Patents

Literature

49results about How to "Good dissociation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

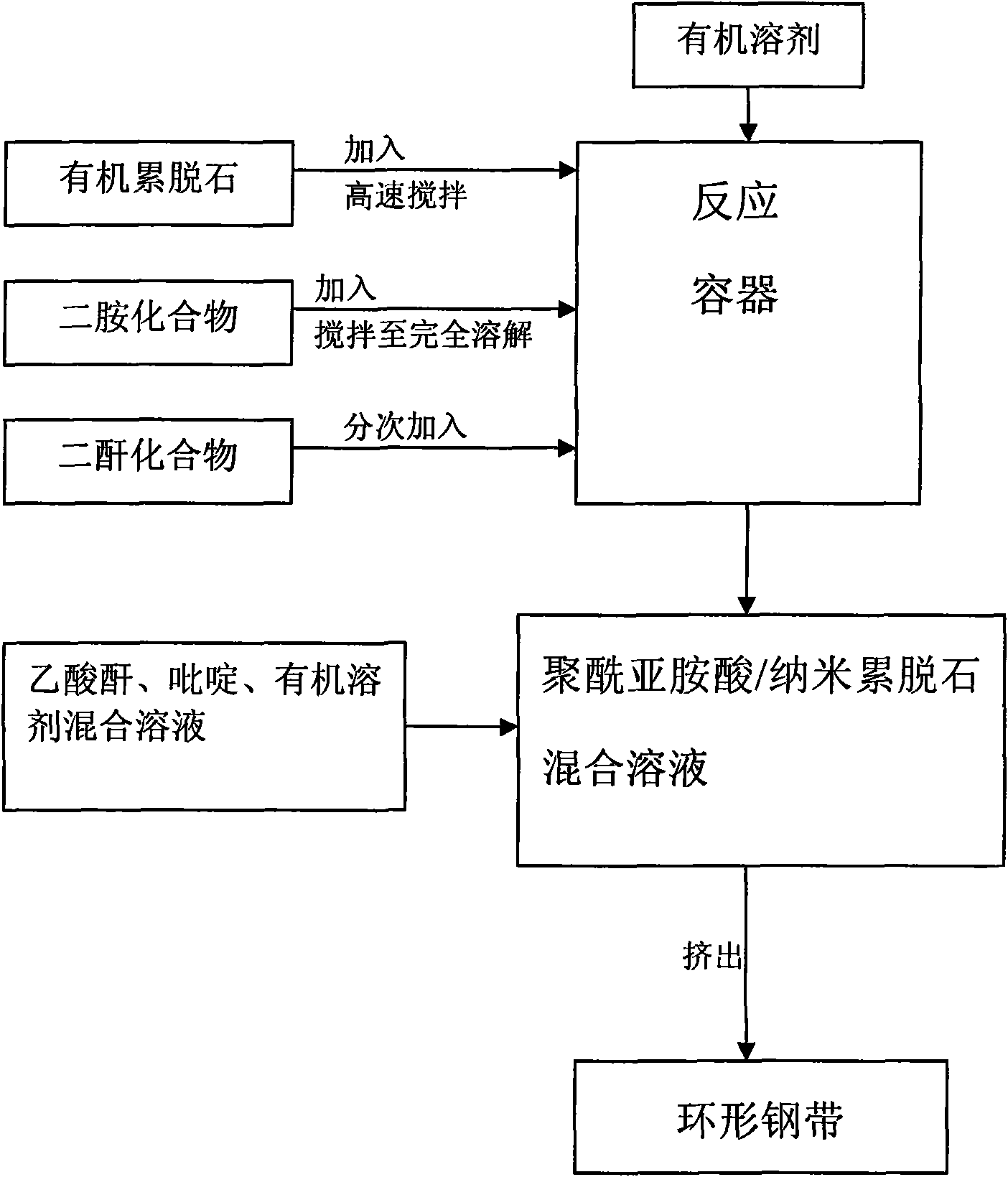

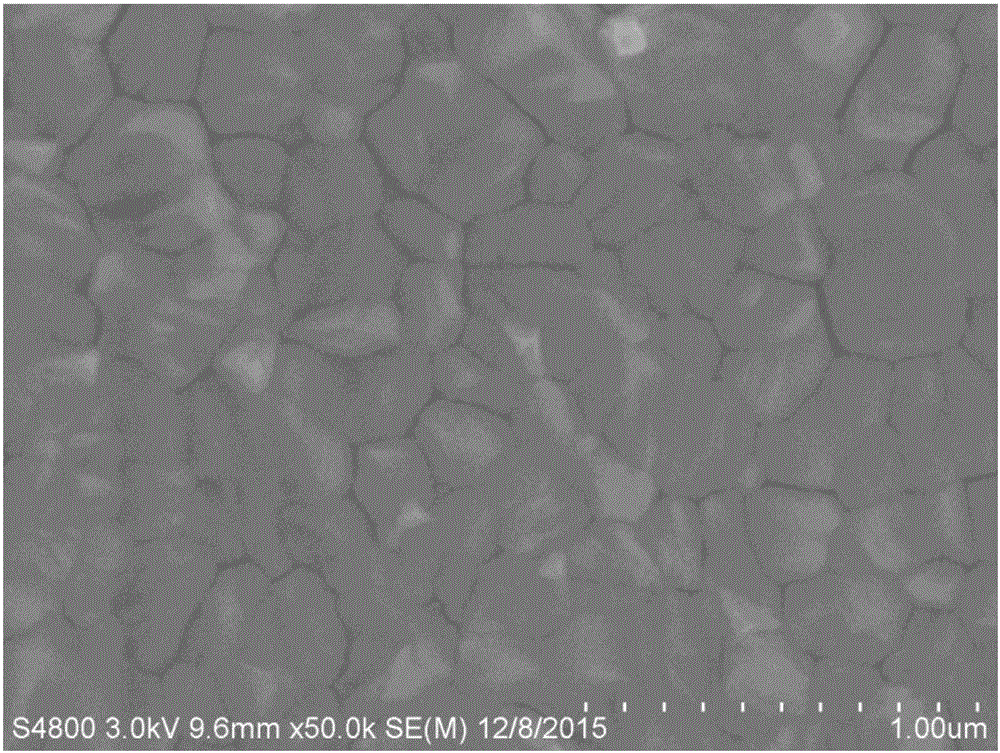

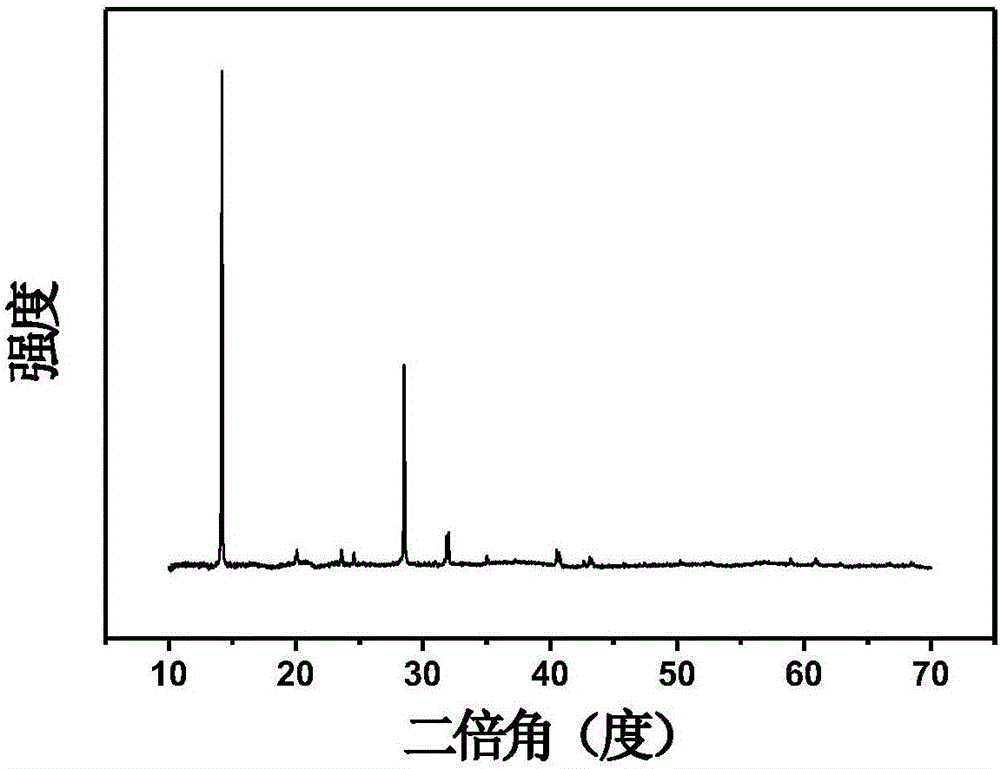

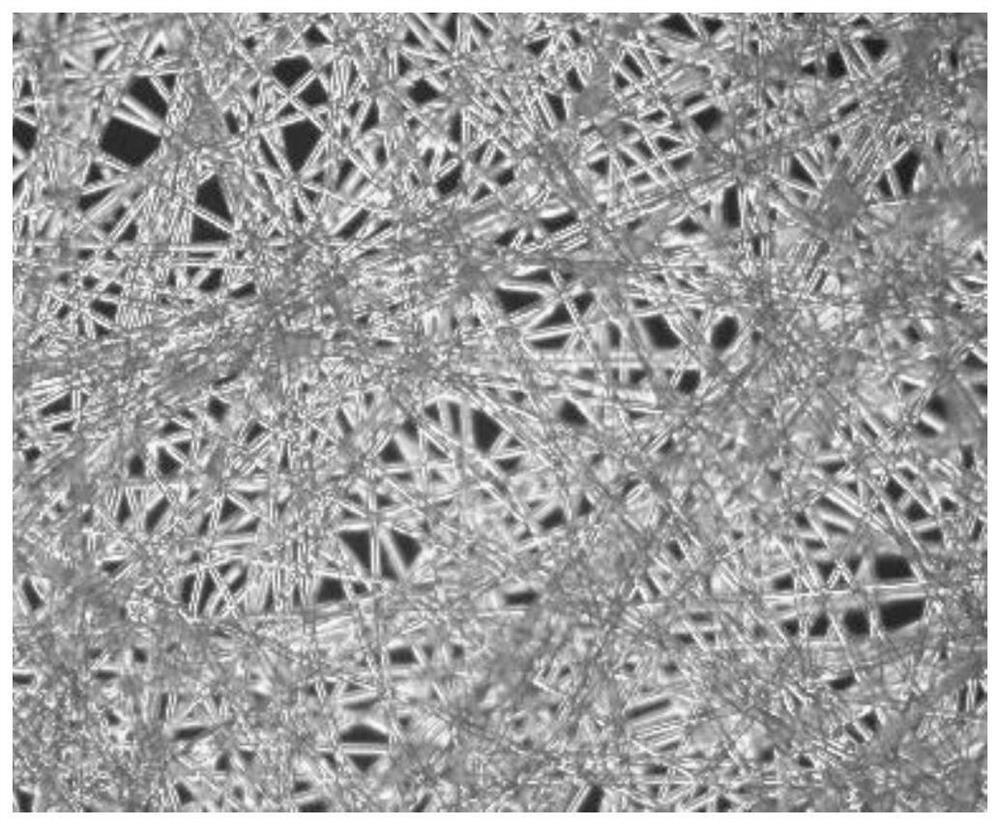

Chemical imidization preparation method of nano rectorite/polyimide film

The invention relates to a chemical imidization preparation method of nano rectorite / polyimide film. A binary surface modifying agent is adopted for organic modifying on rectorite, and the prepared organic rectorite has wider interlamination region and better dissociation effect and is easier to form polyimide / nano rectorite intercalation compound; in-situ polymerization is adopted for adding the organic rectorite, so as to cause the organic rectorite to be more evenly dispersed in polyimide acid; and chemical imidization is used for preparing polyimide nano composite material, so that film forming performance thereof is better. The nano rectorite / polyimide compound film prepared by the invention is improved in thermal stability and size stability with low thermal expansion coefficient.

Owner:西安航天三沃化学有限公司

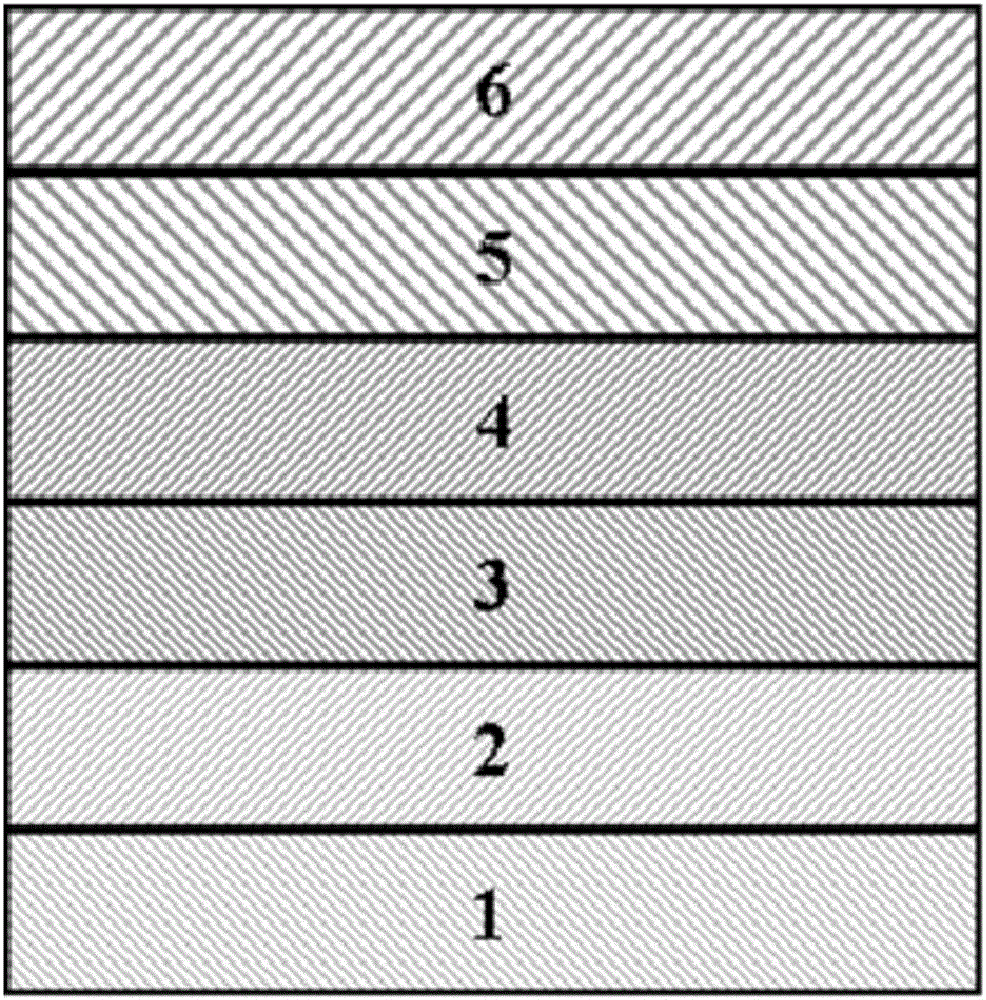

Perovskite photoelectric detector for accelerating electron filtering

ActiveCN106356457AExtended Spectral Response RangeImprove mobility and exciton lifetimeSolid-state devicesSemiconductor/solid-state device manufacturingQuenchingSpectral responsivity

The invention discloses a perovskite photoelectric detector for accelerating electron filtering. The perovskite photoelectric detector comprises a substrate, an anode, an active layer and a compound cathode, wherein a hole-transporting layer is arranged between the anode and the active layer and an electron filtering layer is arranged between the active layer and the compound cathode. According to the invention, a perovskite material, which is characterized by high migration rate, low exciton binding energy, longer exciton life and longer exciton diffusion length, is taken as the active layer of the photoelectric detector, so that the loss of heat exciton in the device is greatly reduced. A novel electron filtering layer is creatively provided; the electrons can be effectively transmitted to the cathode and then collected; the recombination probability of exciton and the quenching effect of electrode to exciton can be greatly reduced; the obtained perovskite photoelectric detector has higher external quantum efficiency and spectral responsivity; the performance is obviously promoted.

Owner:HUAZHONG NORMAL UNIV

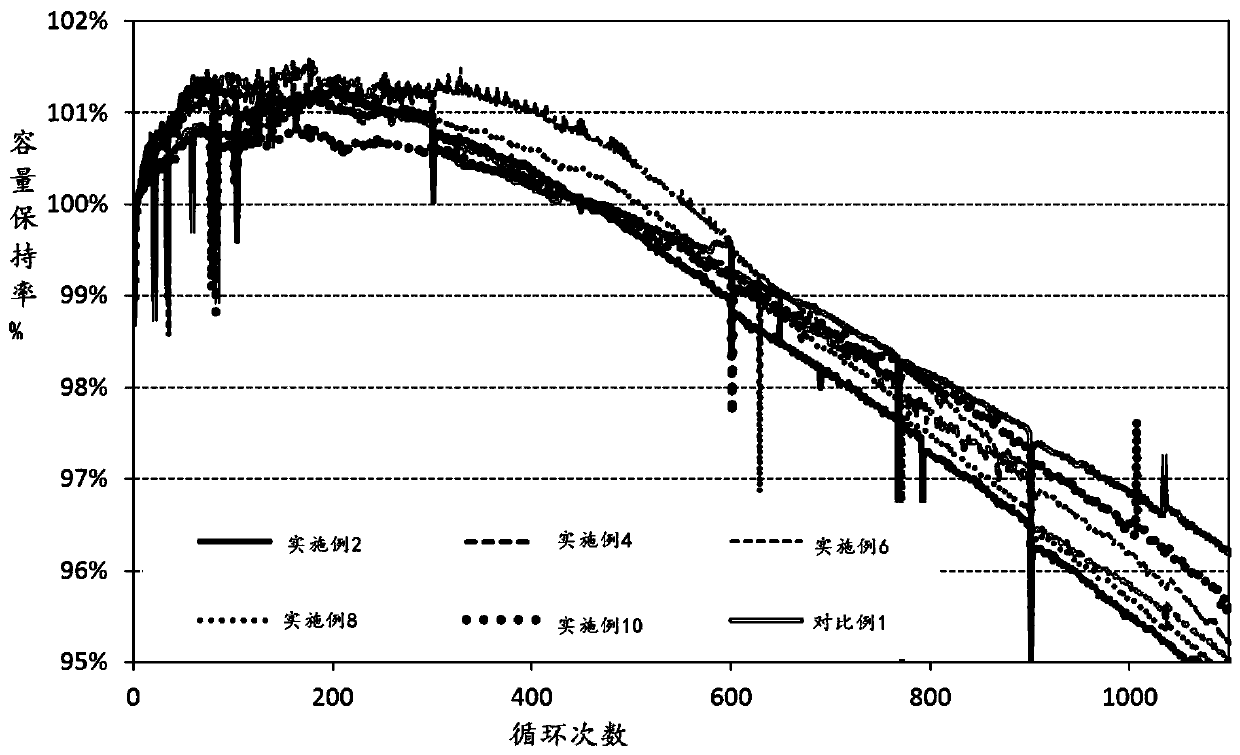

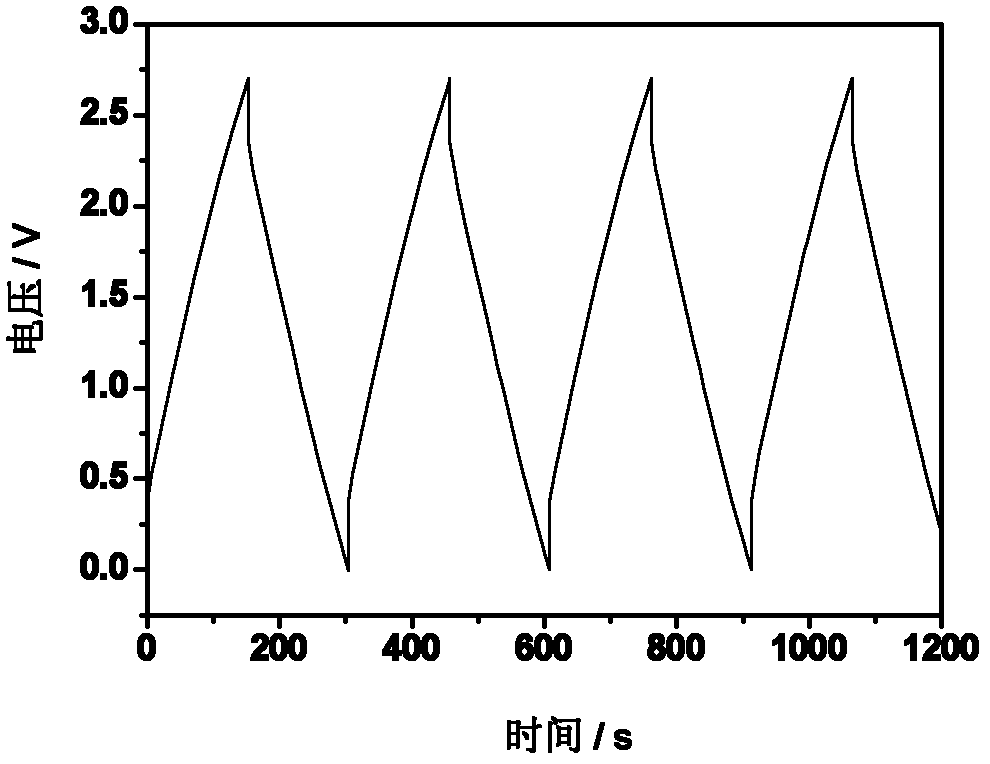

Polymer electrolyte and lithium ion battery comprising same

ActiveCN111138596AImprove electrochemical stabilityImprove high voltage resistance performanceSolid electrolytesSecondary cellsPolymer electrolytesOrganic solvent

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a polymer electrolyte and a lithium ion battery comprising the same. The preparation method of the polymer electrolyte comprises the following steps: (1) dissolving a functional polymer in an organic solvent, and uniformly mixing to obtain a system A, wherein the mass proportion of the functional polymer in the system A is 0.2-30%; (2) uniformly mixing the system A, a lithium salt and a functional additive to obtain a mixed solution; and (3) carrying out in-situ polymerization on the mixed solution to obtain the polymer electrolyte. The polymer electrolyte has good affinity with anions of the lithium salt, has high conductivity, and greatly improves the performances of a semi-solid battery. The semi-solid state lithium ion battery prepared based on an existing lithium ion battery processing technology has good processing performances and electrochemical performances, and has a certain application prospect.

