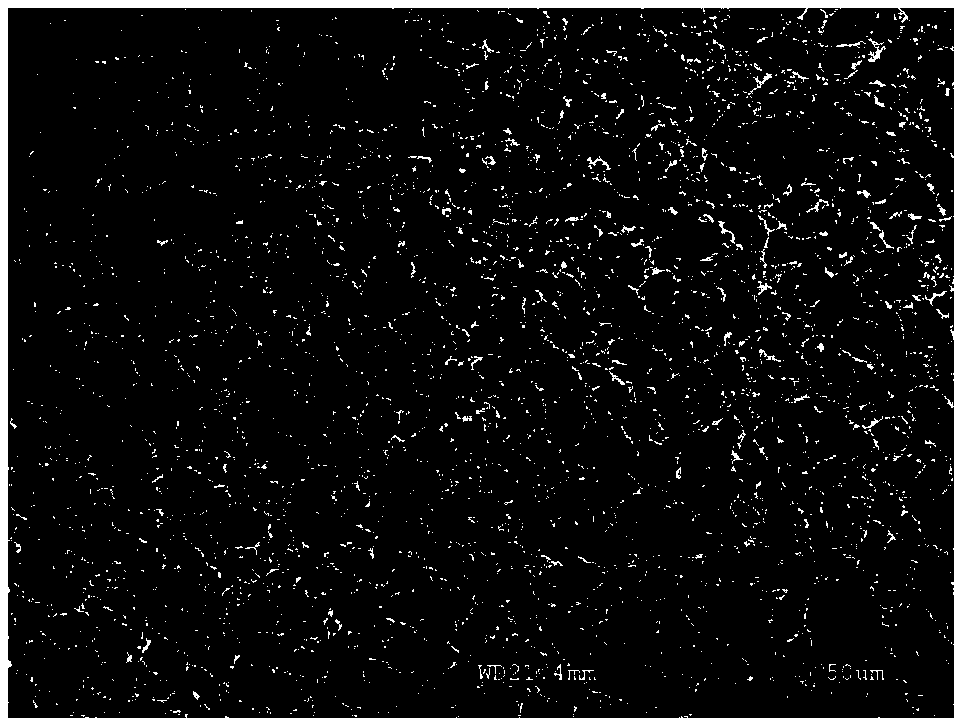

Method for smashing coal gangue through rollers at high pressure and recovering coal

InactiveCN103962230AIncrease the degree of dissociationGood re-election and flotation effectsFlotationWet separationSlagCoal gangue

The invention discloses a method for smashing coal gangue through rollers at high pressure and recovering coal. The method comprises the following steps that the coal gangue is smashed into the size below the upper limit of the feeding particle size suitable for smashing conducted by a high-pressure roller mill; high-pressure roller grinding superfine smashing is conducted on the coal gangue, de-sliming is conducted on the smashed products, the de-slimed products are reselected, and coarse cleaned coal I and gangue slag I are obtained; floatation is conducted after slurry mixing and stirring are conducted on de-slimed slime water, and floatation cleaned coal II and floatation tailings II are obtained; the coarse cleaned coal I and the floatation cleaned coal II are combined and then ground, rougher flotation, concentration and scavenging are respectively conducted on the ground products once, floatation cleaned coal and floatation tailings III are obtained, and gangue slag II is obtained after the floatation tailings II and the floatation tailings III are combined and filter-pressed; the gangue slag I and the gangue slag II are conveyed to a brick factory to serve as raw materials for making bricks or be comprehensively used. According to the method, the dissociation degree of the smashed products is high, the follow-up reselection and floatation effects are good, and therefore coal resources in the coal gangue are recycled and used fully and reasonably.

Owner:UNIV OF SCI & TECH LIAONING

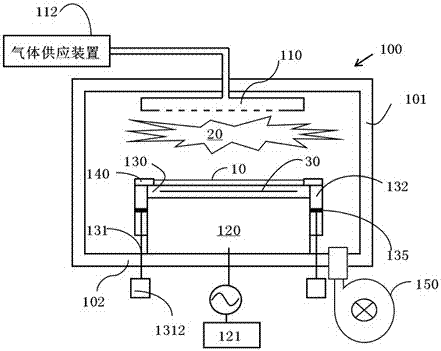

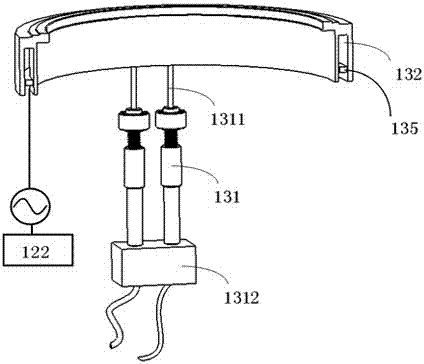

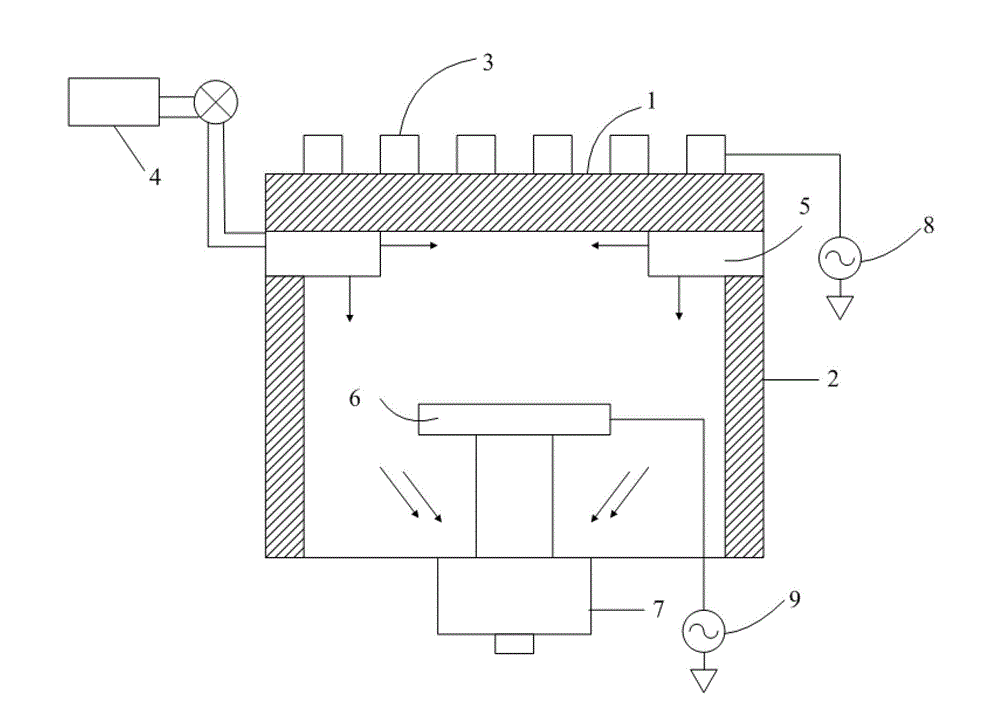

Plasma processing device and method

ActiveCN107154332AIncrease the degree of dissociationGuaranteed cleanlinessElectric discharge tubesHigh concentrationEtching

The invention provides a plasma processing device and a method of processing a substrate in the plasma processing device. The plasma processing device comprises a reaction chamber in which an upper electrode and a lower electrode are arranged. A hollow insulating ring is arranged around the periphery of the lower electrode and is internally provided with a radio frequency coil, and by applying radio frequency power to the radio frequency coil in the cleaning process, the degree of dissociation of the cleaning gas in the edge area can be improved, thereby increasing the concentration of the clean plasma in the edge area. The clean plasma of the high concentration is beneficial for ensuring the clean effect of the component in the edge area. In the etching, the radio frequency coil is grounded to effectively avoid a phenomenon that the radio frequency power applied to the lower electrode produces discharge in the radio frequency coil.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Process for manufacturing lithium sulfur battery

ActiveCN103985913ALow purityPrevent oxidationElectrode thermal treatmentFinal product manufactureSolid state electrolyteHigh rate

The invention discloses a process for manufacturing a lithium sulfur battery. The process comprises the following steps: adding polyacrylonitrile resin micro powder and diatomite into a high-speed mixing stirrer according to a mass ratio of 36-39 to 64-61, adding an NMP solvent which accounts for 6-24 weight percent of the diatomite to serve as a raw material, performing pretreatment, and performing repeated dipping and high-temperature evaporation in an NMP solution of lithium salt (namely a 6-9 weight percent of NMP solution containing lithium polysulfide, lithium methylaminobutyrate, lithium perchlorate and lithium phosphate), thereby preparing a positive material; preparing all-solid-state electrolyte of the lithium sulfur battery from lithium methylaminobutyrate, lithium perchlorate and lithium phosphate; and adsorbing molten metal lithium through pores of carbon-containing diatomite at 630-660 DEG C when metal lithium and the formed carbon-containing diatomite electrode are in a vacuum electric heating furnace, thereby finishing preparation of a negative material. The all-solid-state electrolyte of the lithium sulfur battery prepared by the process has high sulfur containing capacity, high ion transport capacity and high conductive performance, and the high rate performance and high cycle performance of the lithium sulfur battery can be improved.

Owner:威海区域创新中心有限责任公司

Method for continuously separating lignocellulose components

ActiveCN108517707AEfficient separationHigh catalytic efficiencyPretreatment with alkaline reacting compoundsPulping with inorganic basesFiberBlack liquor

The invention discloses a method for continuously separating lignocellulose components. Through various different spiral combination, lignin, hemicellulose and cellulose are continuously separated. The method comprises the concrete steps of 1, cutting stalks into sections by a grass cutting machine; 2, conveying the cut stalks into a drum type water washing machine; cleaning silt and soluble substances in the stalks by hot water; performing cyclic use for several batches on washing water after the silt is filtered; then, performing anaerobic treatment; 3, conveying the cleaned stalks into a double-screw extrusion machine; meanwhile, introducing alkali liquid; performing heat insulation reaction on extrusion materials; 4, conveying the materials after the reaction into a spiral replacementwashing alkali removal machine for extrusion delignification and dealkalization; obtaining lignin alkaline black liquor and waste residue; recovering fine fiber in the black liquor; 5, conveying the obtained residue into a continuous steaming and boiling reactor; performing high-temperature continuous steaming and boiling and performing spray blasting; 6, conveying the sprayed materials into the spiral extrusion machine; extruding and cleaning the residue to obtain hemicellulose hydrolysate and rich-cellulose residue; finally realizing the continuous separation of the lignin, the hemicelluloseand the cellulose.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

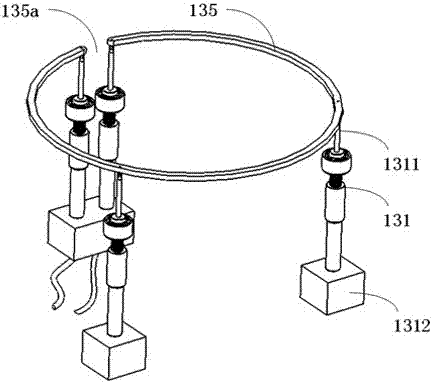

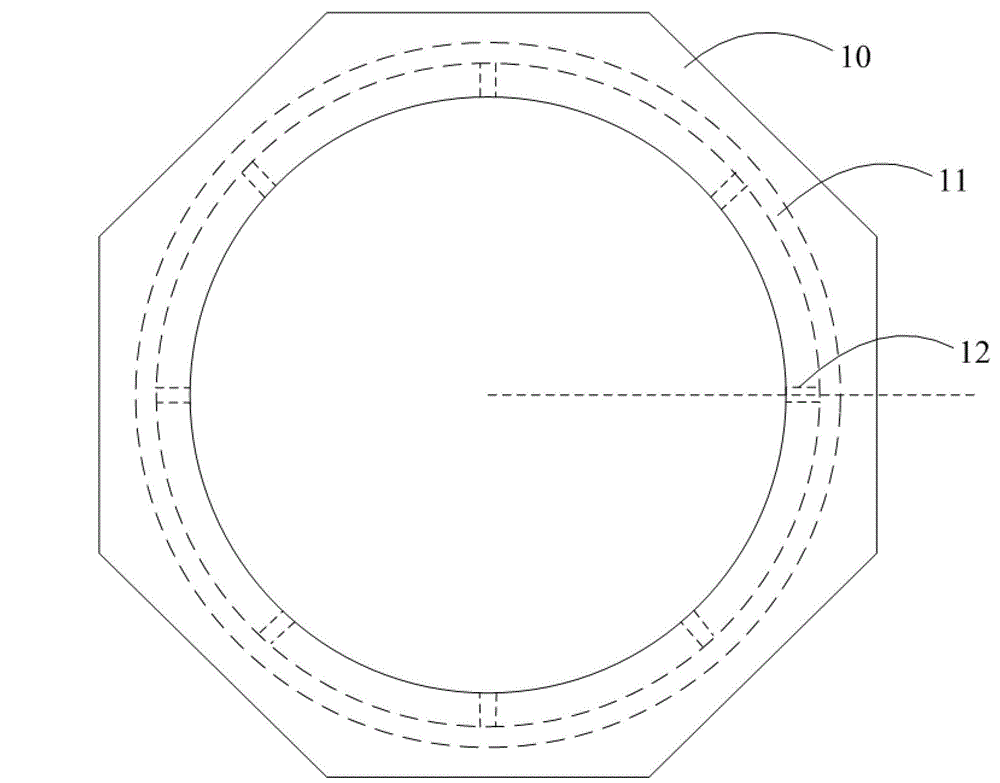

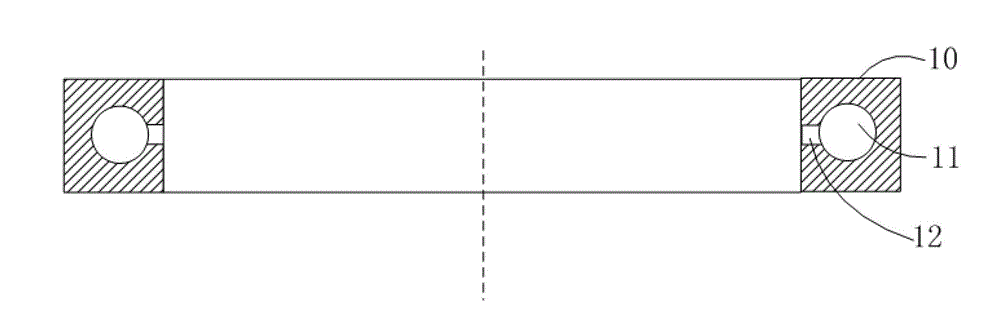

Gas supplying device and plasma processing device

ActiveCN104103484AExtension of timeIncrease the degree of dissociationElectric discharge tubesChemical vapor deposition coatingDevice formProcess engineering

