Air pressure dismantling device and method for waste mobile phone

An air pressure and mobile phone technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, complicated installation and disassembly, etc., and achieve the effect of improving productivity, improving disassembly efficiency, and good dissociation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

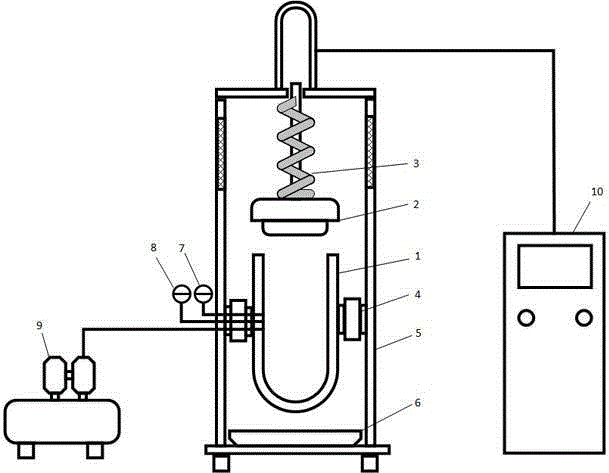

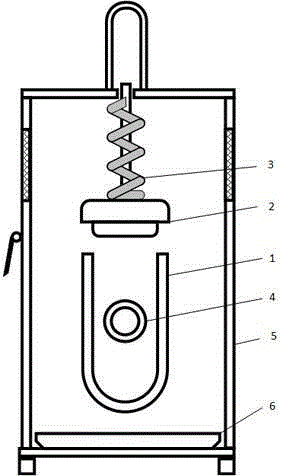

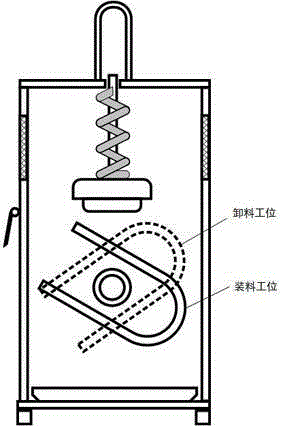

[0039] Design and manufacture a set of air pressure dismantling device for discarded mobile phones, the inner diameter of the tank body 1 is 150mm, and the wall thickness is 10mm. Tank 1 is 400mm high and has an effective volume of 0.007m 3 . 14 discarded mobile phones are loaded into the tank body 1, the tank body 1 is rotated to reach a vertical position, the electric control system 10 is started, and the lid 2 is closed. Start the air compressor 9 to raise the air pressure in the tank to 0.4~0.5MPa and keep it for 2 minutes. Operate the electronic control system 10 and open the cover 2 . After the gas is released, open the cabinet door of the box body 5, rotate the tank body 1, and pour the mobile phone into the material collection tray 6. The dismantling results showed that all 14 mobile phone shells were broken, and the dismantling rate reached 100% at one time. The batteries, LCD screens, circuit boards, shells and other parts can be collected directly by classificati...

Embodiment 2

[0041] Design and manufacture a set of air pressure dismantling device for discarded mobile phones, the inner diameter of the tank body 1 is 150mm, and the wall thickness is 10mm. Tank 1 is 400mm high and has an effective volume of 0.007m 3 . 20 discarded mobile phones are loaded into the tank body 1, the tank body 1 is rotated to reach the value position, the electric control system 10 is started, and the lid 2 is closed. Start the air compressor 9 to raise the air pressure in the tank to 0.3-0.4 MPa and keep it for 3 minutes. Operate the electronic control system 10 and open the cover 2 . After the gas is released, open the cabinet door of the box body 5, rotate the tank body 1, and pour the mobile phone into the material collection tray 6. The results of dismantling showed that among the 20 mobile phones, 17 shells were broken, and the dismantling rate reached 85%. Most of the batteries, LCD panels, circuit boards, shells and other parts can be collected directly by clas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com