Owner:浙江冠宇电池有限公司

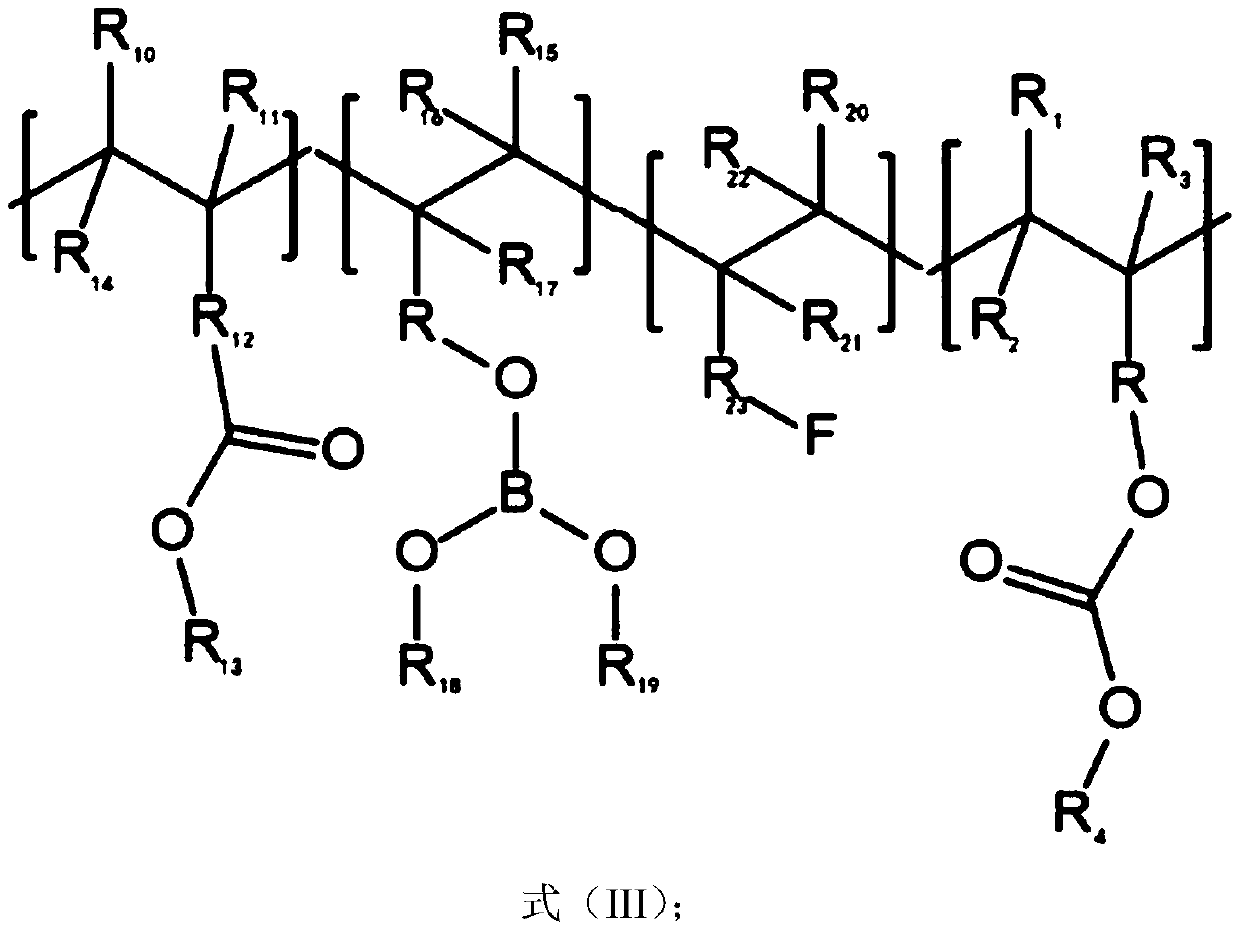

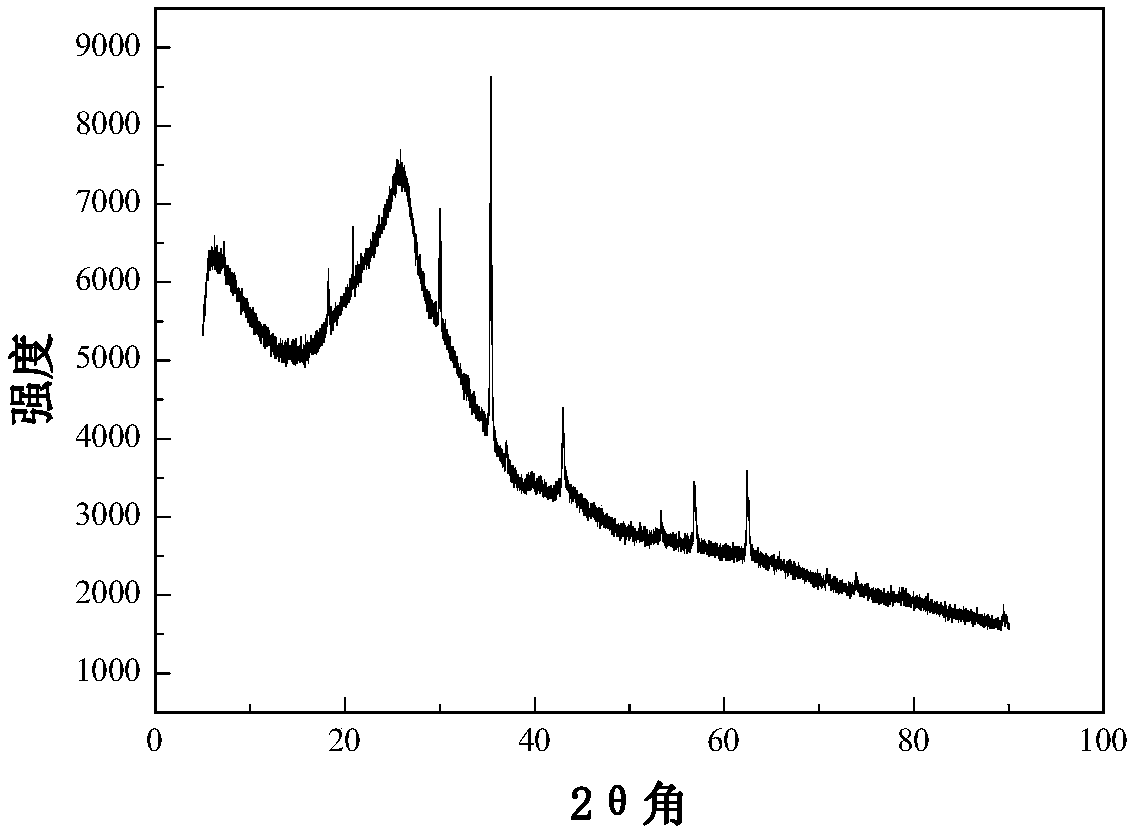

Quantitative analysis method for gasified slag mineral phase

ActiveCN111060417ALow detection limitImprove data accuracyWeighing by removing componentProcess efficiency improvementMetallurgical slagDissolution

The invention relates to a quantitative analysis method for a gasified slag mineral phase. The method comprises the following steps: efficiently separating out iron micro-beads in gasified slag through a magnetic separation process, selectively and completely separating the glass phase and impurities contained in the glass phase in sequence through a crossed two-step acid-alkali method, completelyburning off inorganic carbon particles through high-temperature roasting, obtaining a stable quartz crystal phase as the solid phase, and accurately analyzing the accurate content of all components in the gasified slag. Compared with a traditional hydrofluoric acid dissolution method and an instrument semi-quantitative analysis method, the brand-new analysis method has the advantages of simple operation, good dissociation effect, low impurity detection limit, high data accuracy, mild reaction conditions and the like, has wide applicability, can provide a new thought for quantitative analysisof typical industrial / metallurgical solid waste mineral phases such as fly ash, coal gangue, metallurgical slag and the like, and has important guiding significance for developing a new solid waste high-valued utilization technology.

Owner:CHINA PETROLEUM & CHEM CORP +3

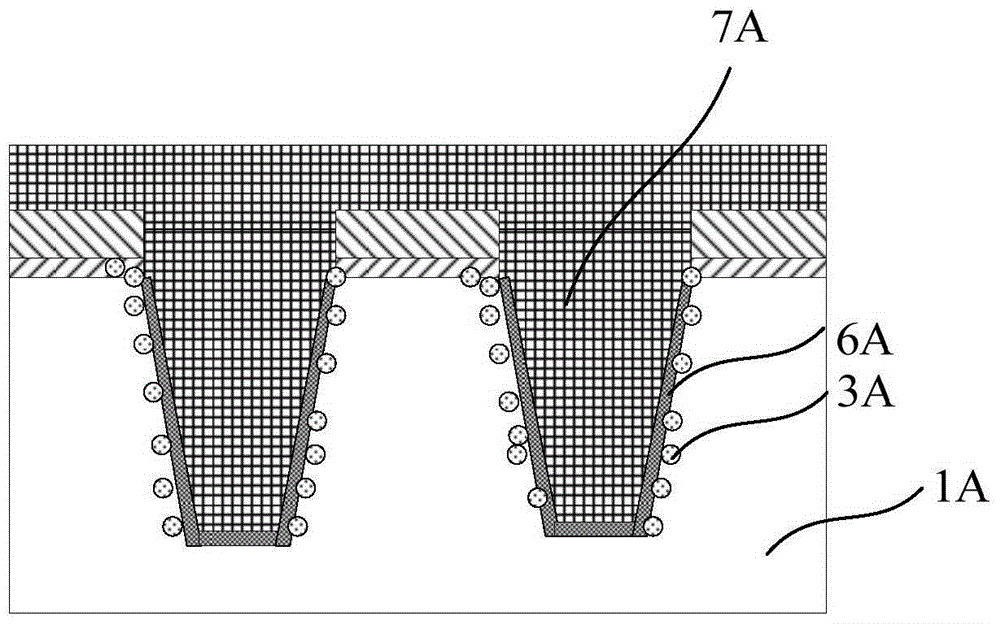

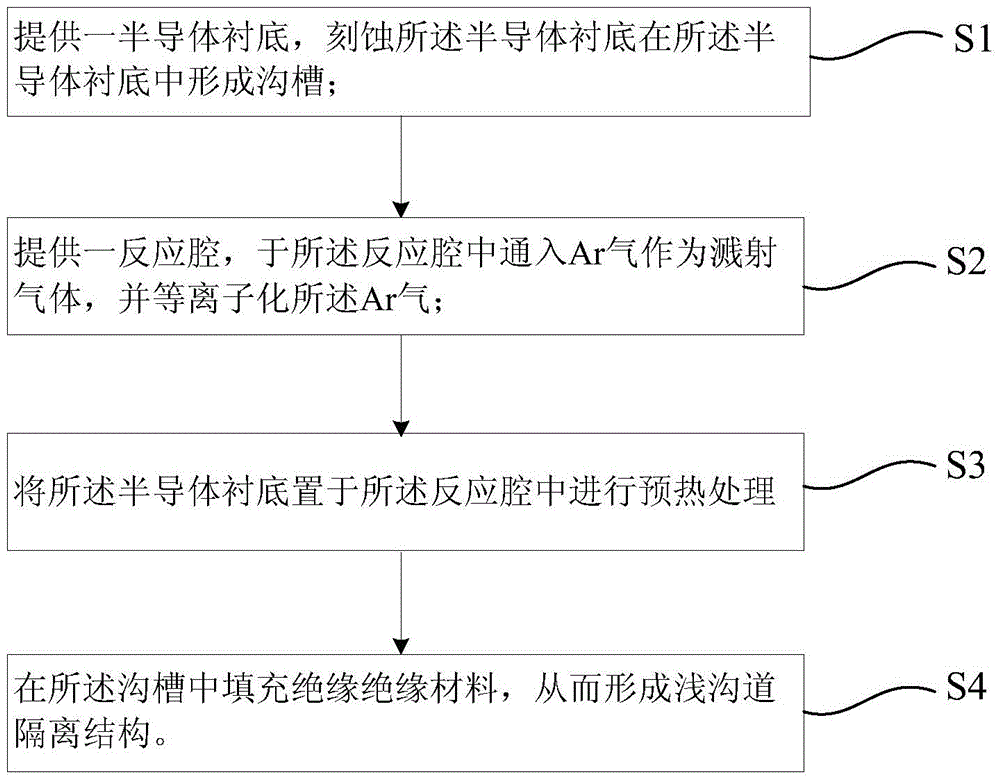

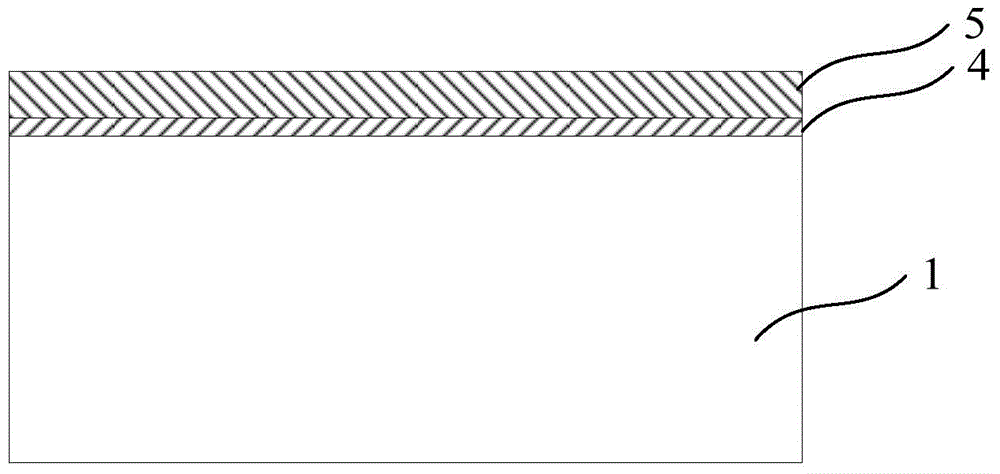

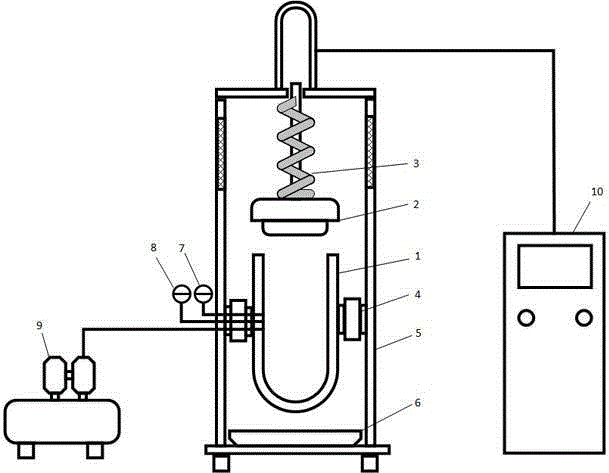

Shallow trench isolation structure preparation method

ActiveCN104835775APrevent oxidationAvoid erosionSemiconductor/solid-state device manufacturingElectrical conductorEngineering

The invention provides a shallow trench isolation (STI) structure preparation method, at least comprising the steps of: providing a semiconductor substrate, and etching the semiconductor substrate to form trenches in the semiconductor substrate; providing a reaction chamber, into which Ar gas is inputted as sputtering gas, and ionizing the Ar gas; placing the semiconductor substrate in the reaction chamber to perform preheating treatment; and filling insulating materials in the trenches so as to form an STI structure. According to the invention, in a semiconductor substrate preheating phase, Ar gas is employed as plasma source gas to replace O2 of the traditional process, thereby preventing the surfaces of the trenches of the semiconductor substrate in the preheating phase from being oxidized and corroded by O plasmas, reducing device leak current, preventing a device from isolation failure, and improving device reliability. In addition, Ar plasmas can improve the dissociation effect of a whole plasma system, which is in favor of performing the filling process smoothly.

Owner:SEMICON MFG INT (SHANGHAI) CORP

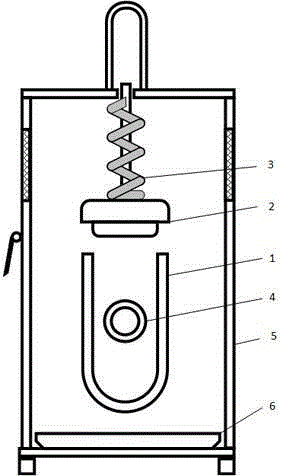

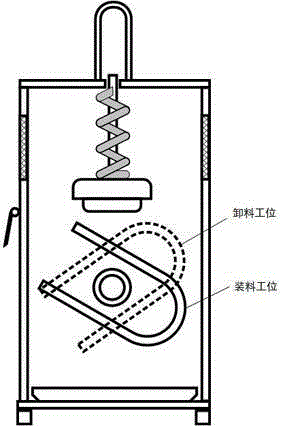

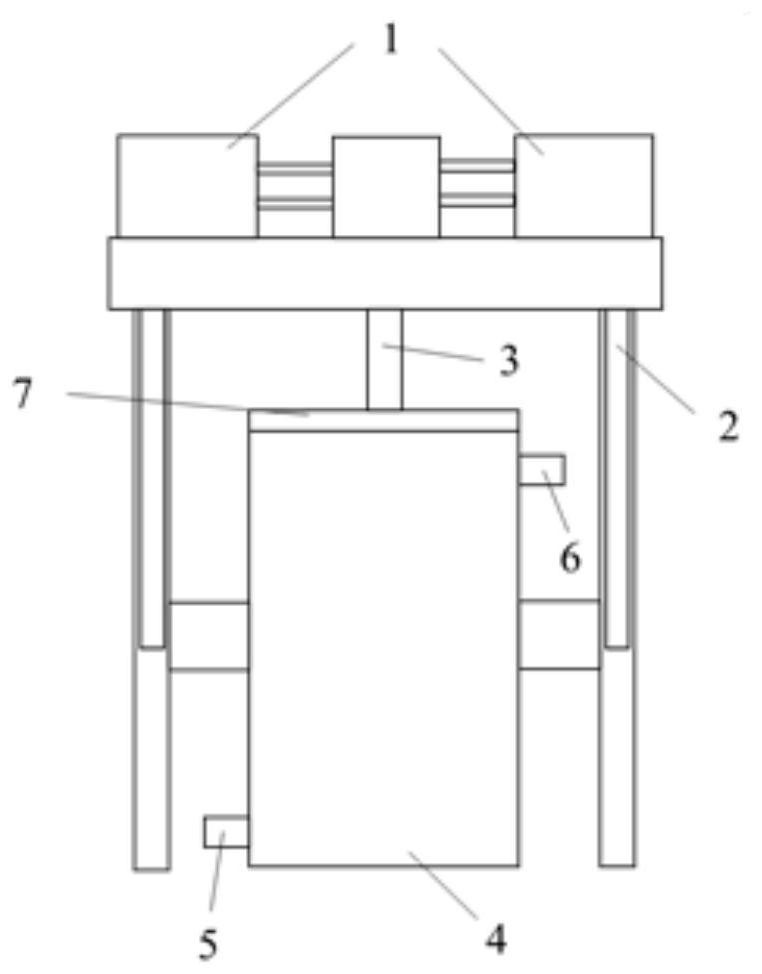

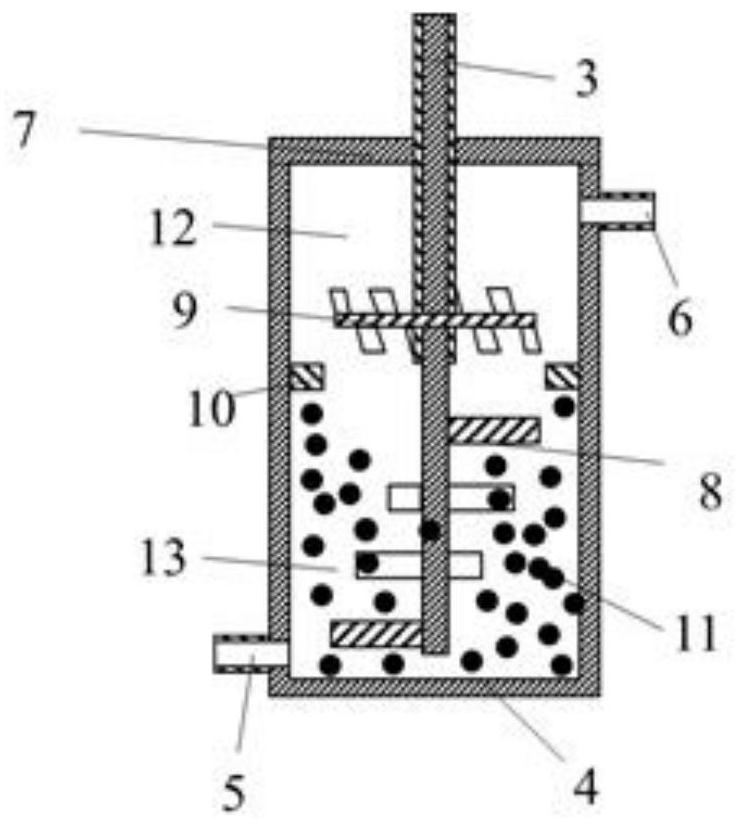

Air pressure dismantling device and method for waste mobile phone

InactiveCN105196035AGood dissociation effectImprove dismantling efficiencyMetal working apparatusElectronic control systemHazardous substance