The present invention discloses a plasma processing device. The plasma processing device comprises a reaction cavity and a gas supplying device arranged above the reaction cavity horizontally, the gas supplying device comprises an annular main body, a gas inlet used for introducing a reaction gas, a gas channel embedded in the annular main body and communicated with the gas inlet, and a plurality of gas spraying holes used for discharging the reaction gas. The gas inlets of the gas spraying holes are connected with the gas channel, and the gas outlets are arranged on an inner side wall of the annular main body, wherein the gas outlets of the gas spraying holes are located above the gas channel, and the axial lines of the gas spraying holes and the axial line of the gas supplying device form a first included angle. The gas supplying device and the plasma processing device of the present invention enable the degree of dissociation of the reaction gas and the density of the generated plasma to be improved effectively.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

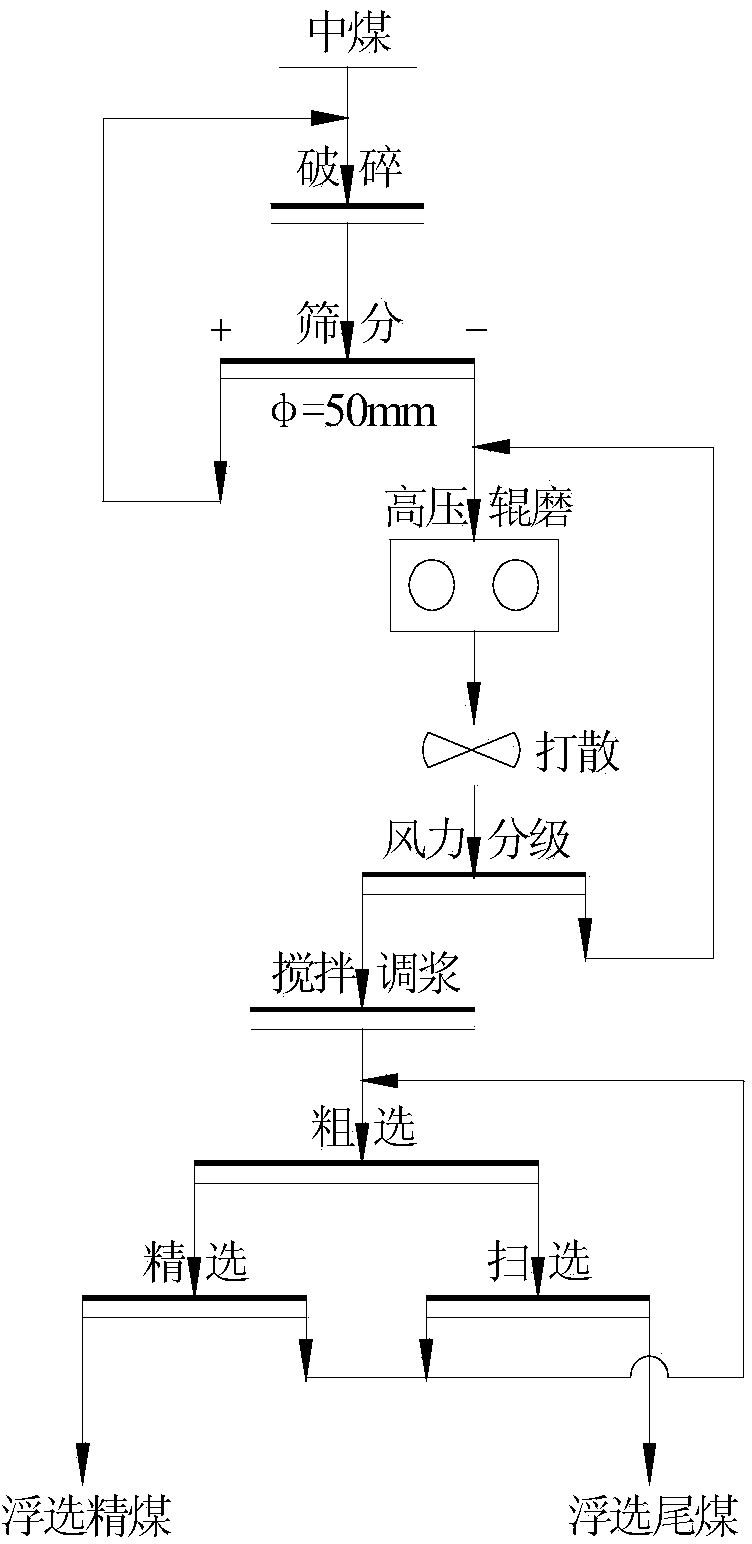

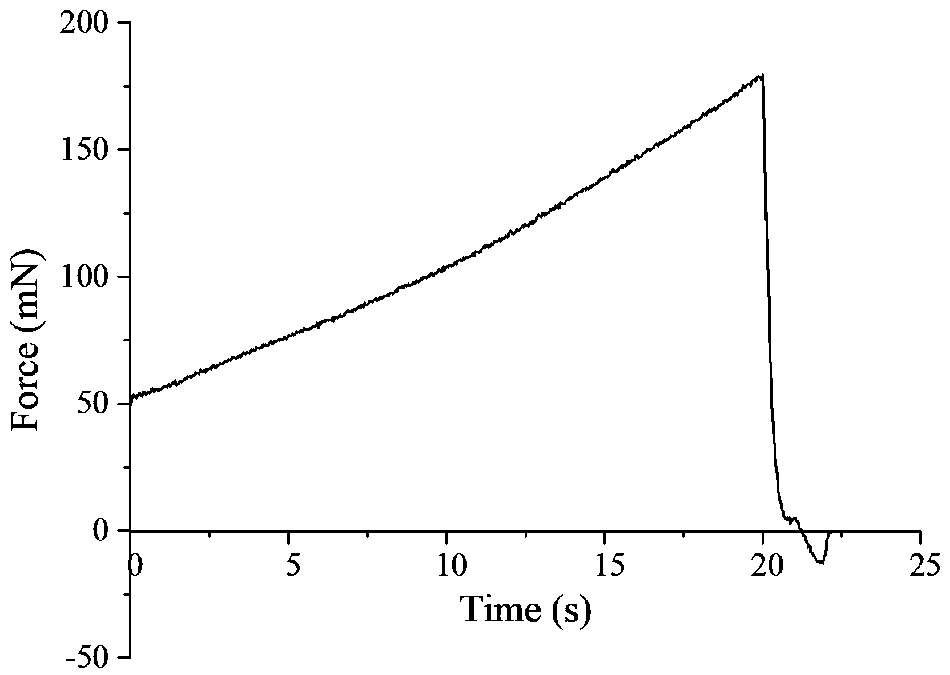

High-pressure roller final grinding and screening method of middling coal

InactiveCN103623932ARemarkable effect of energy saving and consumption reductionIncrease the degree of dissociationFlotationWet separationChemistryEngineering

The invention discloses a high-pressure roller final grinding and screening method of middling coal, and belongs to the technical field of mineral processing. The method comprises the following steps that (1) the middling coal is crushed to be below the upper limit of the grinding particle size of a final grinding system; (2) the work parameters of a high-pressure roller mill are set, after the high-pressure roller mill idles normally, the rotating speed of a feeding belt, the rotating speed of a V type powder concentrator rotor and the rotating speed of a dust collector are set, then a spiral conveyer is started and materials are fed into a high-pressure roller mill hopper in sequence, a roller press flap valve is opened, and a high-pressure roller final grinding experiment is carried out; (3) water is added to high-pressure roller final grinding products for size mixing and stirring, the high-pressure roller final grinding products with the water are fed into flotation equipment, collecting agents and foaming agents are added in sequence to carry out roughing, fine selection and scavenging once, and flotation clean coal and flotation tailing are obtained. Compared with a traditional method that flotation is carried out after the middling coal is crushed and ball-milled, the dissociation degree of the products is high, the follow-up flotation effect is good, and coal resources are fully and reasonably recycled and used.

Owner:UNIV OF SCI & TECH LIAONING

Method for preparing milk gel

PendingCN110495600AHigh strengthImprove water retentionMilk preparationFood ingredient as coagulantCross-linkNetwork structure

The invention belongs to the technical field of dairy products and particularly relates to a method for preparing acidified milk gel. According to the method for preparing the milk gel, milk and a casein solution are sufficiently dissociated by utilizing a calcium ion chelating agent, and are crosslinked with cross-linked enzyme after more junction sites are released, the crosslinking strength canbe improved, the compactness and uniformity of a network structure of the gel formed by acidifying can be improved, and a milk gel product with high strength and good water locking performance can befinally obtained. Compared with a gel product which is formed by directly acidifying a casein solution after enzyme crosslinking, the method can be used for preparing a milk gel product with more compact network structure, higher strength and better water locking performance. The final dairy product can solve the water separating problem, has an elastic taste, and is chewy.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

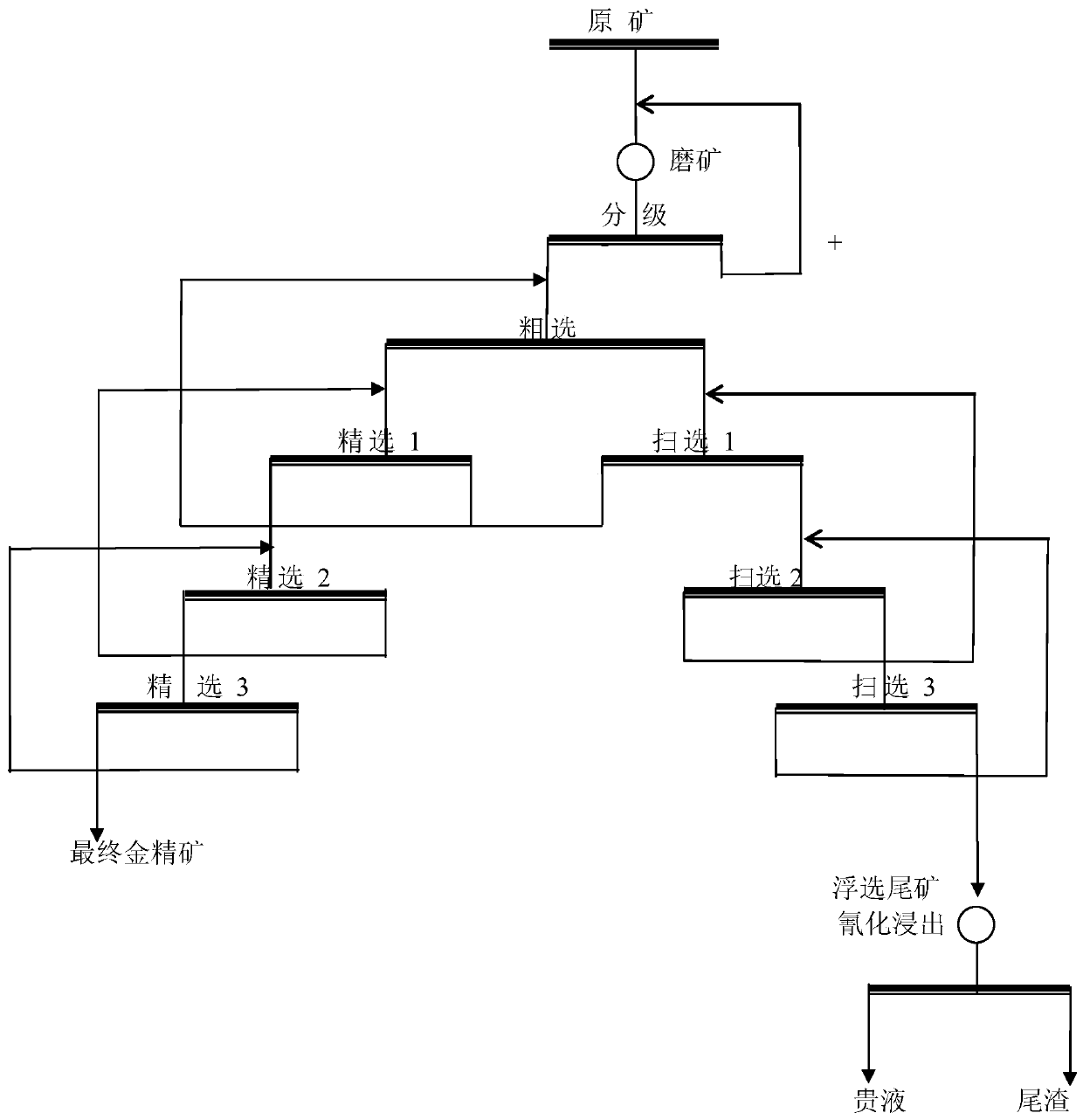

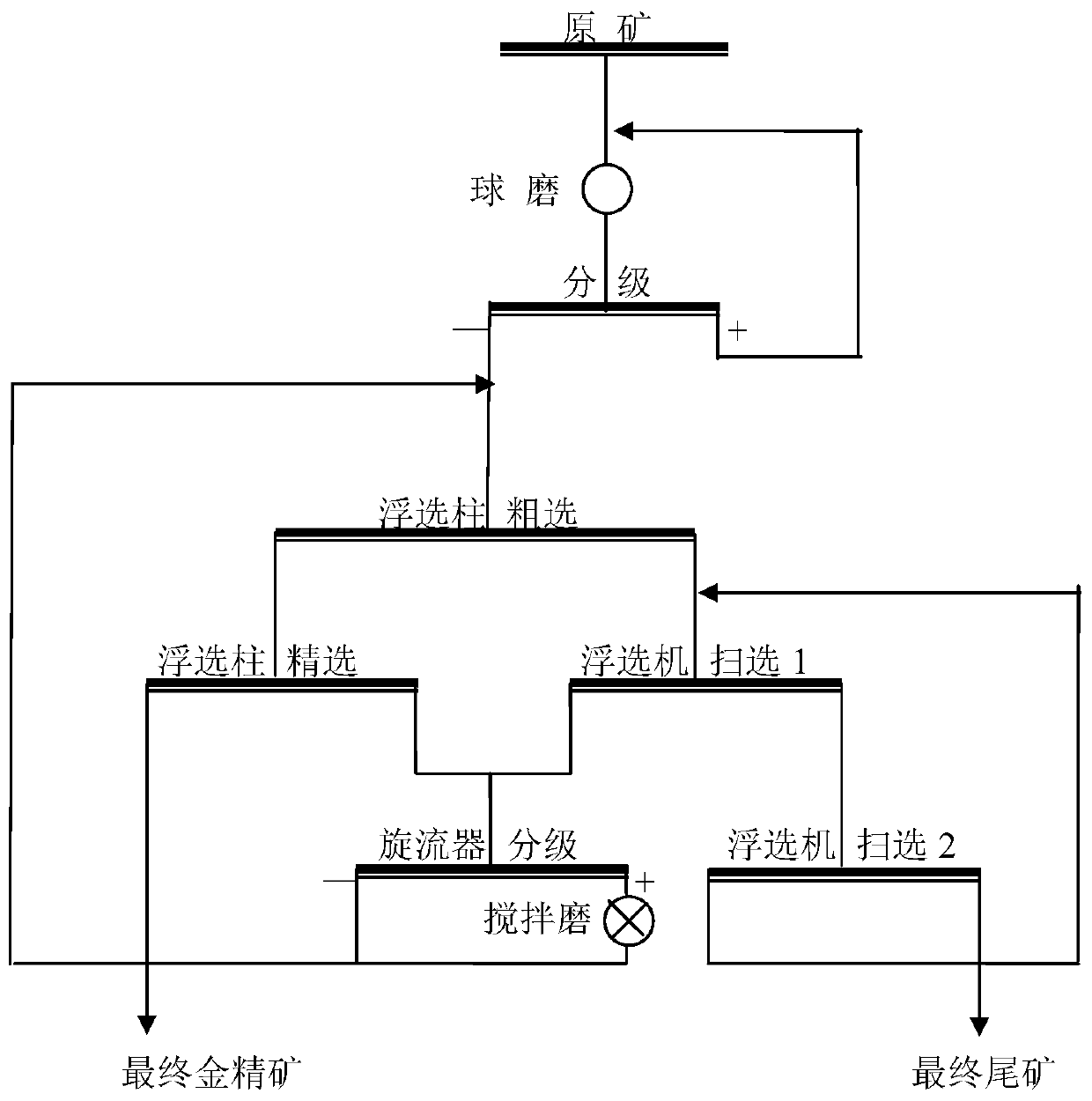

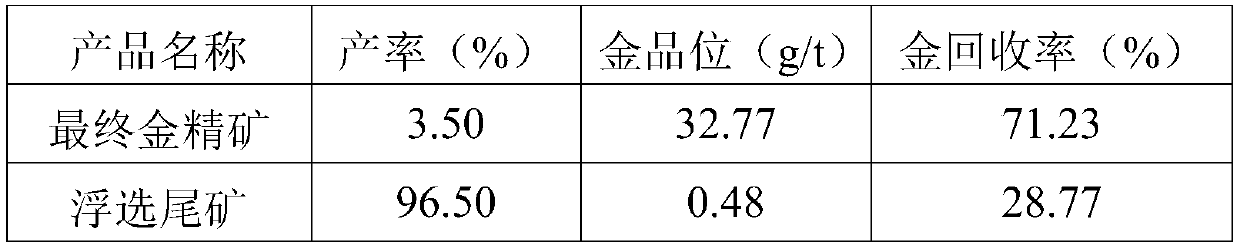

Method for improving recovery rate of gold in semi-primary semi-oxidized gold ore by full flotation process

