Preparation method of all-solid-state fluorine-containing polymer electrolyte membrane and lithium ion battery

An electrolyte membrane and polymer technology, applied in the field of lithium-ion batteries, can solve the problems of low room temperature conductivity, narrow electrochemical window, low conductivity, etc., and achieve the effect of improving room temperature ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

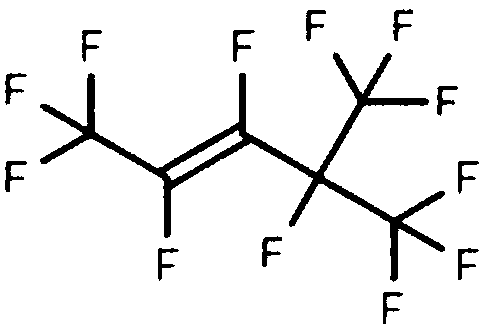

[0034] The all-solid fluorine-containing polymer electrolyte membrane recorded in the present invention is a copolymer all-solid electrolyte membrane of polyether monomer and fluorine-containing vinyl monomer, and its preparation method includes the following steps:

[0035] Step 1: In parts by weight, add 5-50 parts of fluorine-containing vinyl monomers, 40-80 parts of polyether monomers, and 0-3 parts of polyethylene glycol methacrylate-based monomers to 100-300 parts In the solvent, keep a nitrogen or inert gas atmosphere, stir at a speed of 100-800r / min for 10min-120min, then add 0.05-1.00 parts of initiator, then react at 60°C-110°C for 5-48h, and obtain polymerization after purification Object A;

[0036] Step 2: In parts by weight, add 30-80 parts of polymer A, 5-20 parts of lithium salt, 0-10 parts of filler and 0-10 parts of additives into 100-300 parts of solvent, dry nitrogen or inert gas Under the atmosphere, stir at a speed of 100-800r / min, stir for 1-10 hours, the...

Embodiment 1

[0051] An all-solid-state fluorine-containing polymer electrolyte membrane is a copolymer all-solid-state electrolyte membrane of a polyether monomer and a fluorine-containing vinyl monomer, and its preparation method comprises the following steps:

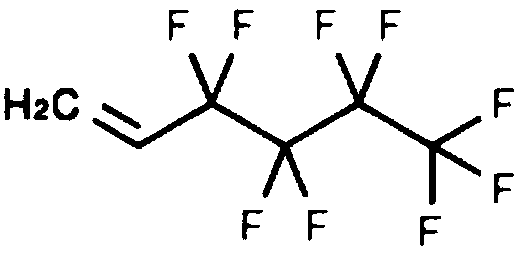

[0052] Step 1: In parts by weight, 3 parts of 1H, 1H, 2H-perfluoro-1-hexene, 2 parts of octafluoropentyl methacrylate, 50 parts of polyethylene glycol methyl ether acrylic acid with a molecular weight of 480 ester, 30 parts of polyethylene glycol methyl ether methacrylate with a molecular weight of 20000, 2 parts of polyethylene glycol methyl methacrylate with a molecular weight of 300, and 1 part of polyethylene glycol monoallyl ether with a molecular weight of 2400, adding In 100 parts of toluene, continue to blow nitrogen, stir at a speed of 800r / min for 10min, then add 1.00 parts of azobisisobutyronitrile, then react at 60°C for 48h, and obtain polymer A after purification;

[0053] Step 2: In parts by weight, 80 parts of poly...

Embodiment 2

[0057] An all-solid-state fluorine-containing polymer electrolyte membrane is a copolymer all-solid-state electrolyte membrane of a polyether monomer and a fluorine-containing vinyl monomer, and its preparation method comprises the following steps:

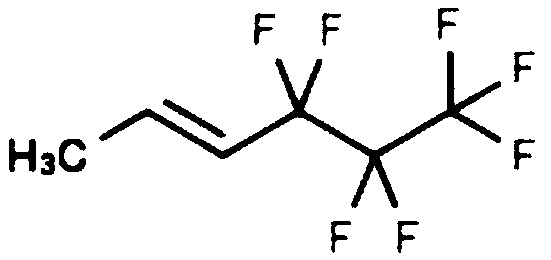

[0058] Step 1: In parts by weight, 20 parts of 4,4,5,6,6,6-octafluoro-2-hexene, 30 parts of hexafluorobutyl methacrylate, 30 parts of polyethylene glycol with a molecular weight of 5000 Alcohol methyl ether acrylate, 10 parts of polyethylene glycol methyl ether methacrylate with a molecular weight of 300, 1 part of polyethylene glycol methyl methacrylate with a molecular weight of 2500, and 1 part of polyethylene glycol monoallyl with a molecular weight of 100 Add ether to 300 parts of benzene, continue argon flow, stir at a speed of 100r / min for 120min, then add 0.05 part of benzoyl peroxide, then react at 110°C for 36h, and obtain polymer A after purification;

[0059] Step 2: In parts by weight, 30 parts of polymer A, 2 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com