The invention discloses an air pressure dismantling device and method for a waste mobile phone. The device comprises an air pressure tank, an air compressor and an electronic control system, wherein the air pressure tank comprises a tank body and a cover, a magnetically controlled switch is arranged between the tank body and the cover, a spring slideway is arranged above the cover, and opening and closing of the cover is controlled by the electronic control system; when the cover is closed, airtight connection is formed between the tank body and the whole cover; the air compressor is connected with the air pressure tank through a pipeline. According to the method, differential pressure inside and outside a mobile phone shell is produced, the mobile phone shell is broken from inside under the action of air pressure, and the purpose of mobile phone dismantling is achieved. The method and the device are green and environment-friendly, production of toxic and harmful substances in an implementation process is avoided, batch, efficient and environment-friendly dismantling of the waste mobile phones is realized, the waste mobile phone dismantling efficiency of an electronic waste dismantling enterprise can be greatly improved, and the labor cost is reduced.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

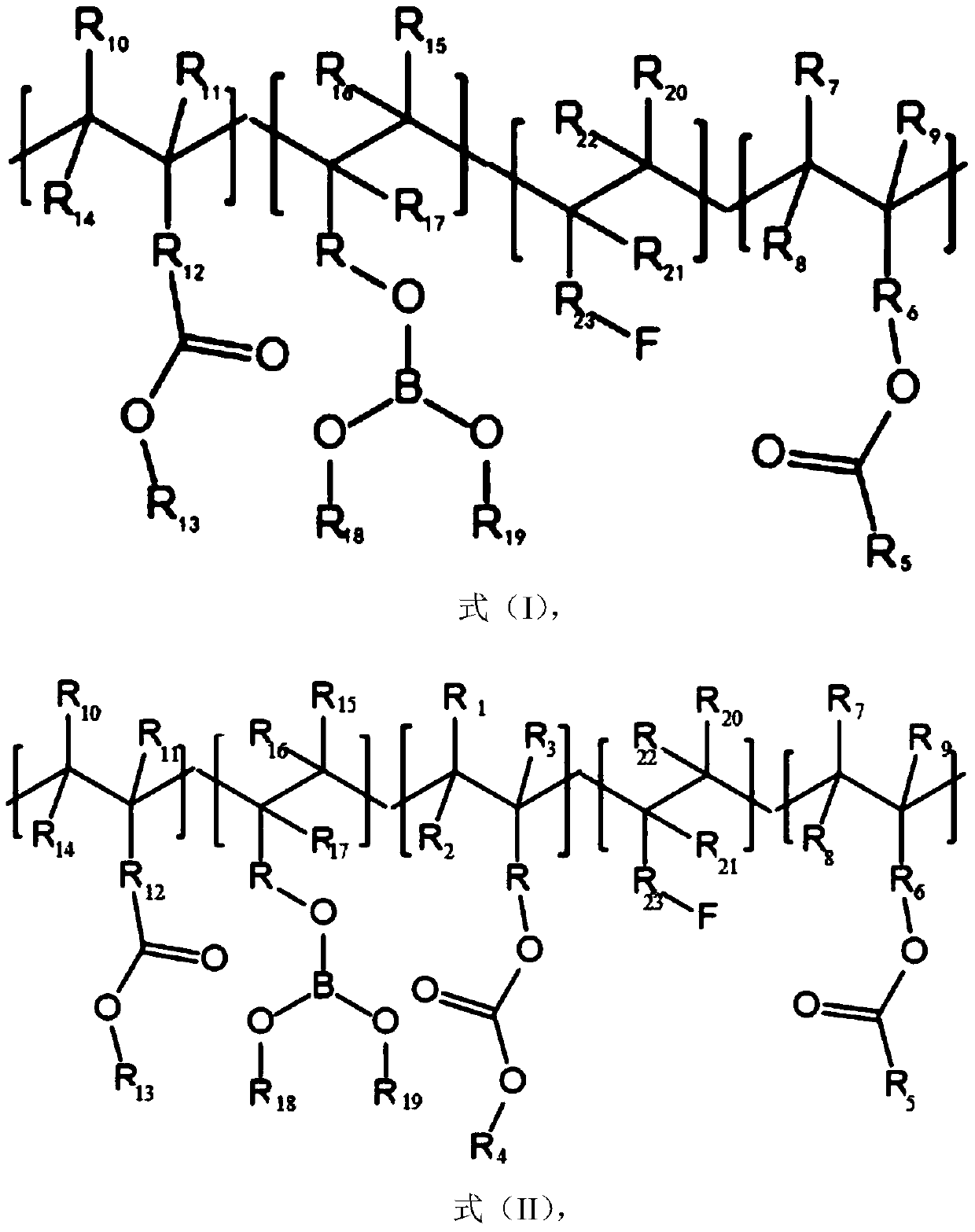

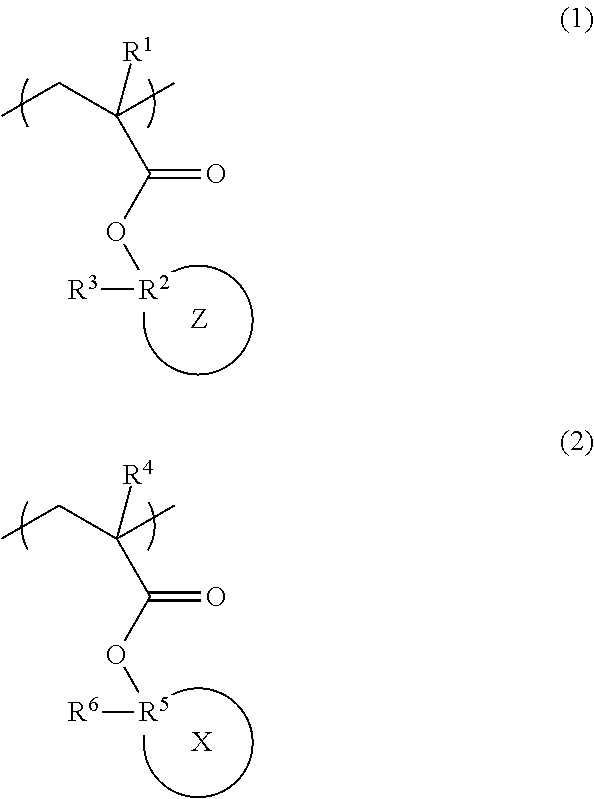

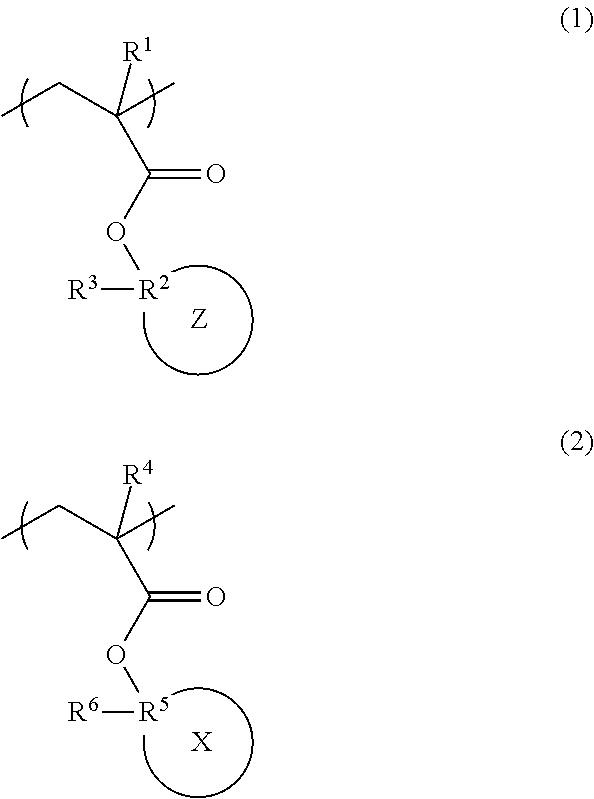

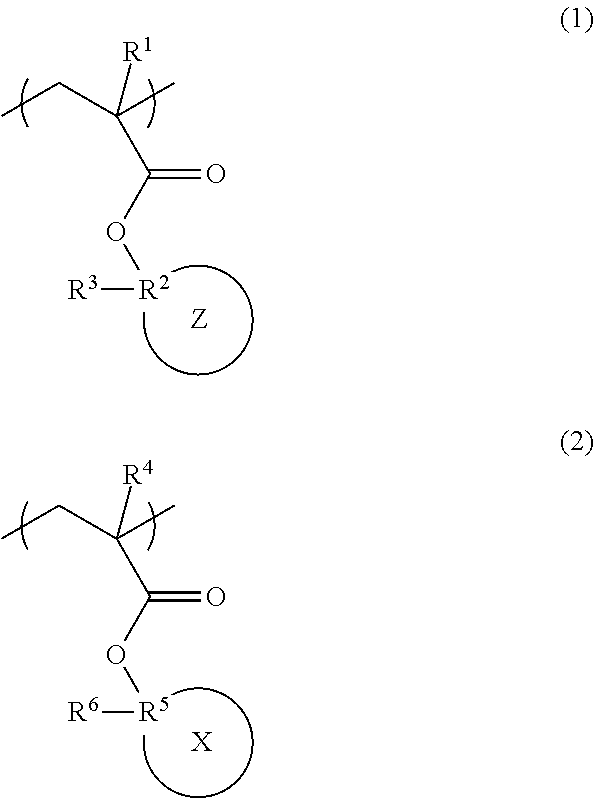

Radiation-sensitive resin composition, polymer, and resist pattern-forming method

ActiveUS20130203000A1Excellent LWR featureControl DimensionsPhotosensitive materialsRadiation applicationsResistRadiation sensitivity

A radiation-sensitive resin composition includes a polymer component, a radiation-sensitive acid generating agent, and a nitrogen-containing compound having a ring structure. The polymer component includes, in an identical polymer or different polymers, a first structural unit represented by a formula (1) and a second structural unit represented by a formula (2). R1 represents a hydrogen atom or a methyl group. Z is a group which represents a divalent monocyclic alicyclic hydrocarbon group taken together with R2. R2 represents a carbon atom. R3 represents a methyl group or an ethyl group. R4 represents a hydrogen atom or a methyl group. X is a group which represents a divalent bridged alicyclic hydrocarbon group having no less than 10 carbon atoms taken together with R5. R5 represents a carbon atom. R6 represents a branched alkyl group having 3 or 4 carbon atoms.

Owner:JSR CORPORATIOON

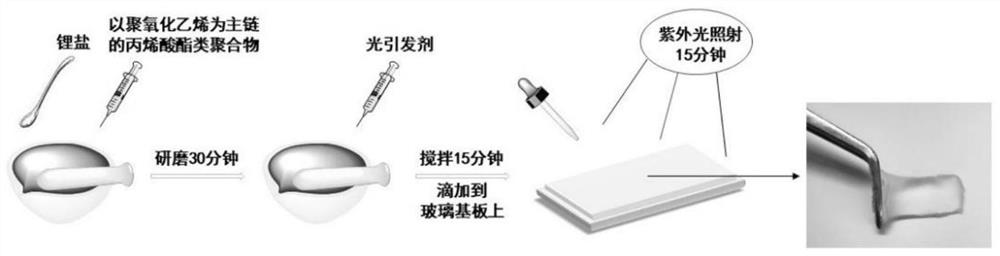

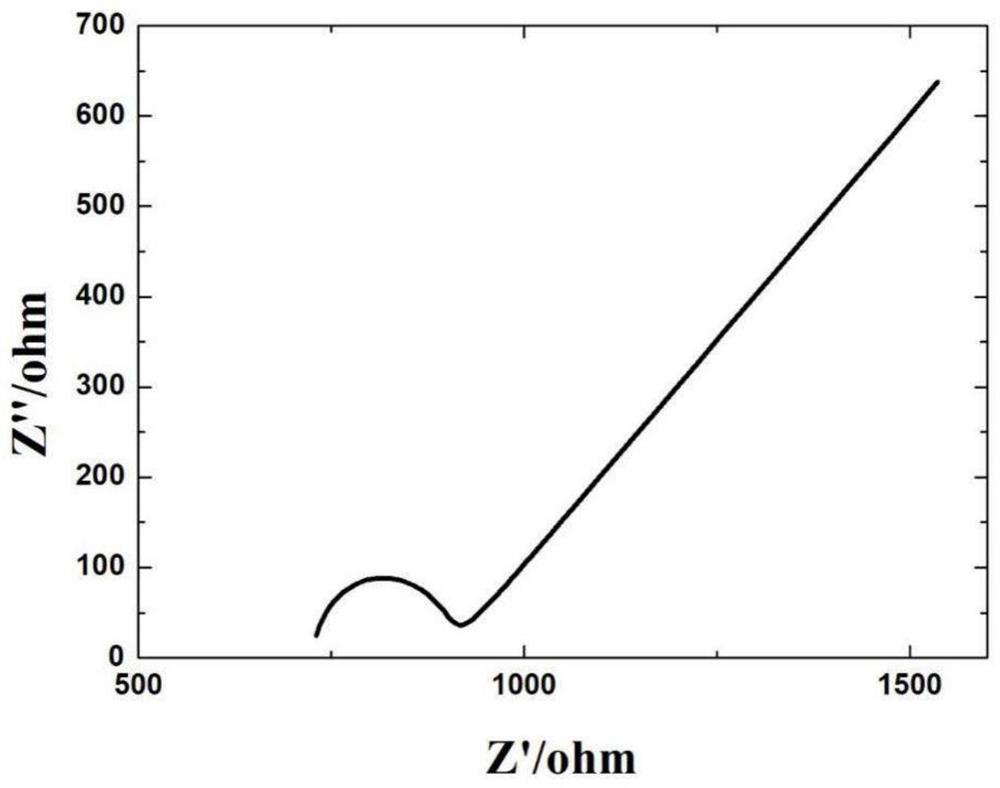

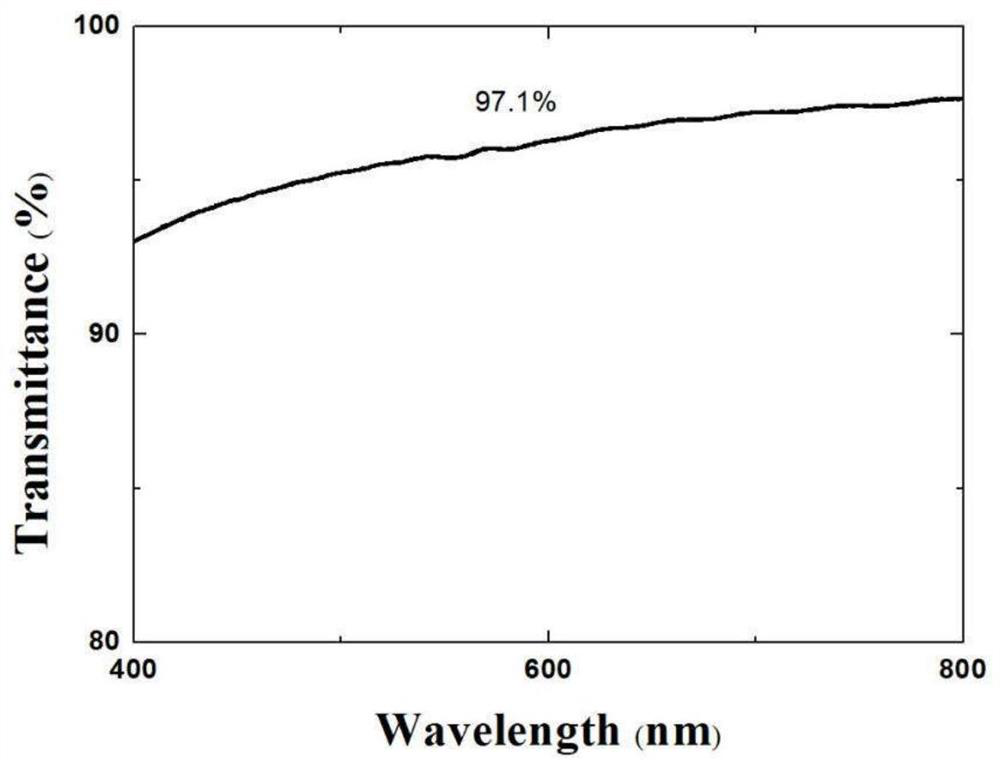

Novel gel electrolyte and application thereof in all-solid-state electrochromic device

InactiveCN111624828AGood mechanical propertiesStrong complexing abilityNon-linear opticsPhotoinitiatorAll solid state

The invention discloses a novel gel electrolyte and application thereof in an all-solid-state electrochromic device, and relates to the technical field of electrochromic devices. The gel electrolyte comprises 85 wt% to 92 wt% of an acrylate polymer with polyoxyethylene as a main chain, 2 wt% to 5 wt% of lithium salt and 3 wt% to 10 wt% of a photoinitiator. According to the invention, the acrylatepolymer taking polyoxyethylene as a main chain is used as a matrix material of the electrolyte, the terminal group of the polymer is an acrylate group which can be cross-linked and polymerized under ultraviolet light, and the polymer has good mechanical properties after being irradiated by ultraviolet light; meanwhile, the polymer takes polyoxyethylene as a main chain and has good complexing capability with lithium ions and dissociation capability with the lithium ions, so that the ionic conductivity of the electrolyte is effectively improved; and in addition, the polymer is kept in a transparent and clear state before and after ultraviolet curing, and the discoloration process of an electrochromic device is not interfered during application.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