The invention provides a method for improving a recovery rate of gold in a semi-primary semi-oxidized gold ore by a full flotation process. The method comprises the following steps: (1) after a raw ore is subjected to grinding, performing rougher flotation by a first-stage flotation column to obtain primary concentrate and primary tailings, and performing cleaner flotation on the primary concentrate by the first-stage flotation column to obtain cleaner tailings and final gold concentrate; (2) performing scavenging flotation on the primary tailings by a first-stage flotation machine to obtain primary scavenging flotation concentrate and primary scavenging flotation tailings, performing scavenging flotation on the primary scavenging flotation concentrate by using a second-stage flotation machine to obtain secondary scavenging flotation concentrate and final tailings, and allowing the secondary scavenging flotation concentrate to return to the first-stage flotation machine for scavengingflotation; and (3) merging tailings having a concentrated gold-supported poor intergrowth body and the primary scavenging flotation concentrate, performing classification operation in a cyclone to obtain a settled sand product and an overflow product, performing grinding on the settled sand product, merging the ground settled sand product with the overflow product to return to a first-stage flotation column for rougher flotation. The method provided by the invention effectively solves the problem that a poor intergrowth body enters tailings in the production process, so that the recovery rateof the gold by flotation is low, and discards cyanide leaching operation in a current process, thereby eliminating environmental hazard of cyanides from a source.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

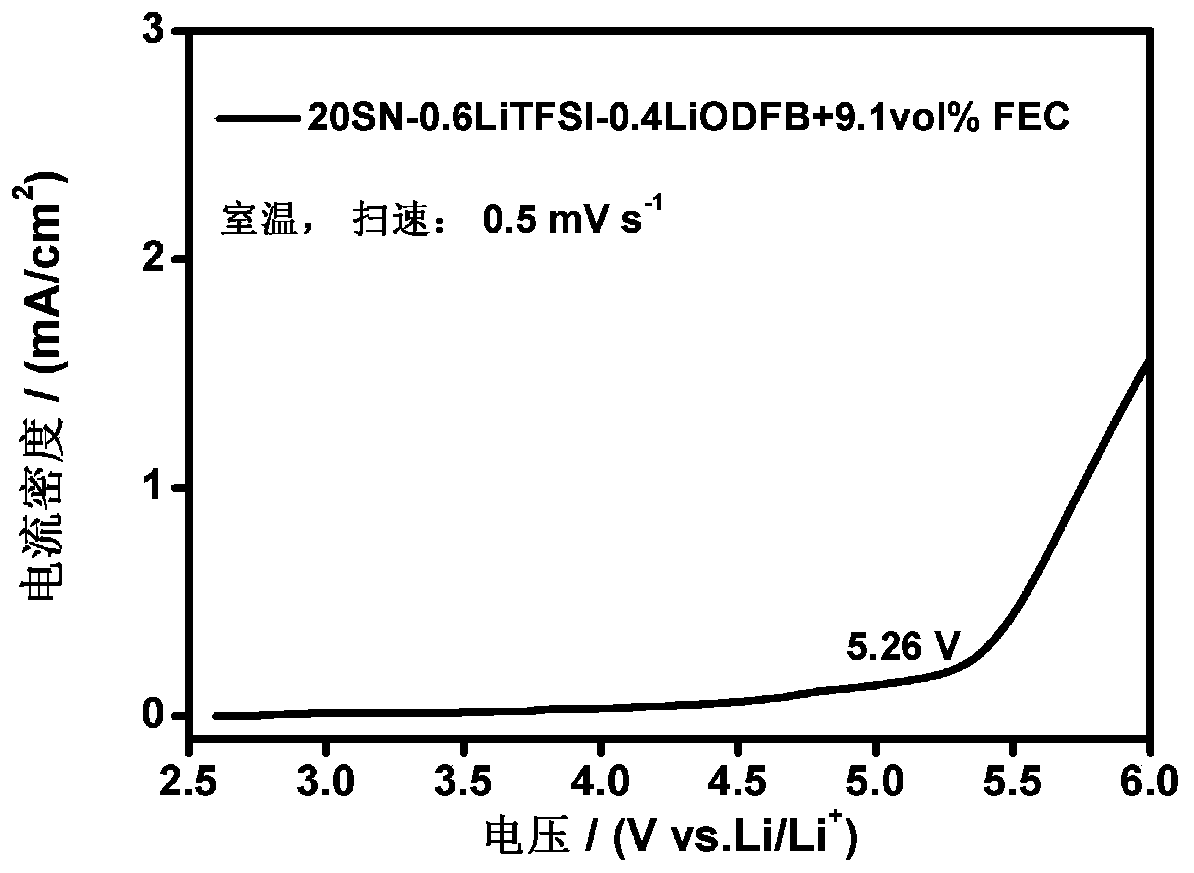

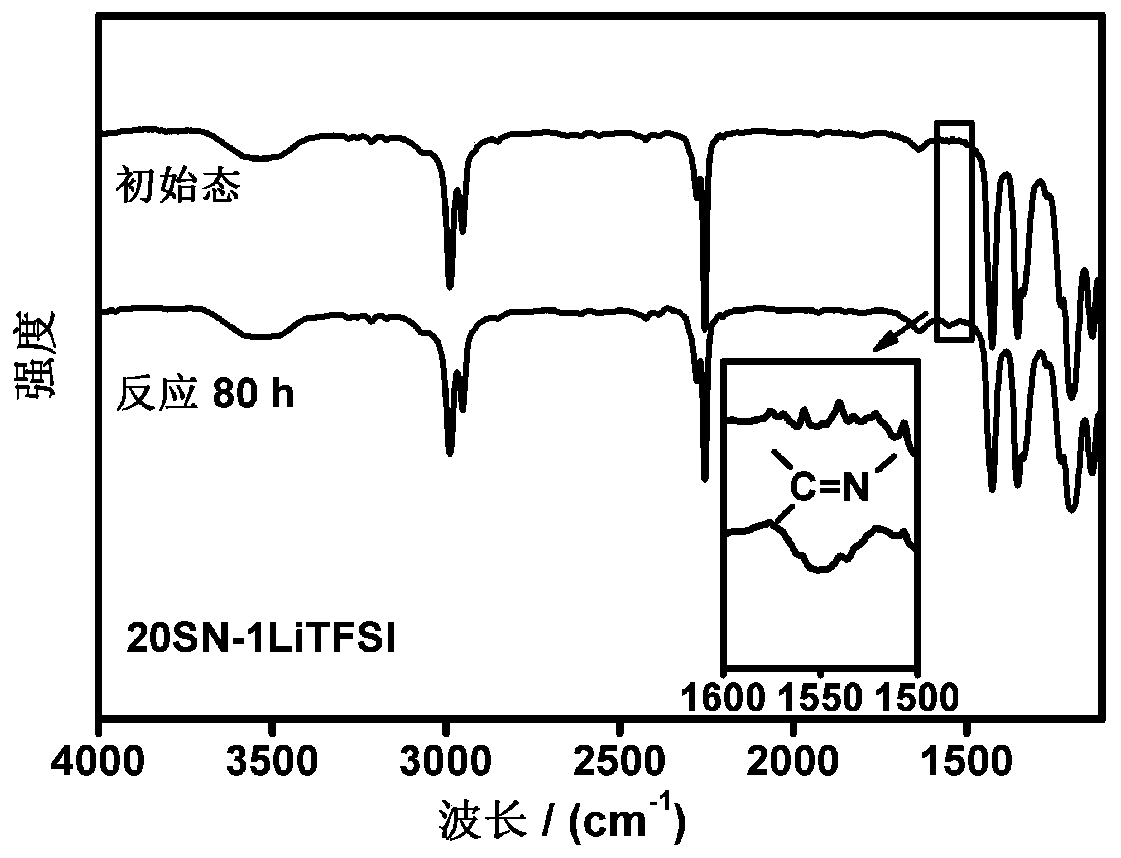

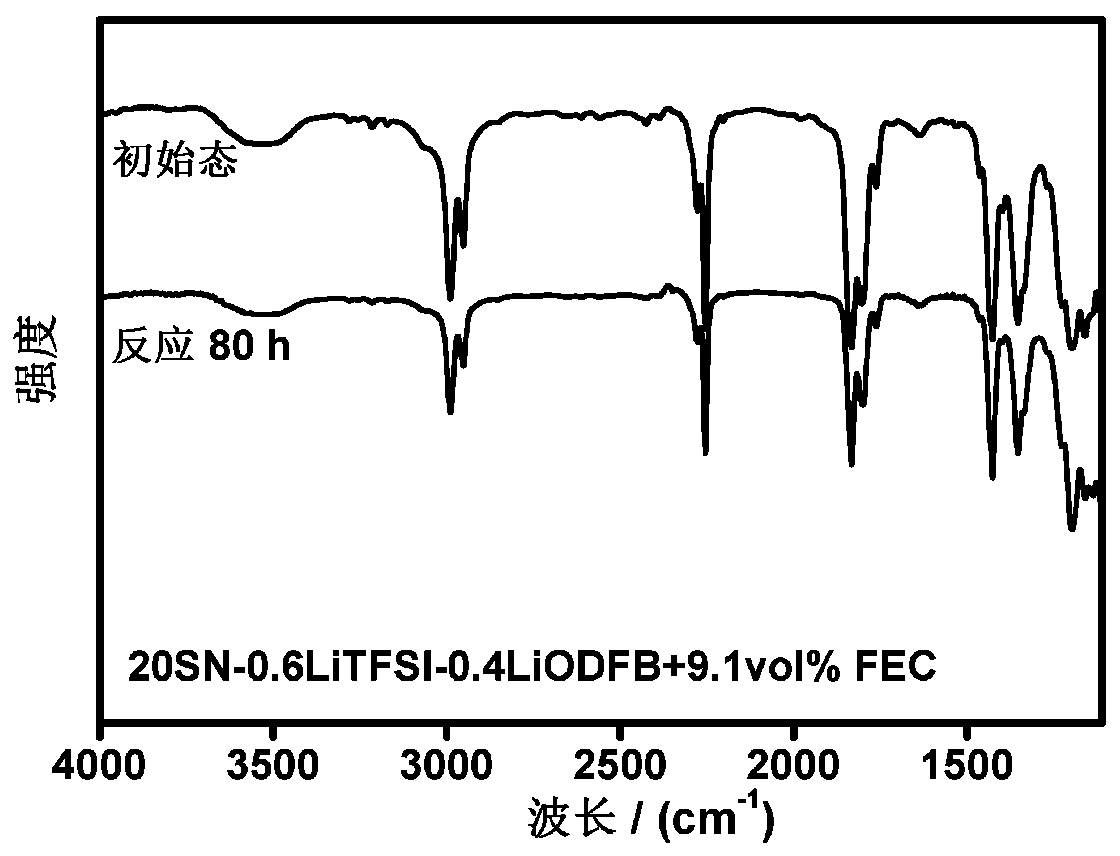

Succinonitrile-based electrolyte coupled with organic lithium salt and fluoroethylene carbonate as well as preparation method and application of electrolyte

ActiveCN110931875AImprove interfacial wettabilityGood dissociation effectSecondary cellsOrganic electrolytesElectrolytic agentMetallic lithium

The invention discloses a succinonitrile-based electrolyte coupled with an organic lithium salt and fluoroethylene carbonate, and relates to the technical field of lithium-ion batteries. The specificscheme is as follows: the succinonitrile-based electrolyte coupled with an organic lithium salt and fluoroethylene carbonate comprises succinonitrile, an organic lithium salt and fluoroethylene carbonate, wherein the molar ratio of the succinonitrile to the organic lithium salt is 100: 1-1:1, the organic lithium salt is a combination of a sulfonyl imide lithium salt and lithium oxalyldifluoroborate, the molar ratio of the sulfonyl imide lithium salt to the lithium oxalyldifluoroborate is 100: 1-1: 1, and the fluoroethylene carbonate accounts for 5-50% of the total volume of the succinonitrile-based electrolyte. The invention further discloses a preparation method of the succinonitrile-based electrolyte and application of the succinonitrile-based electrolyte to a lithium metal battery, theelectrolyte can form an organic-inorganic composite SEI film on the surface of metal lithium, side reaction of succinonitrile and metal lithium is avoided, and the interface stability and electrochemical performance of the battery are remarkably improved.

