High-pressure roller final grinding and screening method of middling coal

A technology of high-pressure roller mills and high-pressure rollers, which is applied to chemical instruments and methods, flotation, solid separation, etc., can solve problems such as unfavorable boiler operation, reduced boiler efficiency, increased heavy oil combustion, etc., and achieves significant energy-saving and consumption-reducing effects , Reasonable recycling and utilization, and the effect of improving sorting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

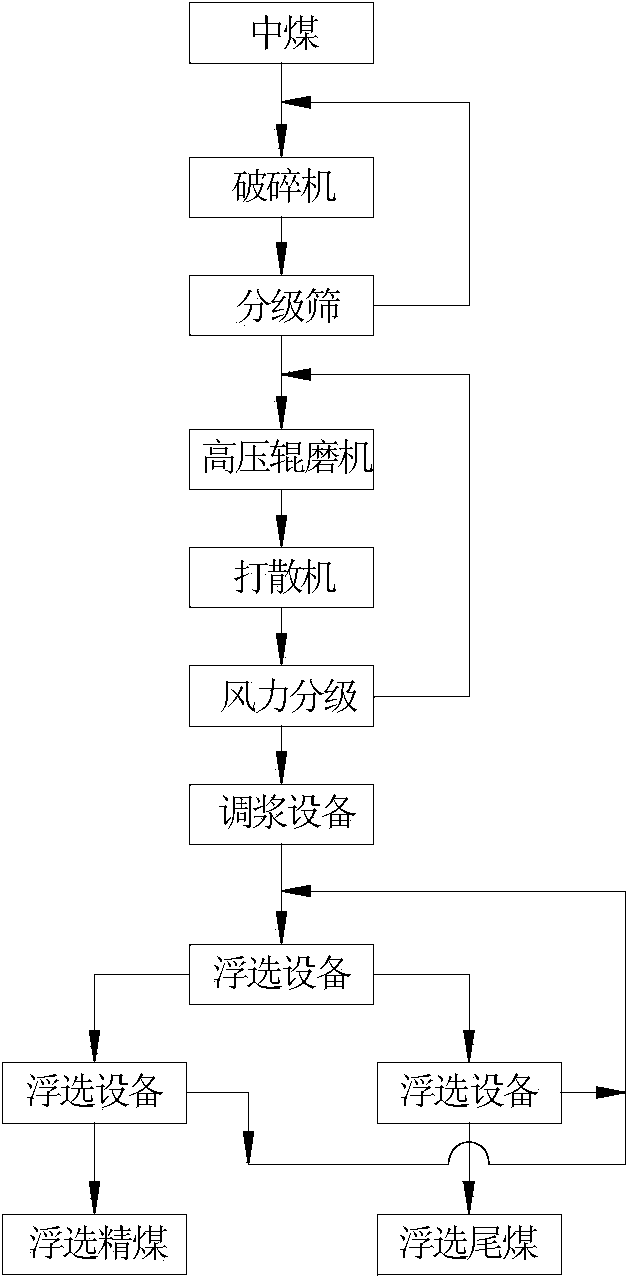