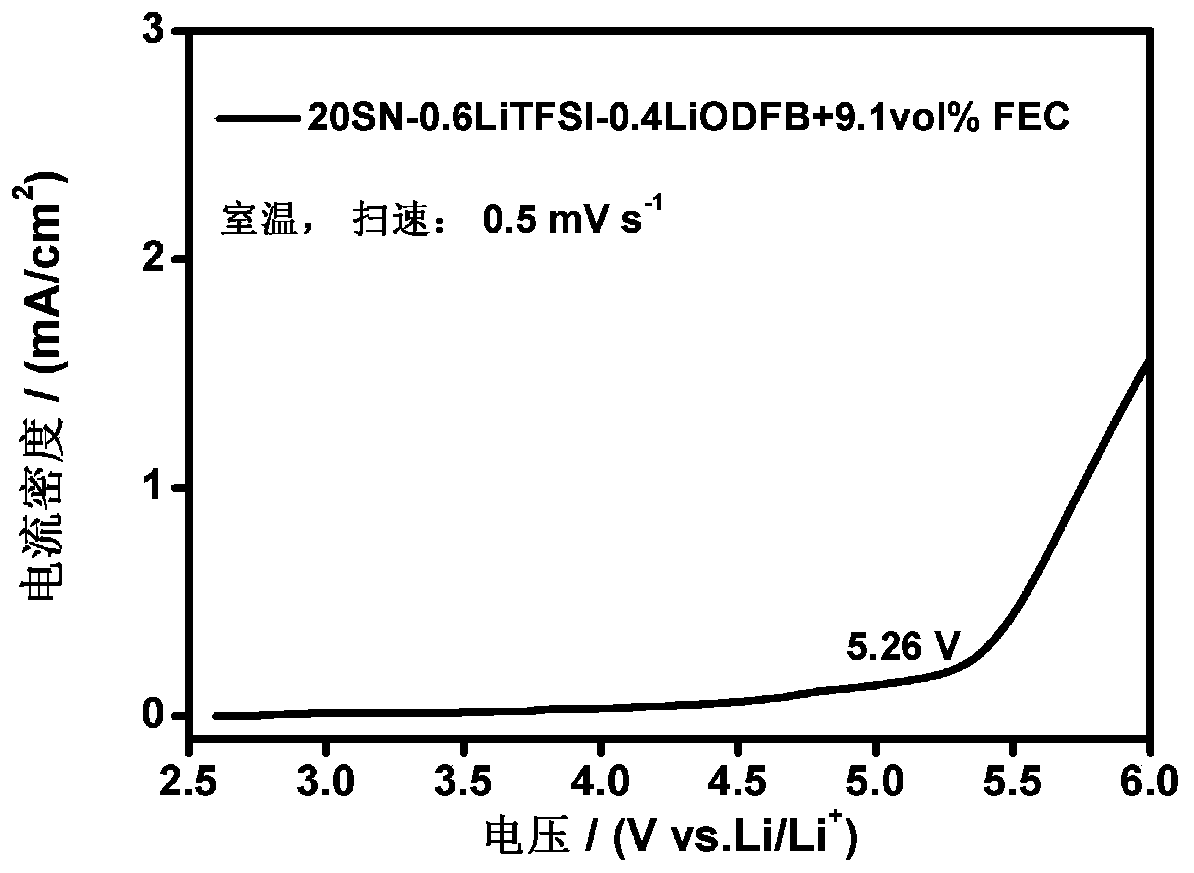

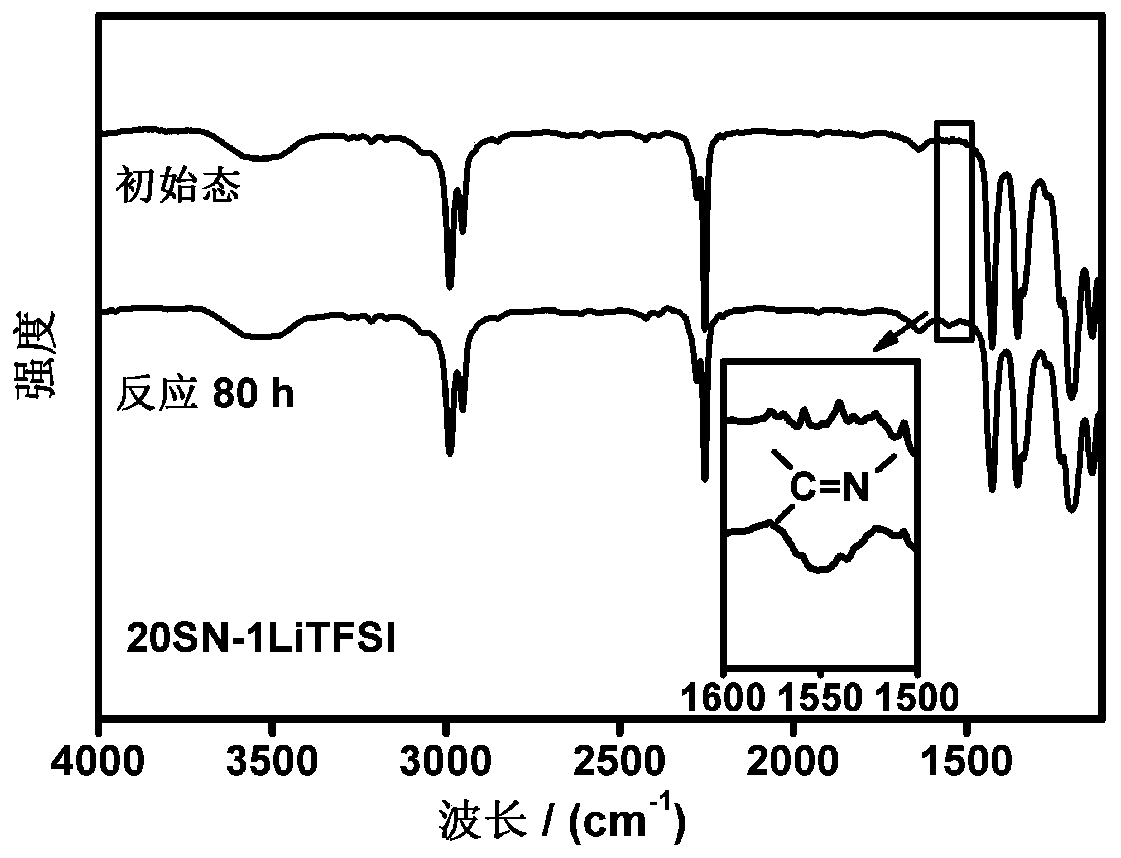

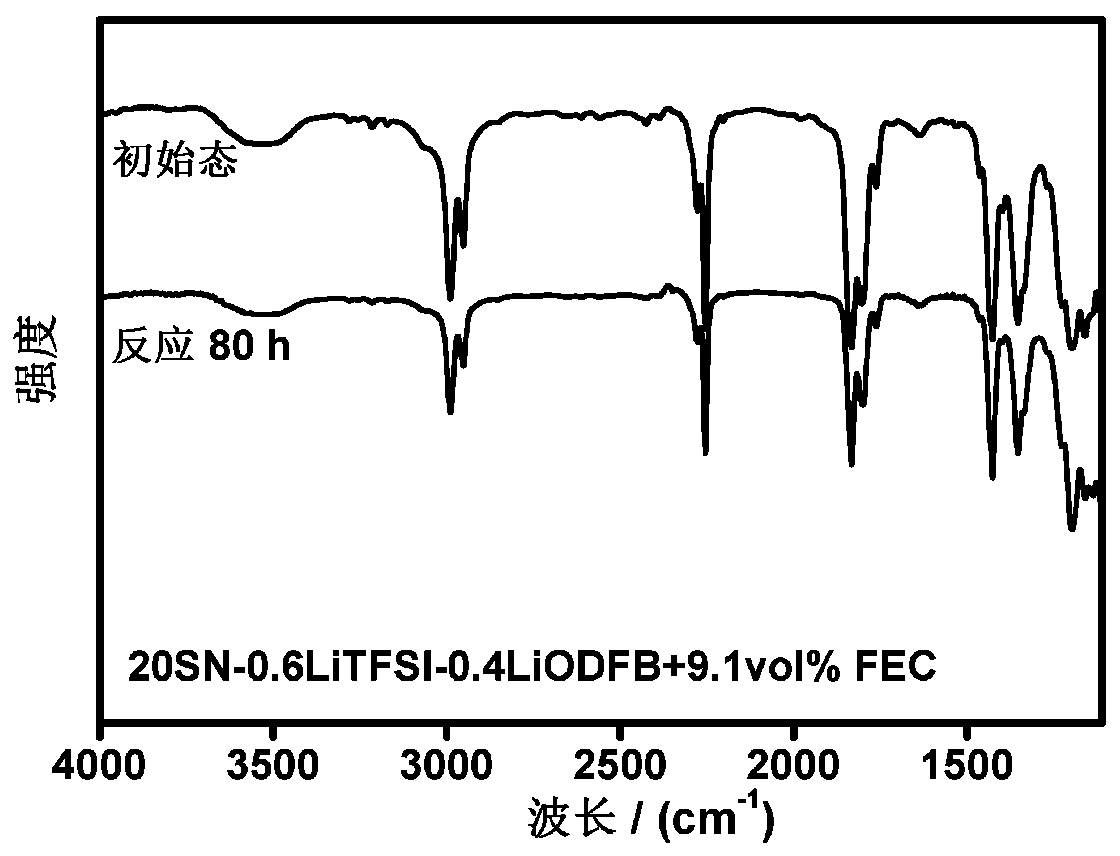

Succinonitrile-based electrolyte coupled with organic lithium salt and fluoroethylene carbonate as well as preparation method and application of electrolyte

ActiveCN110931875AImprove interfacial wettabilityGood dissociation effectSecondary cellsOrganic electrolytesElectrolytic agentMetallic lithium

The invention discloses a succinonitrile-based electrolyte coupled with an organic lithium salt and fluoroethylene carbonate, and relates to the technical field of lithium-ion batteries. The specificscheme is as follows: the succinonitrile-based electrolyte coupled with an organic lithium salt and fluoroethylene carbonate comprises succinonitrile, an organic lithium salt and fluoroethylene carbonate, wherein the molar ratio of the succinonitrile to the organic lithium salt is 100: 1-1:1, the organic lithium salt is a combination of a sulfonyl imide lithium salt and lithium oxalyldifluoroborate, the molar ratio of the sulfonyl imide lithium salt to the lithium oxalyldifluoroborate is 100: 1-1: 1, and the fluoroethylene carbonate accounts for 5-50% of the total volume of the succinonitrile-based electrolyte. The invention further discloses a preparation method of the succinonitrile-based electrolyte and application of the succinonitrile-based electrolyte to a lithium metal battery, theelectrolyte can form an organic-inorganic composite SEI film on the surface of metal lithium, side reaction of succinonitrile and metal lithium is avoided, and the interface stability and electrochemical performance of the battery are remarkably improved.

Owner:HARBIN INST OF TECH

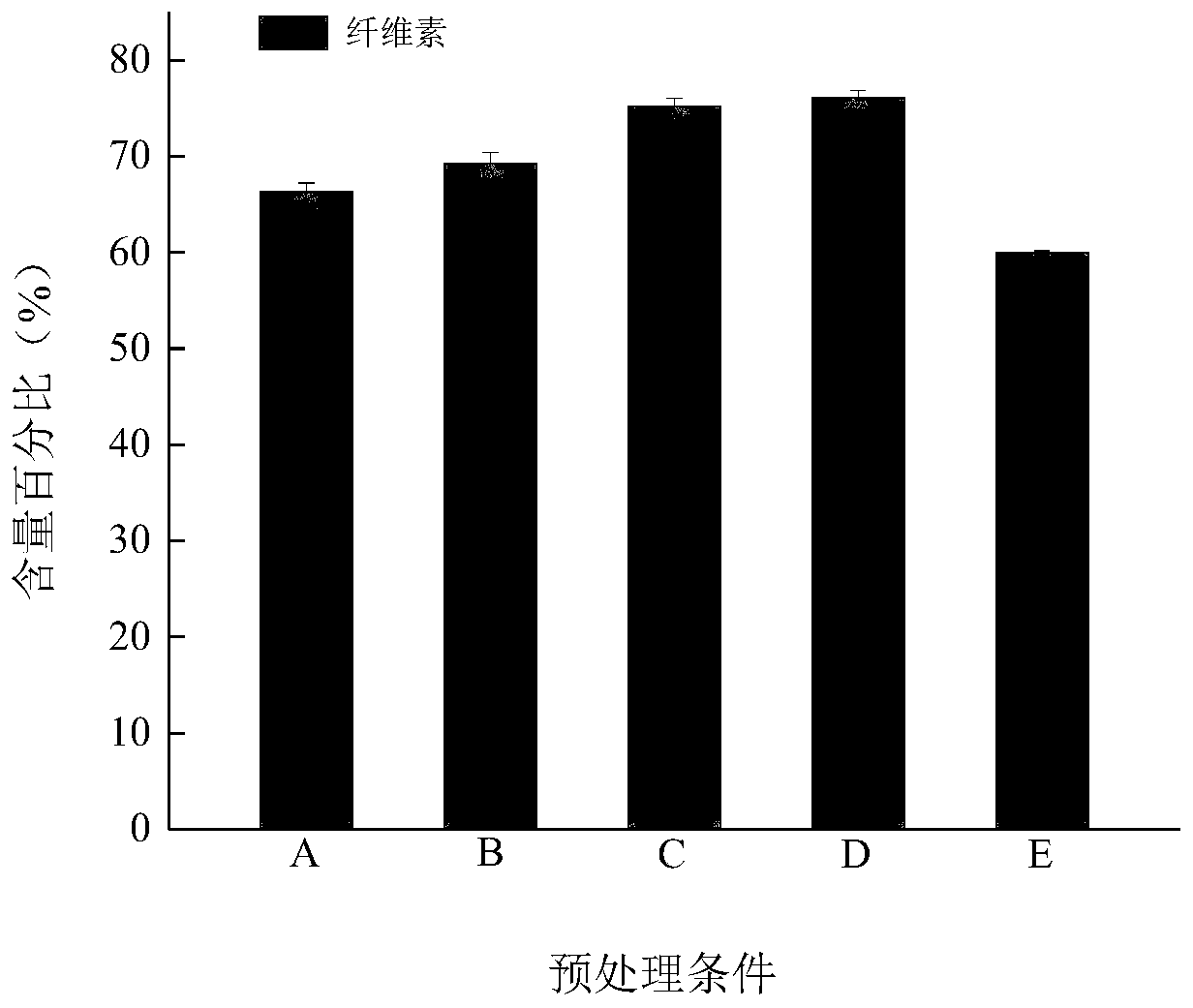

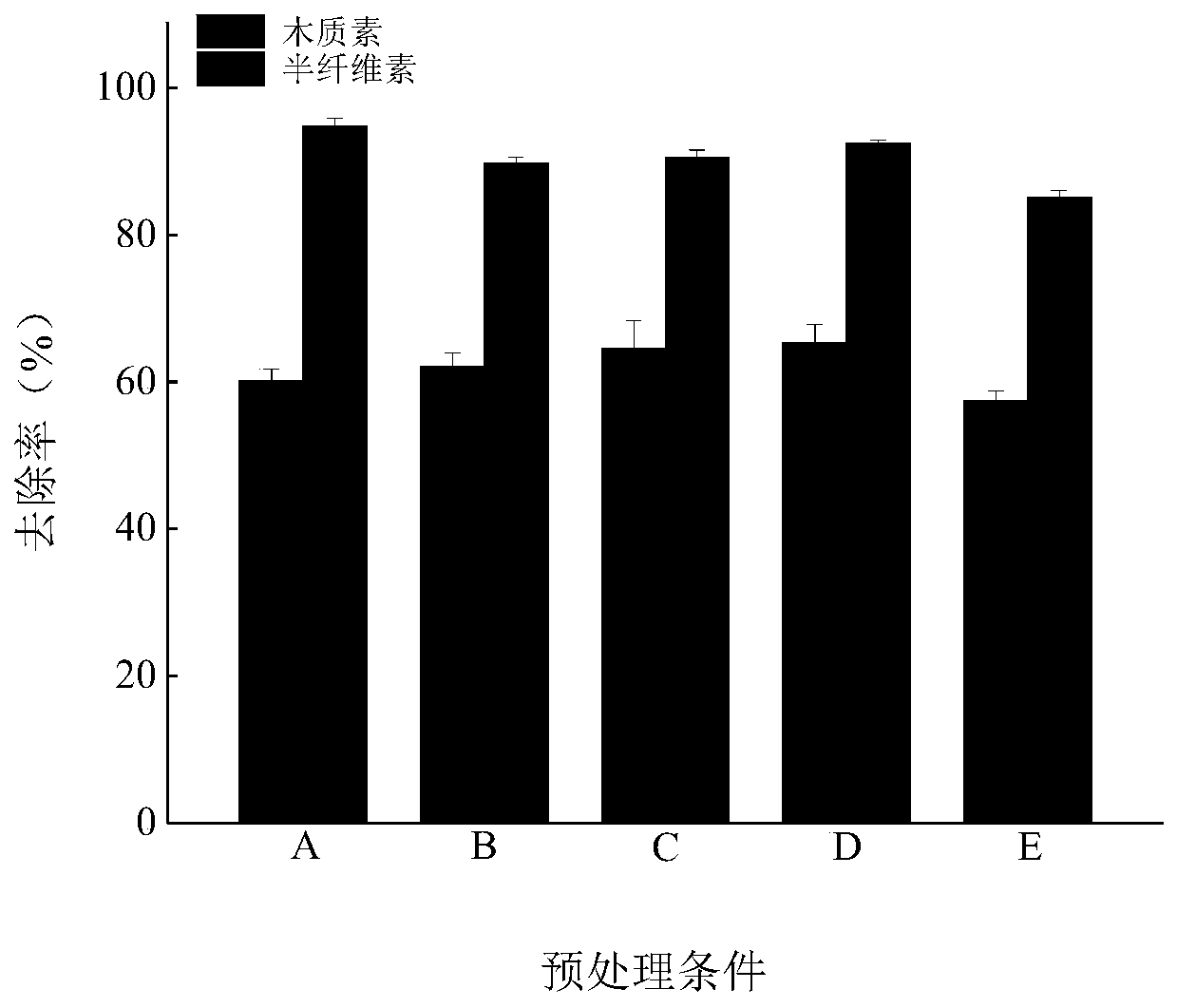

Method for dissociating corn stalks by utilizing ultrasonic microwave enhanced deep eutectic solvent

ActiveCN111321618ATo achieve the purpose of environmental protectionMeet the requirements of sustainable development of green chemistryPulping with organic compoundsOXALIC ACID DIHYDRATEGlycerol

The invention discloses a method for dissociating corn stalks by utilizing an ultrasonic microwave enhanced deep eutectic solvent, and belongs to the technical field of corn stalk component separation. The method comprises the following steps: synthesizing a deep eutectic solvent serving as a solvent by taking choline chloride, oxalic acid and glycerol as raw materials, mixing the deep eutectic solvent with corn stalks according to a certain proportion, putting the mixture into a multi-frequency combined ultrasonic emitter, processing the mixture in the ultrasonic emitter for a period of time,taking out the mixture, putting the mixture into a microwave digestion instrument to carry out digestion; after the reaction is finished, regenerating the corn stalks in the system, and measuring thecomponents. The constructed deep eutectic solvent is cheap, natural and pollution-free, and the selected ultrasonic microwave system not only has an outstanding effect, but also can realize the deconstruction of corn stalks under mild conditions. The method is a novel method for dissociating corn stalk components.

Owner:JIANGSU UNIV

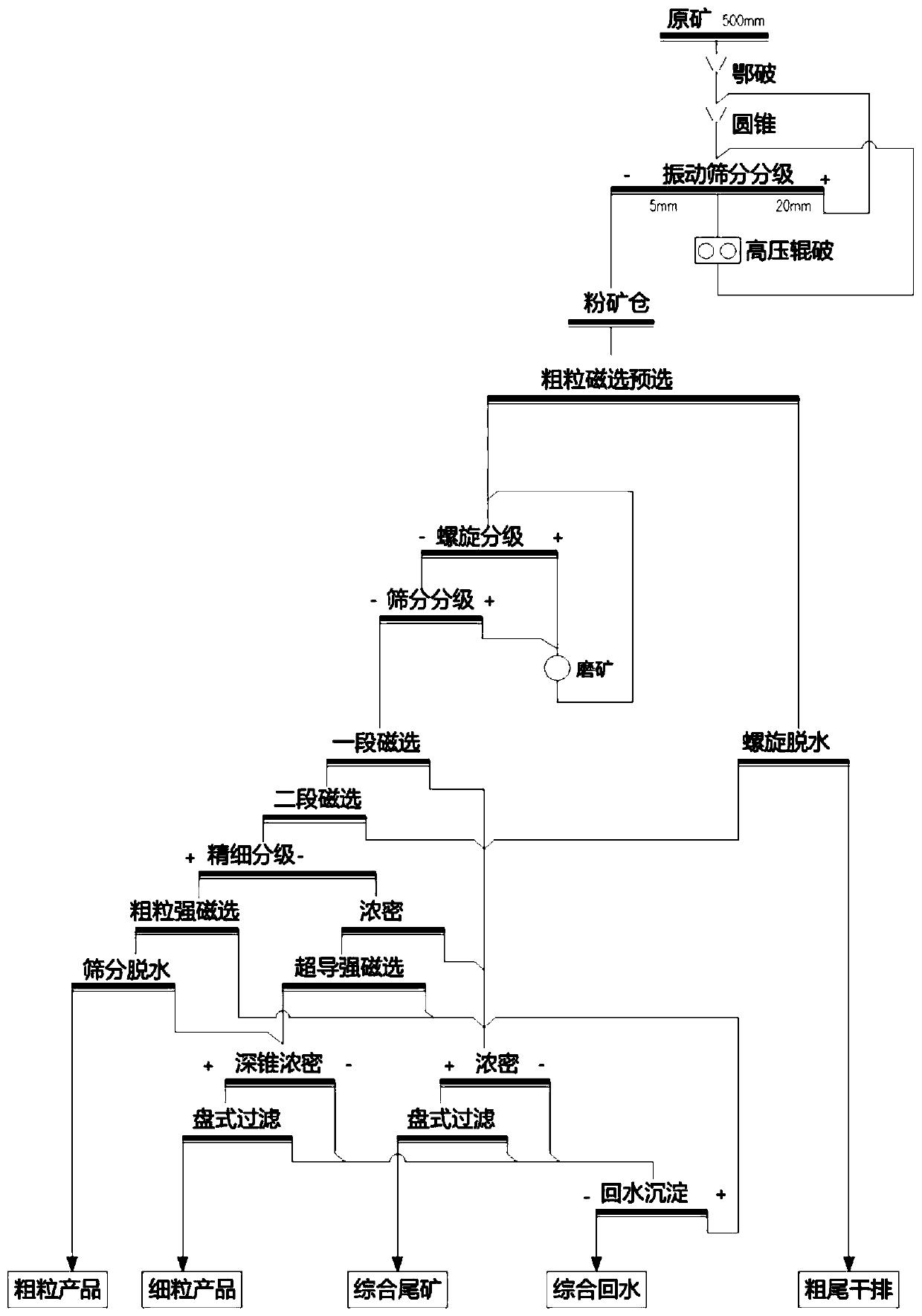

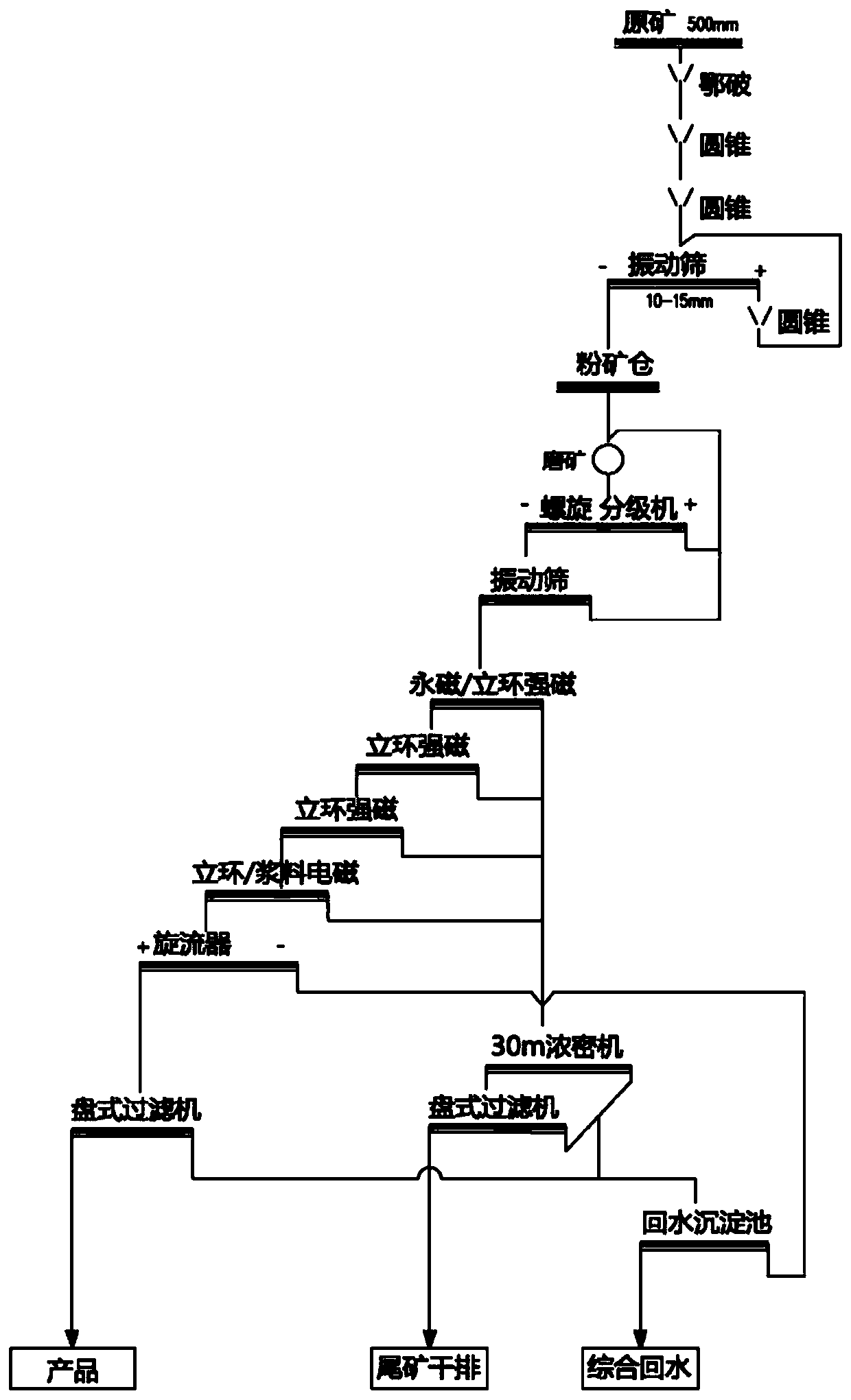

Method for improving quality, reducing cost and improving efficiency of ceramic raw materials prepared from granite stone waste rocks