Owner:HARBIN INST OF TECH

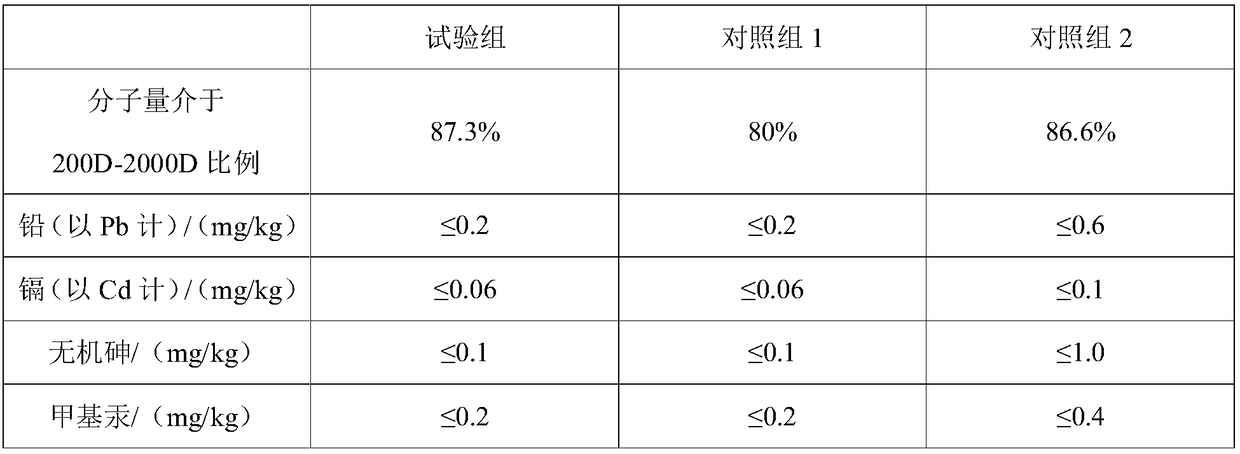

Method for extracting collagen polypeptide from fish scale

InactiveCN109293766APollution is less harmfulImprove stabilityConnective tissue peptidesPeptide preparation methodsIonHeavy metals

The invention discloses a method for extracting collagen polypeptide from fish scale. The method comprises the following steps: pretreatment, extraction, hydrolysis, metal removal, and purification; wherein a hydrolysis step is characterized by comprising the following steps: fish scale collagen and subtilisin are added to distilled water and the materials are completely dissolved, t-butylhydroperoxide and stevioside are added, the pH value is adjusted, and double-frequency ultrasonic assisted enzymatic hydrolysis is carried out on an enzymatic hydrolysate in a constant temperature water bath;a trace amount of t-butylhydroperoxide and stevioside generate synergism, which can increase the degree of hydrolysis of collagen and increase the enzymatic hydrolysis rate of subtilisin; wherein a metal removal step is characterized by comprising the following steps: starch xanthate and mulberry polysaccharide are added to the enzymatic hydrolysate, and the steps of mixing, reacting, and filtering through diatomite are carried out to obtain fish scale collagen polypeptide clear liquid; and the starch xanthate and mulberry polysaccharide have higher removal rates of heavy metal ions. The method has the beneficial effects that the method for extracting the collagen polypeptide from fish scale provided by the invention has the advantages of easy control, complete hydrolysis, large proportion of polypeptide in the product, easy absorption by the body, and low content of heavy metals.

Owner:新昌县赛因斯生物科技有限公司

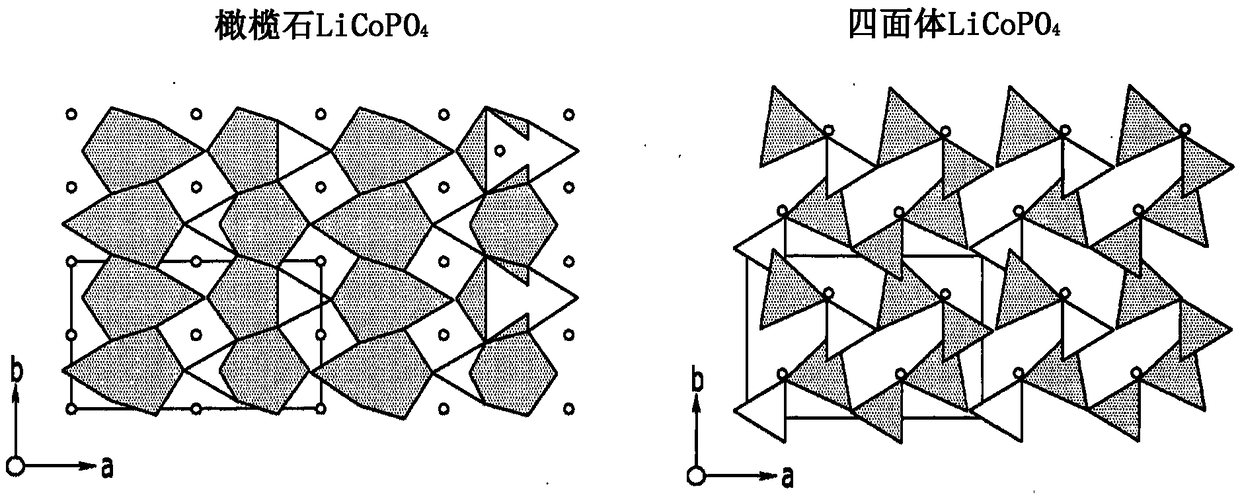

Positive electrode active material particles each comprising core containing lithium cobalt oxide and shell containing lithium cobalt phosphate and method for manufacturing same

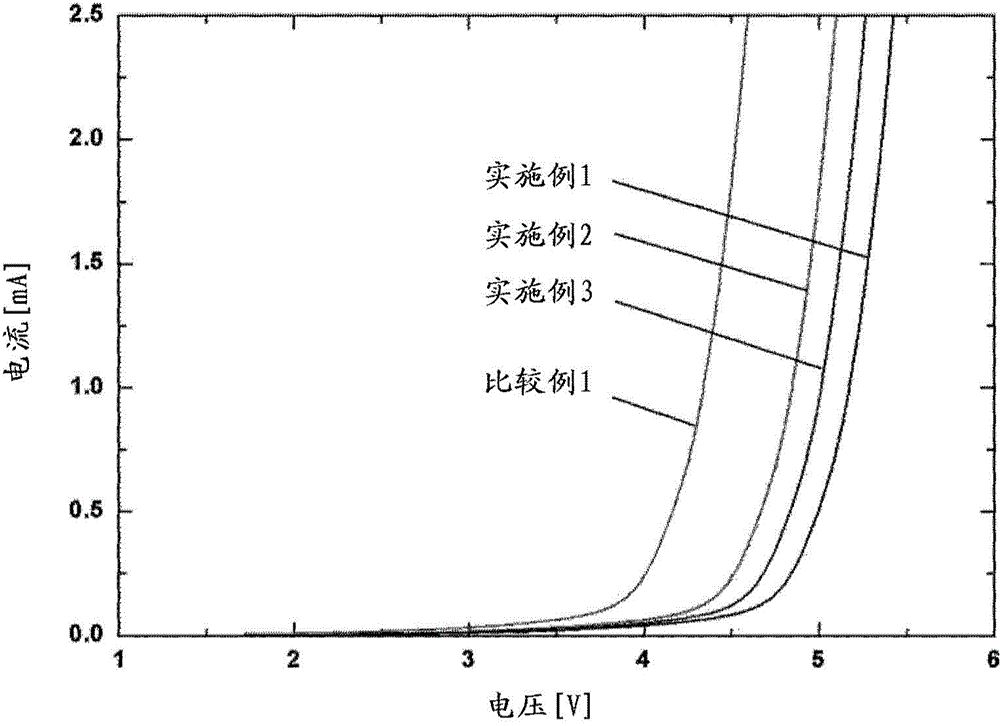

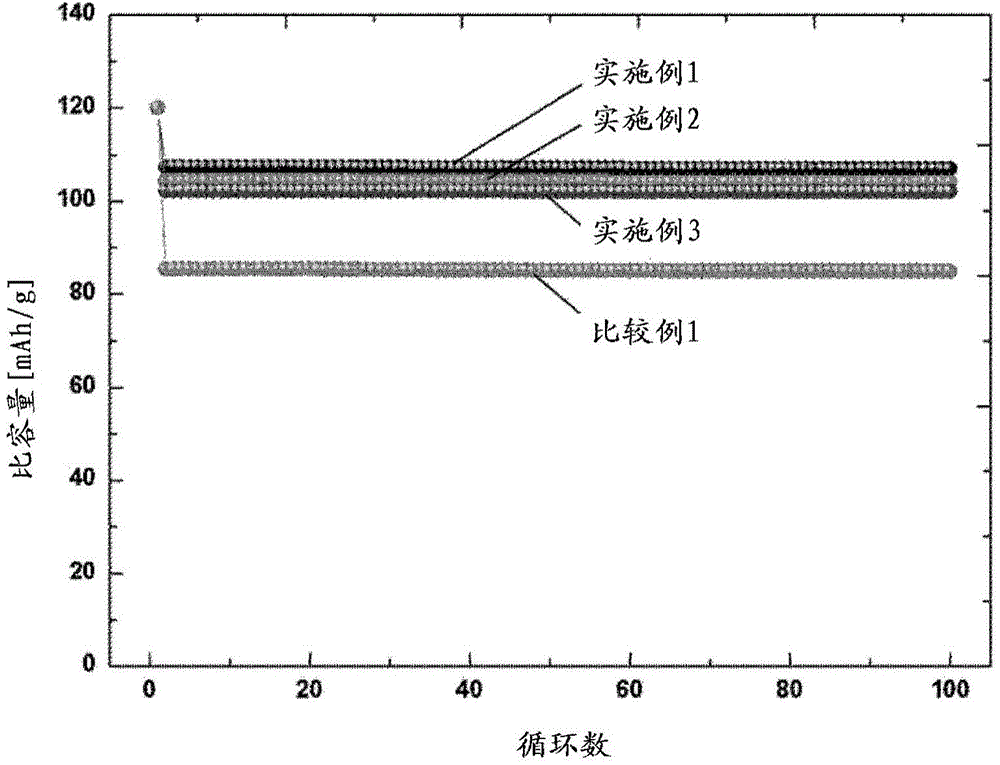

ActiveCN109417165AImprove performanceHigh ion conductivityFinal product manufacturePositive electrodesLithiumHalogen

The present invention provides positive electrode active material particles each comprising: a core containing a lithium cobalt oxide represented by chemical formula 1 below; and a shell positioned ona surface of the core and containing a lithium cobalt phosphate represented by chemical formula 2 below, wherein the shell has a tetrahedral phase: LiaCo<1-x>MxO<2-y>Ay (1), wherein M is at least oneof Ti, Mg, Zn, Si, Al, Zr, V, Mn, Nb, and Ni, A is oxygen-substituted halogen, 0.95 <= a <= 1.05, 0<= x<= 0.2, 0<= y<= 0.2, and 0<= x+y<= 0.2; and LibCoPO4 (2) wherein, 0<= b<= 1.

Owner:LG ENERGY SOLUTION LTD

Paraffin hydrofining catalyst and preparation method thereof

PendingCN111097489AGood dispersionIncrease profitMolecular sieve catalystsPetroleum wax refiningMolecular sievePtru catalyst

The invention discloses a paraffin hydrofining catalyst and a preparation method thereof. A carrier of the paraffin hydrofining catalyst comprises aluminum oxide, layered clay and a Y-type molecular sieve; nickel and molybdenum are taken as active metal components; taking the mass of the paraffin hydrofining catalyst as a reference, the paraffin hydrofining catalyst comprises 2.0%-35.0% of molybdenum oxide, and 0.5%-20.0% of nickel oxide; the dispersity of the active metal components is as follows: IMo / IAl is 0.15-0.30, and INi / IAl is 0.07-0.15. The paraffin hydrofining catalyst is high in active metal utilization rate, high in active metal dispersity and high in activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

