Patents

Literature

50results about How to "Improve high voltage resistance performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-woven ceramic membrane with excellent closed-pore performance for lithium ion battery and technology

ActiveCN103199209AReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsCeramic coatingPore diameter

The invention provides a non-woven ceramic membrane with excellent closed-pore performance for a lithium ion battery. The non-woven ceramic membrane comprises a non-woven base material and coatings with the closed-pore performance. The non-woven ceramic membrane is characterized in that the coatings with the closed-pore performance are uniformly coated on the two surfaces of the non-woven base material, the thickness of the non-woven ceramic membrane for the lithium ion battery is 30-50mu m, the porosity of the non-woven ceramic membrane is 40-60%, the average pore diameter of the non-woven ceramic membrane is 0.1-0.5mu m, the closed-pore temperature of the non-woven ceramic membrane is 120-130 DEG C, and the membrane rupture temperature of the non-woven ceramic membrane is 300-500 DEG C. The invention also provides a preparation technology of the non-woven ceramic membrane with the excellent closed-pore performance for the lithium ion battery. The non-woven ceramic membrane has the advantage that the disintegration or explosion of the battery is not easy cause; the adhesive power between the ceramic coating and the base material is increased, and no powder falls off the surface of the membrane under the conditions of bending, rubbing and the like; the consistency of the membrane thickness is substantially improved; and the non-woven ceramic membrane has good high temperature resistance performance, high ion penetrability, low resistance and stable electrochemical property.

Owner:CHINA HAISUM ENG

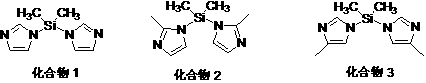

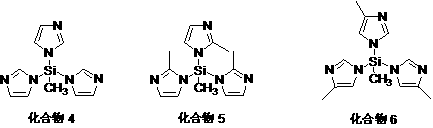

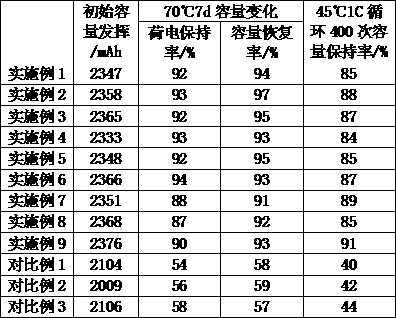

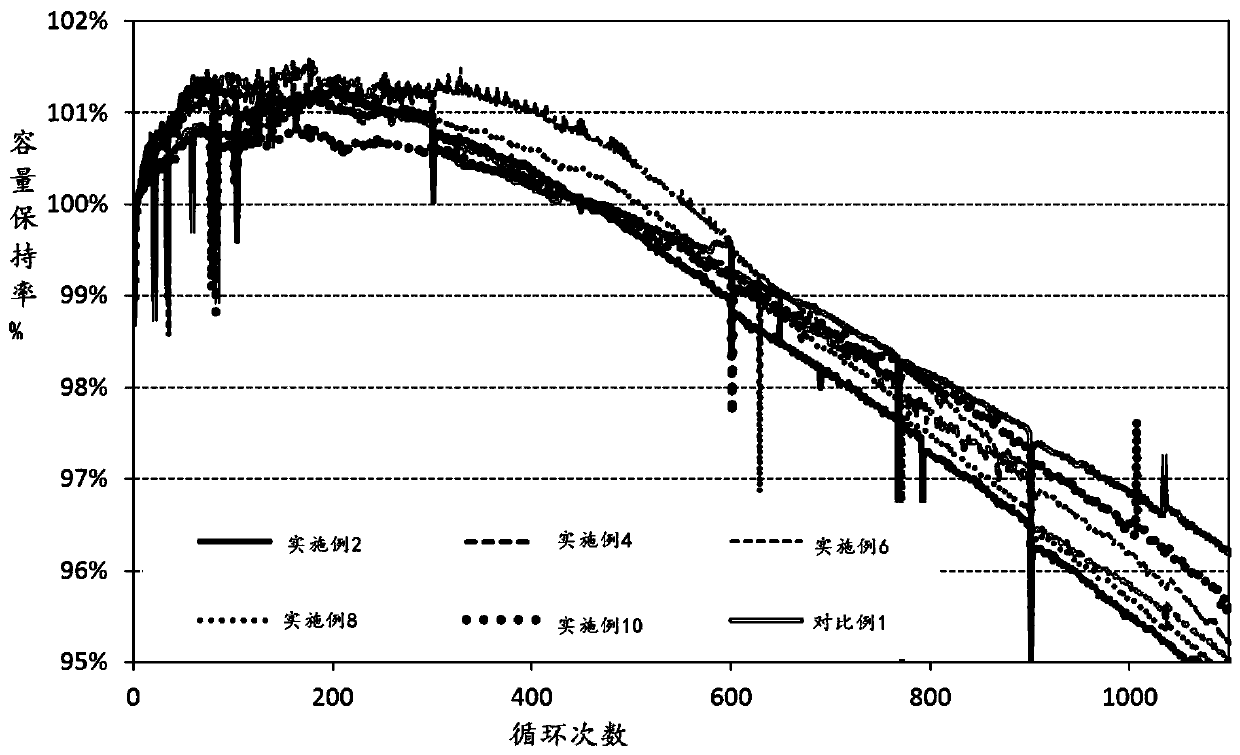

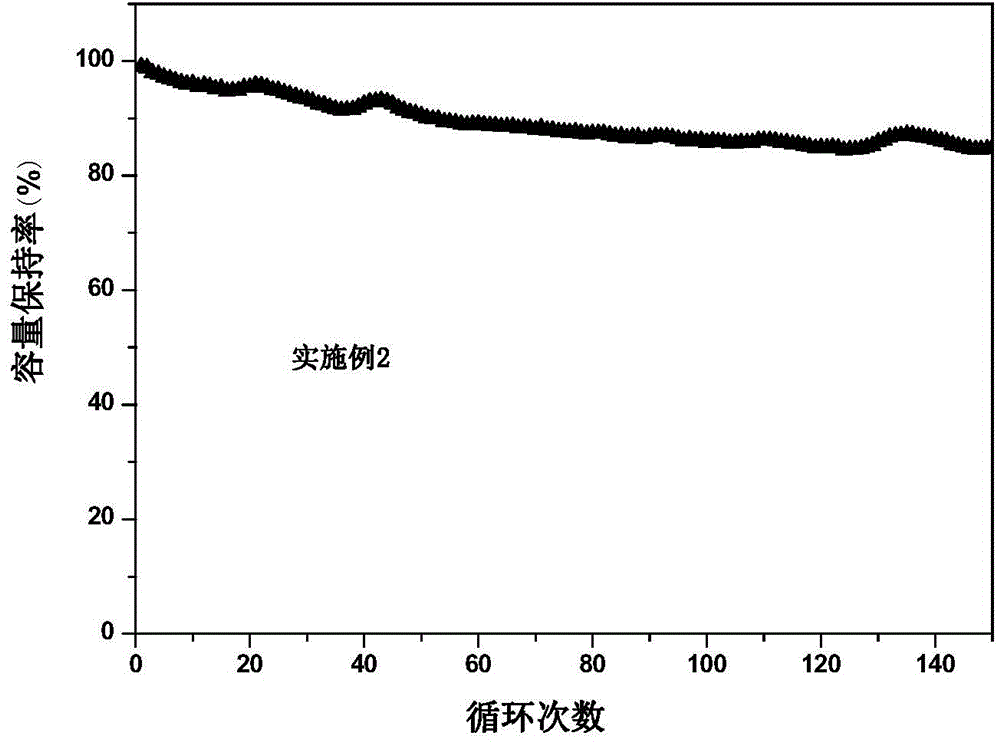

Electrolyte containing novel additive for lithium ion battery and lithium ion battery

InactiveCN110931865AImprove high voltage resistance performanceLess side effectsSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentElectrical battery

The invention provides the electrolyte containing the novel additive for the lithium ion battery and the lithium ion battery, wherein the electrolyte can effectively improve the cycle performance, thestorage performance and the safety performance of the lithium ion battery. The electrolyte comprises an electrolyte main body and a silicon-containing diimidazole compound; the lithium ion battery comprises a positive plate, a negative plate, a diaphragm and the electrolyte, when the silicon-containing diimidazole compound is used as an electrolyte additive, an interface film with excellent electrochemical stability and ionic conductivity can be formed on an interface of a positive electrode material and a negative electrode material of the lithium ion battery; meanwhile, the additive has a Si-N bond structure, so that the additive can react with H<2>O / HF, the reaction of LiPF<6> and H<2>O is inhibited, the HF content is reduced, the storage stability and the thermal stability of the electrolyte are improved, and the high-temperature cycle performance of the battery is improved. The invention is applied to the field of lithium ion batteries.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

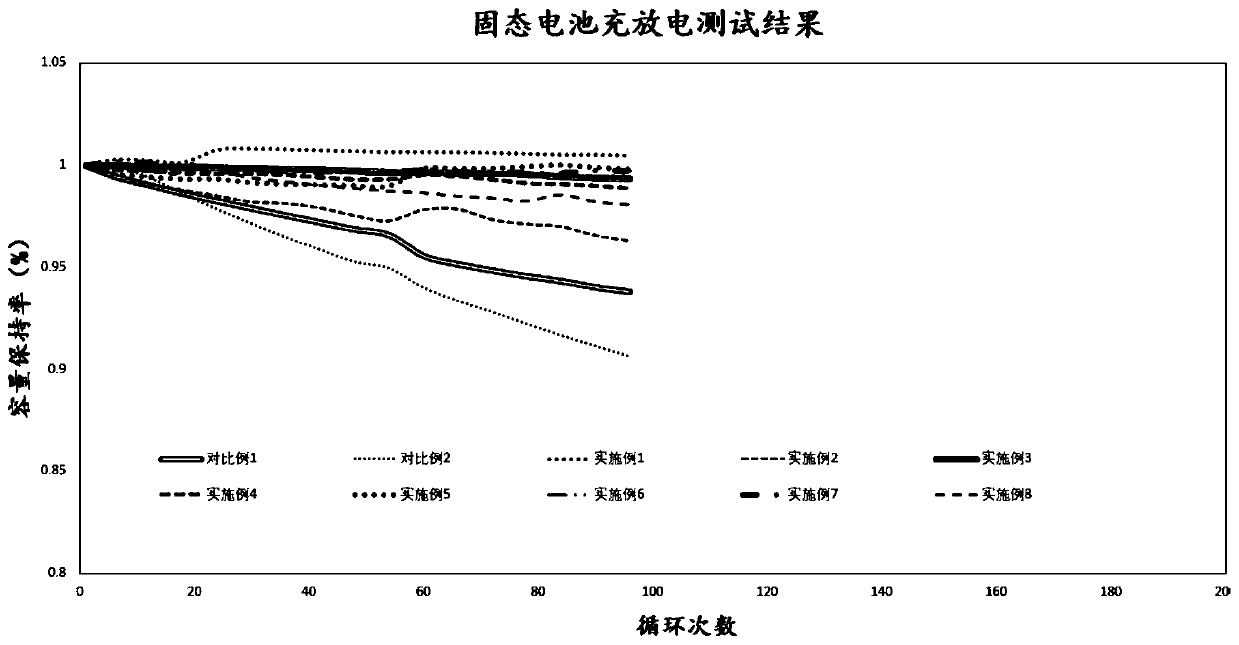

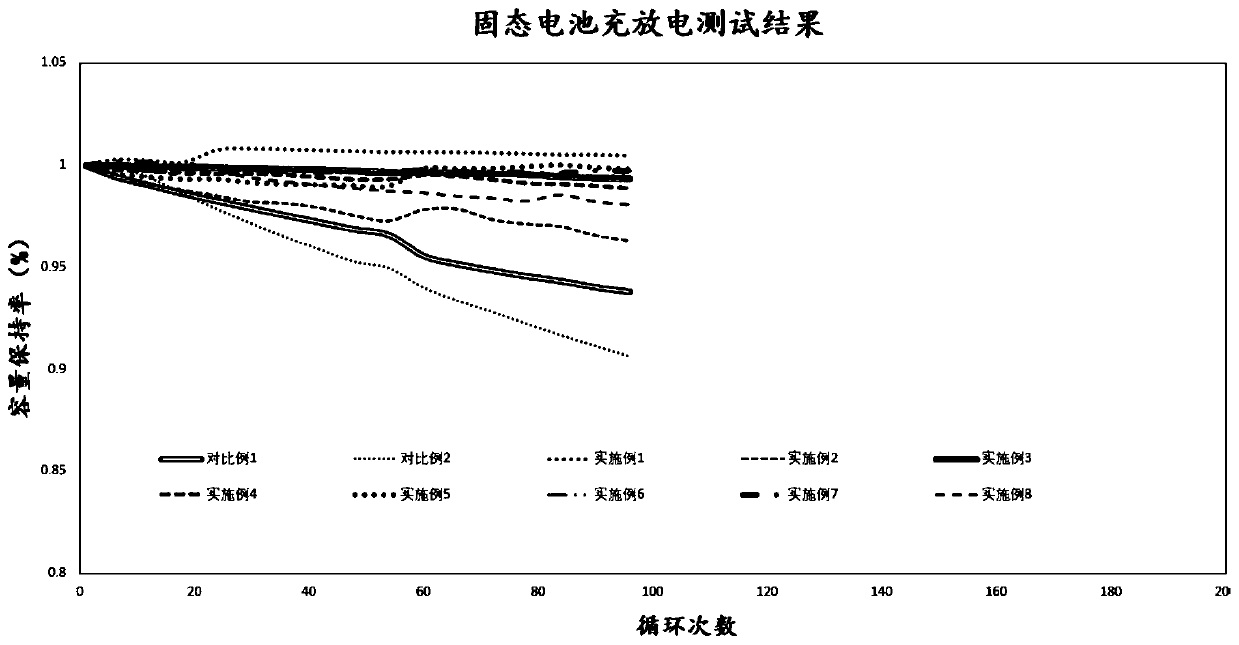

Polymer electrolyte and lithium ion battery comprising same

ActiveCN111138596AImprove electrochemical stabilityImprove high voltage resistance performanceSolid electrolytesSecondary cellsPolymer electrolytesOrganic solvent

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a polymer electrolyte and a lithium ion battery comprising the same. The preparation method of the polymer electrolyte comprises the following steps: (1) dissolving a functional polymer in an organic solvent, and uniformly mixing to obtain a system A, wherein the mass proportion of the functional polymer in the system A is 0.2-30%; (2) uniformly mixing the system A, a lithium salt and a functional additive to obtain a mixed solution; and (3) carrying out in-situ polymerization on the mixed solution to obtain the polymer electrolyte. The polymer electrolyte has good affinity with anions of the lithium salt, has high conductivity, and greatly improves the performances of a semi-solid battery. The semi-solid state lithium ion battery prepared based on an existing lithium ion battery processing technology has good processing performances and electrochemical performances, and has a certain application prospect.

