Method for continuously separating lignocellulose components

A lignocellulose and quality technology, which is applied in the fields of fiber raw materials, fiber raw material processing, textiles and paper making, etc., can solve problems such as poor results, and achieve the effect of improving the effect of enzymatic hydrolysis and saccharification, improving catalytic efficiency and efficient dealkalization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

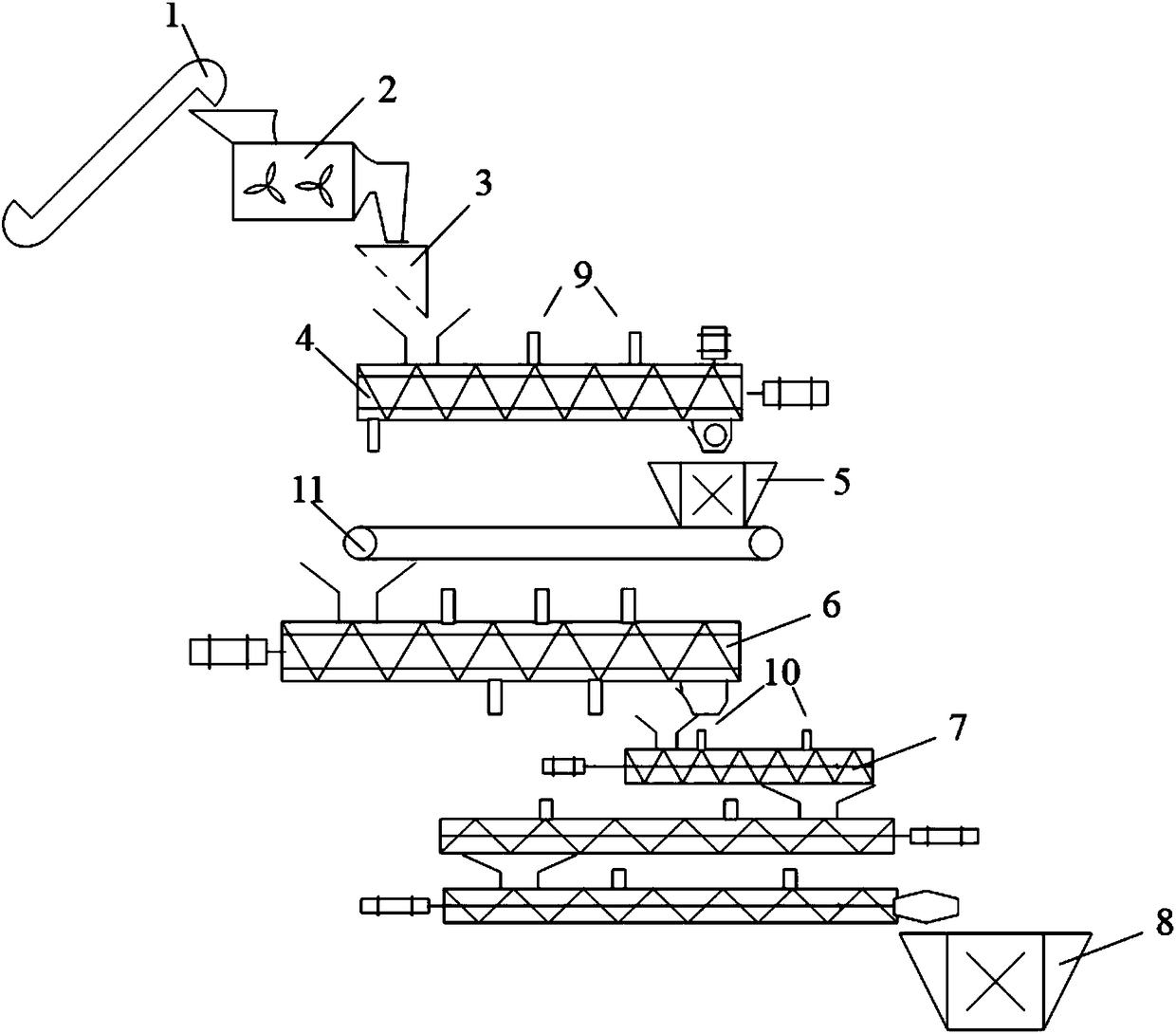

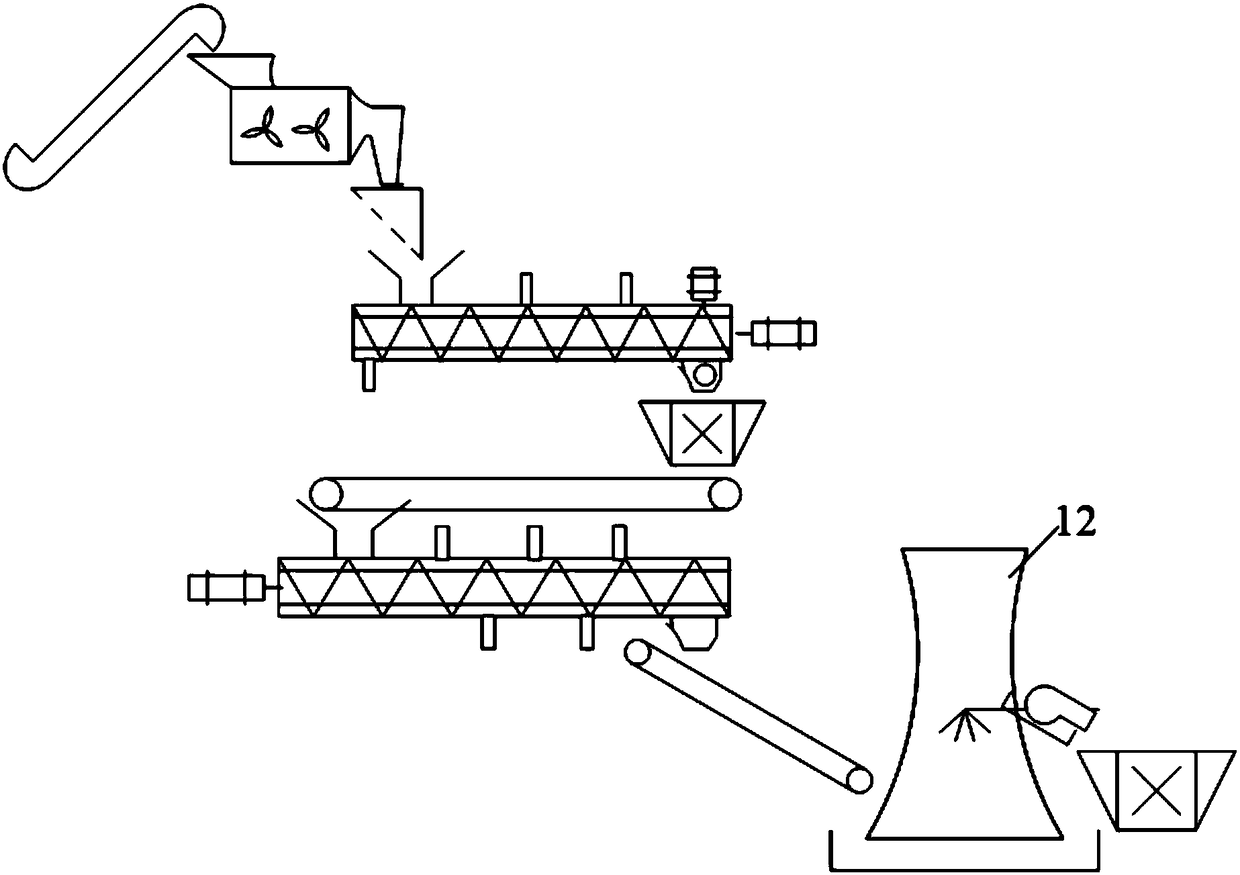

[0034] First cut the corn stalks into 2-8cm small pieces. Add it into the drum washing machine 2 to rinse the silt and soluble matter, and the washed water filters the silt and recycles multiple batches for anaerobic treatment. When the cleaned corn stalks pass through the filter 3, they are extruded and dehydrated and enter the first section of the twin-screw extruder 4. At the same time, 5% NaOH solution was pumped in to obtain alkaline catalyzed stalks, which were then placed in an insulated bin for 60 minutes. Transport the material after the heat preservation reaction to the screw displacement washing dealkalization machine, pump in clean water for countercurrent washing, and obtain lignin alkaline black liquor and dealkalization material. Transport the dealkalized material to the screw feeder at the front of the single helical tubular reactor to form a plug, and at the same time, feed high-temperature steam at 180°C into the reactor, and the high-temperature steam penet...

Embodiment 2