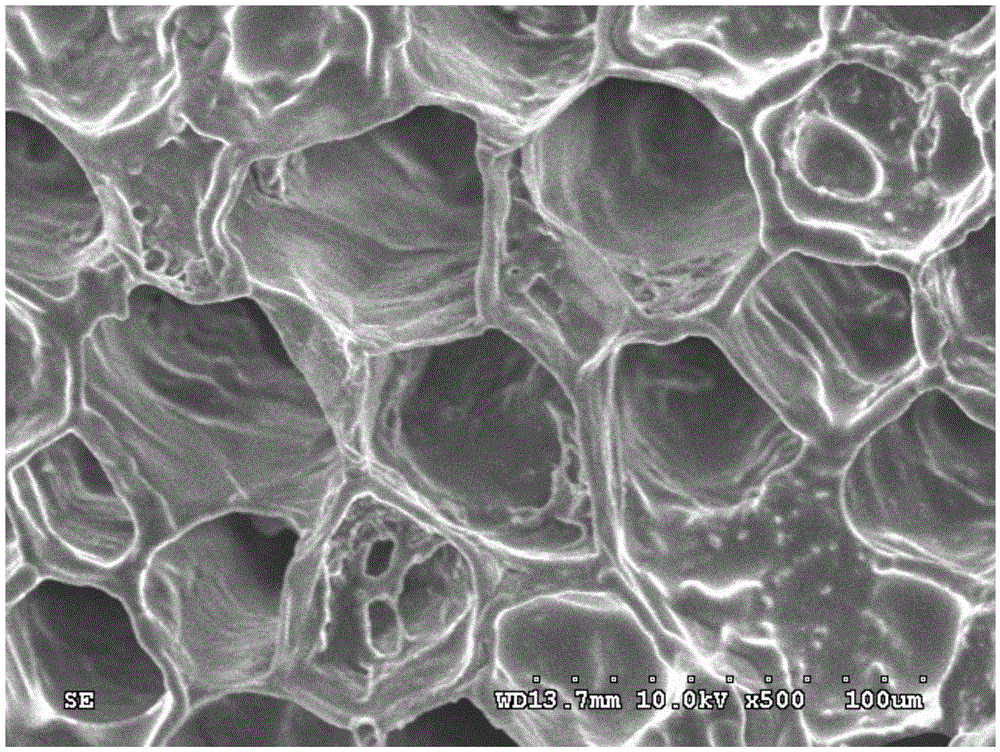

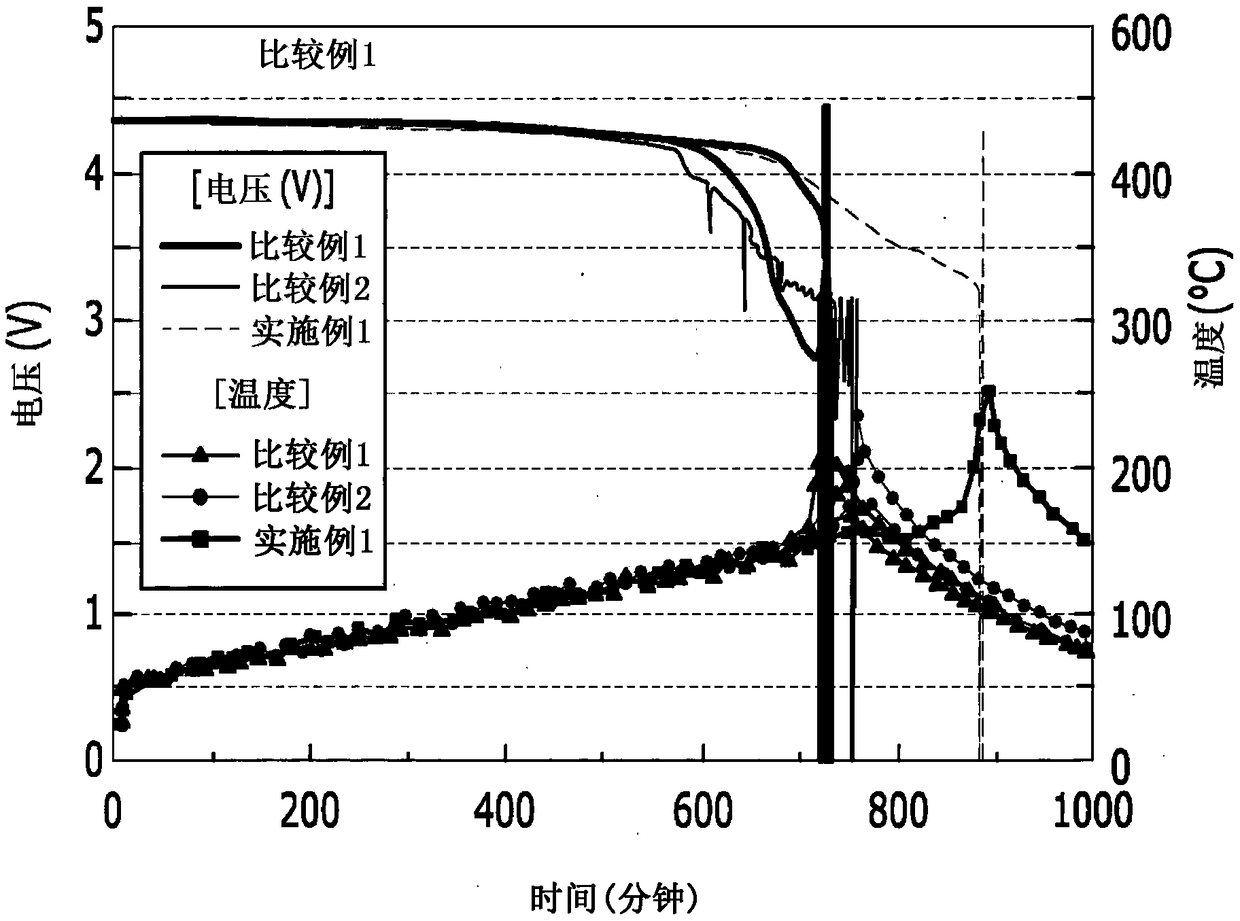

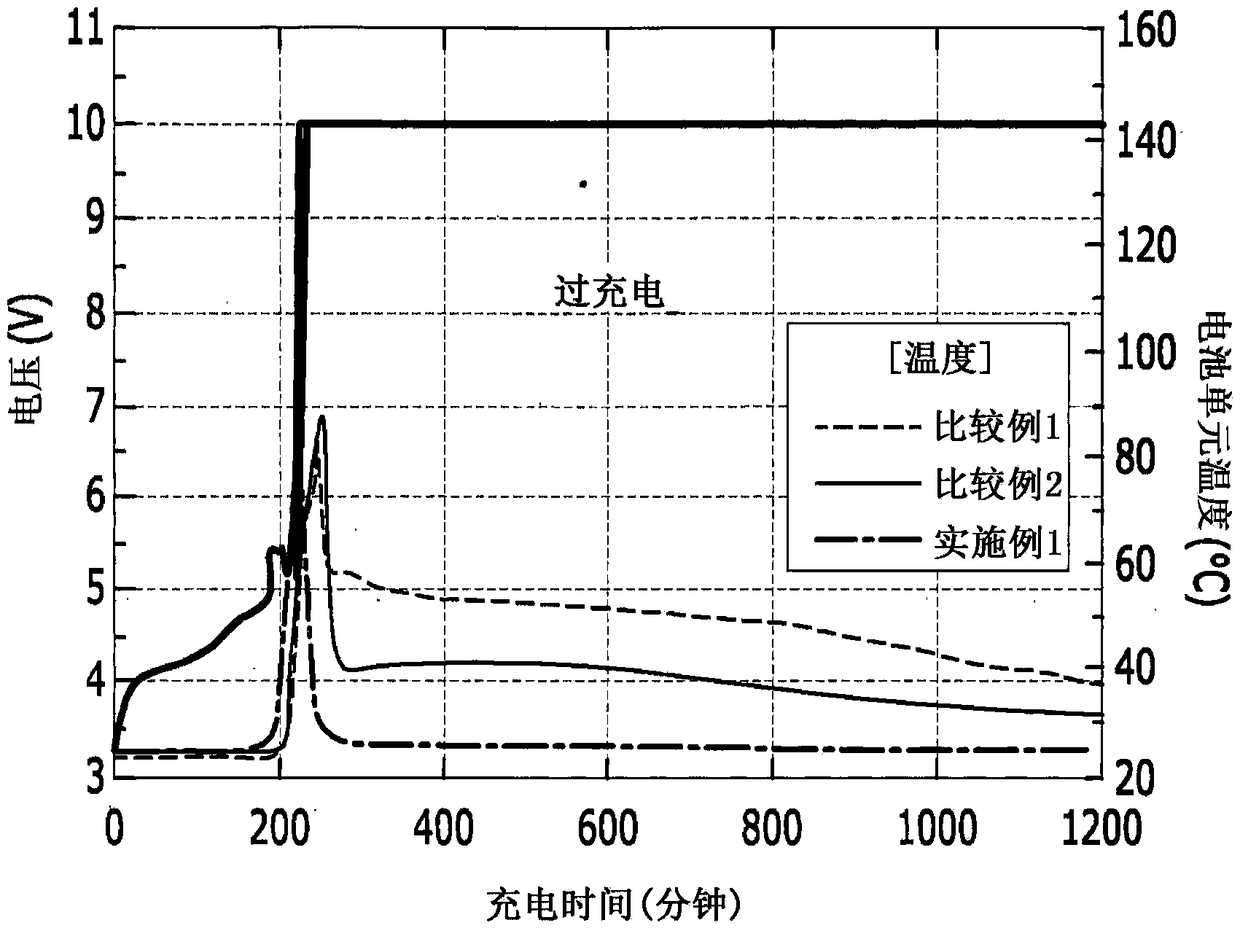

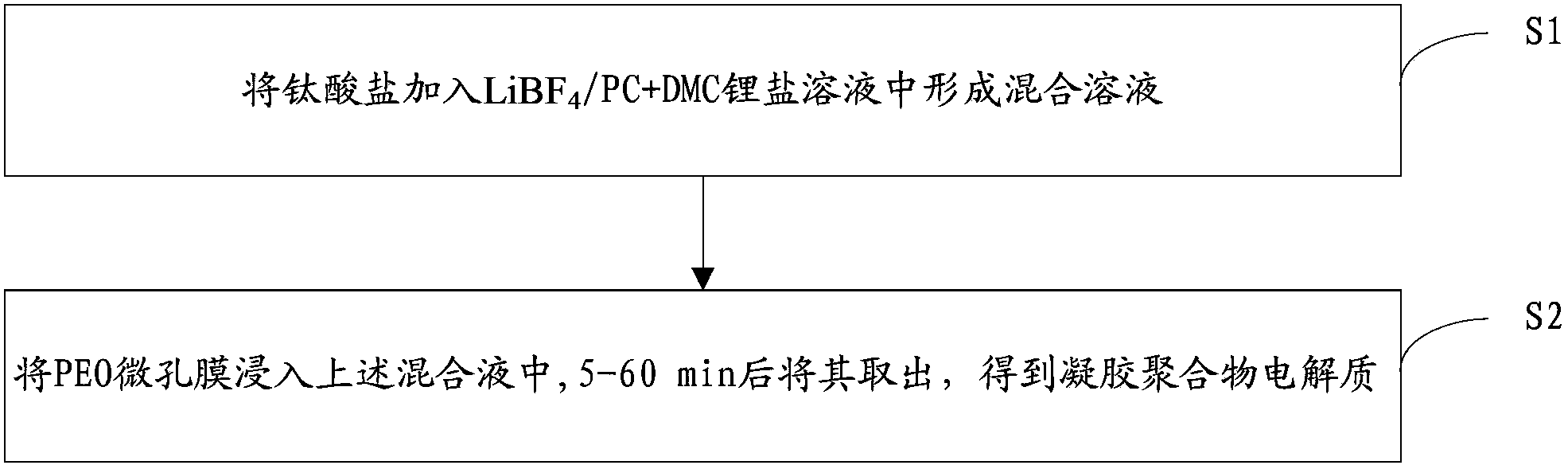

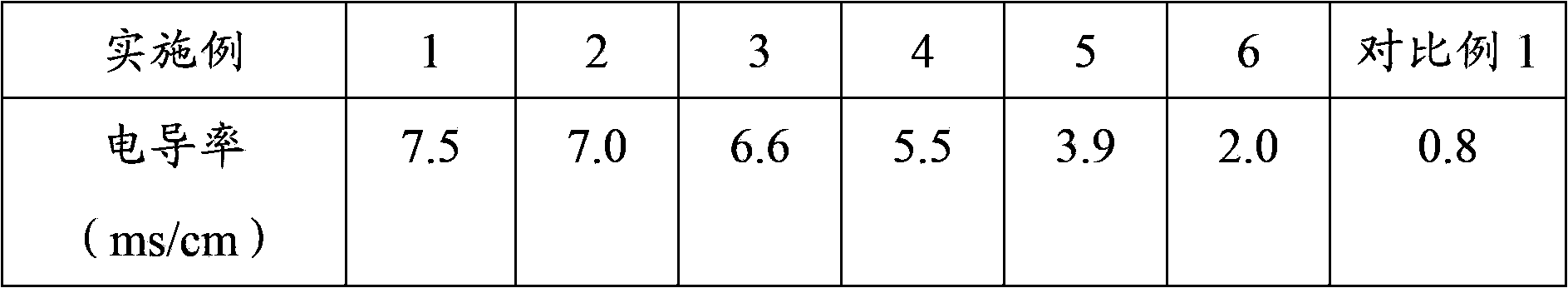

PEO-based gel polymer electrolyte and preparation method thereof

InactiveCN103456989AImprove conductivityIncrease the degree of dissociationSecondary cellsPolymer electrolytesPolymer science

The invention belongs to the field of electrolytes and discloses a PEO-based gel polymer electrolyte and a preparation method thereof. The PEO-based gel polymer electrolyte comprises a PEO matrix, a LiBF4 / PC+DMC lithium salt and a titanate, wherein a mole ratio of LiBF4 to the titanate is 1: 0.001 to 1: 0.05. The titanate of the PEO-based gel polymer electrolyte can adsorb BF4<-> and form a coordination compound so that a LiBF4 dissociation degree is improved and lithium ion transport number is increased and thus conductivity is greatly improved. In a lithium ion battery, the PEO-based gel polymer electrolyte cannot be leaked, has good safety and greatly improves conductivity.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

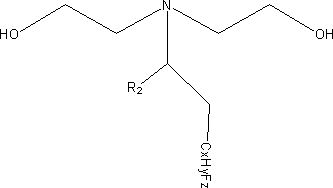

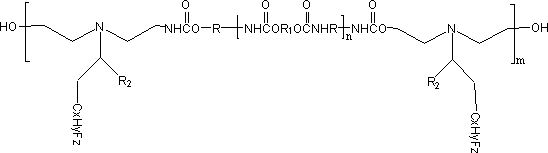

Fluorine-containing polyurethane solid-state composite electrolyte and preparation method thereof

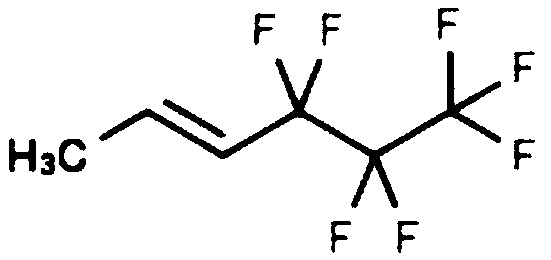

ActiveCN111786016AHigh conductivity at room temperatureEfficient mixingSolid electrolytesSecondary cellsSolid state electrolyteComposite electrolyte

The invention discloses a fluorine-containing polyurethane solid-state composite electrolyte and a preparation method thereof, wherein the electrolyte is composed of fluorine-containing polyurethane,an inorganic solid-state electrolyte and a lithium salt. The preparation method comprises the following steps: S1, preparing a fluorine-containing dihydroxy monomer; S2, preparing fluorine-containingpolyurethane; and S3, preparing a fluorine-containing polyurethane solid-state composite electrolyte. According to the invention, polyether polyurethane is used as a solid-state electrolyte matrix, and the molecular chain of polyether polyurethane contains a large amount of ether groups, so that the conductivity of lithium ions at room temperature can be effectively improved; a synthesized novel fluorine-containing dihydroxy monomer is used as a chain extender to prepare fluorine-containing polyurethane, so that a fluorine structure is introduced to effectively improve the electrochemical stability of polyurethane electrolyte so as to improve the dissociation degree of a lithium salt to a certain extent and improve the conductivity of lithium ions; the fluorine-containing structure effectively improves the mechanical properties and processability of the polyurethane solid-state electrolyte in polyurethane; and the polyurethane solid-state electrolyte is prepared through organic-inorganic compounding, so that the lithium ion conductivity is effectively improved, and the thermal stability and the mechanical property of the electrolyte membrane are improved.

Owner:东莞格林德能源有限公司

Solid polymer electrolyte membrane and preparation method thereof

ActiveCN111769320AImprove ionic conductivityImprove mechanical propertiesFinal product manufactureElectrolyte accumulators manufacturePolymer electrolytesPolyether polyurethane

The invention discloses a solid polymer electrolyte membrane and a preparation method thereof. The solid polymer electrolyte membrane is composed of a polymer and a lithium salt, and the preparation method comprises the following steps: S1, preparing a polyurethane / polyimide solution; S2, preparing a polyurethane / polyimide / lithium salt mixed solution; and S3, coating to form a film, and drying toobtain the electrolyte membrane. Polyimide is adopted to modify polyether polyurethane, a molecular chain contains more ether groups, the room-temperature ionic conductivity is improved, sulfuryl anda fluorine-containing structure are introduced into the polymer molecular chain, the electrochemical stability of the polymer electrolyte can be effectively improved, the dissociation degree of lithium salt is improved to a certain extent, and the ionic conductivity of the polymer electrolyte is improved. Meanwhile, polyether polyurethane provides toughness for the polymer electrolyte membrane, polyimide provides rigidity for the polymer electrolyte membrane, and the mechanical property and the chemical stability of the electrolyte membrane are improved.