Owner:浙江冠宇电池有限公司

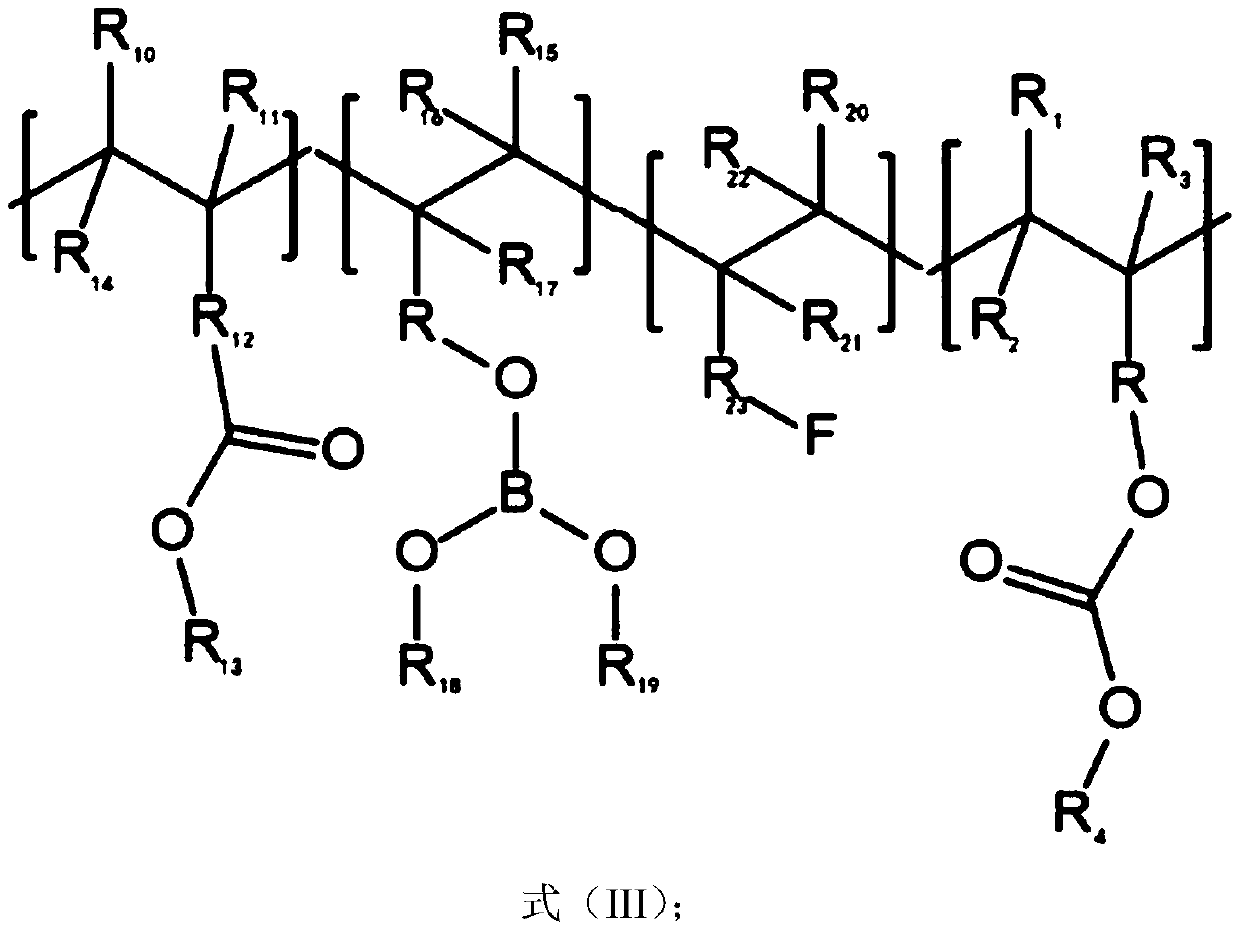

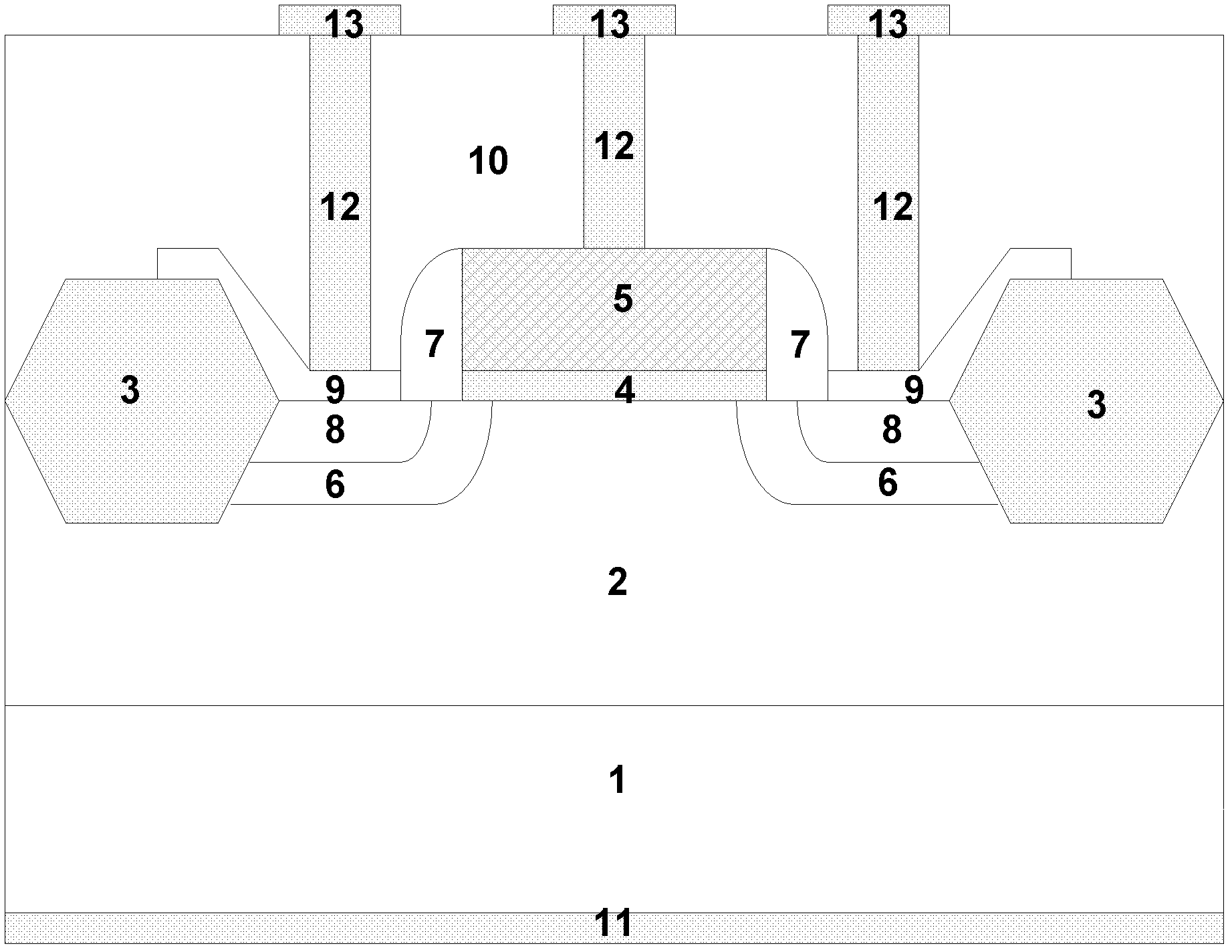

High-voltage resistant tunneling transistor and preparation method thereof

InactiveCN102544104AImprove breakdown resistanceImprove high voltage resistance performanceSemiconductor/solid-state device manufacturingDiodeGate dielectricMetal

The invention provides a high-voltage resistant tunneling transistor and a preparation method thereof. The tunneling transistor comprises a drain, an epitaxial layer, a buried layer, a source, a gate dielectric, a grid, a source metal layer and a drain metal layer. According to the tunneling transistor disclosed by the invention, the breakdown resistance capacity of the device under a closed state can be improved, the on resistance of the device is reduced, the power consumption under a large current is reduced, the heat radiation capacity of the device is improved, and the properties of the device under the large current are optimized. According to the preparation method disclosed by the invention, the low-doped or intrinsic epitaxial layer is prepared on the drain, so that the on resistance of the device can be reduced and the power consumption under the large current is reduced; and a non-heavy doped p area is prepared near the source and a non-heavy doped n area is prepared near the drain, so that the breakdown resistance capacity of the device under the closed state can be improved.

Owner:TSINGHUA UNIV

High-voltage-resistant tunneling field effect transistor (TFET) and preparation method thereof

ActiveCN102569363AImprove high voltage resistance performanceImprove breakdown resistanceSemiconductor/solid-state device manufacturingDiodeGate dielectricEngineering

The invention provides a high-voltage-resistant tunneling field effect transistor (TFET) and a preparation method thereof. The TFET comprises a semiconductor substrate, a channel region, a first buried layer, a second buried layer, a source region, a drain region, a gate dielectric and a gate, wherein the channel region is formed in the semiconductor substrate and comprises one or more shallow trench isolations (STI); the first buried layer and the second buried layer are formed in the semiconductor substrate and are positioned on two sides of the channel region respectively; the first buried layer has the first non-heavy doping type; the second buried layer has the second non-heavy doping type; the source region and the drain region are formed in the semiconductor substrate and are positioned on the first buried layer and the second buried layer respectively; the source region has the first heavy doping type; the drain region has the second heavy doping type; the gate dielectric is formed on the STI of the channel region; and the gate is formed on the gate dielectric. The STI is arranged in an active region of the substrate so as to enlarge a superficial area of a channel, and the effect is equivalent to that of elongating the channel; and therefore, the high-voltage resistance of the TFET is improved.

Owner:TSINGHUA UNIV

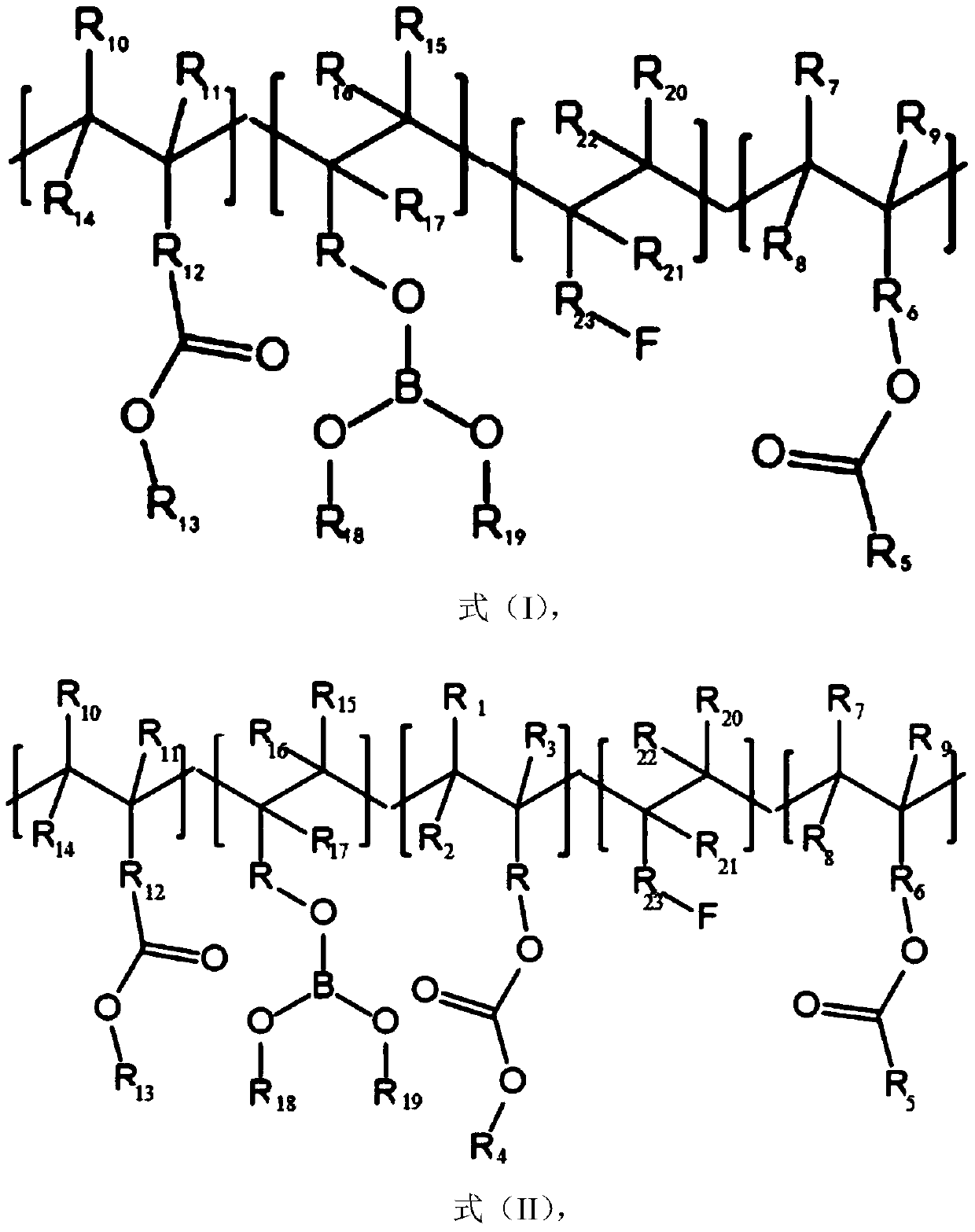

Solid polymer electrolyte containing boron-fluorine structure as well as preparation method and application thereof

