Quantitative analysis method for gasified slag mineral phase

A quantitative analysis and gasification slag technology, which is applied in the direction of analyzing materials, weighing and measuring devices by removing certain components, can solve the problems of low detection limit of analysis methods, harsh reaction conditions, and low data accuracy, and achieve The effect of low detection limit of impurities, mild reaction conditions and high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

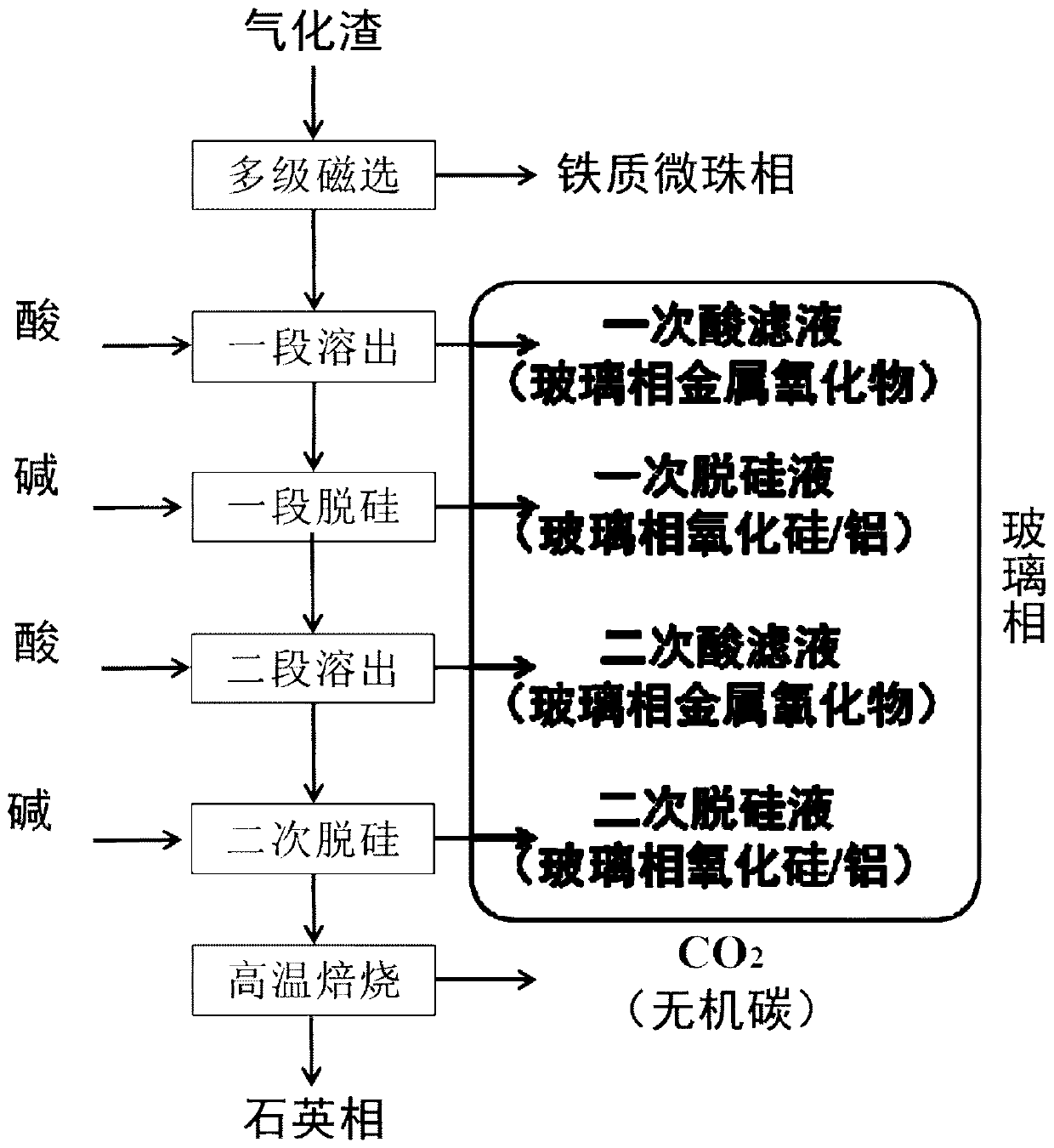

[0031] Taking coal gasification slag in Ordos area as an example, as figure 1 As shown, the quantitative analysis method of gasification slag ore phase in this embodiment is:

[0032] (1) Take 100g of gasification slag and put it into a magnetic separator, and carry out secondary magnetic separation (two magnetic separations) under a magnetic field strength of 2000Gs. The content of the obtained iron microspheres is about 3.62g, and the iron microspheres 3.62%;

[0033] (2) the remaining 96.38g solid material is mixed with the nitric acid whose hydrogen ion concentration is 4mol / L, and the reaction temperature is 95°C, and the liquid-solid ratio is 3:1. Calcium, magnesium) leaching mass is 10.27g, remaining 86.11g;

[0034] (3) Mix the remaining 83.11g of primary pickling slag with a sodium hydroxide solution with a hydroxide ion concentration of 4mol / L, and react for 180min under the conditions of a reaction temperature of 75°C and a liquid-solid ratio of 3:1, and enter Th...

Embodiment 2

[0040] Taking the coal gasification slag in the Ordos area as an example, the quantitative analysis method of the gasification slag ore phase in this embodiment is:

[0041] (1) Take 100g of gasification slag and put it into a magnetic separator, and carry out 4-stage magnetic separation (4 magnetic separations) under a magnetic field strength of 5000Gs. The content of the obtained iron microspheres is about 3.67g, and the content of iron microspheres 3.67%;

[0042] (2) The remaining 96.37g solid material is mixed with hydrochloric acid with a hydrogen ion concentration of 10mol / L, and the reaction temperature is 55°C, and the liquid-solid ratio is 7:1. Calcium, magnesium) leaching quality is 12.63g, remaining 83.7g;

[0043] (3) Mix the remaining 83.7g of primary pickling slag with a sodium hydroxide solution with a hydroxide ion concentration of 1mol / L, and react for 120min under the conditions of a reaction temperature of 125°C and a liquid-solid ratio of 8:1, and enter ...

Embodiment 3

[0050] Taking the coal gasification slag in Shanxi as an example, the quantitative analysis method of gasification slag ore phase in this embodiment is as follows:

[0051] (1) Get 100g gasified slag and put it into the magnetic separator, under the magnetic field strength of 3000Gs, carry out three-stage magnetic separation (magnetic separation for three times), the obtained iron microsphere content is about 4.76g, and the iron microsphere content is 4.76%;

[0052] (2) the remaining 95.24g solid material is mixed with the nitric acid that the hydrogen ion concentration is 3mol / L, is 85 ℃ at reaction temperature, and reacts 120min under the condition that liquid-solid ratio is 5:1, metal oxide (iron, aluminium, Calcium, magnesium) leaching mass is 8.36g, remaining 86.88g;

[0053] (3) Mix the remaining 86.88g of primary pickling slag with a sodium hydroxide solution with a hydroxide ion concentration of 3mol / L, and react for 90min under the conditions of a reaction temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com