Owner:东莞格林德能源有限公司

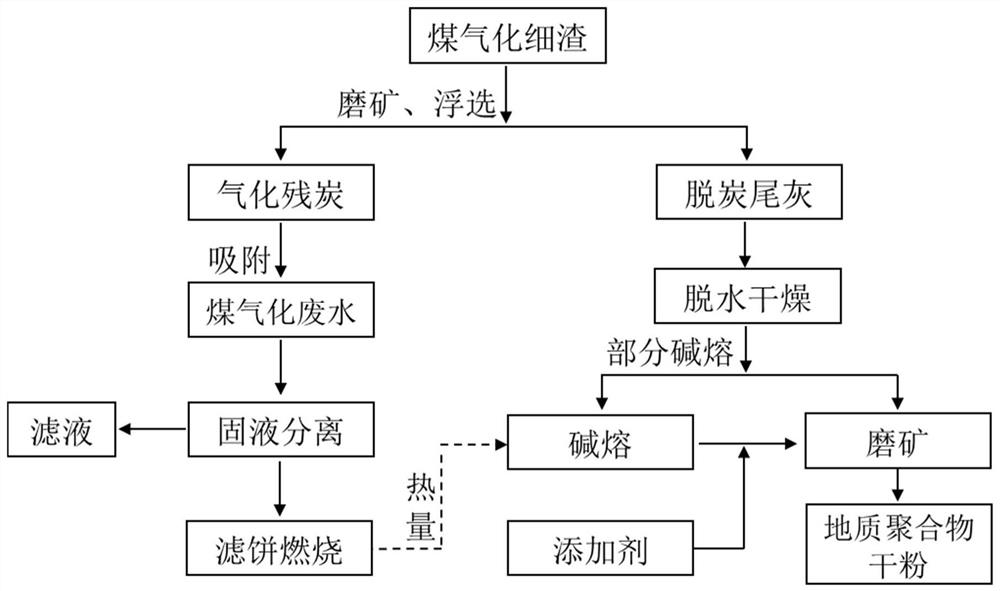

All-component comprehensive utilization method of coal gasification fine slag

ActiveCN113333436AIncrease the degree of dissociationSimple processWater treatment parameter controlSolid waste disposalThermodynamicsSlag

The invention relates to the technical field of solid waste comprehensive utilization, in particular to an all-component comprehensive utilization method of coal gasification fine slag. The method is used for preparing geopolymer dry powder from coal gasification fine slag, and comprises the following steps: carrying out charcoal-ash separation on the coal gasification fine slag by utilizing ore grinding and flotation, respectively carrying out wastewater adsorption utilization and alkali fusion treatment on charcoal ash, and mixing the treated charcoal ash with ore grinding to prepare the geopolymer dry powder. Water can be directly added in the geopolymer dry powder obtained by the all-component comprehensive utilization method for use, the geopolymer dry powder can be quickly solidified at normal temperature, is high in tensile strength, and obviously improves the feasibility of the coal gasification fine slag in the field of geopolymer utilization.

Owner:CHINA UNIV OF MINING & TECH

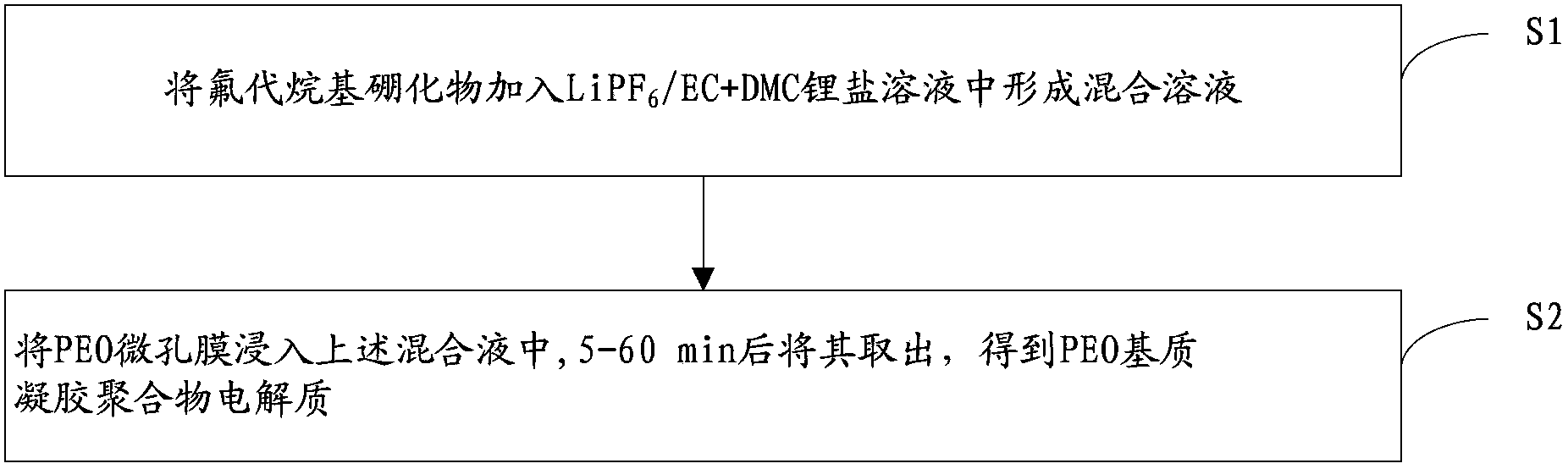

PEO-based gel polymer electrolyte and preparation method thereof

InactiveCN103456986AIncrease the number of transfersImprove conductivitySecondary cellsLithium electrodeCoordination complex

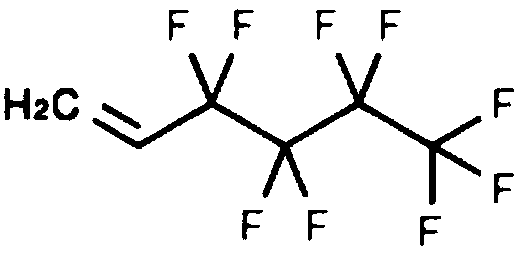

The invention belongs to the field of electrolytes and discloses a PEO-based gel polymer electrolyte and a preparation method thereof. The PEO-based gel polymer electrolyte comprises a PEO matrix, a LiPF6 / EC+DMC lithium salt and a fluoroalkyl boride, wherein a mole ratio of LiPF6 to the fluoroalkyl boride is 1: 0.001 to 1: 0.05. The fluoroalkyl boride of the PEO-based gel polymer electrolyte can form a coordination compound with PF6<-> so that a LiPF6 dissociation degree is improved and lithium ion transport number is increased and thus conductivity is greatly improved. In a lithium ion battery, the PEO-based gel polymer electrolyte does not leak, has good safety and greatly improves conductivity.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of soft-shelled turtle peptide

InactiveCN109234342AIncrease contentHigh purityConnective tissue peptidesPeptide preparation methodsCyclohexeneFreeze-drying

The invention discloses a preparation method of soft-shelled turtle peptide. The method comprises the steps of: pulverizing the raw material of the turtle, adding an aqueous solution containing 3,4,5-trihydroxy-1-cyclohexene-1- formic acid and puerarin and putting them into the twin-screw cooking heat together; In the feed inlet of the extruder, the thick slurry is hot extruded, and the papain restriction enzyme is added, the enzymatic hydrolysate is centrifuged, the supernatant is collected, and the dried turtle collagen is freeze-dried; the turtle collagen and Bacillus subtilis are collected. The protease is dissolved in distilled water, and then t-butanol and stevioside are added in sequence to hydrolyze the enzymatic hydrolysate; the enzymatic hydrolysate is decolorized, ultrafiltration membrane is removed, nanofiltration membrane is concentrated, and freeze-dried to obtain turtle collagen peptide. The beneficial effects are as follows: the preparation method of the turtle peptideof the invention does not require acid-base pretreatment, the purity of the turtle protein is high, the extraction rate of the turtle peptide is high, and the extraction time is short.

Owner:新昌县赛因斯生物科技有限公司

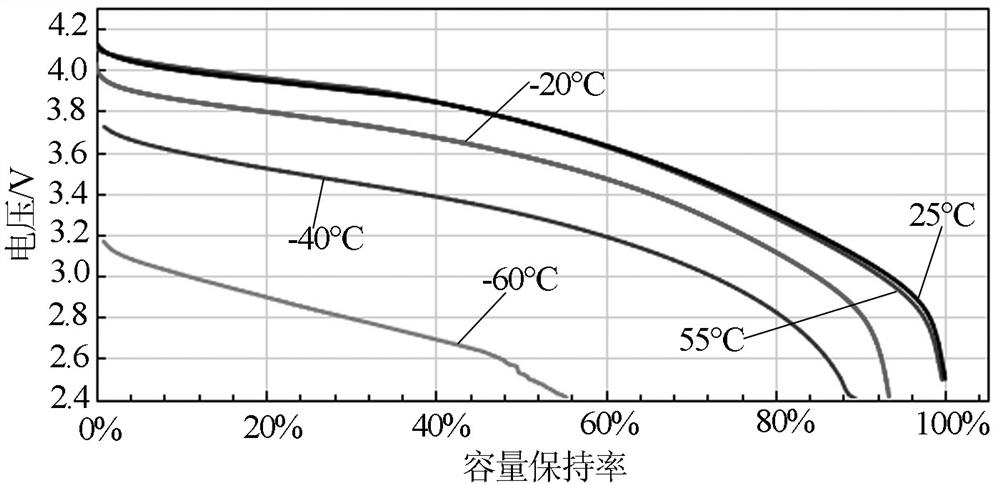

Ultralow-temperature lithium ion battery electrolyte

ActiveCN113036223AImprove performanceLow viscositySecondary cellsOrganic electrolytesElectrolytic agentElectronic conductivity

The invention discloses an ultralow-temperature lithium ion battery electrolyte, and belongs to the technical field of lithium ion batteries. The electrolyte comprises a solvent, a lithium salt and an additive. The solvent is a mixed solvent composed of carbonic esters, ethers and acetic esters. The lithium salt is a mixed lithium salt consisting of lithium hexafluorophosphate, lithium bis (fluorosulfonyl) imide, lithium difluorophosphate and lithium bis (trifluoromethane) sulfonyl imide. The additive is a mixed additive composed of vinylene carbonate, fluoroethylene carbonate, lithium nitrate and dichloromethane. Compared with the conventional electrolyte, the ultralow-temperature electrolyte prepared by the invention has the advantages that: the conductivity is improved by 400% or more, the interfacial film of the negative electrode of the lithium battery is effectively improved, and the polarization effect is reduced.

Owner:TIANNENG BATTERY GROUP

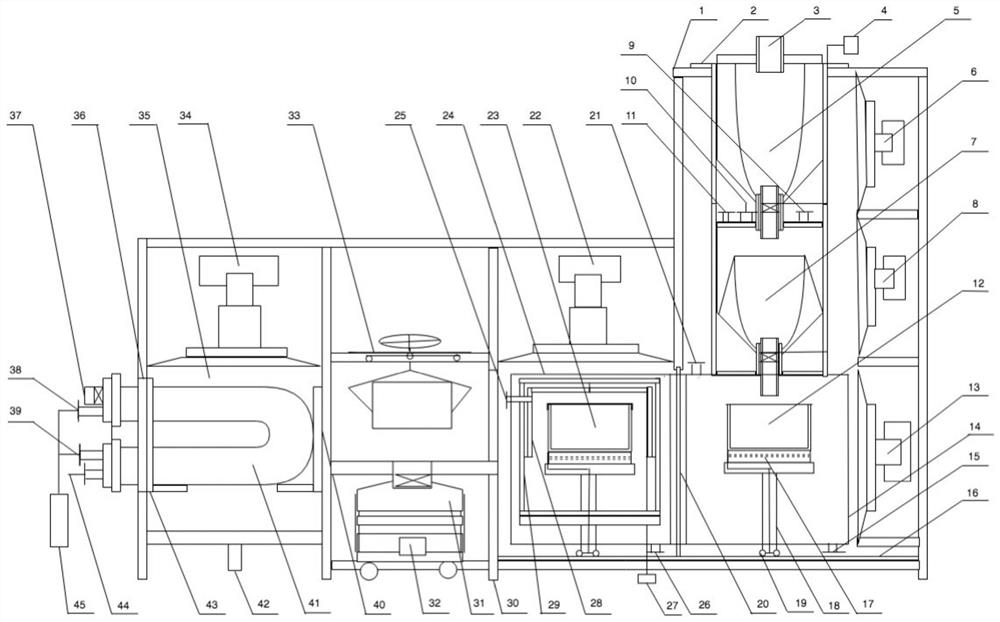

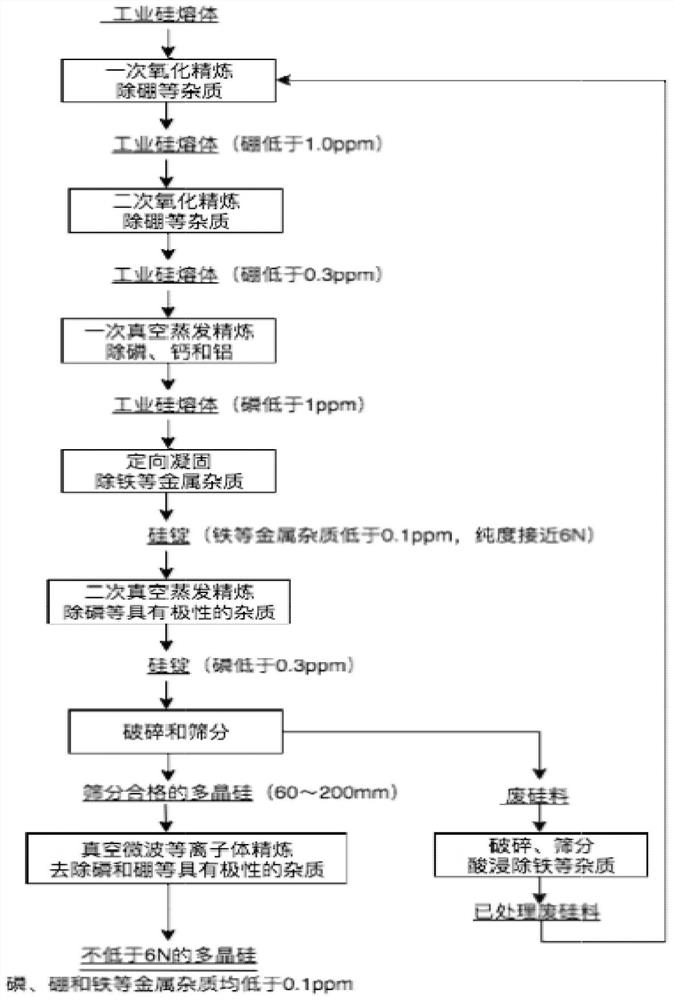

Method and device for preparing 6N polycrystalline silicon by vacuum microwave refining of industrial silicon

ActiveCN112624122AConducive to technology upgradesAvoid pollutionFinal product manufactureSilicon compoundsSingle crystalSolar cell

The invention discloses a method and a device for preparing 6N polycrystalline silicon by vacuum microwave refining of industrial silicon, wherein the method comprises the following steps: flowing industrial silicon melt into a primary oxidation refining furnace, introducing mixed gas I, adding SiO2 powder to perform primary oxidation refining, flowing into a secondary oxidation refining furnace, vacuumizing the system, and introducing mixed gas II; then adding SiO2 powder to perform secondary oxidation refining, enabling the mixture to flow into a directional solidification crucible to be subjected to primary vacuum evaporation and directional solidification refining, and heating the materials to be subjected to secondary vacuum evaporation refining; cooling and taking out the silicon ingot, removing the head, tail and edge portions, and crushing and screening the product; then feeding the product into a reactor and vacuumizing the equipment, feeding argon and mixed gas III, and carrying out microwave plasma vacuum evaporation and oxidizing volatilization refining to prepare polycrystalline silicon of which the purity is not less than 6N, the content of metal impurities such as boron, phosphorus, iron and the like is less than 0.1 ppm, the resistivity is about 2.5 ohm.cm. According to the invention, the quality requirement of the polycrystalline silicon solar cell material is met, and the high-quality and high-efficiency monocrystalline silicon solar cell material can be obtained through subsequent casting or single crystal drawing.