ActiveCN111162312AEasy to processImprove conductivitySolid electrolytesFinal product manufactureCross linkerLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a solid polymer electrolyte containing a boron-fluorine structure as well as a preparation method andapplication of the solid polymer electrolyte. The preparation method of the solid polymer electrolyte comprises the following steps of S1, adding a vinyl boron-fluorine monomer, a vinyl polyether monomer, a modified monomer and a functional polymer into a solvent, adding an initiator for reaction, and performing purification treatment to obtain a polymer system B; S2, adding the polymer system B,a lithium salt, a filler and an auxiliary agent into the solvent, adding a cross-linking agent to obtain a mixed solution, uniformly coating a mold with the mixed solution, and then reacting; S3, obtaining the solid polymer electrolyte; assembling the obtained solid polymer electrolyte, a positive pole piece and a negative pole piece into a solid battery cell, then welding tabs, and carrying outheat treatment and packaging treatment to obtain the lithium ion battery. The solid polymer electrolyte containing the boron-fluorine structure has good high voltage resistance, high conductivity andlithium metal compatibility.

Owner:ZHUHAI COSMX BATTERY CO LTD

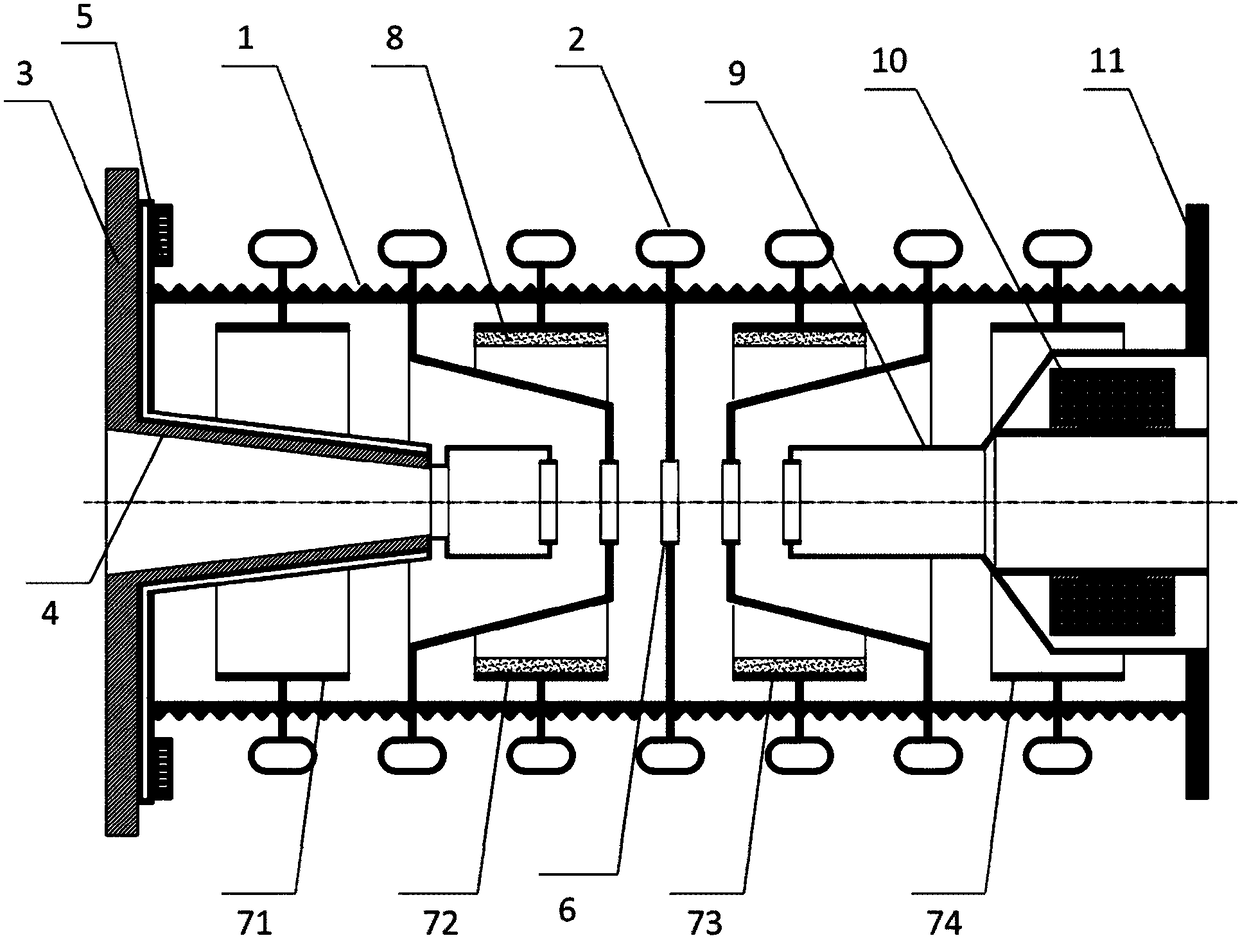

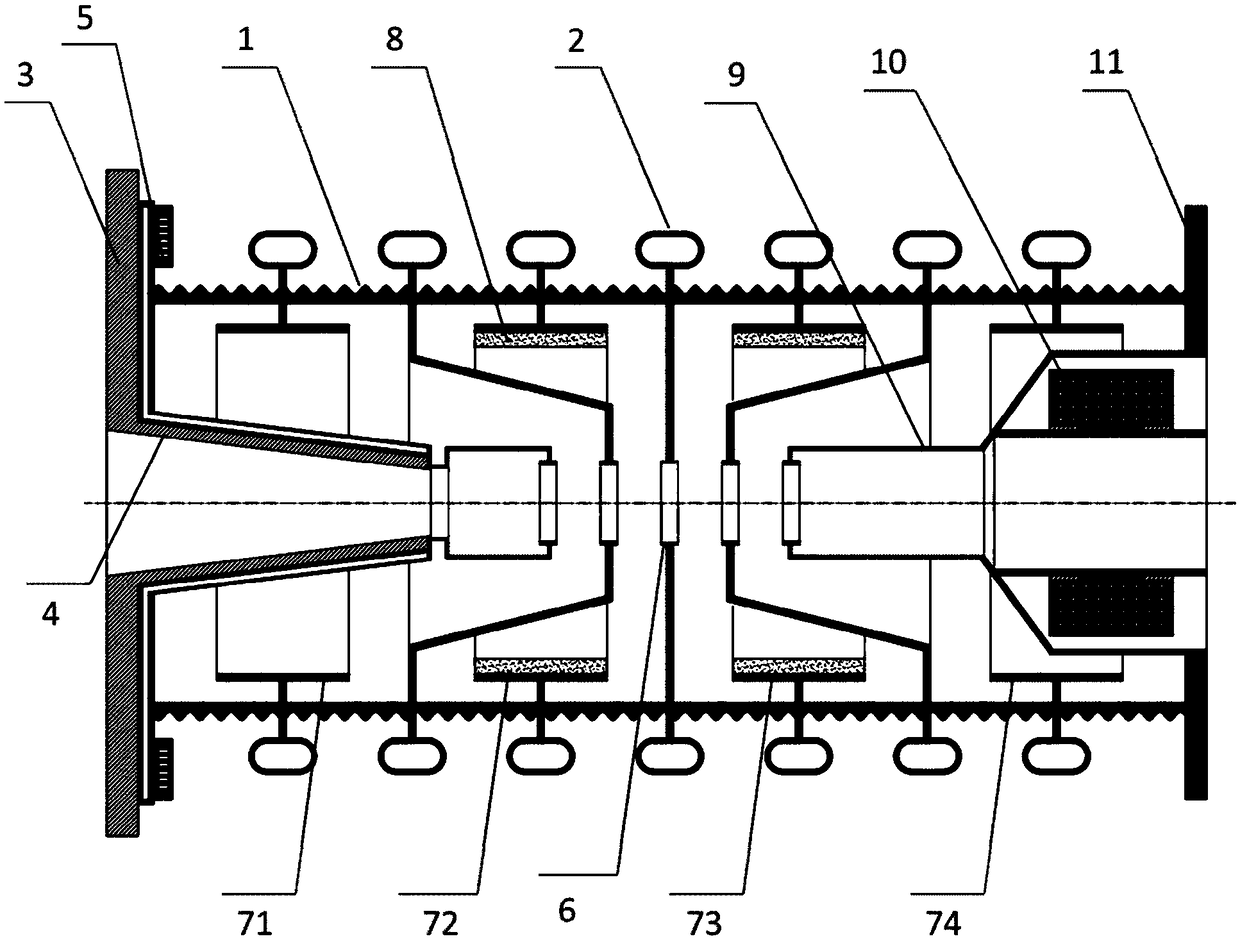

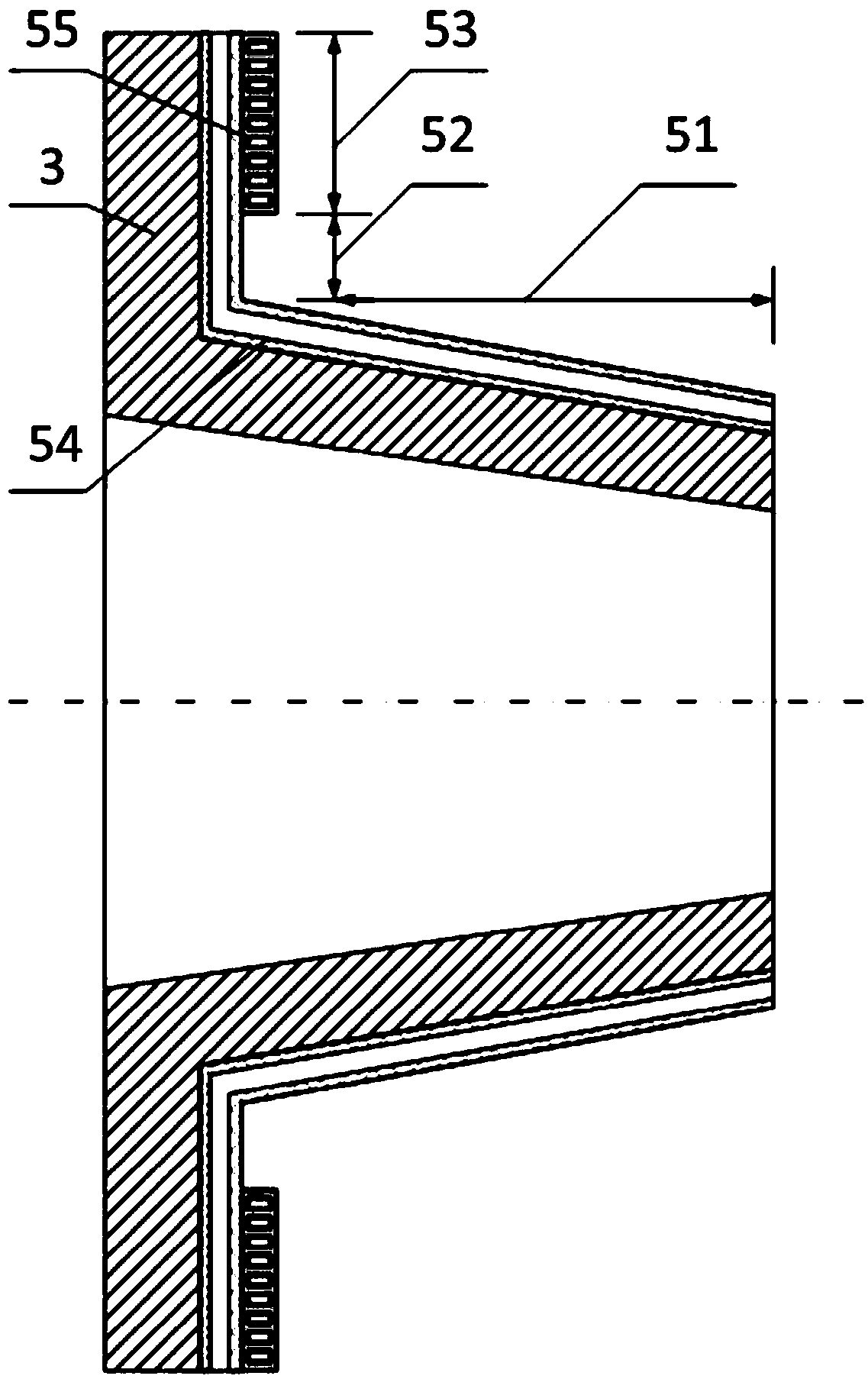

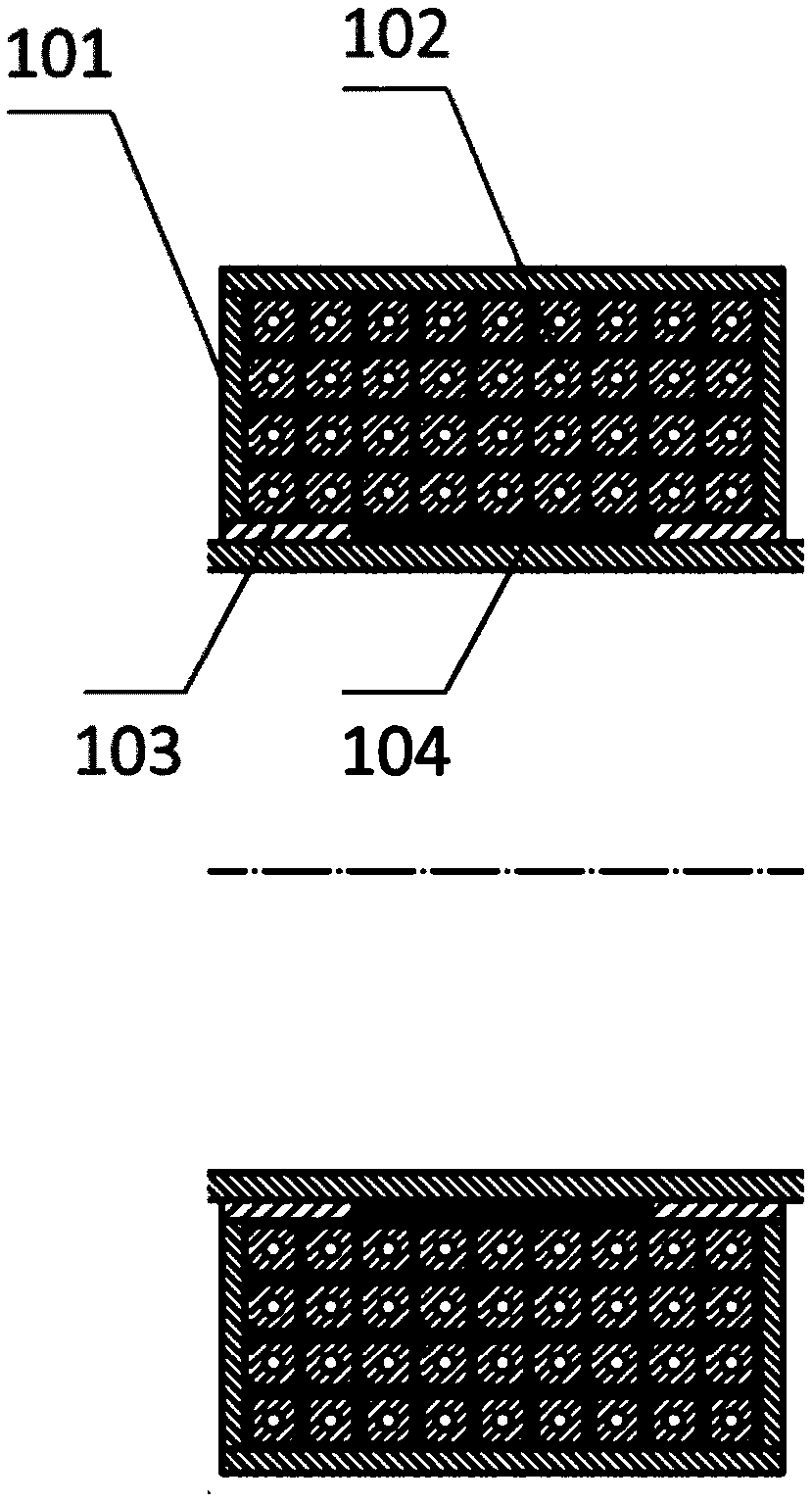

Rear-mounted magnetic-mirror field high-current ion acceleration system

ActiveCN108271310AReduced divergence lossImprove high voltage resistance performanceAcceleratorsIon beamIon acceleration

The invention discloses a rear-mounted magnetic-mirror field high-current ion acceleration tube. The rear-mounted magnetic-mirror field high-current ion acceleration tube comprises an external insulating magnetic ring, a grading ring and an internal inlet flange, an inlet beam-limiting conical cylinder, an ultra-thin heat tube, an acceleration electrode, shielding electrodes, weak correcting magnets, an outlet conical cylinder, a magnetic mirror apparatus and an outlet flange; the outer surface of the insulating magnetic ring is waveform and plated with glaze; the ultra-thin heat tube is arranged on the periphery of the inlet beam-limiting conical cylinder; the two shielding electrodes in the middle are provided with the weak correcting magnets respectively; and the magnetic mirror apparatus is mounted on the outlet flange. By virtue of the rear-mounted magnetic-mirror field high-current ion acceleration tube provided by the invention, the high-voltage ignition risk of the accelerationtube is lowered, and high-current ion beam acceleration stability is improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Computer mouse cell material and preparation method thereof