ActiveCN110743684AImprovement of comprehensive technical and economic indicatorsIncrease throughputMagnetic separationGrain treatmentsMachining processGlass-ceramic

The invention provides a method for improving quality, reducing cost and improving efficiency of ceramic raw materials prepared from granite stone waste rocks. The method comprises the following steps: multi-stage crushing, laminated crushing, coarse grain pre-selection, pre-grading, partial ore grinding, multi-stage magnetic separation, grading separation, superconducting strong magnetic separation, grading dehydration and the like. The method is a pollution-free and environment-friendly physical technology in the whole process; compared with a traditional process, the comprehensive technicaland economic indexes are obviously improved, high-quality glass and ceramic raw materials with the K2O content of 6-10wt%, the Na2O content of 0.5-3.5wt%, the SiO2 content of 65-74wt% and the Fe2O3 content of 0.15wt% and the whiteness of 60-68 are obtained, the whiteness of the product is improved from 50-53 to 60-68 degrees, the yield is improved from 51-55% to 65-72%, and the treatment capacitycan be improved by 13-18%; the product structure is refined and diversified, and a proper product is provided for material homogenization, energy conservation and consumption reduction in the downstream glass and ceramic industry machining process.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

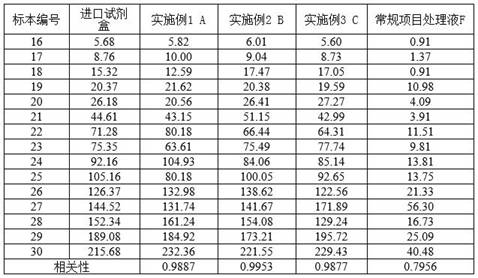

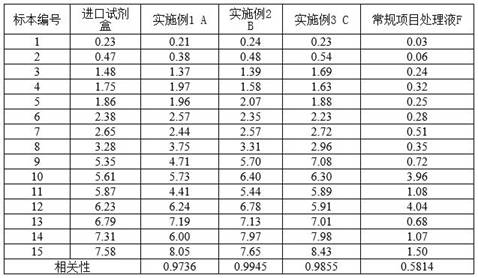

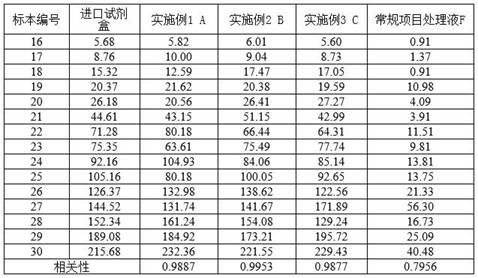

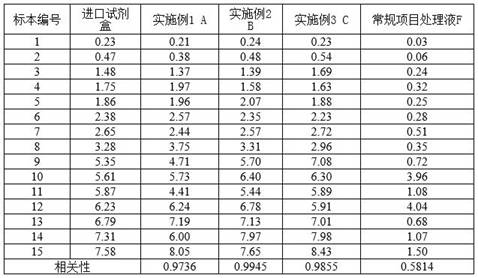

Dissociating agent universally used for TT3 and TT4 in serum and preparation method thereof

ActiveCN112362432AGood dissociation effectAccurate valuePreparing sample for investigationBiological testingActive agentSurface-active agents

The invention discloses a dissociating agent universally used for TT3 and TT4 in serum. The dissociating agent comprises the following components in percentage by mass: 0.01%-0.1% of metal chelate; 0.01%-1.0% of an N heterocyclic compound; 0.05%-0.2% of a stabilizing agent; 0.2%-1.0% of a surfactant; and 0.5%-4.0% of an auxiliary agent and the balance of water. The dissociation agent disclosed bythe invention has a good dissociation effect, can be used as a sample pretreatment solution in an A-work project detection reagent, can well dissociate bound TT3 and TT4 in serum from respective transport proteins to enable the TT3 and TT4 to be in a free state, and then detects and verifies the content of the TT3 and TT4 in the free state by adopting a chemiluminiscence immunoassay method, and therefore, the measured value of the sample result is more accurate. The invention also provides a preparation method of the dissociating agent universally used for TT3 and TT4 in serum.

Owner:GUANGZHOU KEFEN BIOTECH CO LTD

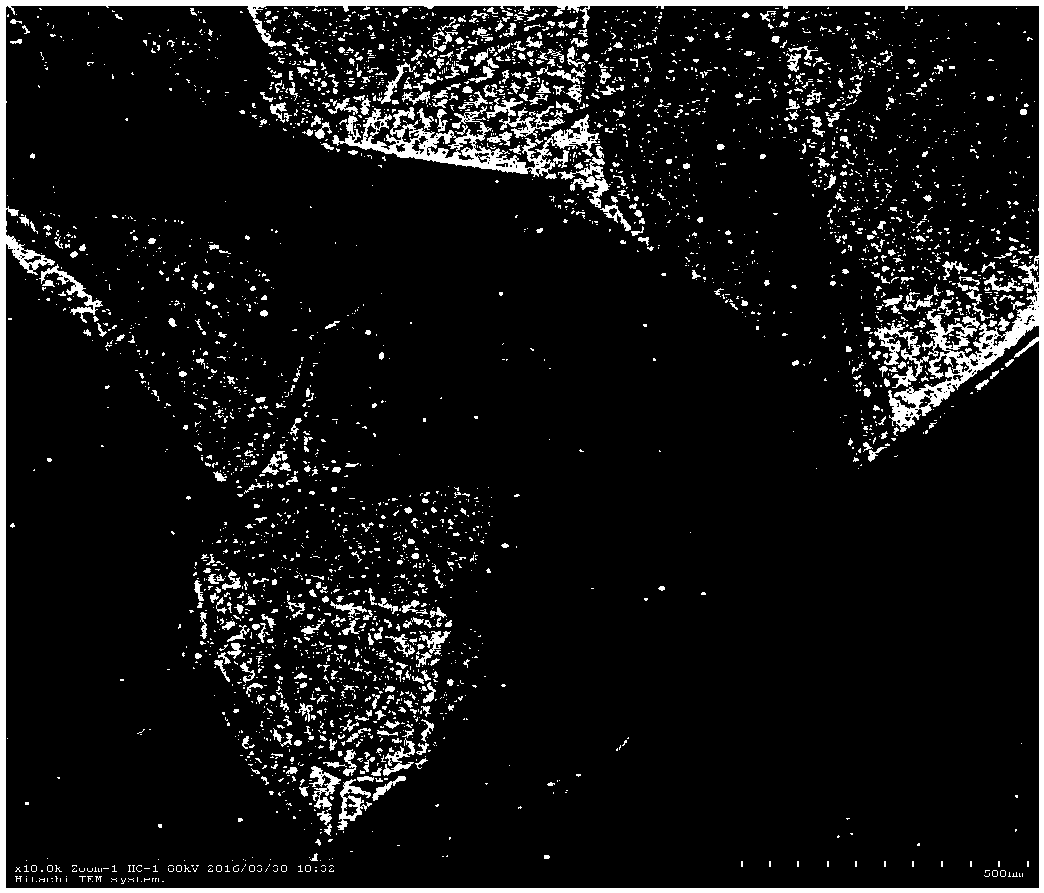

Method for preparing magnetic graphene oxide by using NH3.H2O-NH4NO3 solution

The invention discloses a method for preparing magnetic graphene oxide by using an NH3.H2O-NH4NO3 solution. The method comprises the following steps: preparing a graphene oxide solution, mixing the graphene oxide solution, an iron salt solution and the NH3.H2O-NH4NO3 solution, heating the obtained solution to 50-70 DEG C, and heating the solution to 70-90 DEG C under an ultrasonic condition to prepare the magnetic graphene oxide. The method has the remarkable advantages of stabilization of the production process through effectively combining ultrasonic treatment with the NH3.H2O-NH4NO3 solution, simplicity in operation, and production of the magnetic graphene oxide having superior performances.

Owner:NANJING NORMAL UNIVERSITY

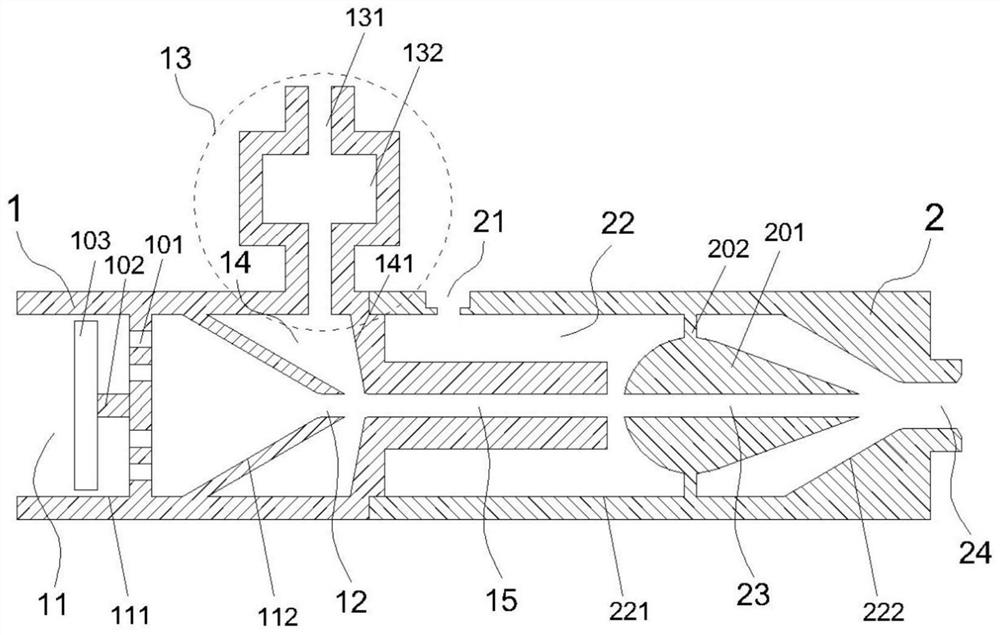

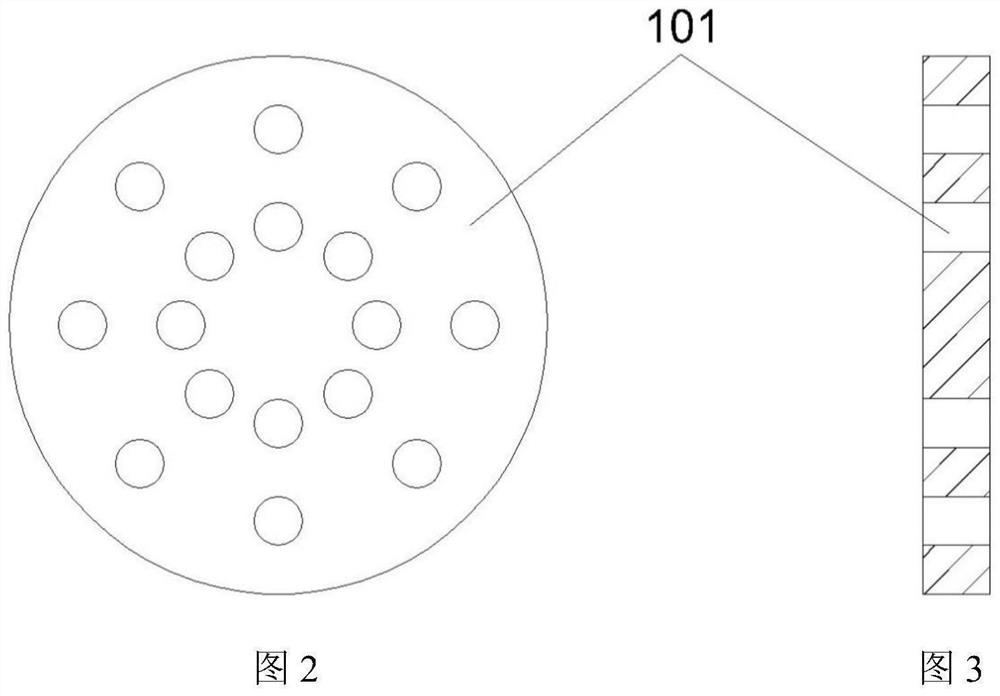

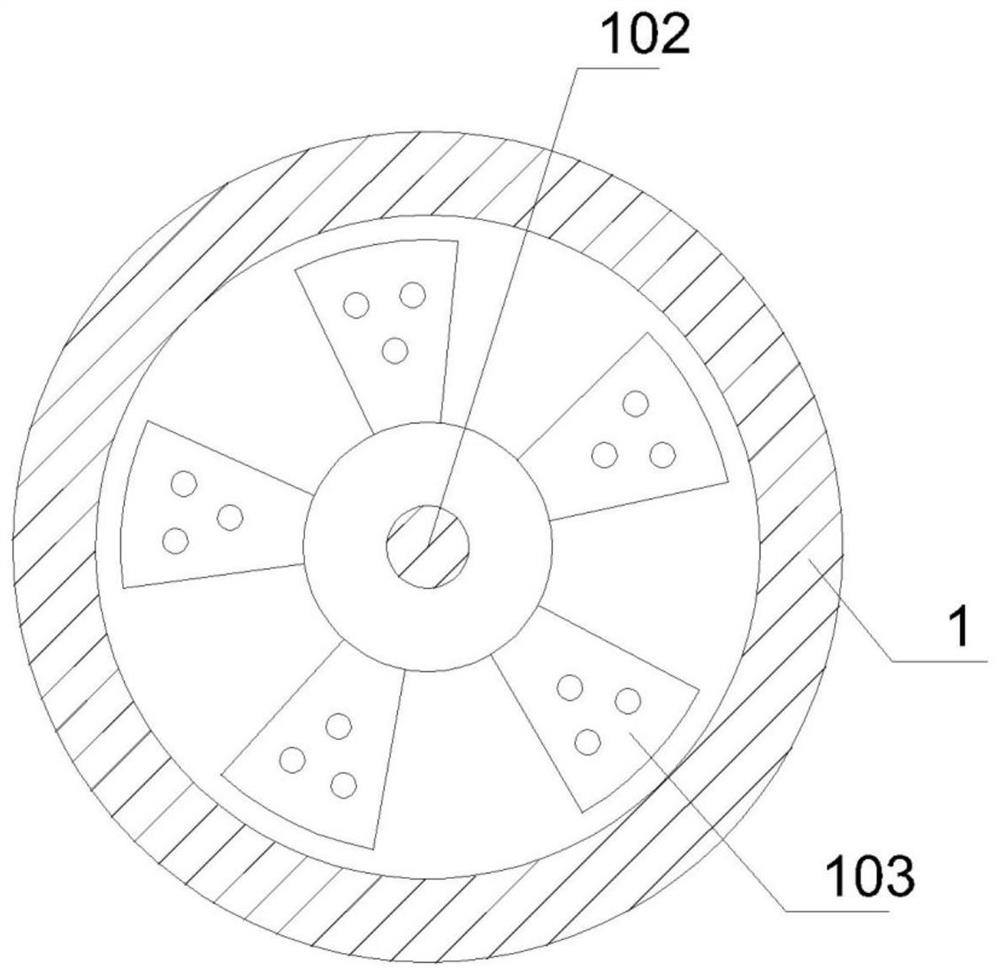

Two-stage type cavitation bubble generator

ActiveCN112023741AEffective protectionInhibition of ruptureFlow mixersTransportation and packagingJet flowEngineering

The invention discloses a two-section type cavitation bubble generator which comprises a first cavitation section and a second cavitation section, wherein the first cavitation section comprises a first jet chamber, a compression channel, a gas chamber and a mixing channel; The first jet chamber, the compression channel, the gas cavity and the mixing channel are sequentially communicated in the fluid flowing direction. The second cavitation section comprises a second jet chamber with an opening in one end, an outlet channel for outputting fluid and a center body; the open end of the second jetchamber is connected with the fluid output end of the first cavitation section, and the other end of the second jet chamber is communicated with the outlet channel; a low-pressure fluid inlet communicated with the second jet chamber is formed in the wall of the second jet chamber; the center body is arranged in the middle of the second jet chamber and fixedly connected with the second jet chamber,and a center body channel used for mixing fluid and gas is formed in the radial center of the center body. The cavitation bubble generator has high cavitation efficiency, the cavitation action rangeof a single generator is wide, the cavitation bubble generator can be effectively used for a high-sulfur slag dissociation process, the slag-sulfur separation effect is improved, and a good foundationis provided for subsequent flotation sulfur extraction.

Owner:CENT SOUTH UNIV

A low ink pulping method for waste paper reuse

ActiveCN107119480BGood dissociation effectHigh deinking rateWashing/displacing pulp-treating liquorsDigestersFiberSteam cooking

The invention discloses a low-ink pulping method through waste paper recycling. The method includes the following steps that 1, waster paper is collected, and beating is conducted to obtain shredded paper sheets; 2, the shredded paper sheets are subjected to micro-fermentation treatment; the shredded paper sheets obtained after micro-fermentation treatment are soaked and subjected to floating selection and ink removal; 4, after sediment is washed and impurities are removed, dehydration treatment is conducted; 5, materials obtained after dehydration are subjected to high-pressure steam-cooking and sterilization and softening; 6, the materials obtained after steaming and softening are subjected to extrusion impregnation and kneading homogenization; 7, digestion, fiber separation and defibering are conducted in sequence; 8, after purification and concentration, the final materials are stored for standby application. When the waste paper high in fiber quality is recycled for pulping, a good ink removal effect can be obtained through mutual complementation and synergistic interaction of pre-micro-fermentation treatment, post-micro-fermentation treatment and subsequent working sections.