Owner:KUNMING UNIV OF SCI & TECH

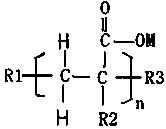

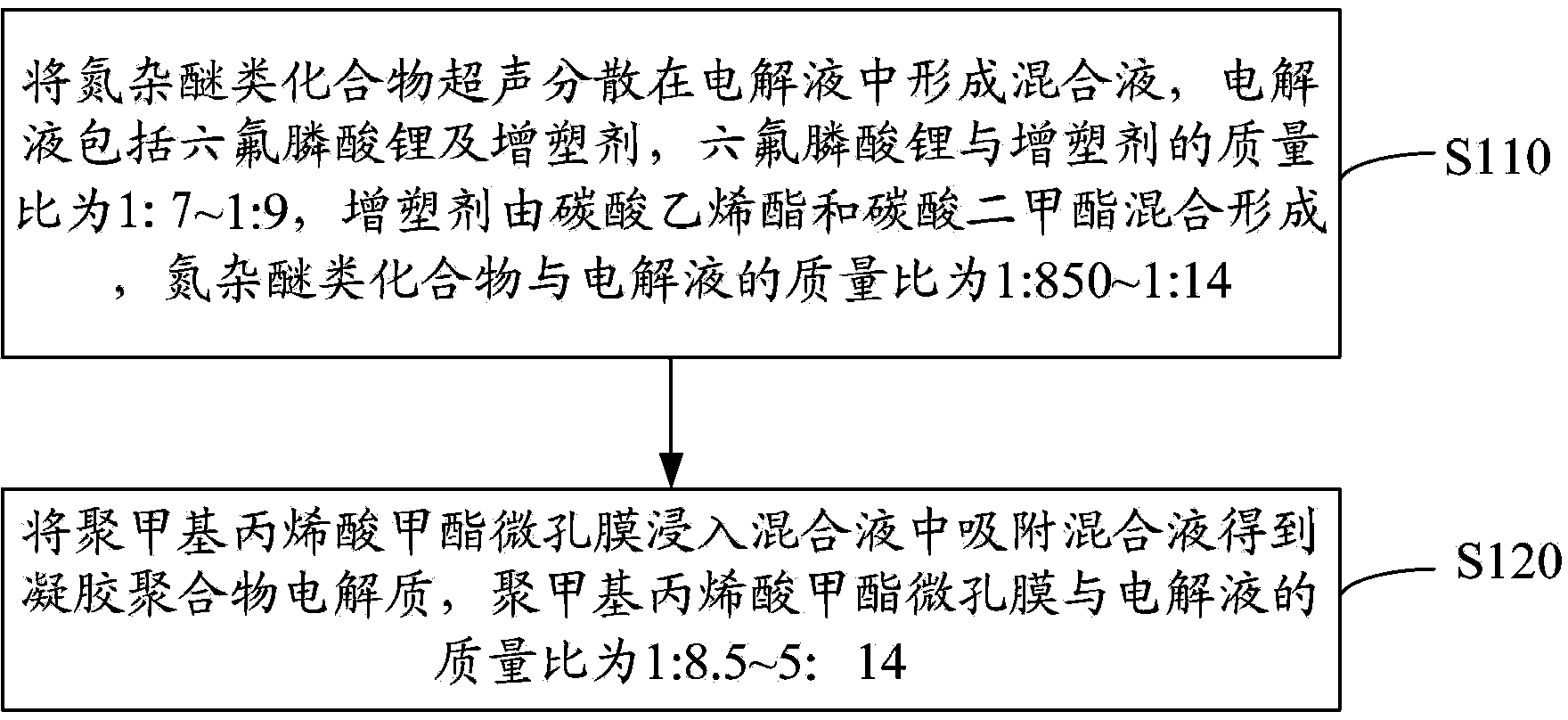

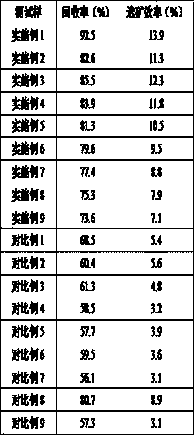

Gel polymer electrolyte and preparation method thereof

InactiveCN103811805AImprove conductivityIncrease the degree of dissociationElectrolyte accumulators manufacturePolymer electrolytesPolymer science

The invention relates to a gel polymer electrolyte, which includes polymethyl methacrylate, and an electrolyte solution and an aza-ether compound adsorbed in the polymethyl methacrylate. Specifically, in the gel polymer electrolyte, the mass content of the polymethyl methacrylate is 10%-25%, the mass content of the electrolyte solution is 70%-85%, and the mass content of the aza-ether compound is 0.1%-5%. The electrolyte solution comprises lithium hexafluorophosphonate and a plasticizer in a mass ratio of 1:7-1:9, and the plasticizer is formed by mixing of ethylene carbonate and dimethyl carbonate. The gel polymer electrolyte has high conductivity. And the invention also provides a preparation method of the gel polymer electrolyte.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Preparation method of novel flotation collector

The invention discloses a preparation method of a novel flotation collector. The preparation method comprises the steps that cotton oil fatty acid is taken as a raw material and then subjected to saponification treatment to obtain cotton oil fatty acid soap, citric acid, sodium silicate, sodium carbonate, sodium oleate and phenoxyacetic acid composite products are added, and composite fatty acid citrate-based carboxylic acid containing multi-element carboxyl is obtained and applied to phosphate ore flotation by serving as a phosphate ore collector. The synthetic agent has the characteristics of being good in water solubility, high in collecting capability, good in selectivity and good in low temperature resistance, has the advantages of being low in agent dosage and production cost compared with unmodified fatty acid, and has the important significance for reducing the flotation cost and improving the flotation efficiency.