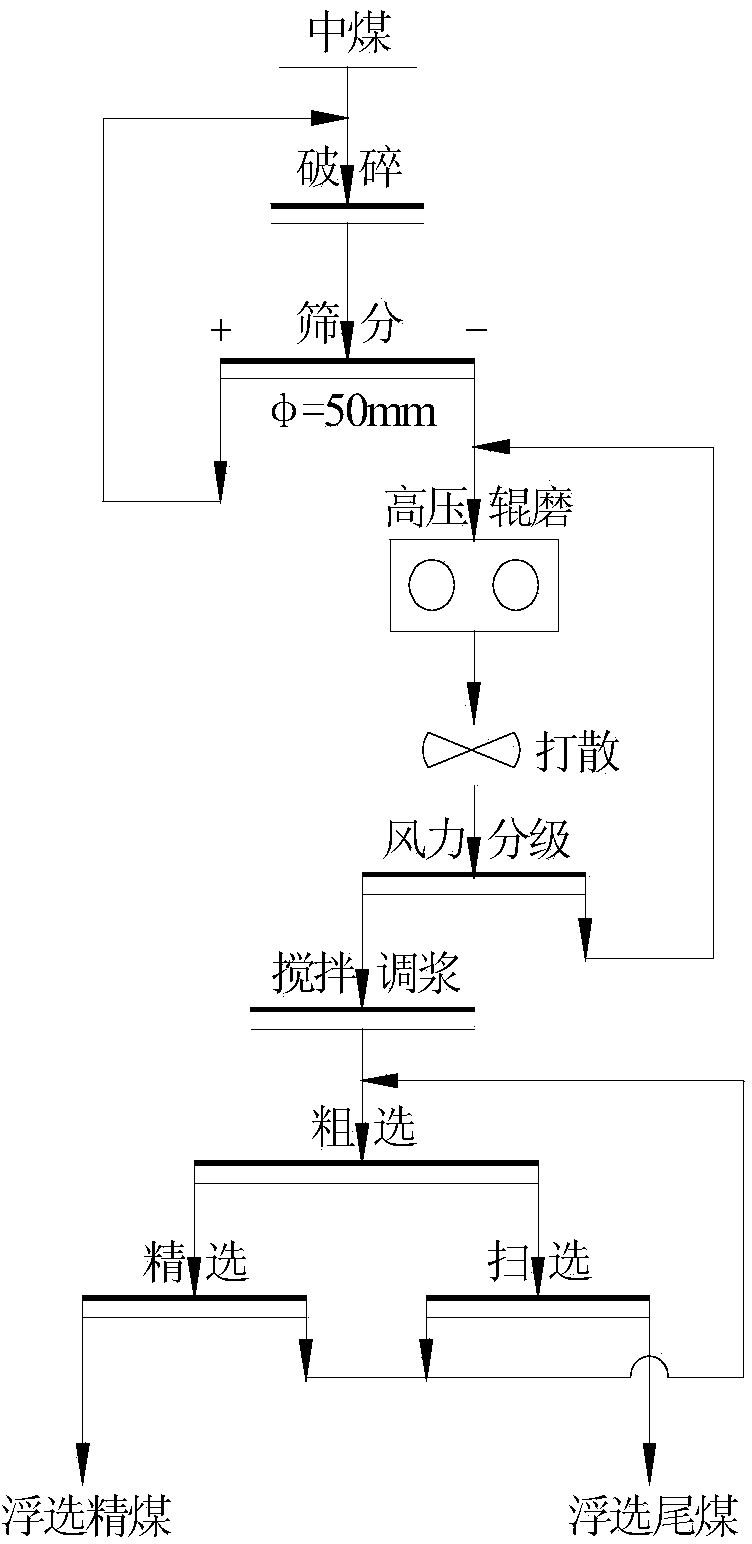

[0022] China Coal is selected coal from the coking coal washing plant, the particle size is less than 200mm, and the ash content is 24.00%. The high-pressure roller final grinding system is used to carry out flotation after the medium coal is pulverized. The process steps are as follows:

[0023] (1) Medium coal is crushed with a cone crusher, and the crushed products should be screened with a sieve with a sieve hole of 30mm. The material on the screen is returned to the cone crusher for crushing, and the material under the screen enters the silo;