Owner:JIANGSU HAOYU ELECTRONICS TECH

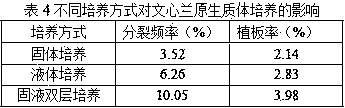

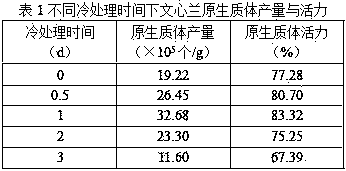

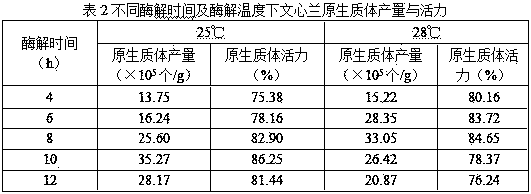

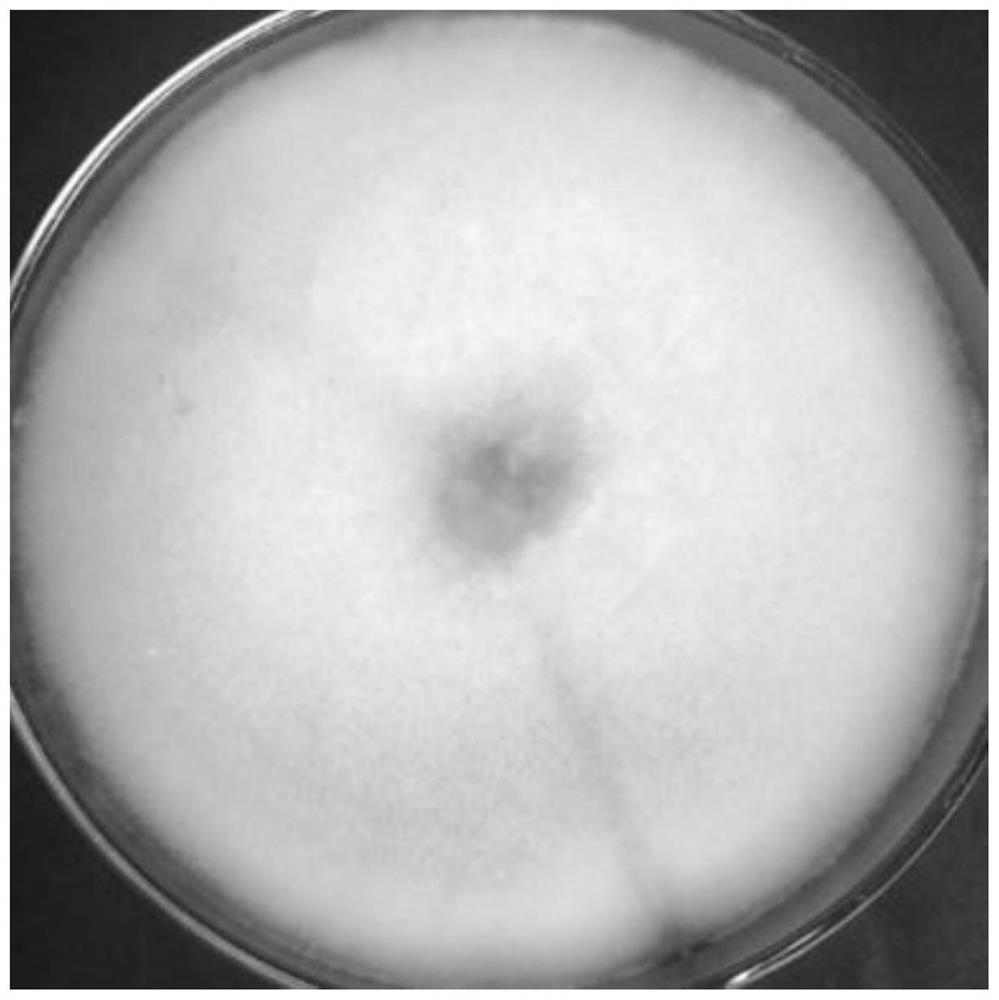

Oncidium protoplast dissociation and culture method

PendingCN111286484AGood dissociation effectIncrease productionCell culture mediaPlant cellsGermplasmOncidium

The invention provides an oncidium protoplast dissociation and culture method which comprises the following steps: taking oncidium protocorm-like bodies as starting materials, carrying out callus induction culture and 4-5 times of subculture to obtain vigorously growing calluses with loose structures for dissociation of protoplasts; carrying out cold treatment on calluses at 4 DEG C for 1 d, putting the calluses into a mixed enzyme solution, carrying out shaking table oscillation enzymolysis for 8-10 h, and purifying protoplasts by using an interface method to obtain a large amount of oncidiumprotoplasts with high activity; continuously using the culture medium for solid-liquid double-layer culture, so that the obtained oncidium protoplast cells can normally grow and continuously split to form small cell clusters, the maximum splitting frequency reaches 10.16%, and the maximum plate planting rate reaches 4.03%. The invention provides a scientific basis for cell fusion, somatic cell hybridization, genetic transformation and germplasm innovation by utilizing oncidium protoplast.

Owner:陈俊敏

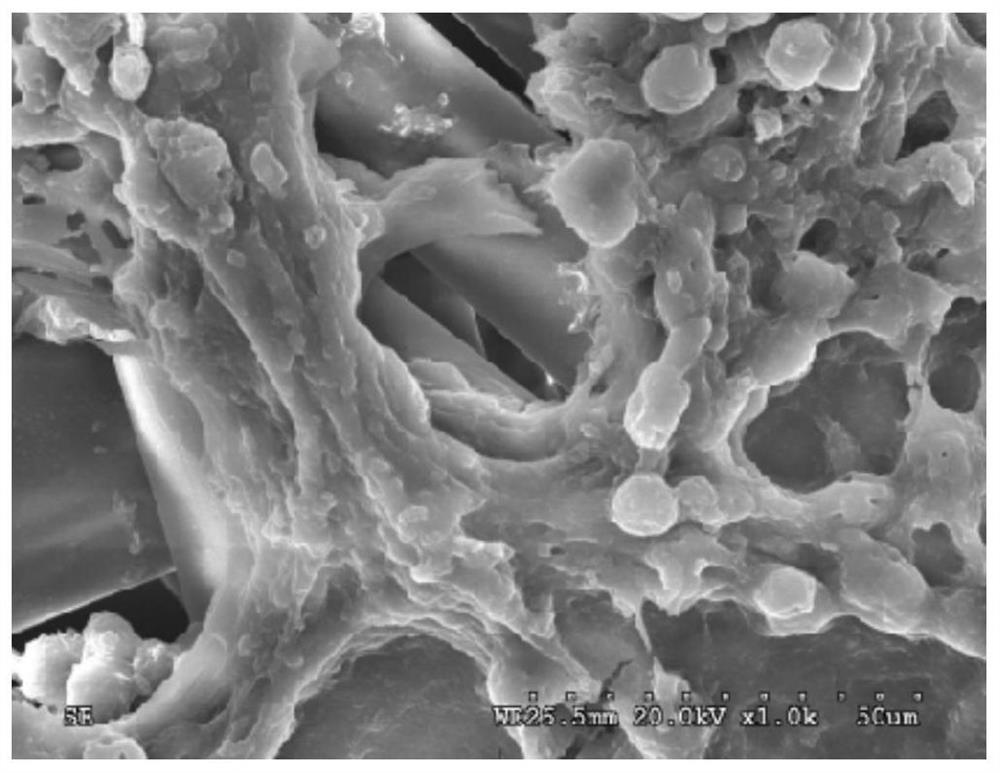

Integrated continuous production type clay dissociation-modification-drying method

InactiveCN106426546AProtective structureGood fluffing efficiencyClay processing apparatusSolventPre treatment

The invention discloses an integrated continuous production type clay dissociation-modification-drying method. The method comprises the following steps: fully mixing and soaking clay in a dispersion solvent; uniformly adding the pretreated clay and a modifier in a meshed co-rotating twin screw extruder, adjusting the extrusion parameter, and utilizing strong shearing force of the meshed co-rotating twin screw extruder at a meshed position to loosen and tear clay aggregate; and further drying the extruded clay to obtain micro-nano clay powder in the soft gathering state, and recycling the solvent at the same time. According to the invention, the strong shearing force of the meshed co-rotating twin screw extruder at the meshed position is utilized to loosen and tear the clay aggregate, so that the requirements for equipment are low, the process is easy to control, environmental friendliness is realized, the energy consumption and the cost are low, and large-scale continuous environmental-friendly production can be realized.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

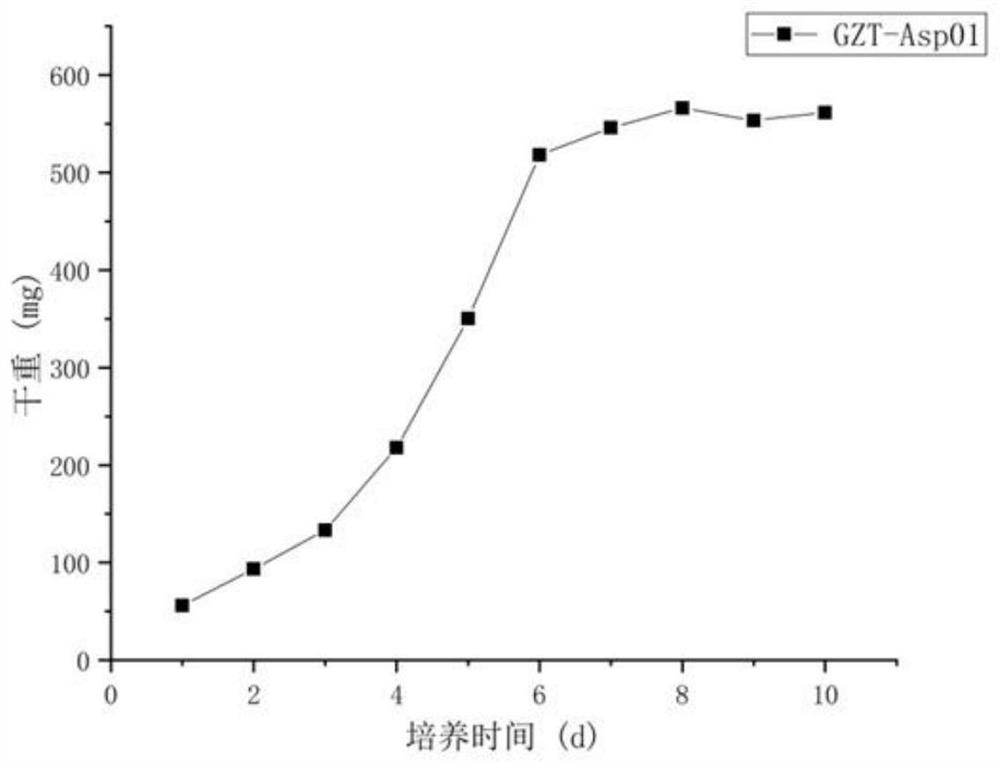

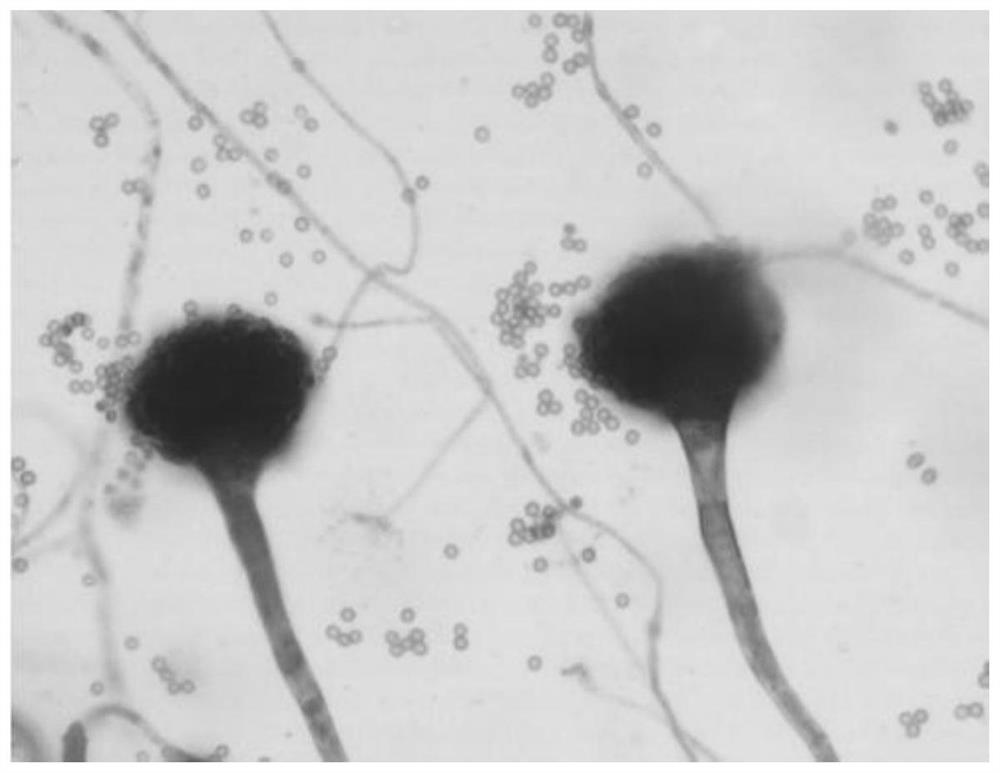

Coal gangue microbial fungal fertilizer and preparation method thereof

ActiveCN113979790ARealize resource reuseEffective dissociationBio-organic fraction processingMicroorganism based treatmentBiotechnologyAspergillus fumigatus

The invention discloses a coal gangue microbial fungal fertilizer and a preparation method thereof. The fertilizer comprises or is a product obtained by treating raw materials with aspergillus fumigatus GZT-Asp01; the main component of the raw materials is coal gangue or coal gangue; the method for treating the raw materials by using the aspergillus fumigatus GZT-Asp01 comprises the following steps: crushing the raw materials, and preparing the aspergillus fumigatus GZT-Asp01 into a bacterial solution; and under continuous stirring, spraying the bacterial liquid on the crushed raw materials, performing uniform stirring, timed overturning, temperature control treatment and airing to obtain a product. According to the coal gangue microbial fungal fertilizer disclosed by the invention, the coal gangue is treated by using the aspergillus fumigatus GZT-Asp01, so that insoluble phosphorus, potassium, calcium, nitrogen and other components in the coal gangue can be effectively converted into available phosphorus, quick-acting potassium, exchangeable calcium, hydrolytic nitrogen and other nutritional components which can be absorbed by plants, and resource reutilization of the coal gangue is realized; in addition, the technological process for dissociating the coal gangue through the aspergillus fumigatus GZT-Asp01 is remarkable in effect, low in cost and environmentally friendly.

Owner:中国烟草总公司贵州省公司

Multifunctional wet ultrafine grinding device

ActiveCN113695027AAchieve ultra-fine grindingAchieve scrubbingCleaning using toolsGrain treatmentsEngineeringSuperfine grinding

The invention provides a multifunctional wet ultrafine grinding device. The multifunctional wet ultrafine grinding device comprises a transmission device, a rack, a stirring shaft and a stirring barrel, wherein the stirring barrel is arranged below the rack; the transmission device is fixedly connected to the upper part of the rack; and the top end of the stirring shaft is connected with the transmission device and extends into the stirring barrel, the stirring shaft comprises an upper section and a lower section, a scrubbing section stirring shaft of the upper section and an ultrafine grinding section stirring shaft of the lower section are arranged in an inner and outer double-layer jacket manner, the scrubbing section stirring shaft is provided with a scrubbing impeller along the radial direction of the stirring barrel, and the ultrafine grinding section stirring shaft is provided with an ultrafine grinding impeller along the radial direction of the stirring barrel. The multifunctional wet ultrafine grinding device is a multifunctional vertical stirring mill, has ultrafine grinding and scrubbing functions at the same time, can achieve ultrafine grinding and scrubbing of powder at a time, and is small in particle sizes of products and good in dissociation effect, and convenient and efficient wet ultrafine grinding equipment is provided for mineral separation of refractory minerals.