Owner:隆化县新村矿业有限公司

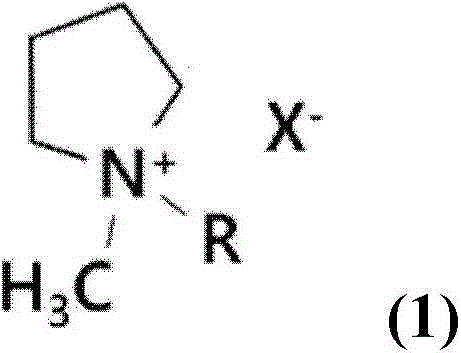

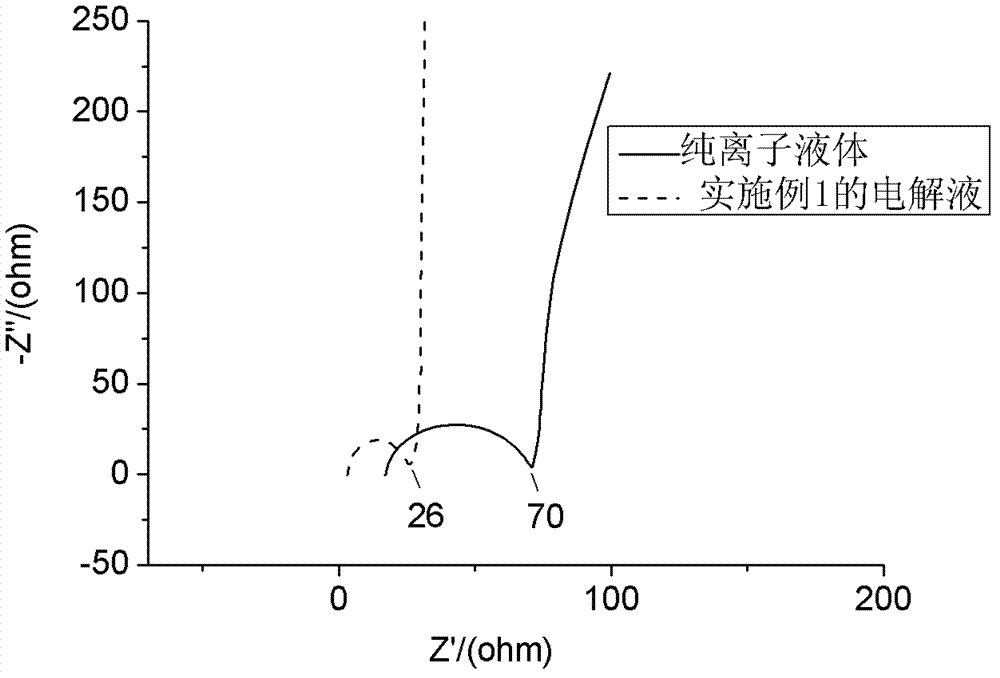

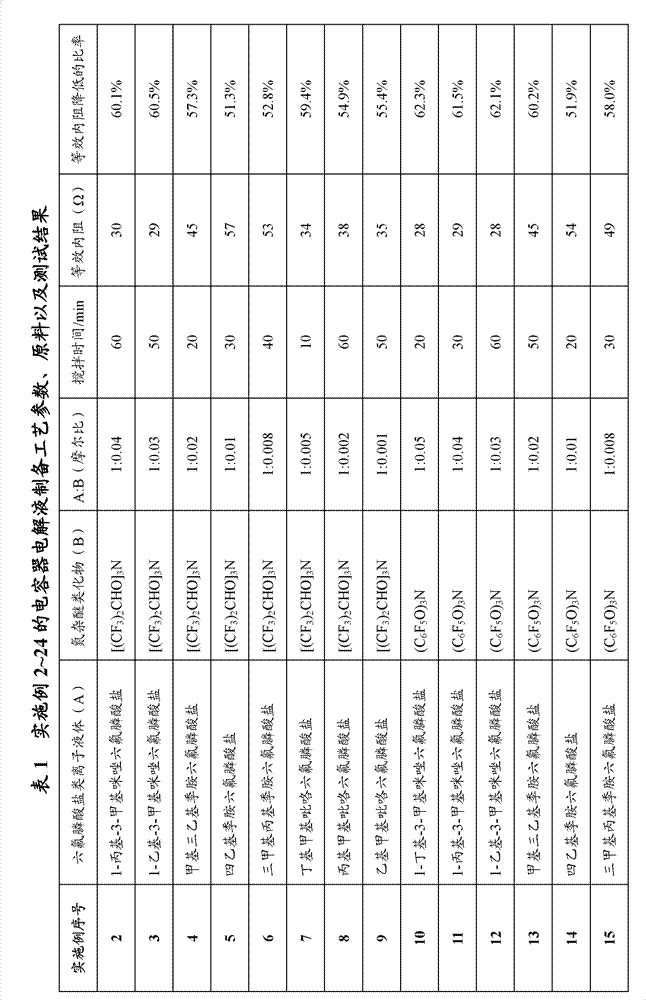

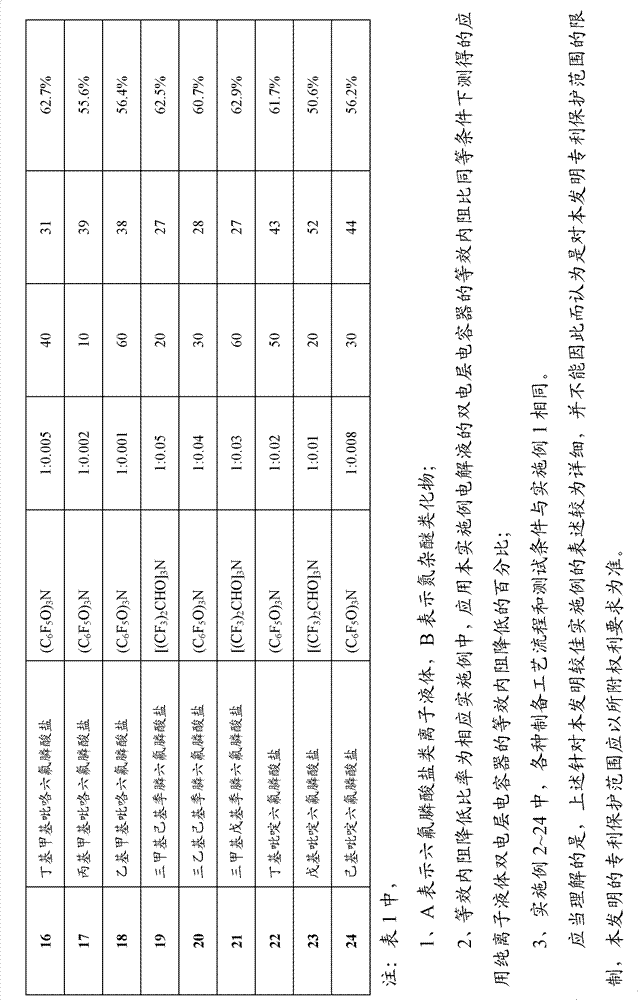

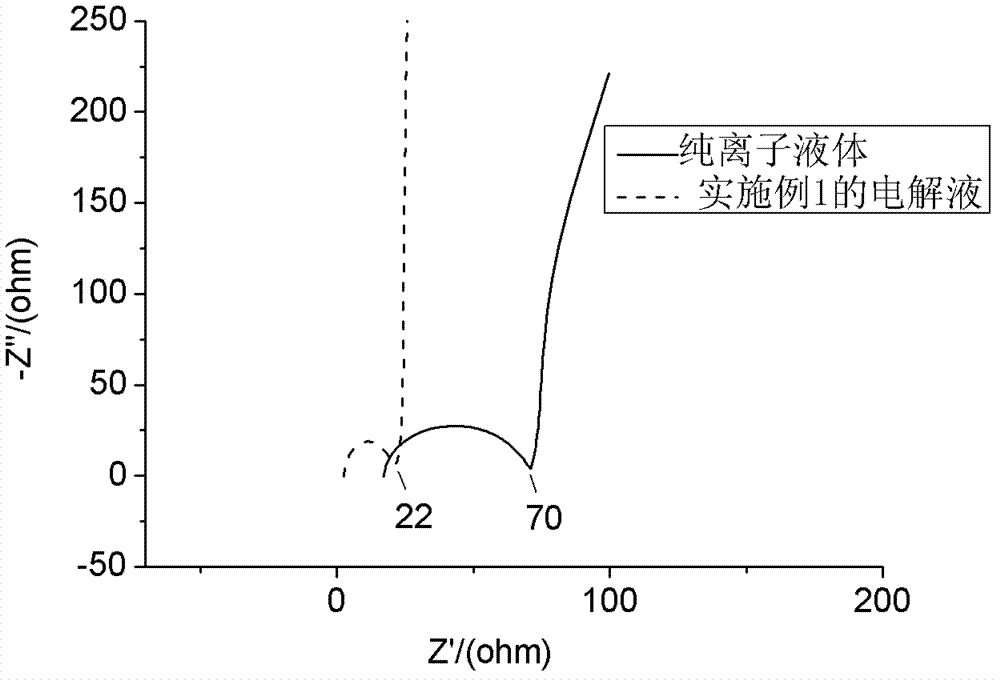

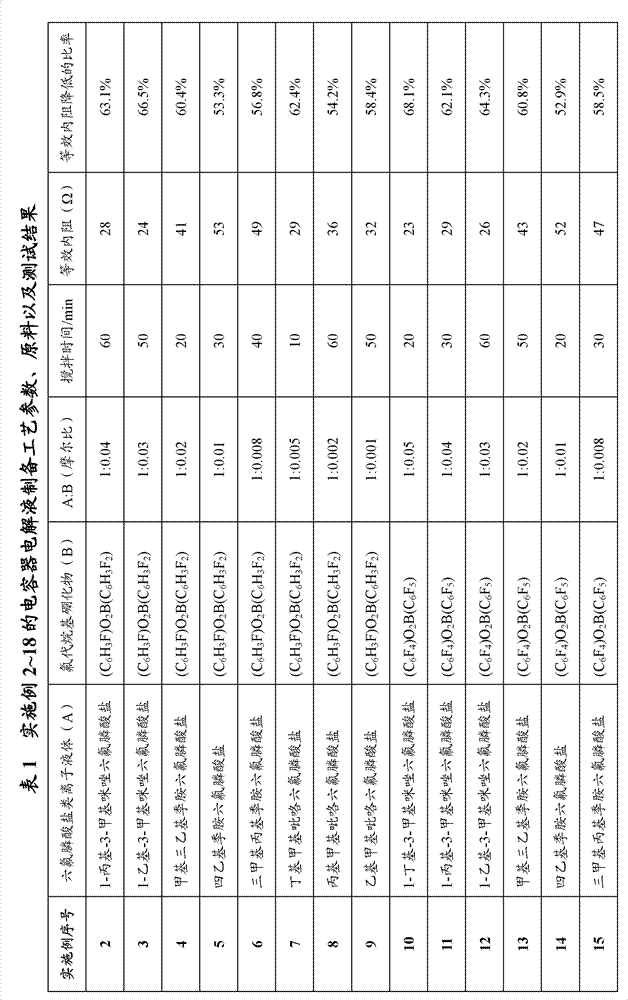

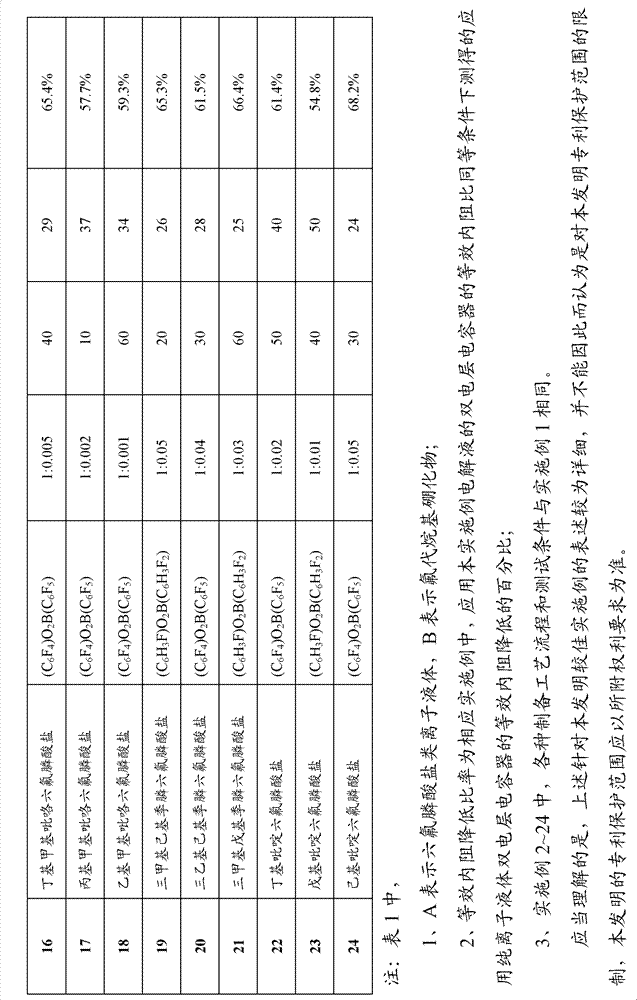

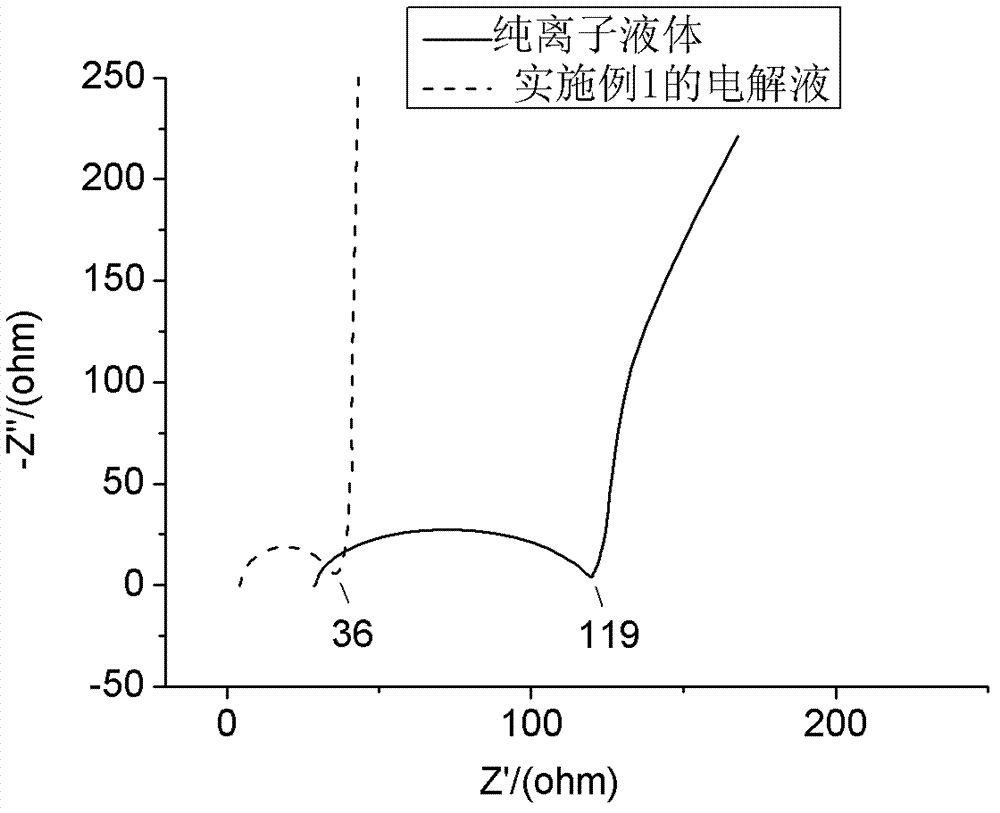

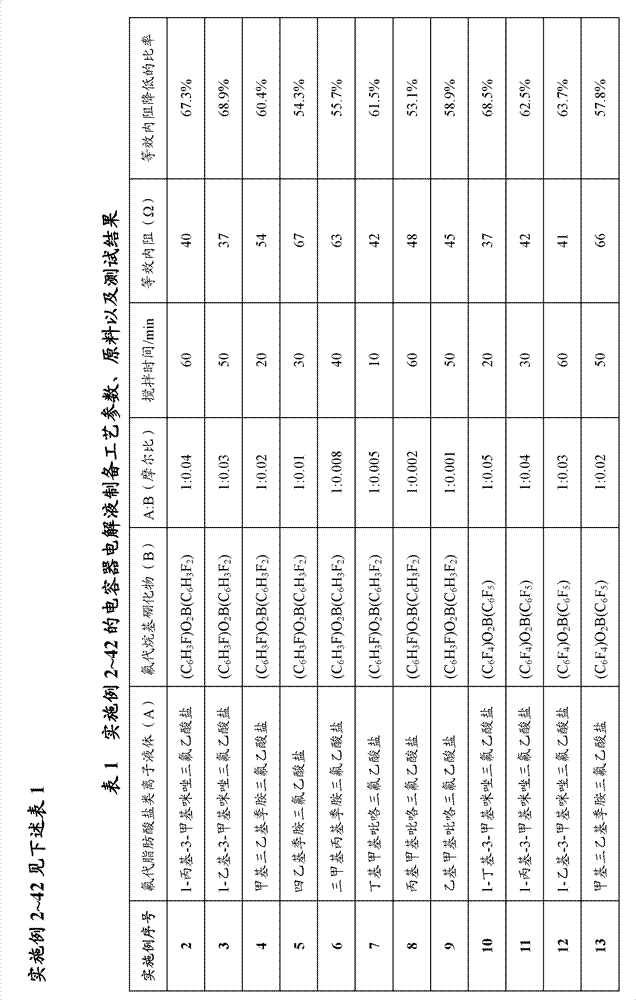

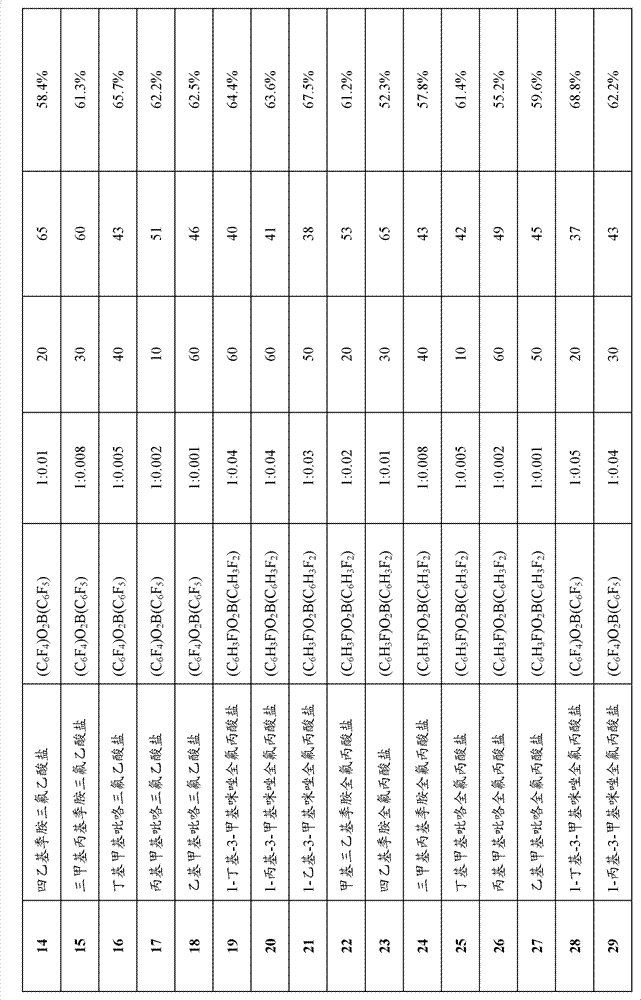

Electrolyte and electrical double-layer capacitor

InactiveCN102956361AImprove conductivityReduce equivalent internal resistanceHybrid capacitor electrolytesHexafluorophosphateSolubility

The invention belongs to the field of electrochemistry, and discloses an electrolyte and a capacitor using the electrolyte. The electrolyte comprises hexafluorophosphate ionic liquid and an aza-ether compound with a molar ratio of 1:(0.001-1):0.05. The invention further provides the electrolyte used for the double-layer capacitor, the electrolyte is formed by mixing the hexafluorophosphate ionic liquid with the aza-ether compound, the aza-ether compound can form a coordination compound with PF6-, and accordingly dissociation level of the hexafluorophosphate ionic liquid is increased, conductivity of the hexafluorophosphate ionic liquid is greatly increased, and equivalent internal resistance of the double-layer capacitor is greatly lowered. The aza-ether compound is used as addictive, the conductivity of the hexafluorophosphate ionic liquid can be improved greatly by only needing less than 5% of the total mass of the hexafluorophosphate ionic liquid, the conductivity of the hexafluorophosphate ionic liquid is improved by adding organic solvent so that the hexafluorophosphate ionic liquid which is low in solubility and is dissolved by a great quantity of organic liquid is dissolved, and usage cost of the electrolyte is greatly saved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

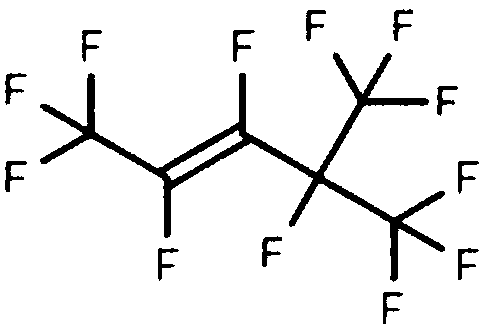

Electrolyte and double-electric-layer capacitor

InactiveCN102956363AImprove conductivityReduce equivalent internal resistanceHybrid capacitor electrolytesHexafluorophosphateChemistry

The invention belongs to the field of electrochemistry and discloses electrolyte and a double-electric-layer capacitor. The electrolyte comprises hexafluorophosphate ionic liquid and fluorinated alkyl boride in the molar ratio of 1:0.001-1:0.05. The electrolyte for the double-electric-layer capacitor is obtained by mixing the hexafluorophosphate ionic liquid with the fluorinated alkyl boride, and the fluorinated alkyl boride and PF6- can form a complex, so that the dissociation degree of the hexafluorophosphate ionic liquid is increased, conductivity of the electrolyte is increased greatly, and equivalent internal resistance of the double-electric-layer capacitor is lowered greatly. The fluorinated alkyl boride is used as additives, the conductivity of the electrolyte is increased greatly only with the fluorinated alkyl boride accounting for not more than 5% of the total mass of the electrolyte, and if organic solvents are added to increase the conductivity, a great amount of organic liquid is needed to dissolve the hexafluorophosphate ionic liquid low in dissolvability, so that consumption cost of the electrolyte is saved greatly.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Capacitor with double electric layers and electrolyte for capacitor

ActiveCN102956362AReduce equivalent internal resistanceReduce use costHybrid capacitor electrolytesBorideInternal resistance

The invention belongs to the field of electrochemistry, and discloses a capacitor with double electric layers and electrolyte for the capacitor. The electrolyte for the capacitor with the double electric layers comprises fluoro-fatty acid salt ionic liquid and fluoro-alkyl boride, and the molar ratio of the fluoro-fatty acid salt ionic liquid to the fluoro-alkyl boride ranges from 1:0.001 to 1:0.05. The electrolyte for the capacitor with the double electric layers is prepared by mixing the fluoro-fatty acid salt ionic liquid with the fluoro-alkyl boride, complexes can be formed by the fluoro-alkyl boride and fluoro-fatty acid radicals, accordingly, the dissociation degree of the fluoro-fatty acid salt ionic liquid is increased, the conductivity of the fluoro-fatty acid salt ionic liquid is greatly improved, and equivalent internal resistance of the capacitor with the double electric layers is greatly reduced. Besides, the fluoro-alkyl boride is used as an additive, an effect of greatly improving the conductivity can be realized only by utilizing the fluoro-alkyl boride with the dosage lower than 5% of the total mass, while a large amount of organic liquid is required to dissolve low-dissolvability fluoro-fatty acid salt ionic liquid when organic solvents are added to improve conductivity in the prior art, accordingly, the dosage of the electrolyte for the capacitor with the double electric layers is greatly reduced, and the cost of the electrolyte for the capacitor with the double electric layers is greatly saved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com