The invention discloses a computer mouse cell material, and belongs to the technical field of a mouse material. The material comprises the following raw materials, by weight part, 25-30 parts of polycarbonate, 15-18 parts of fluorosilicone rubber, 40-50 parts of an acrylonitrile-butadiene-styrene copolymer, 12-14 parts of glass fiber, 4-8 parts of diatomite, 18-20 parts of cast stone powder, 6-8 parts of silicon nitride, 3-5 parts of silicone oil, 5-7 parts of paraffin, 10-14 parts of phosphate, 8-10 parts of zinc oxide, 2-4 parts of essence, 16-18 parts of a plasticizer, 1-3 parts of a stabilizer and 1-3 parts of an antistatic agent. The invention further discloses a preparation method of the material. The material is small in environmental pollution and excellent in wear resistance and high temperature resistance and gives off fragrance.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Environment-friendly rubber sound insulation building material and preparation method thereof

InactiveCN107298776AGood tear strength and fatigue resistanceGood weather aging resistanceWeather resistanceEnvironmental resistance

The invention discloses an environment-friendly rubber sound-insulating building material, which comprises the following raw materials in parts by weight: 50-60 parts of isoprene rubber, 20-30 parts of fluorosilicone rubber, 3-5 parts of heat stabilizer, and 0.5-0.9 parts of crosslinking agent , 5-9 parts of rare earth oxide filler, 4-8 parts of glass microspheres, 3-5 parts of vulcanizing agent PDM, 2-4 parts of silane coupling agent, 6-10 parts of ore powder. The sound-insulating building material of the present invention has excellent sound-insulating performance and good waterproof effect, is more compact in structure than traditional non-woven materials, has superior sound-insulating and noise-reducing effects, has good mechanical properties, and has strong weather resistance; meanwhile, the preparation method of the present invention , the material cost is low, the raw material is easy to obtain, and the process is simple, easy to operate and realize industrial production, and has high practical value and good application prospect.

Owner:合肥一片美环保科技有限公司

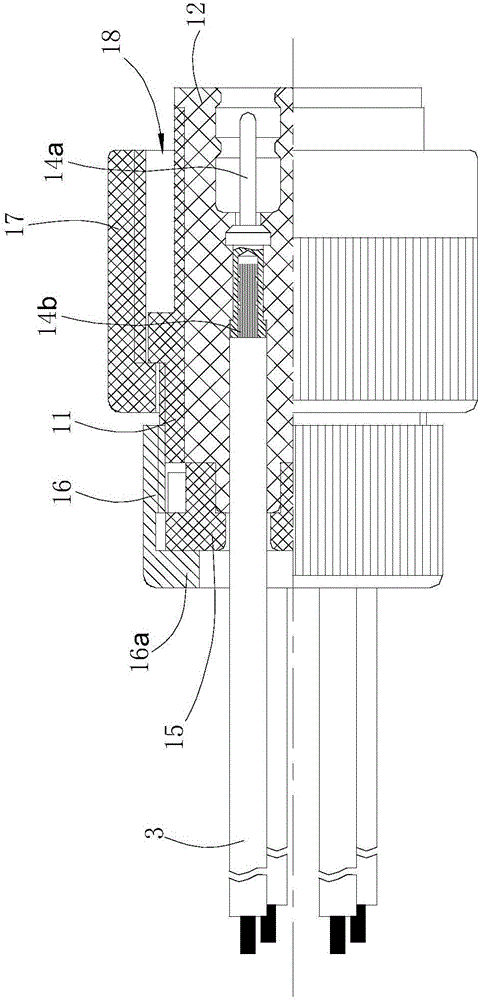

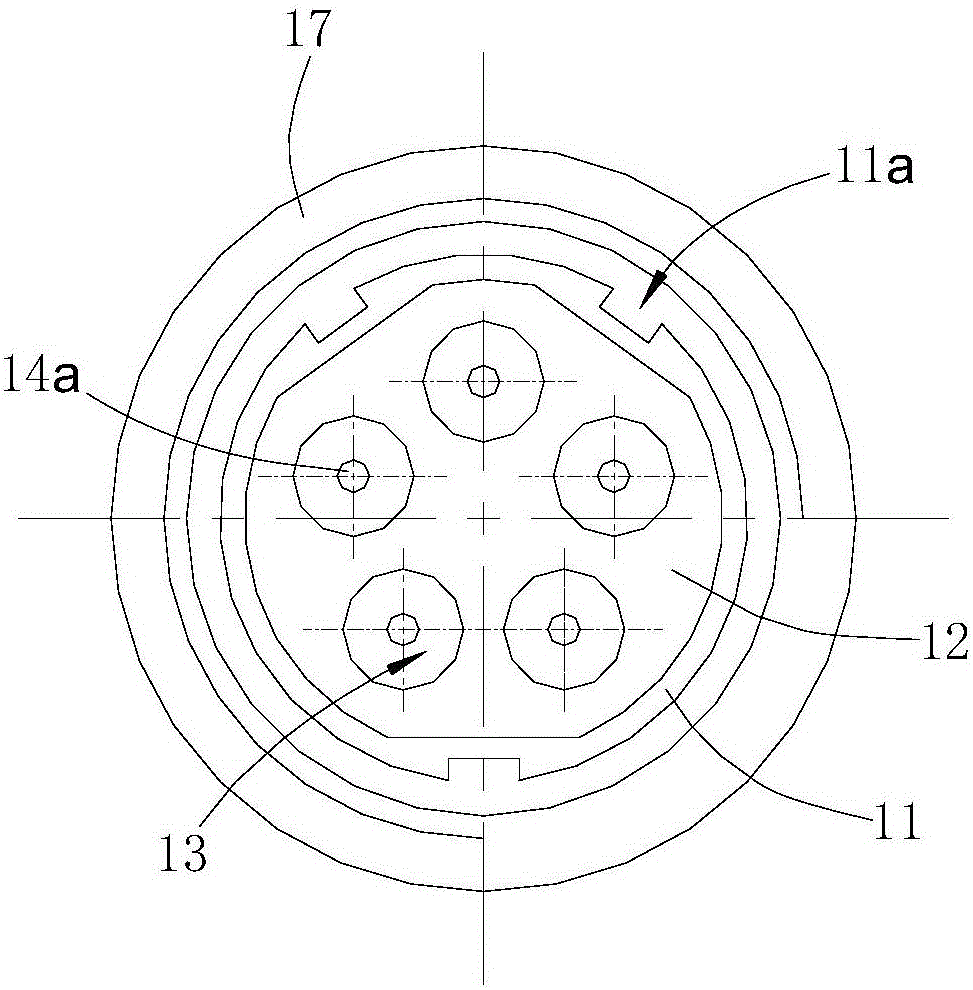

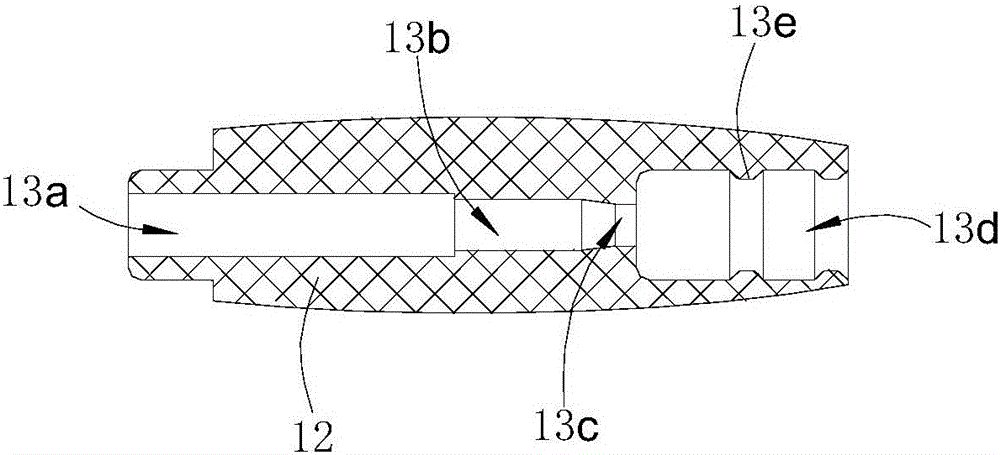

Small multi-core high-voltage connector

ActiveCN105958242AImprove high voltage resistance performanceEffective blockingIncorrect coupling preventionSecuring/insulating coupling contact membersMiniaturizationHigh tension leads

The invention discloses a small multi-core high-voltage connector, comprising a socket and a plug, wherein a plug mounting plate of the plug is sleeved inside a plug shell and provided with a plurality of first mounting holes, a plug pressure plate is fixed on the plug mounting plate, pin components are correspondingly arranged in the first mounting holes, each pin component comprises a pin portion and a pin connecting seat, and a high-voltage lead is connected with the pin connecting seat of the pin component; a mounting division plate extends inside a socket shell of the socket, mounting protrusions are formed on the mounting division plate, a second mounting hole is formed in each mounting protrusion, a jacket is arranged in an assembly chamber, a socket pressure plate is arranged in the socket shell, a jack component comprises a jack connecting seat and a jack portion, and a high-voltage lead is connected with the jack connecting seat of the jack component. The connector for connection and transmission of high-voltage signals ensures the transmission of multi-channel and high-voltage signals by adopting a unique interface sealing structure, and is mounted and used in a small space to meet the development requirement of aerial electronic equipment for miniaturization.