[0036] First cut the corn stalks into 2-8cm small pieces. Add it into the drum washing machine 2 to rinse the silt and soluble matter, and the washed water filters the silt and recycles multiple batches for anaerobic treatment. When the cleaned corn stalks pass through the filter 3, they are extruded and dehydrated and enter the first section of the twin-screw extruder 4. At the same time, 2% NaOH solution was pumped in to obtain alkaline catalyzed stalks, which were then placed in an insulated bin for 30 minutes. Transport the material after the heat preservation reaction to the screw displacement washing dealkalization machine, pump in clean water for countercurrent washing, and obtain lignin alkaline black liquor and dealkalization material. Transport the dealkalized material to the screw feeder at the front of the single helical tubular reactor to form a material plug, and at the same time feed 140°C high-temperature steam and 0.2% sulfuric acid solution into the reactor,...

Embodiment 3

[0038]First cut the corn stalks into 2-8cm small pieces. Add it into the drum washing machine 2 to rinse the silt and soluble matter, and the washed water filters the silt and recycles multiple batches for anaerobic treatment. When the cleaned corn stalks pass through the filter 3, they are extruded and dehydrated and enter the first section of the twin-screw extruder 4. At the same time, 4% NaOH solution was pumped in to obtain alkaline catalyzed stalks, which were then placed in an insulated bin for 60 minutes. Transport the material after the heat preservation reaction to the screw displacement washing dealkalization machine, pump in clean water for countercurrent washing, and obtain lignin alkaline black liquor and dealkalization material. Transport the dealkalization material to the screw feeder at the front of the single helical tubular reactor to form a material plug, and at the same time feed 160°C high-temperature steam and 0.5% sulfuric acid solution into the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com