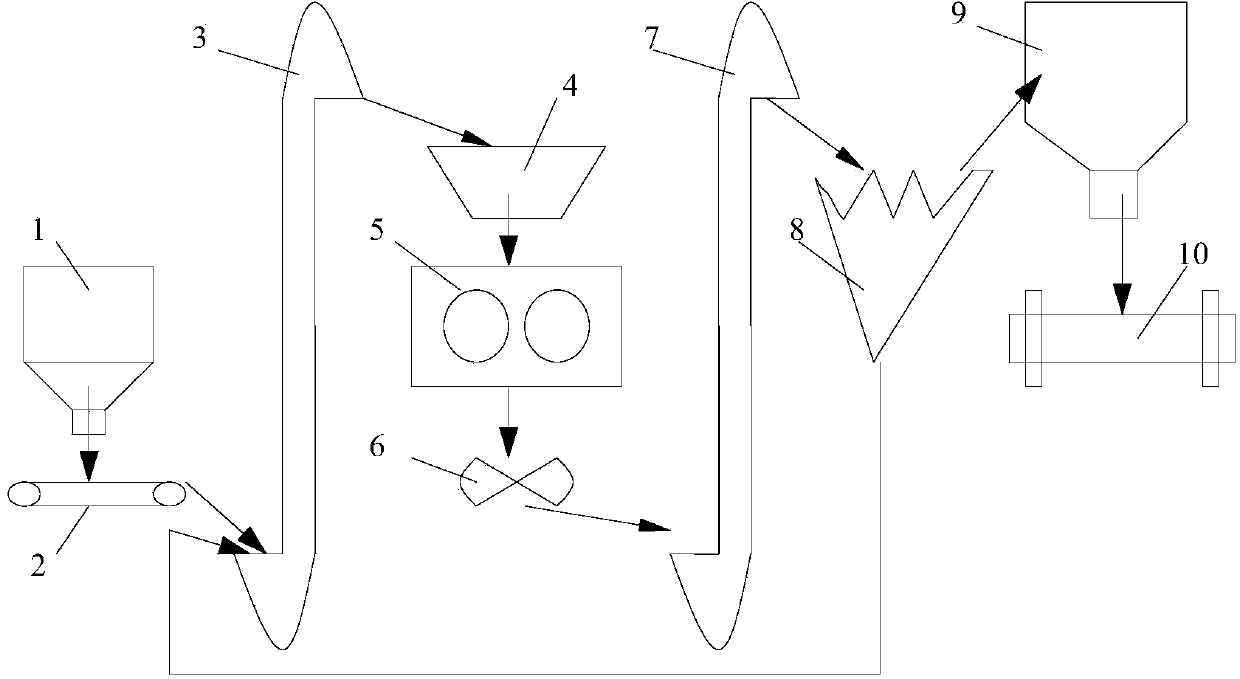

[0024] (2) Set the working parameters of the high-pressure roller mill, the high-pressure roller crushing is completely open, the pressure between the rollers is 6.0MPa, the roller speed is 10r / min, and the roller gap is 3mm. After the high-pressure roller mill runs normally, set the speed of the feeding belt to 0.25m / s, the speed of the rotor of the V-type powder classifier to 50r / min, and the speed of the dust collector to 3000r / ...

Embodiment 2

[0028] China Coal is selected coal from the coking coal washing plant, the particle size is less than 50mm, and the ash content is 39.05%. The high-pressure roller final grinding system is used to carry out flotation after the medium coal is pulverized. The process steps are as follows:

[0029] (1) Medium coal is crushed by a high-pressure roller mill. The crushed product should be screened with a sieve with a mesh size of 10mm. The material on the screen is returned to the high-pressure roller mill for crushing, and the material under the screen enters the silo;

[0030] (2) Set the working parameters of the high-pressure roller mill, the high-pressure roller crushing is completely open, the pressure between the rollers is 3.0MPa, the roller speed is 20r / min, and the roller gap is 2mm. After the high-pressure roller mill runs normally, set the speed of the feeding belt to 0.5m / s, the speed of the rotor of the V-type powder classifier to 200r / min, and the speed of the dust co...

Embodiment 3

[0034] China Coal is selected coal from the coking coal washing plant, the particle size is less than 50mm, and the ash content is 21.84%. The high-pressure roller final grinding system is used to carry out flotation after the medium coal is pulverized. The process steps are as follows:

[0035] (1) Medium coal is crushed by a jaw crusher. The crushed products should be screened with a sieve with a sieve hole of 20mm. The material on the screen is returned to the jaw crusher for crushing, and the material under the screen enters the silo;

[0036] (2) Set the working parameters of the high-pressure roller mill, the high-pressure roller crushing belt edge material circulation, the pressure between the rollers is 4.0MPa, the roller speed is 30r / min, and the roller gap is 3mm. After the high-pressure roller mill runs normally, set the speed of the feeding belt to 0.25m / s, the speed of the rotor of the V-type powder classifier to 300r / min, and the speed of the dust collector to 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com