Owner:中国电子科技集团公司第四十研究所

High-temperature-resistant, high-voltage-resistant and high-load adhesive for lithium ion battery and battery positive pole piece applying same

PendingCN113214779AGood high temperature resistanceGood bonding performanceSecondary cellsPositive electrodesDiaminePolyamide

The invention provides a high-temperature-resistant, high-voltage-resistant and high-load adhesive for a lithium ion battery and a battery positive pole piece applying the same, and belongs to the technical field of preparation methods of electrode materials. The rigidity and flexibility of the molecular chain of the polyimide adhesive are regulated and controlled by controlling the number of ether bonds in the molecular chain, so that the high-temperature-resistant, high-voltage-resistant and high-load adhesive for the lithium ion battery is provided. According to the adhesive, diamine and dicarboxylic anhydride which contain different numbers of ether bonds are subjected to polycondensation to form a polyamide acid glue solution, and the polyamide acid glue solution is subjected to thermal imidization treatment to obtain the polyimide adhesive. The adhesive disclosed by the invention is excellent in high-temperature resistance, high-voltage resistance and adhesive performance, compared with a traditional adhesive positive pole piece, the lithium ion battery positive pole piece applying the adhesive can load more active substances, the specific discharge capacity of a lithium ion battery is improved, the high-temperature resistance and high-voltage resistance of the pole piece are also obviously improved, and the cycle performance and the service life of the lithium ion battery are improved.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Method for preparing flame-retardant plastic shells for lead-acid storage batteries

The invention belongs to the technical field of lead-acid storage batteries, and discloses a method for preparing flame-retardant plastic shells for lead-acid storage batteries. The method includes steps of preparing modified brucite; preparing modified mica; preparing modified composite flame retardants; mixing raw materials with one another; carrying out injection molding and the like. Sodium bicarbonate is loaded on diatomaceous earth to obtain the composite flame retardants. The method has the advantages that the prepared plastic shells for the lead-acid storage batteries are high in mechanical strength and impact-resistant strength; the flame-retardant plastic shells are good in toughness and high in tensile strength and bending modulus; the flame-retardant plastic shells are good inflame-retardant property, and the flame-retardant properties of the flame-retardant plastic shells are far higher than requirements on flame-retardant properties of plastics in national standards; theflame-retardant plastic shells are excellent in heat stability and good in high-voltage-resistant performance.

Owner:ZHEJIANG CHANGTONG SCI & TECH

Nanometer material-modified rubber-gel electrolyte film and preparation method and application

InactiveCN109326821AImprove liquid absorption capacityImprove securityMaterial nanotechnologySolid electrolytesIon transport numberNew energy

The invention discloses a preparation method of a nanometer material-modified rubber-gel electrolyte and application of the nanometer material-modified rubber-gel electrolyte, and belongs to the technical field of new energy materials. Nanometer material-modified rubber-gel electrolyte film is prepared from a nanometer material, rubber and an organic electrolyte; the weight percentage of the nanometer material is 10-40wt%, the weight percentage of the rubber is 20-50wt%, and the weight percentage of the organic electrolyte is 3-60wt%. The nanometer material-modified rubber-gel electrolyte is simple in preparation method route, mild in operation condition, environmentally friendly in preparation process, good in stability, good in metal interface compatibility, and large and stable in deformation space, and energy storage device short circuits and dendritic crystals can be effectively prevented; more importantly, due to outstanding organic electrolyte adsorption capability of the nanometer material modified rubber-gel electrolyte, the ionic conductivity and a transference number of ions are well improved.

Owner:XIANGTAN UNIV

Wearproof and stretch-proof cable jacket material

The invention discloses a wearproof and stretch-proof cable jacket material, prepared from the following raw materials in parts by weight: 40 to 50 parts of methyl vinyl silicone rubber, 20 to 30 parts of urea resin, 5 to 15 parts of butadiene styrene rubber, 5 to 15 parts of fluorinated silicone rubber micro powder, 1 to 3 parts of cerium oxide, 3 to 6 parts of organic calcium, 5 to 10 parts of glass fiber, 1 to 7 parts of anti-hydrolysis agent, 2 to 5 parts of vulcanizing agent, 8 to 15 parts of pine tar oil, 4 to 8 parts of heavy crystalline silicon powder, 3 to 10 parts of ethylene vinylacetate copolymer, 2 to 5 parts of compatilizer, 1 to 3 parts of flame retardant and 8 to 18 parts of wearproof powder. The wearproof and stretch-proof cable jacket material has the advantages of beingcorrosion-proof, stretch-proof and long in service life, and the like, the mechanical strength of a cable jacket can be effectively improved, the cable jacket is prevented from being broken in a use process, the service life of a cable is prolonged; according to the cable jacket material, by using the fluorinated silicone rubber micro powder and the cerium oxide, a cable material has excellent heat resistance, cold resistance, high voltage resistance and weathering aging resistance, and further has excellent hydrogen solvent resistance, oil resistance and acid and alkali resistance and a lowersurface energy property.

Owner:安徽天大铜业有限公司

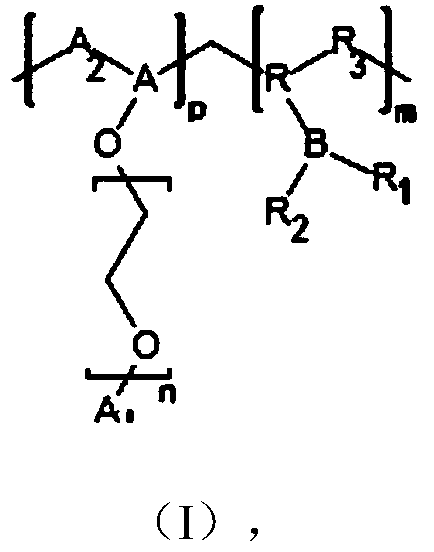

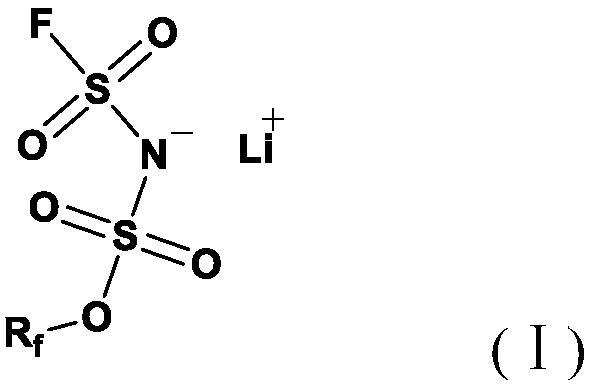

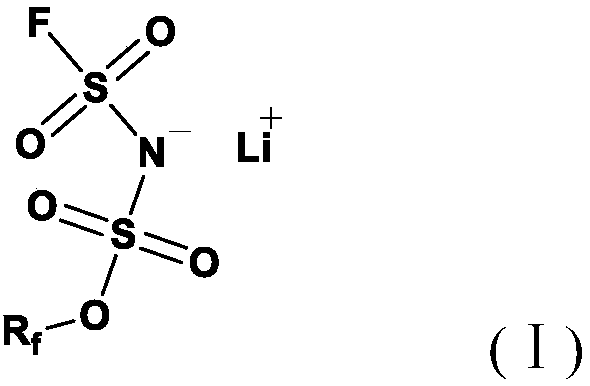

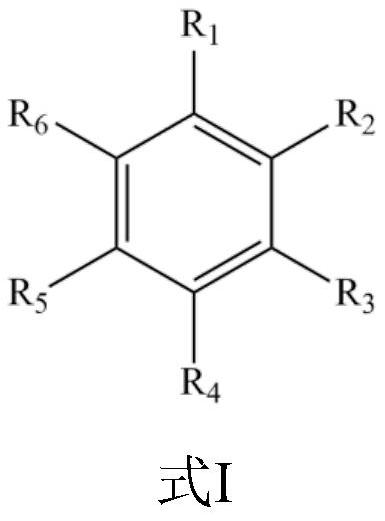

a non-aqueous electrolyte

ActiveCN105633469BGood compatibilityImprove thermal stabilitySecondary cellsOrganic electrolytesSolid state electrolyteKetone

The invention discloses a non-aqueous electrolyte. The non-aqueous electrolyte comprises the following constituents based on mass: 10-20 parts of compound shown in structural formula (I), 5-12 parts of other lithium salts, 2-5 parts of 1,4-butanediol sulphate, 10-12 parts of adiponitrile, 15-25 parts of pimelicdinitrile, 10-15 parts of octanedinitrile, 8-20 parts of sebaconitrile, 20-40 parts of 4-fluorine-1,3-dioxolane-2-ketone, 5-10 parts of ethylene carbonate, 2-5 parts of propylene carbonate, 5-12 parts of fluoroethylene carbonate, 4-8 parts of carbonated hydroxybenzene olefin ester, 3-5 parts of overshoot resistant additive, 0.5-1.5 parts of flame retardant agent and 1-2 parts of hexamethyl disilazane or triphenyl phosphate. The lithium salts containing oxalate radial groups also can form a solid-state electrolyte membrane on the surface of a positive electrode, the high-voltage resistant performance of a battery can be improved; and the lithium salts containing the oxalate radial groups are friendly to an environment, and the environment cannot be polluted due to the electrolyte problem during disassembly and recycle of the battery.

Owner:武汉市瑞华新能源科技有限公司

High temperature and high voltage resisting electrolyte for lithium ion battery

ActiveCN104701571AImprove interface impedanceImprove cycle performanceSecondary cellsOperating temperature rangeLithium electrode

The invention relates to an electrolyte for a lithium ion battery. The electrolyte includes lithium salt, an organic solvent and an additive, and tris (trimethylsilyl) boron is adopted as the additive. The electrolyte is applied to the lithium ion battery, the work voltage of the electrolyte ranges from 4.5 V to 4.7 V, the work temperature range is the indoor temperature of 60 DEG C, the good high temperature and high voltage resisting circulating performance is achieved, and the high temperature and high voltage functional nonaqueous electrolyte is simple and easy to obtain.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Cable sheath material used for electric engineering and preparation method of material

InactiveCN107266778AEasy to makeLittle environmental pollutionPlastic/resin/waxes insulatorsAluminium hydroxideAntioxidant

The invention discloses a cable sheath material used for electric engineering, and belongs to the technical field of cable sheath materials. The cable sheath material comprises the following raw materials in parts by weight: 10-20 parts of high-density polyethylene, 70-80 parts of an ethylene-vinyl acetate copolymer, 12-16 parts of fluorosilicone rubber, 8-12 parts of ethylene-propylene-diene-terpolymer rubber, 1-3 parts of stearic acid, 6-8 parts of brominated polystyrene, 7-9 parts of syderolite, 2-4 parts of a phosphate, 5-7 parts of aluminium hydroxide, 6-8 parts of nano-silica, 1-3 parts of an antioxidant, 0.5-1.5 parts of an ultraviolet light absorber, 17-19 parts of a plasticizer and 1-2 parts of an antistatic agent. The invention also discloses a preparation method of the cable sheath material used for electric engineering. The cable sheath material used for electric engineering provided by the invention is simple in preparation, low in environmental pollution, and has good mechanical strength and flame retardance.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Capacity-increasing, energy-saving and inflaming-retarding power cable

InactiveCN103165240AImprove insulation performanceImprove waterproof performancePower cables with screens/conductive layersPower cableInsulation layer

The invention provides a capacity-increasing, energy-saving and inflaming-retarding power cable. The portion outside a conductor of the capacity-increasing, energy-saving and inflaming-retarding power cable is sequentially wrapped by a conductor shielding layer, an insulation layer, an insulation shielding layer, a copper strip lapping layer, a galvanized steel strip armoring layer, an inflaming-retarding layer and a sheath layer. The capacity-increasing energy-saving and inflaming-retarding power cable has the advantages of being energy-saving, tensile, fire-proof, weather-resistant, good in bending radius and the like, and especially suitable for being used as main line cables in projects like power stations, airports, train stations, subways, buildings and tunnels.