Owner:苏州中材非金属矿工业设计研究院有限公司

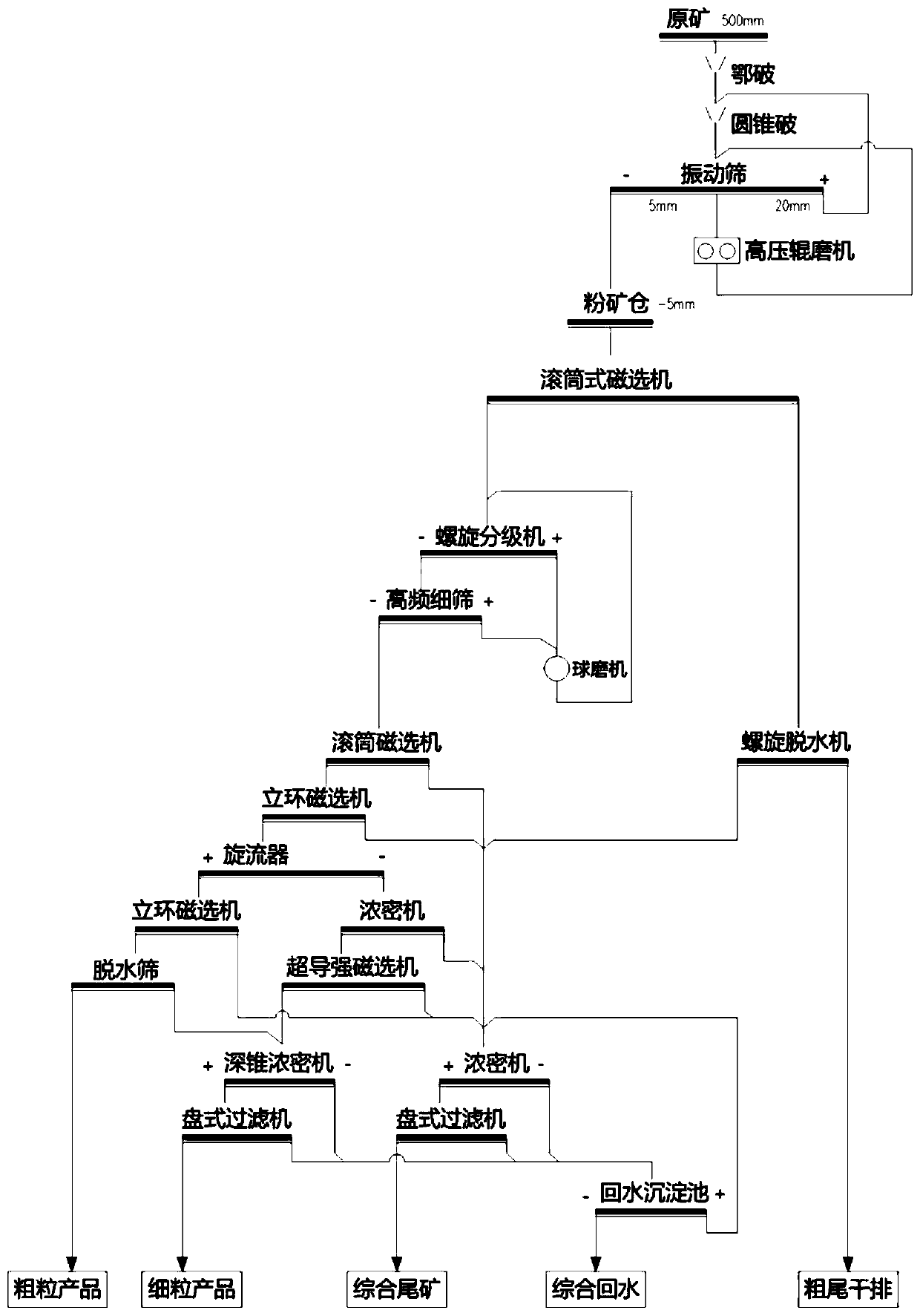

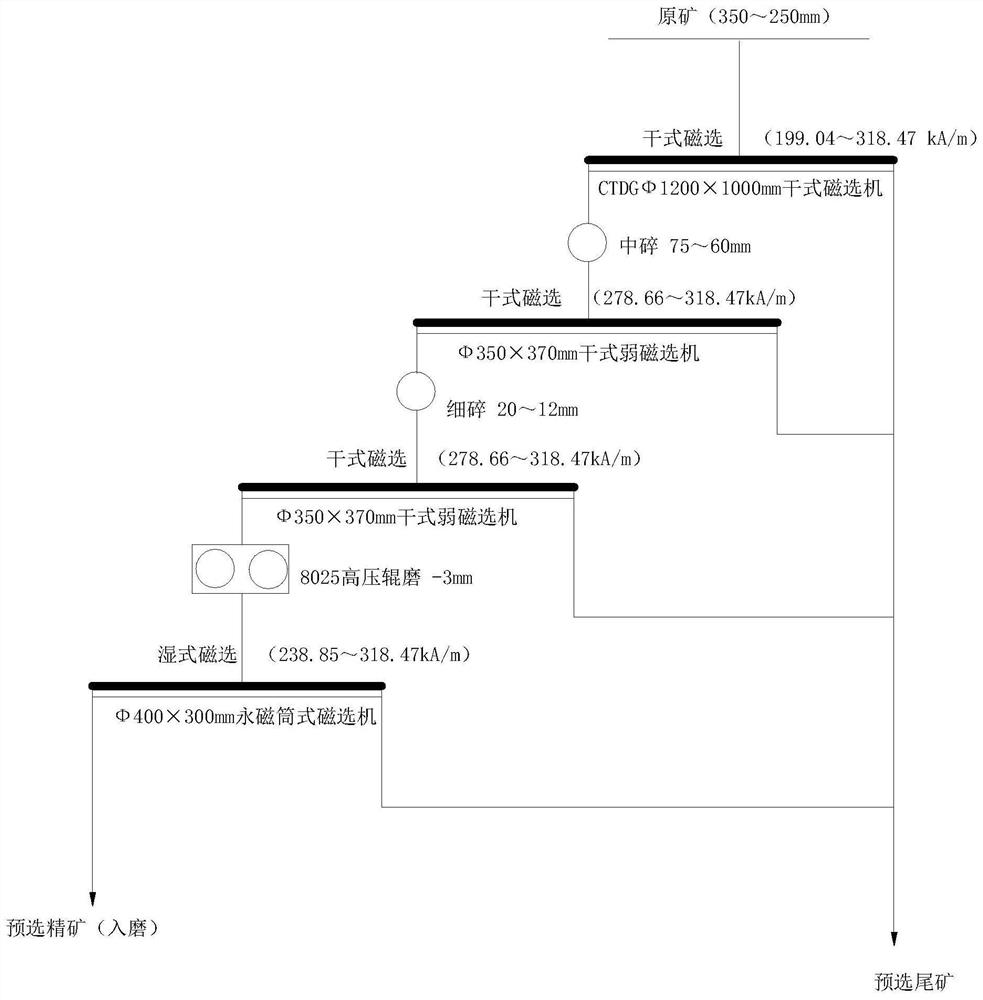

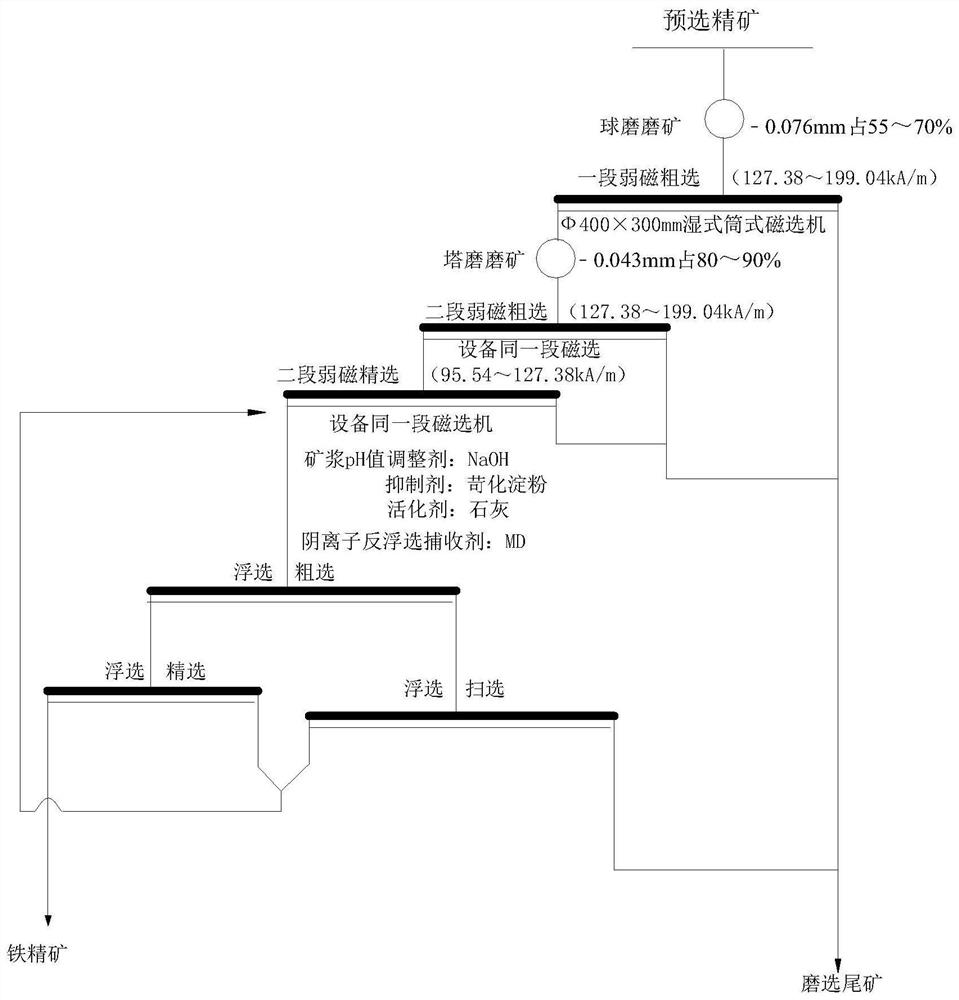

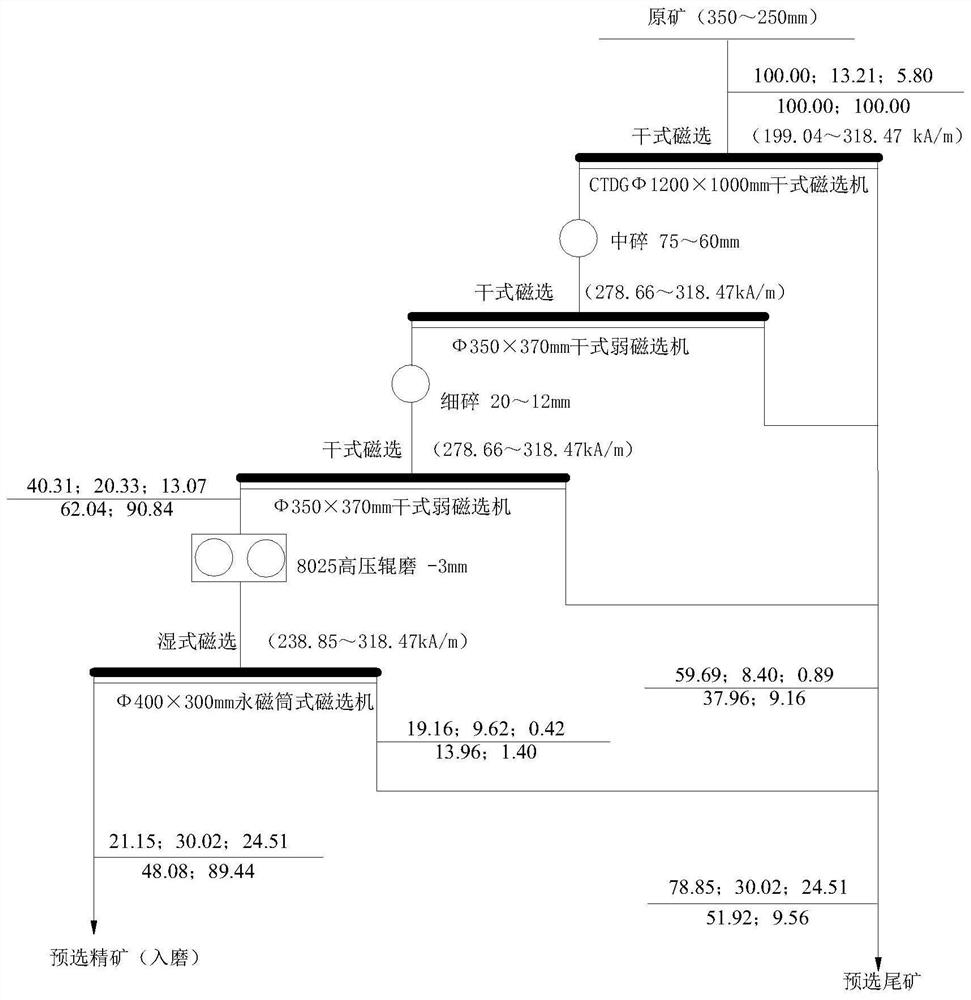

Beneficiation method for recovering high-grade iron ore concentrate from iron-containing waste rocks in waste dump

PendingCN113877718AEmission reductionReduce the amount of feedWet separationMining engineeringWaste dump

The invention discloses a beneficiation method for recovering high-grade iron ore concentrate from iron-containing waste rocks in a waste dump. The high-grade iron ore concentrate with the TFe content larger than or equal to 65.0% is obtained through the steps of 1, raw ore stage crushing and stage dry type magnetic separation waste throwing operation, 2, fine crushing dry type pre-selection concentrate high-pressure roller grinding-wet type magnetic separation tailing throwing operation, 3, wet type magnetic separation pre-selection concentrate stage grinding-stage wet type magnetic separation operation and 4, magnetic separation concentrate anion reverse flotation operation in sequence, building material products with different lumpiness and different size fractions can be produced, and the resource utilization rate of the iron-containing waste rocks reaches up to 80%. By means of the beneficiation method, a conventional crushing-high-pressure roller milling selective disintegrating technology is adopted for pre-selecting and tailing throwing, so that the discharge amount of fine tailings is reduced, and the ore grinding amount is reduced; and a superfine grinding technology including a vertical tower mill is adopted for pre-selecting the concentrate, the number of ball-milling grinding sections is reduced, the dissociation performance of ore is improved, the particle size distribution of the ore is more uniform, the condition for obtaining the high-quality iron ore concentrate is met, and the energy-saving, consumption-reducing and emission-reducing effects are remarkable.

Owner:包钢集团矿山研究院(有限责任公司) +3

Low-ink pulping method through waste paper recycling

ActiveCN107119480AGood dissociation effectHigh deinking rateWashing/displacing pulp-treating liquorsDigestersFiberPaper recycling

The invention discloses a low-ink pulping method through waste paper recycling. The method includes the following steps that 1, waster paper is collected, and beating is conducted to obtain shredded paper sheets; 2, the shredded paper sheets are subjected to micro-fermentation treatment; the shredded paper sheets obtained after micro-fermentation treatment are soaked and subjected to floating selection and ink removal; 4, after sediment is washed and impurities are removed, dehydration treatment is conducted; 5, materials obtained after dehydration are subjected to high-pressure steam-cooking and sterilization and softening; 6, the materials obtained after steaming and softening are subjected to extrusion impregnation and kneading homogenization; 7, digestion, fiber separation and defibering are conducted in sequence; 8, after purification and concentration, the final materials are stored for standby application. When the waste paper high in fiber quality is recycled for pulping, a good ink removal effect can be obtained through mutual complementation and synergistic interaction of pre-micro-fermentation treatment, post-micro-fermentation treatment and subsequent working sections.

Owner:JIANGSU HAOYU ELECTRONICS TECH

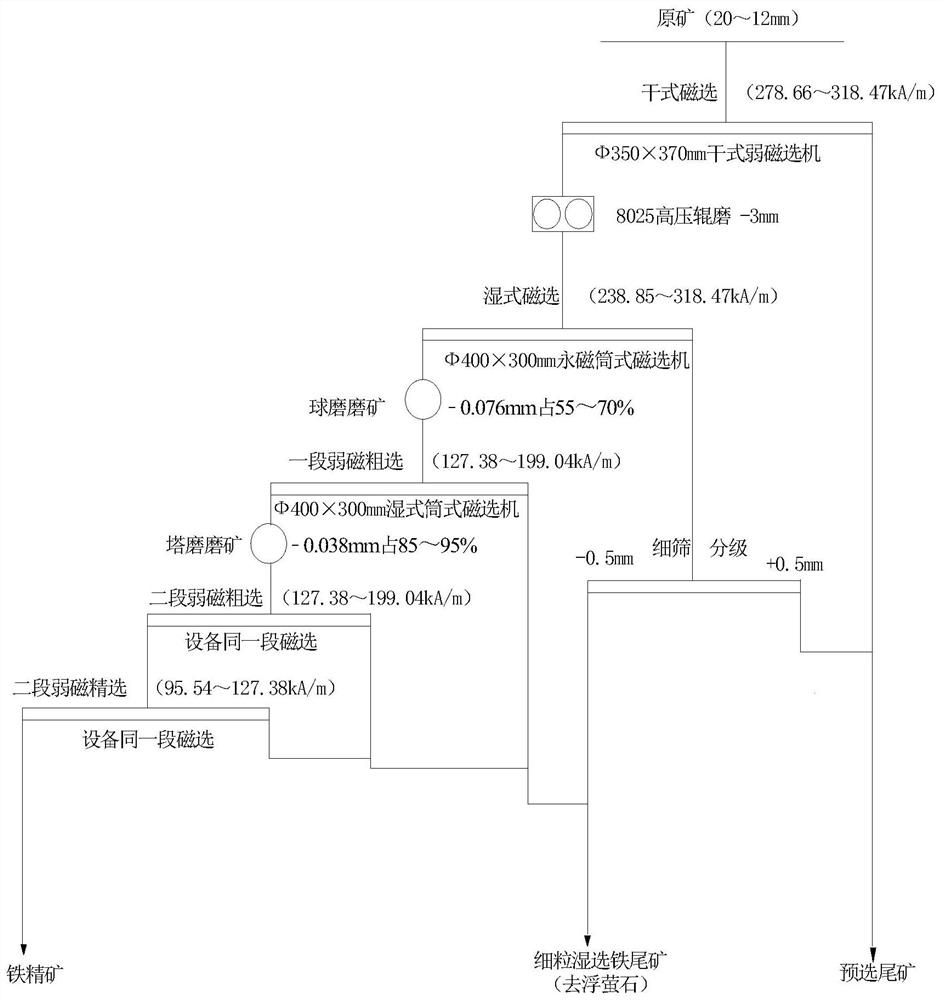

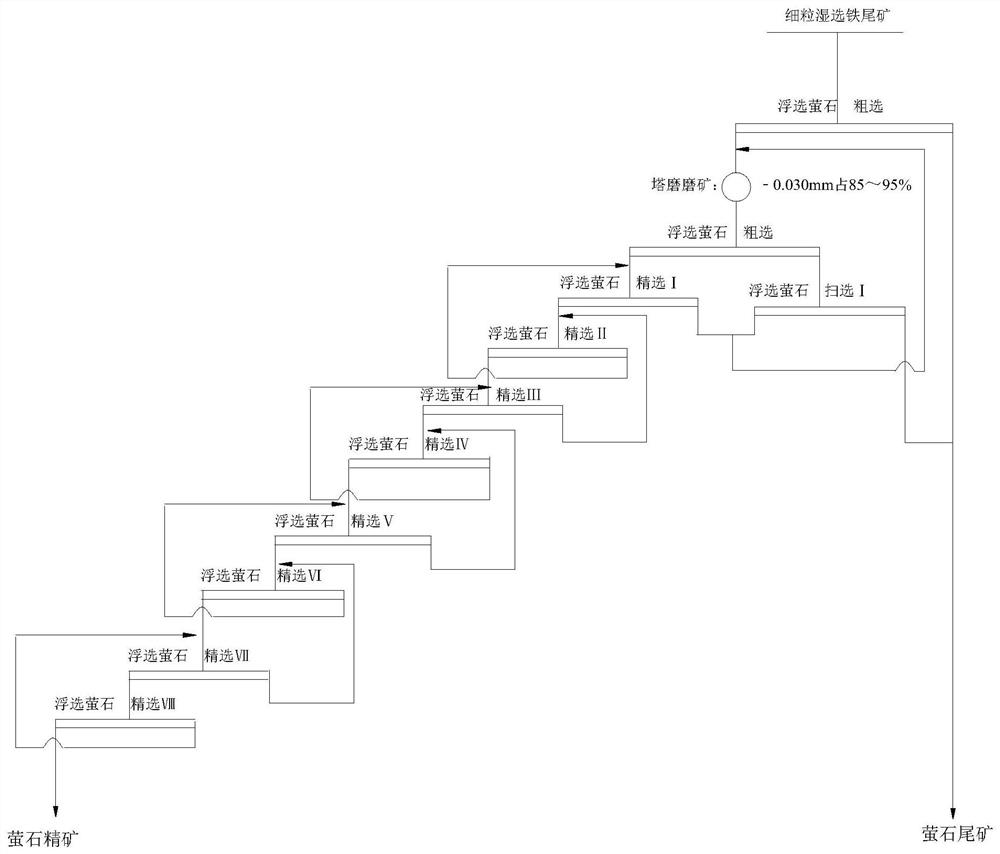

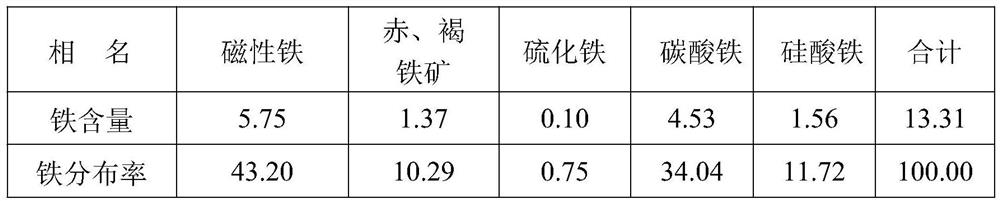

Beneficiation method for recycling extremely-low-grade iron and fluorite resources in iron-containing surrounding rock

PendingCN113941442AEmission reductionReduce grinding amountMagnetic separationGrain treatmentsMining engineeringMineralogy

The invention discloses a beneficiation method for recycling extremely-low-grade iron and fluorite resources in iron-containing surrounding rock. The beneficiation method comprises the following steps: (1) crushing raw ore, and carrying out dry magnetic separation, pre-separation and waste discarding operation; (2) carrying out high-pressure roller grinding-wet magnetic separation pre-operation on the dry-separated concentrate; (3) carrying out wet magnetic separation and pre-selection of concentrate ore stage grinding-stage wet magnetic separation operation; and (4) conducting fluorite recovery flotation operation on iron separation tailings. According to the method, the conventional crushing-high-pressure roller milling selective crushing technology is adopted for pre-selection and tailing discarding, coarse-grain tailings with the yield being nearly 60% can be discarded, the discharge amount of fine-grain tailings is greatly reduced, the ore grinding amount is remarkably reduced, the ore grinding energy consumption is reduced by 55% or above, and the energy-saving and consumption-reducing effects are remarkable. The tailings pre-selected by dry magnetic separation and the upper part of the fine screening and classifying screen are sold as building material products, the yield is up to 60% or above, and the total yield is up to 70% or above by adding high-grade iron ore concentrate and fluorite concentrate which are subsequently recycled, so that waste is turned into wealth, harm is turned into good, and an unexpected effect is achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +3

Negative ion functional inorganic pigment

InactiveCN111808466AOvercome the problem of not easy escapeGood dissociation effectCoatingsCalcium hydroxideInorganic pigments

Negative ion functional inorganic pigment is disclosed, and mainly comprises the following raw materials in parts by weight: 50-60 parts of calcium hydroxide, 5-15 parts of silica fume, 5-10 parts ofsilica sol, 1-3 parts of ternary composite negative ion powder, 2-6 parts of graphene oxide, 4-6 parts of silicone oil, 5-20 parts of a coloring agent and 95-105 parts of deionized water. Improvementis carried out on the basis of a previous first-generation coating formula, transition from the coating field to the pigment field is achieved, and the characteristic of sufficient release or standardrelease of negative ions is reserved.

Owner:成都森态源环保科技有限公司

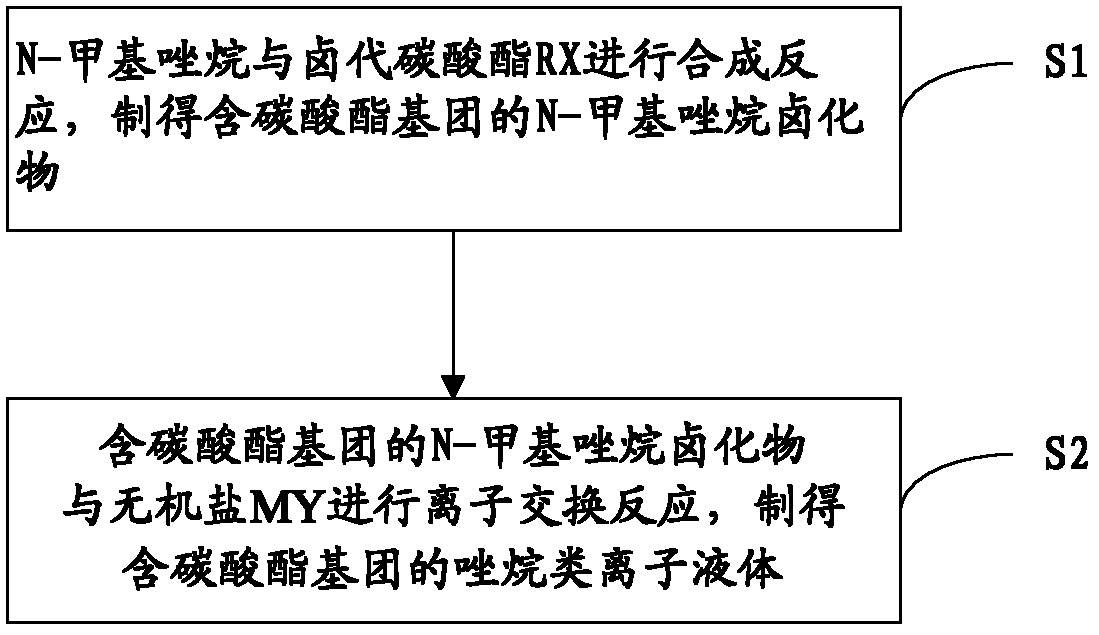

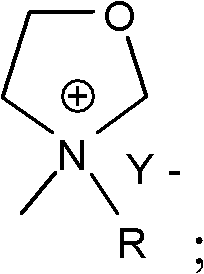

Oxazolidines ionic liquid containing carbonic ester perssad and preparation method and application thereof

InactiveCN103130786AImprove performanceImprove solubilityOrganic chemistryElectrolytic capacitorsLithiumCarbonate ester

The invention belongs to the ionic liquid field and discloses an oxazolidines ionic liquid containing carbonic ester perssad and a preparation method and application thereof. The ionic liquid has the following structural formula. In the formula, R is 0<=n<=4, and Y- is selected from BF4- or PF6- or (CF3SO2)2N- or CF3SO3-. According to the oxazolidines ionic liquid containing the carbonic ester perssad, the performance of the ionic liquid can be improved through the fact that the carbonic ester perssad is brought into intopositive ions. On the one hand, in an electrolyte solution containing lithium salt, the carbonic ester structure has a good dissolving and dissociation function on the lithium salt; and on the other hand, the ionic liquid containing the carbonic ester structure can generate SEI films well, so that the electrochemical stability of the ionic liquid electrolyte solution can be improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Cell mass digestion and dissociation promoting liquid and cell counting method

ActiveCN113564051AHigh dissociation efficiencySimple ingredientsMicrobiological testing/measurementMicroorganism lysisSurface-active agentsBiophysics

The present application provides a cell mass digestion and dissociation promoting liquid and a cell counting method. The cell mass digestion and dissociation promoting liquid comprises the following raw materials in percentage by mass: 1%-5% of polyethylene glycol octylphenol ether; 0.1%-4% of alkyl glycoside; 0.1%-1% of non-surface active agent type sulphobetaine; 0.1%-1% of zwitterionic detergent; 1%-10% of pH regulator; and the balance water. The cell digestion and dissociation promoting liquid can realize digestion and dissociation of cell masses by destroying lipid bilayers of cells, dissolving cytoplasm and cell membranes and destroying weak intermolecular binding bonds, and has high dissociation efficiency on the cell masses, so that the cell counting method provided by the present application can realize rapid and low-cost determination of the number of cells cultured on a support material in a bioreactor.