Owner:上海上力电线电缆有限公司

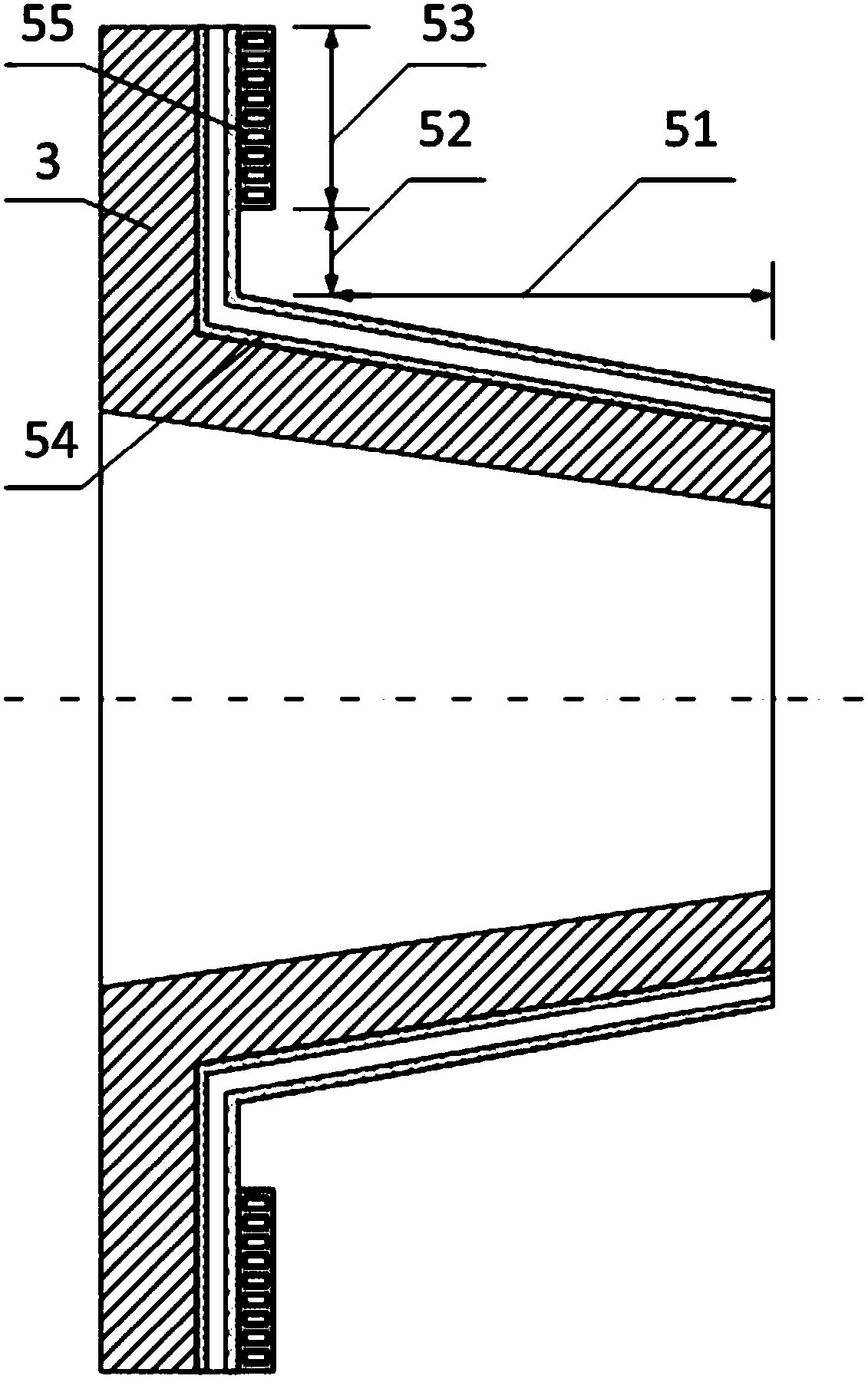

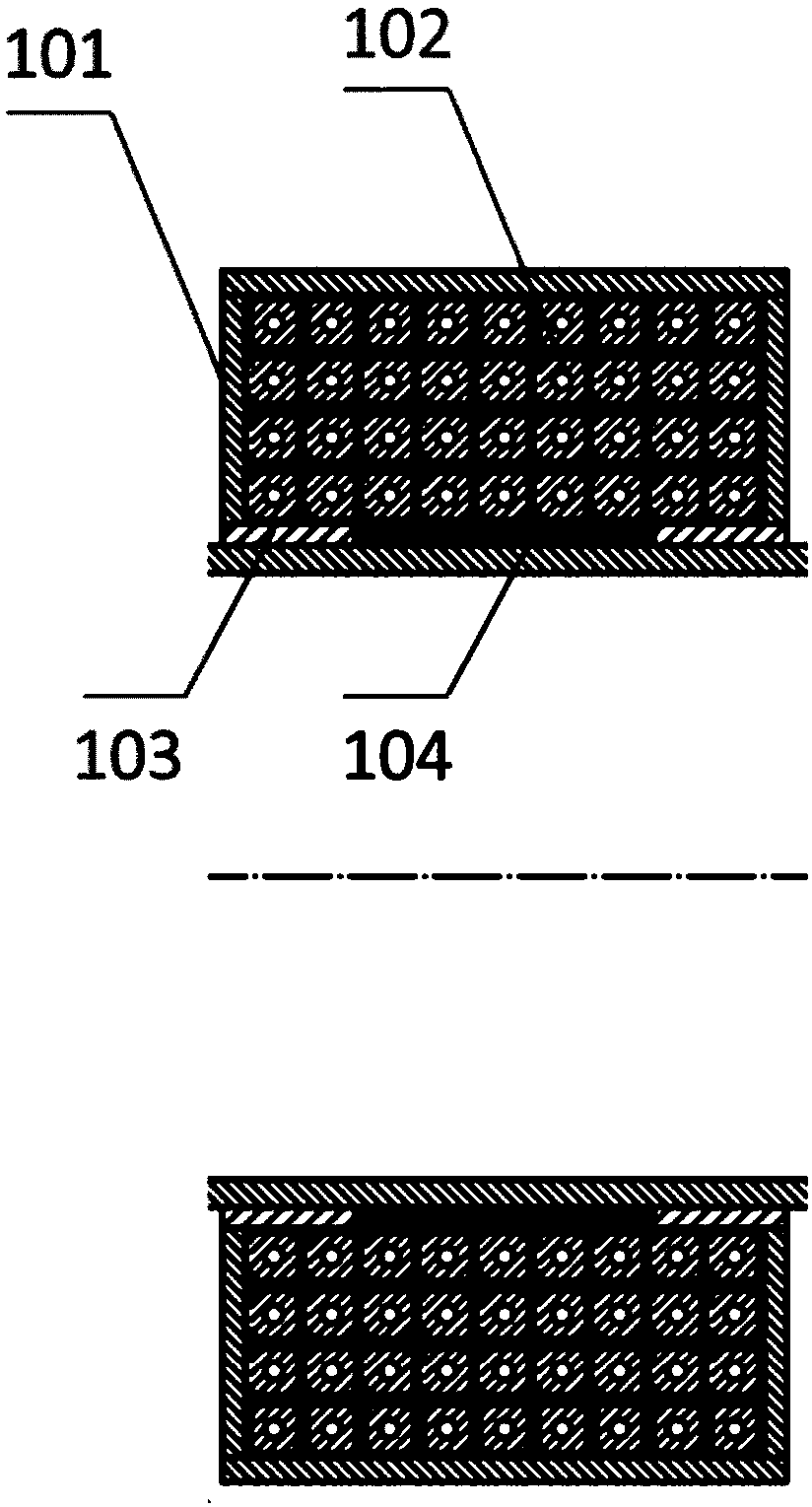

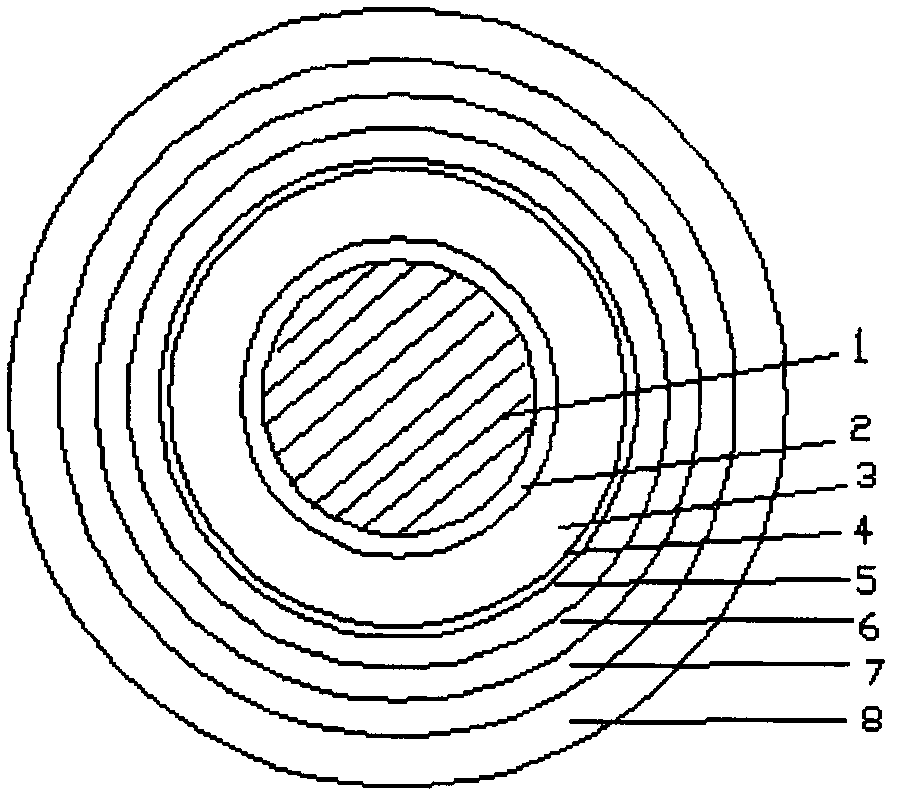

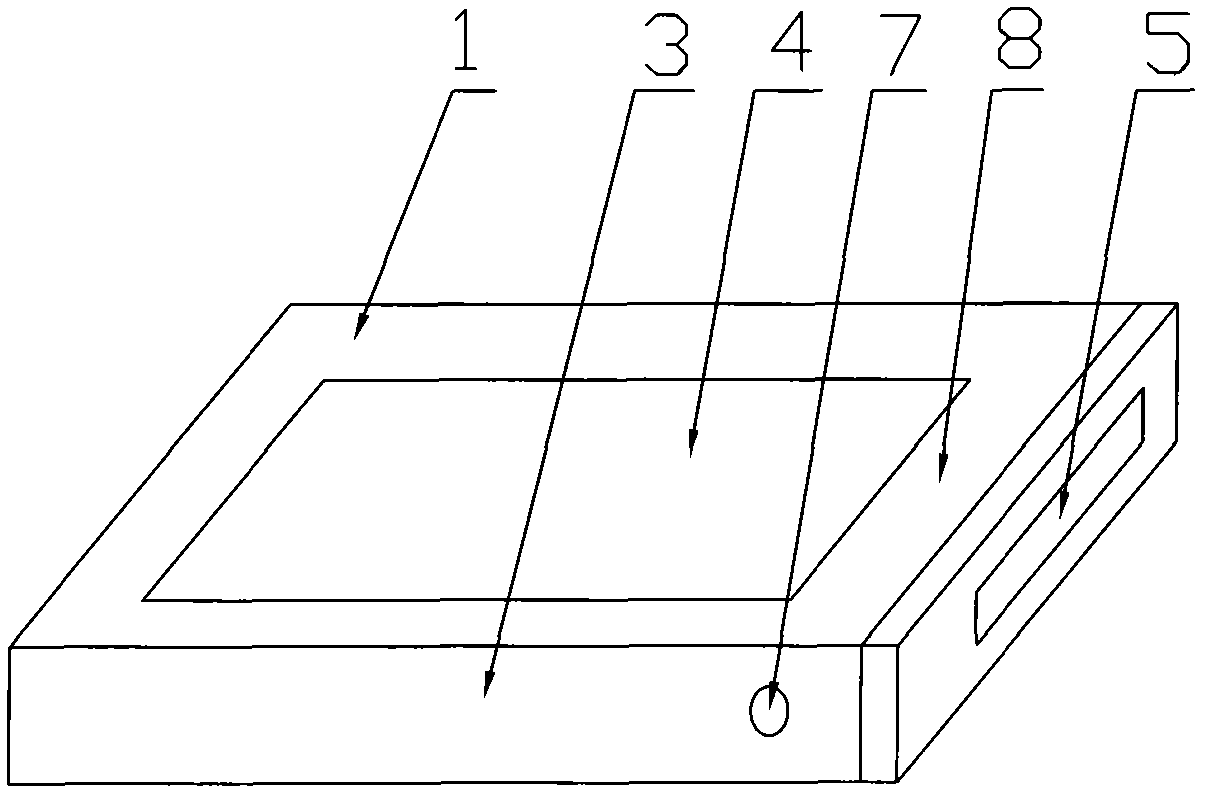

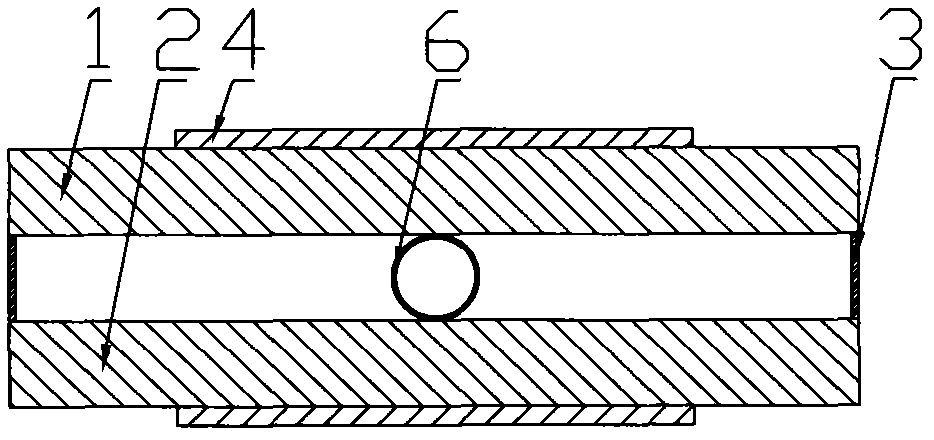

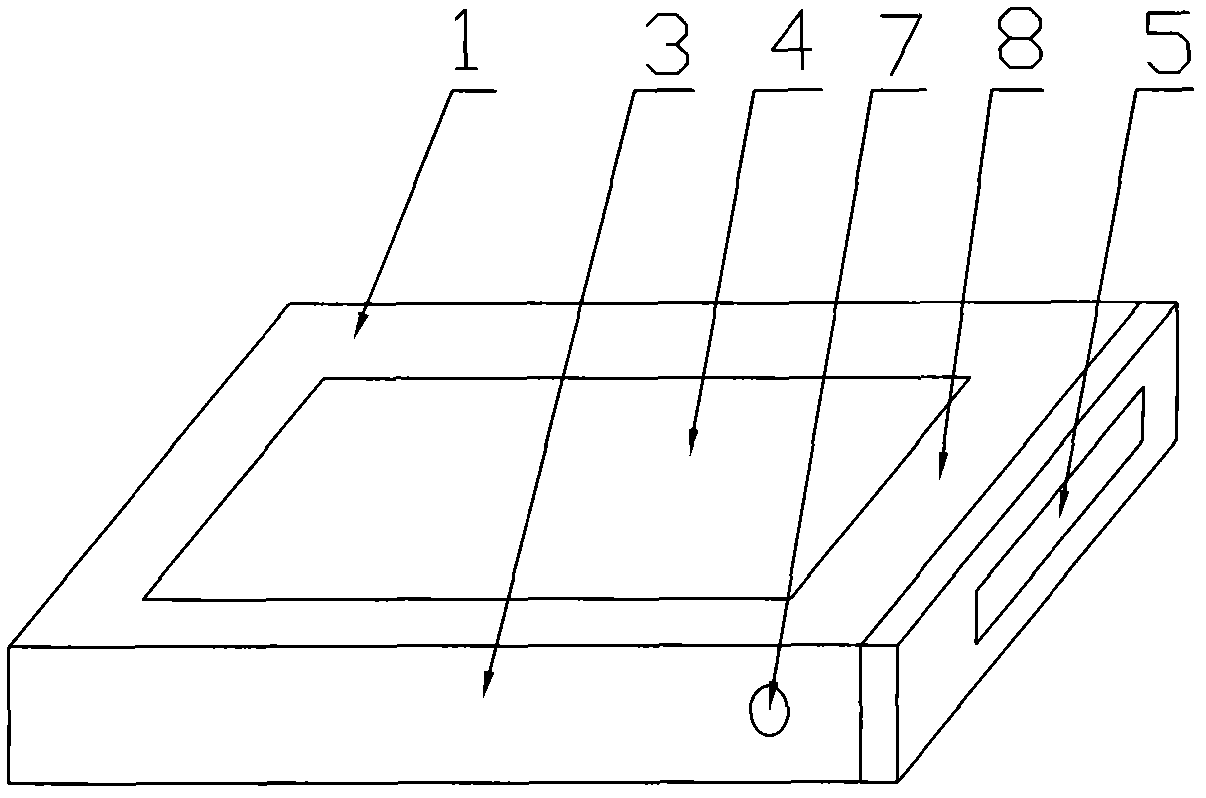

Flat plate type totally-sealed low-temperature plasma excitation source

InactiveCN102325422AImprove thermal stabilityImprove spectral informationPlasma techniqueLow temperature plasmaTin

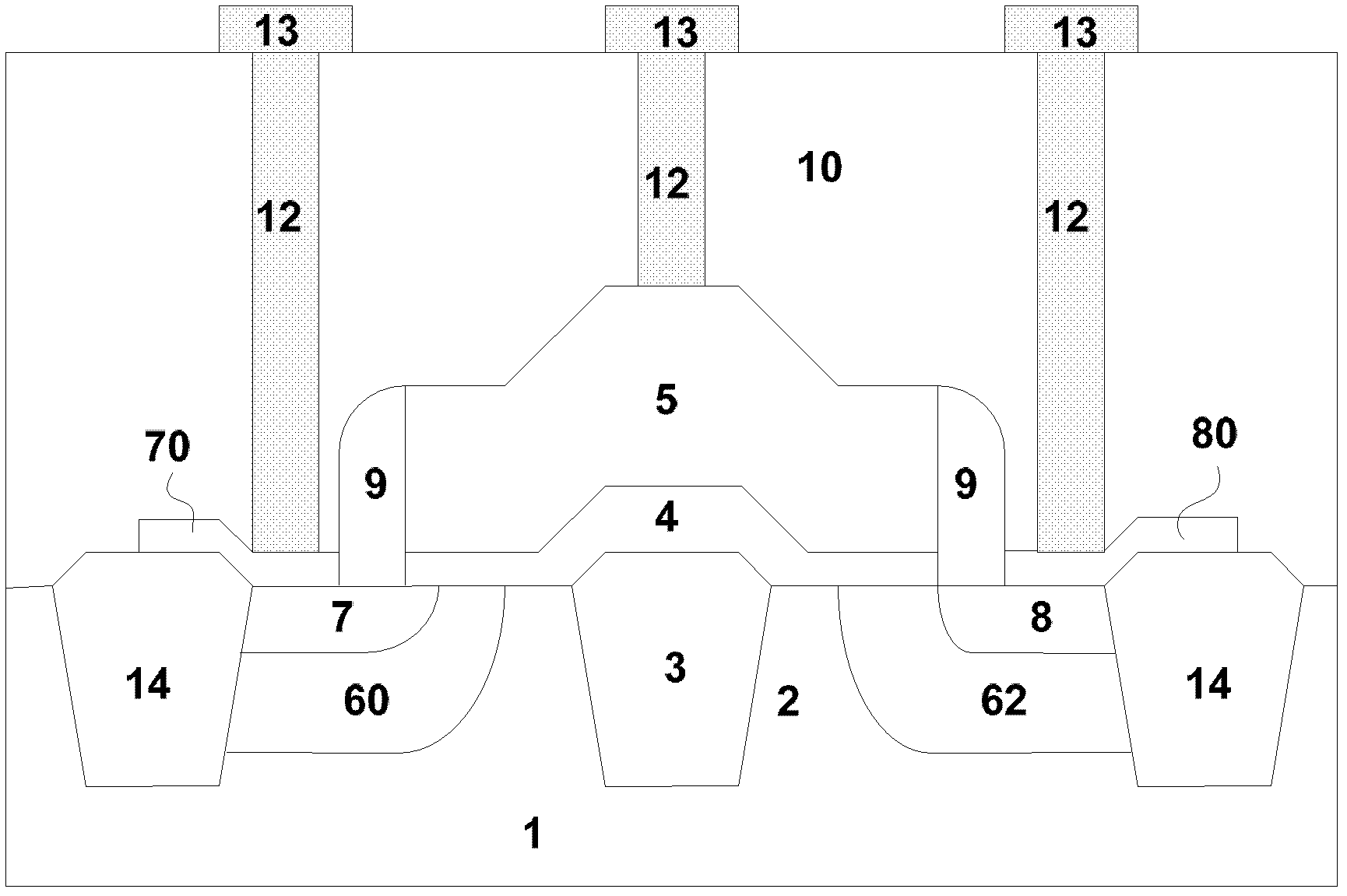

The invention provides a flat plate type totally-sealed low-temperature plasma excitation source based on a dielectric barrier discharge technology, wherein the flat plate type totally-sealed low-temperature plasma excitation source is both capable of eliminating air background interferences and improving the detection sensitivity of a target component. In a technical solution, the flat plate type totally-sealed low temperature plasma excitation source is characterized by being composed of upper ceramic pieces (1), lower ceramic pieces (2) and surrounding side faces (3); the upper ceramic pieces (1) and the lower ceramic pieces (2) are adhered in parallel through the surrounding side faces (3) to form a hollow discharge chamber (8); tin foil paper (4) is respectively adhered on the upper ceramic pieces (1) and the lower ceramic pieces (2) to be used as discharge electrodes; and quartz window pieces (5), air inlets (6) and exhaust ports (7) are respectively arranged on the surrounding side faces (3).

Owner:QINGDAO JIAMING MEASUREMENT & CONTROL TECH

Non-woven ceramic diaphragm and process for lithium-ion batteries with excellent closed-cell performance

ActiveCN103199209BReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsElectrical batteryCeramic coating