Owner:GUANGDONG UNISUN BIOTECHNOLOGY CO LTD

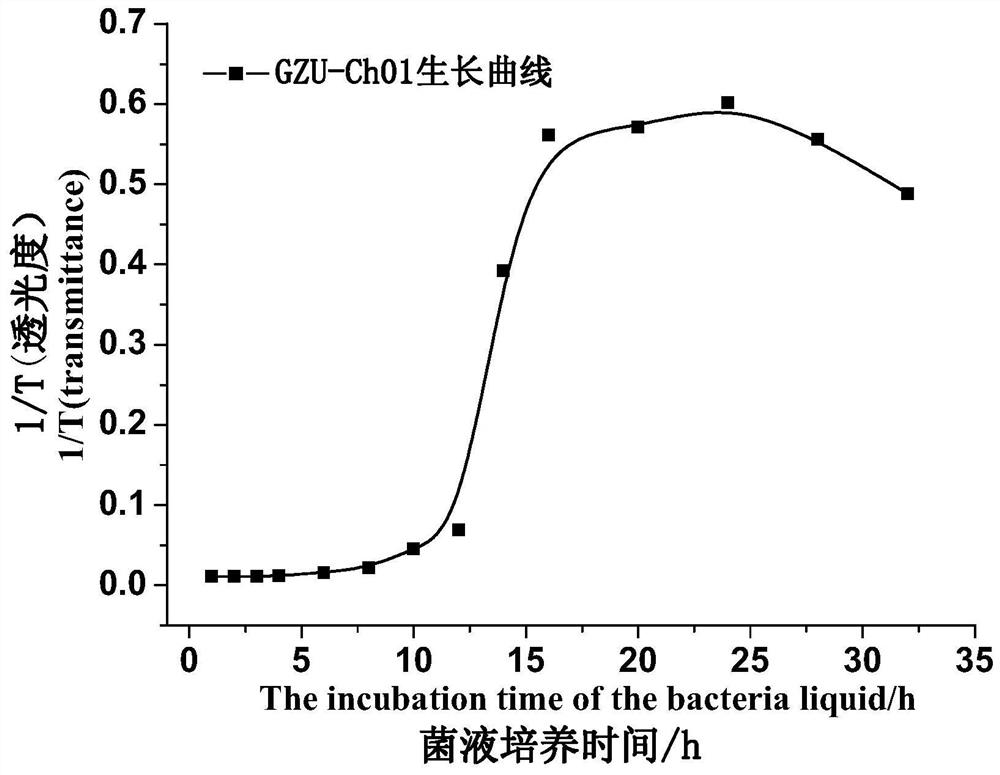

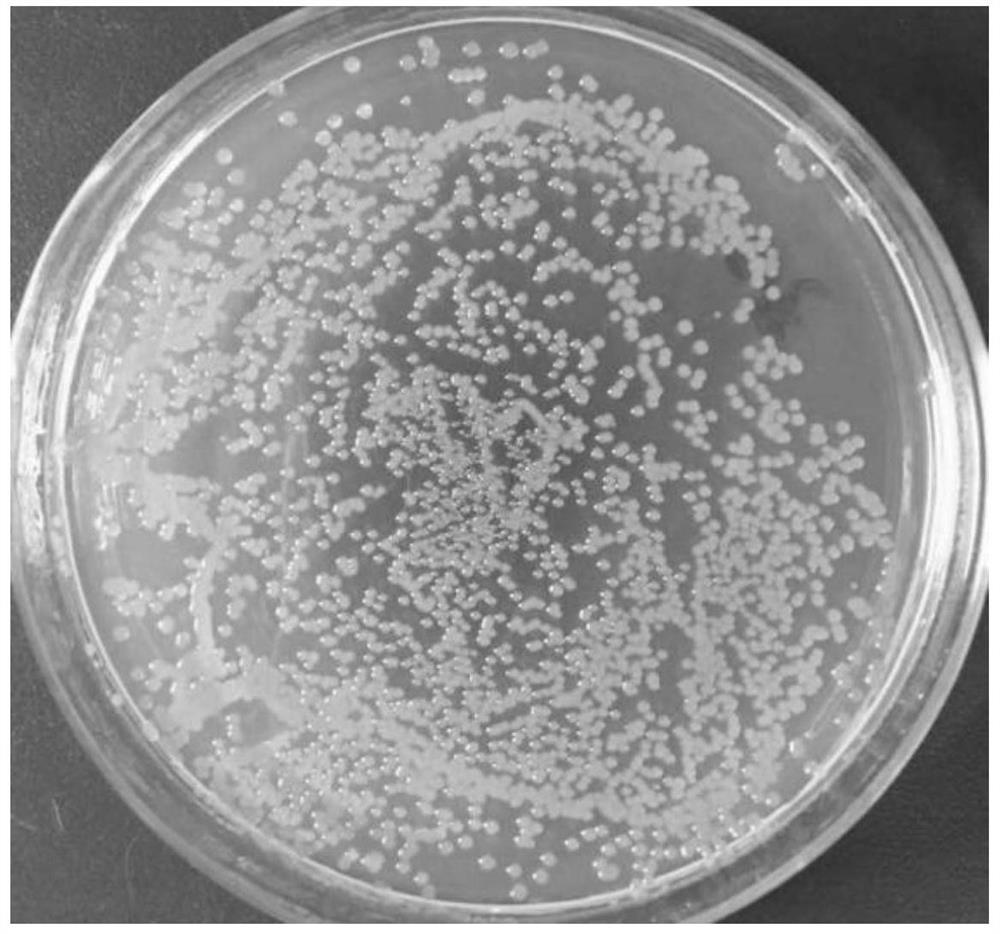

A kind of Chryseobacterium bacterial strain and application thereof

ActiveCN109943498BStrong targetingGood dissociation effectBacteriaMicroorganism based processesPotassiumBiology

The invention discloses a strain of the genus Chryseobacterium and an application thereof. The strain is Chryseobacterium sp; National Object Collection Center, the collection number is CCTCCNO: M2017810. Chryseobacterium sp GZU-Ch01 of the present invention can effectively decompose insoluble potassium, phosphorus, silicon, calcium, sulfur and other components in coal gangue to become available potassium, available phosphorus, available silicon, exchangeable calcium, effective Sulfur, etc. are used as nutrients absorbed by plants. In particular, GZU‑Ch01 can effectively dissociate insoluble potassium in coal gangue, making it into available potassium, which provides a valuable source of potassium resources. The gangue is mixed with other potassium-containing minerals such as potassium feldspar, which can further increase the potassium content in the mineral and microbial compound fertilizer based on coal gangue.

Owner:GUIZHOU UNIV

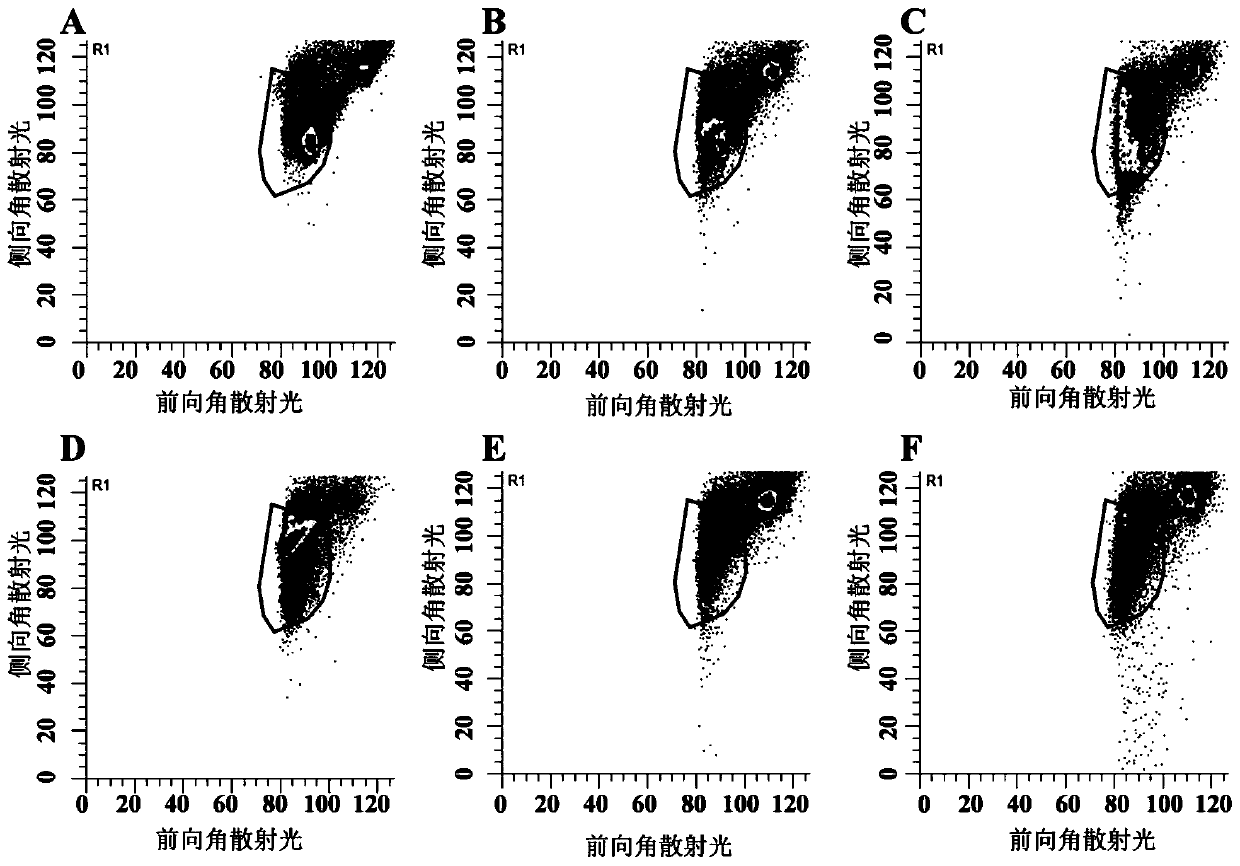

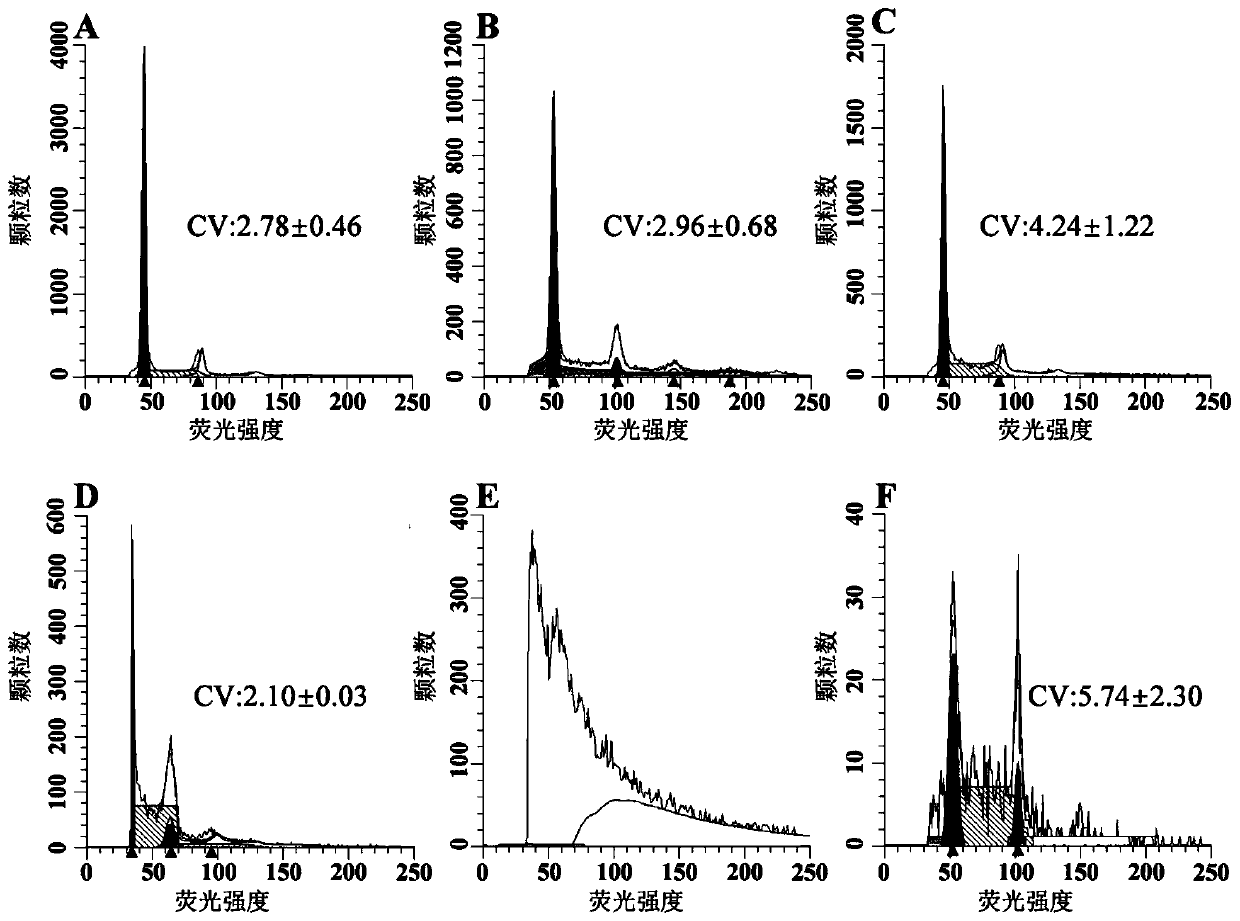

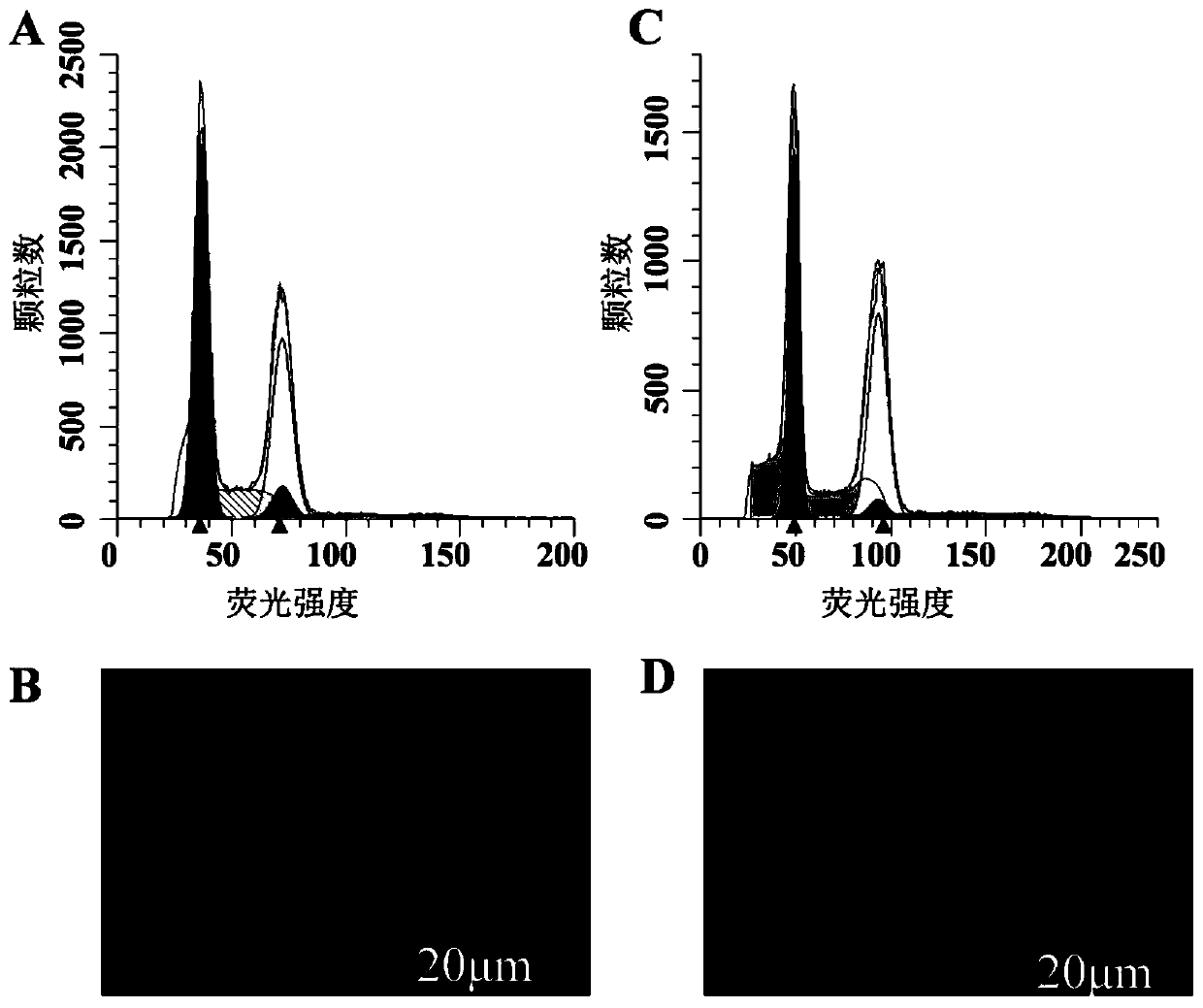

Soybean cell nucleus dissociation liquid suitable for flow cytometry analysis and application thereof

PendingCN111504746AGood dissociation effectImprove applicabilityPreparing sample for investigationActive agentPloidy

The invention belongs to the field of biology, and particularly relates to a soybean cell nucleus dissociation solution suitable for flow cytometry analysis and application thereof. The soybean cellnucleus dissociation liquid suitable for flow cytometry analysis comprises 45mM magnesium chloride, 20mM MOPS, 30 mM of sodium citrate and 30 mM of a non-ionic surface active agent; the nuclear dissociation liquid provided by the invention has good applicability on different soybean varieties, not only has a good nuclear dissociation effect on soybean leaves and root tissues, but also is reliablein corresponding cell cycle analysis experiment result, and provides technical support for further researching the influence of adversity on the soybean intrakaryotic replication level; and a foundation is laid for simply, conveniently, quickly and accurately researching the content, the cell cycle and the genetic ploidy of the soybean cell nucleus DNA by using a flow cytometry.

Owner:YANGZHOU UNIV

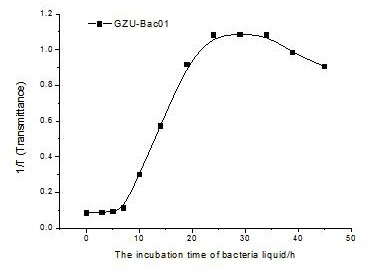

A kind of Bacillus mobilis and its application

ActiveCN112760270BIncrease profitRelieve stressBacteriaMicroorganism based processesMicroorganismBacilli

The invention discloses a mobilis bacillus and application thereof. The Bacillus mobilis is named Bacillus mobilis GZU‑Bac01 (Bacillus mobilis GZU‑Bac01), and was deposited in the China Center for Type Culture Collection on December 7, 2020, with the preservation number CCTCC NO: M 2020863. Bacillus mobilis GZU-Bac01 of the present invention has the nutrient element that can dissociate and release solidification, as: nitrogen, phosphorus, potassium, calcium etc., and dissociation effect is good, and cost is low, and environmental protection, adopts microbial bacterium (Bacillus mobilis GZU‑Bac01) method for dissociating coal gangue to prepare microbial fertilizers, which not only converts insoluble and / or insoluble nutrients in coal gangue into soluble components, but also releases the soil after it is applied to the soil The solidified nitrogen, phosphorus, potassium, calcium, etc. in the plant can be transformed into nutrients directly absorbed and utilized by plants. At the same time, GZU‑Bac01 can also effectively release insoluble phosphorus and / or insoluble phosphorus in other phosphorus-containing minerals. phosphorus.

Owner:GUIZHOU UNIV

A dissociating agent commonly used in serum for tt3 and tt4 and its preparation method

ActiveCN112362432BGood dissociation effectAccurate valuePreparing sample for investigationBiological testingActive agentMetal chelate

Owner:GUANGZHOU KEFEN BIOTECH CO LTD

Composition extracted from animal organs

InactiveCN102961403BGood dissociation effectLow costUnknown materialsBlood disorderAnimal scienceMedicine

The invention relates to a composition extracted from animal organs, wherein the animal organs are selected from livers, small intestines, large intestines and lungs, and animals are selected from cows, pigs, sheep and dogs.

Owner:青岛亚博生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com