Owner:CHINA HAISUM ENG

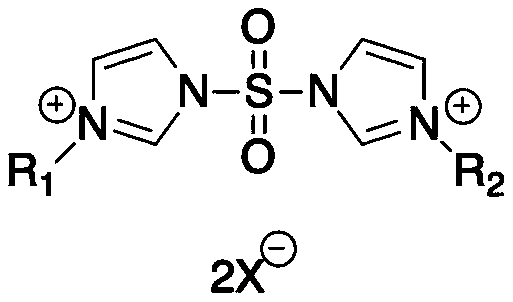

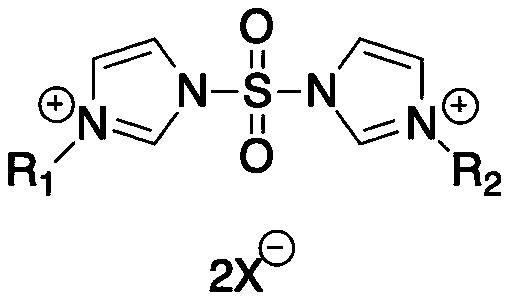

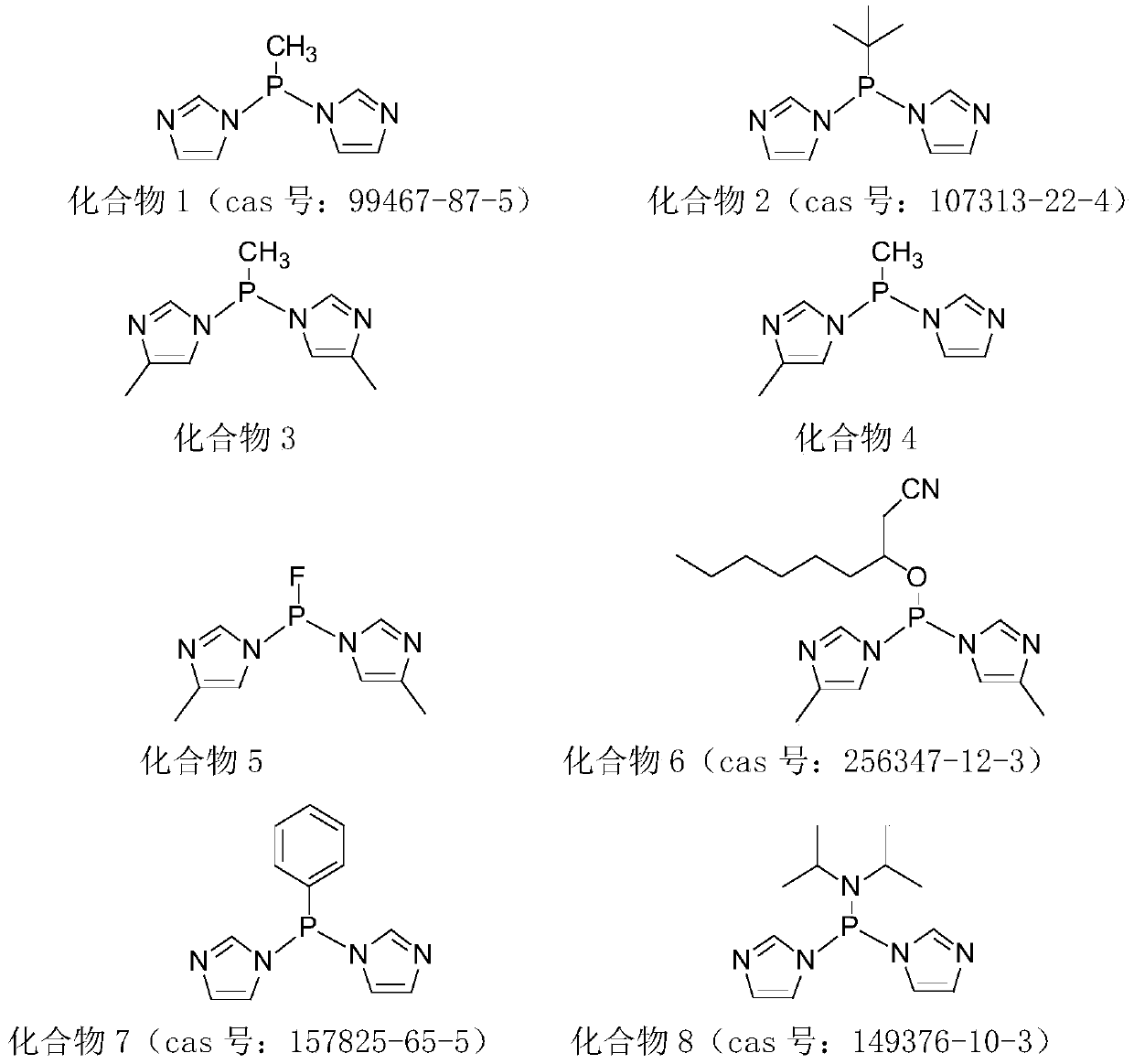

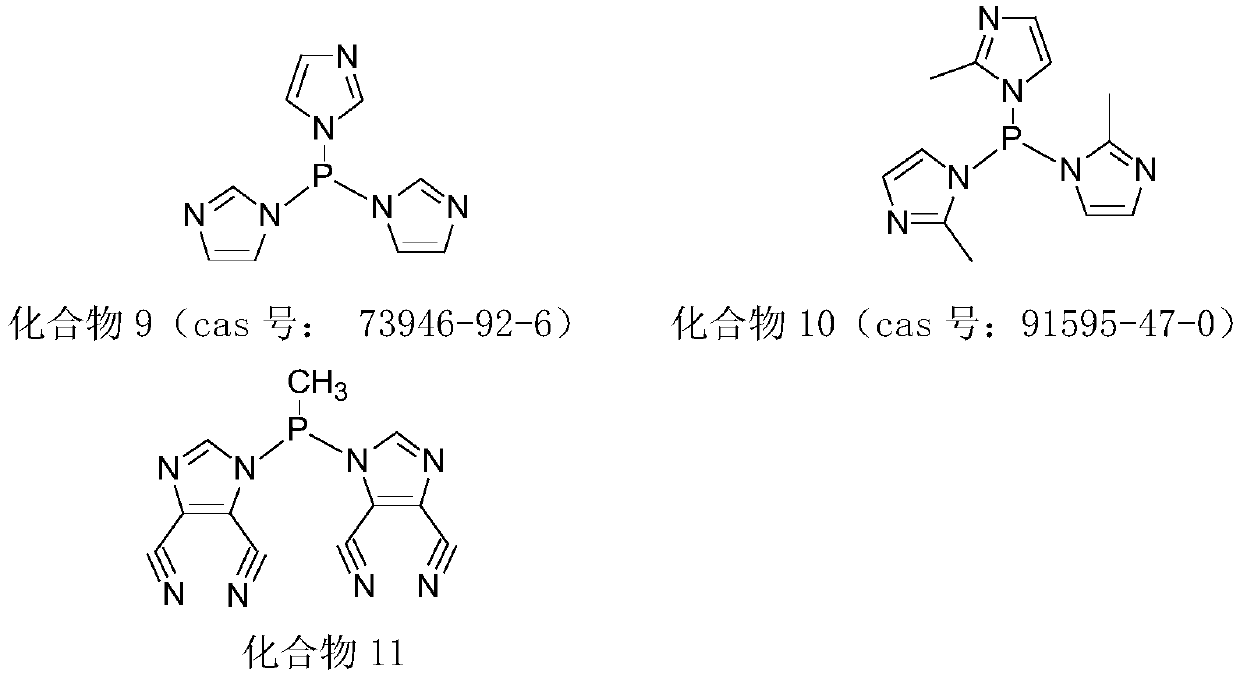

Preparation method of sulfonyldiimidazole-based ionic liquid

InactiveCN110305066ANovel structureHigh reaction yieldOrganic compound preparationSecondary cellsAlkaneSulfonyl chloride

The invention discloses a preparation method of a sulfonyldiimidazole-based ionic liquid. The preparation method comprises the steps of adding a certain quantity of imidazole into a nonaqueous solvent, stirring to allow full dissolution, reducing the reaction temperature, dropwise adding sulfonyl chloride, removing the nonaqueous solvent after reaction, crystallizing to obtain sulfonyldiimidazoleintermediate, continuing to dissolve the intermediate in another nonaqueous solvent, dropwise adding a halogenated alkane, and allowing to react to obtain alkyl-substituted sulfonyldiimidazole bromide; dissolving the alkyl-substituted sulfonyldiimidazole bromide in water, adding a lithium salt, carrying out ion exchanging, and separating and extracting to obtain the sulfonyldiimidazole-based ionicliquid. The sulfonyldiimidazole-based ionic liquid provided herein has novel structure and high reaction yield; when applied as a lithium-ion battery electrolyte additive, the sulfonyldiimidazole-based ionic liquid can improve evidently the high voltage resistance of batteries.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

High-adhesion shock-resistant sealant for insulating glass and preparation method thereof

InactiveCN107245319AEasy to makeHigh impact strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesSealantSilicon dioxide

The invention discloses a high-adhesion shock-resistant sealant for insulating glass, belonging to the technical field of sealants. The high-adhesion shock-resistant sealant for insulating glass comprises the following raw materials in parts by weight: 45-50 parts of organic hydroxy silicone, 14-16 parts of organic methyl silicone, 11-13 parts of methylsilane, 14-17 parts of modified silicon dioxide, 7-9 parts of red phosphorus, 4-6 parts of resorcinol bis(diphenyl phosphate), 8-10 parts of calcium carbonate, 3-5 parts of titanium dioxide, 1-3 parts of dibutyltin dilaurate, 2-4 parts of aminosilane, 3-5 parts of fluorosilicone rubber, a right amount of water, 1-2 parts of antibacterial agent and 9-11 parts of plasticizer. The invention also discloses a preparation method of the high-adhesion shock-resistant sealant for insulating glass. The sealant has the advantages of simple preparation process, favorable flame retardancy, favorable high-temperature resistance, excellent shock strength, excellent adhesion capacity and long service time.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

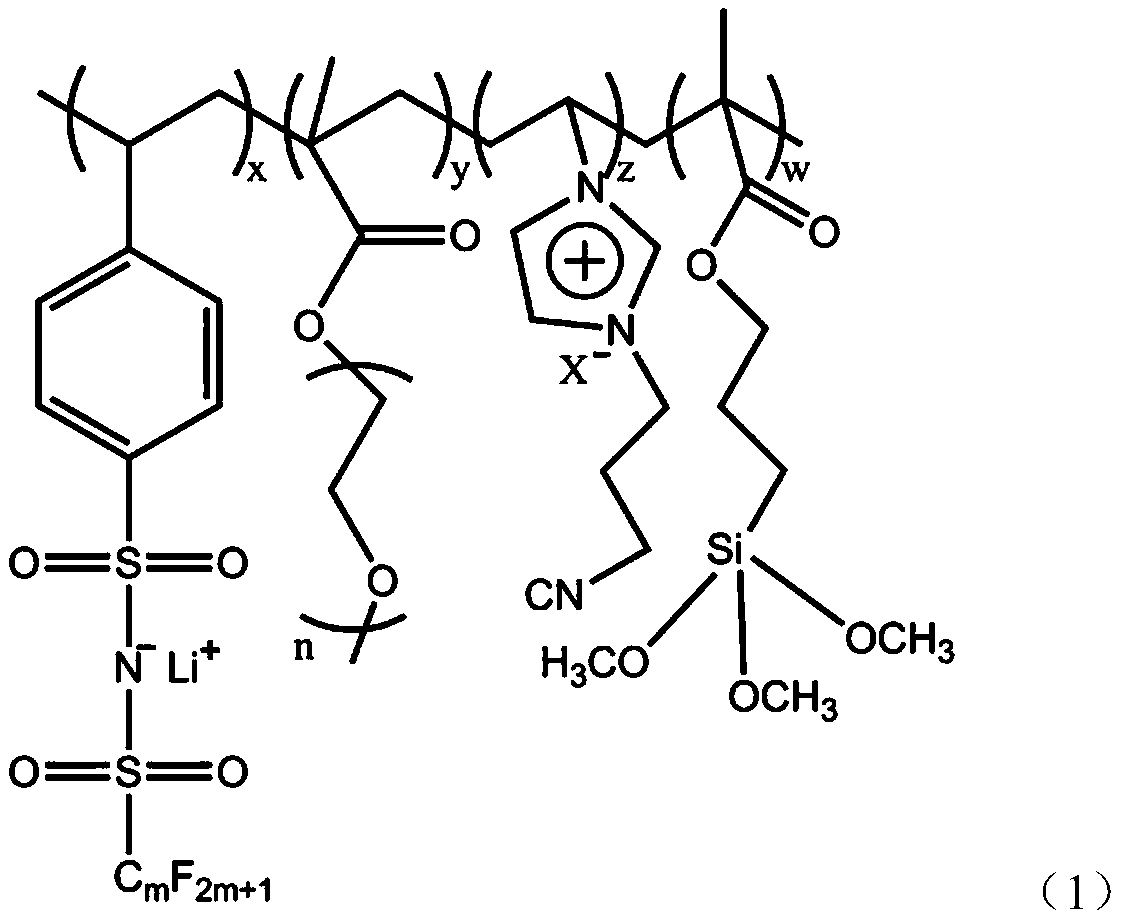

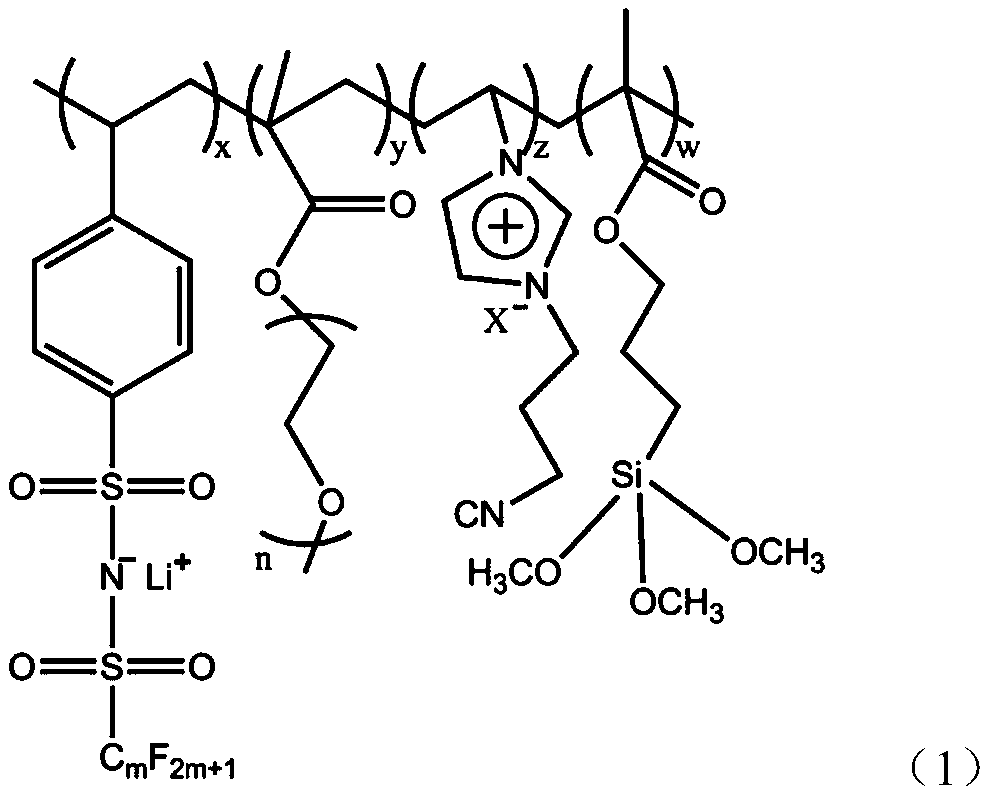

Preparation and application method of composite single-ion solid electrolyte

ActiveCN110336080AImprove securityReduce concentration polarizationMaterial nanotechnologyFinal product manufactureUltraviolet lightsSolvent

The invention relates to a preparation technology of lithium ion battery electrolytes, and aims to provide a preparation and application method of a composite single-ion solid electrolyte. The methodcomprises the steps of: taking p-styryl fluoro alkyl sulfimide lithium, acrylate polyether, nitrile imidazole type ionic liquid and a silane coupling agent KH-570, and performing free radical polymerization under the stirring condition and the initiation of ultraviolet light to prepare a copolymer; uniformly dispersing the copolymer and an inorganic nano material in a solvent to prepare a castingsolution; pouring the casting solution on a clean membrane-making glass mould uniformly, and transferring the membrane-making glass mould to a vacuum drying oven; and performing heating to completelyvolatilize the solvent, dehydrating, condensing and crosslinking the polymer to obtain a membranous composite single-ion solid electrolyte. The composite single-ion solid electrolyte obtained by the invention has the higher ionic conductivity and lithium ion transference number and good thermal stability and electrochemical stability, and has the excellent long-cycle performance and high-voltage resistance when used in a lithium ion battery; and moreover, the preparation method is simple and mild in condition and is capable of achieving large-scale production.

Owner:ZHEJIANG UNIV

High-voltage-resisting cable material and preparation method thereof

InactiveCN105949588AImprove heat resistanceImprove cold resistancePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethylenePolymer science

The invention discloses a high-voltage-resisting cable material which is prepared from, by weight, 7-8 parts of fluorinated silicone rubber micro powder, 0.6-0.8 part of amino resin, 0.4-0.6 part of cerium oxide, 8-9 parts of fluorocarbon rubber micro powder, 6-8 parts of magnesium hydrate, 9-10 parts of polyacrylonitrile, 6-7 parts of polylactic acid, 3-4 parts of polyoxyethylene, an appropriate amount of dimethylformamide, an appropriate amount of composite solvent with the volume ratio of dimethylformamide to dichloromethane being 1:1, an appropriate amount of methyl methacrylate, an appropriate amount of isopropylthioxanthone, 20-25 parts of ethylene-vinyl acetate copolymer and 80-85 parts of low-density polyethylene. The cable material has the excellent heat resistance, cold resistance, high voltage resistance, weather resistance, aging resistance and the like due to the fact that the fluorinated silicone rubber micro powder, the cerium oxide and fluorocarbon rubber micro powder are adopted, and also has the excellent hydrogen type solvent resistance, oil resistance, acid-base resistance and lower surface energy, the using voltage of the cable material is increased, and the using range is enlarged; by adding the magnesium hydrate, the flame resistance of the cable material is improved, and no poison gas is decomposed out.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

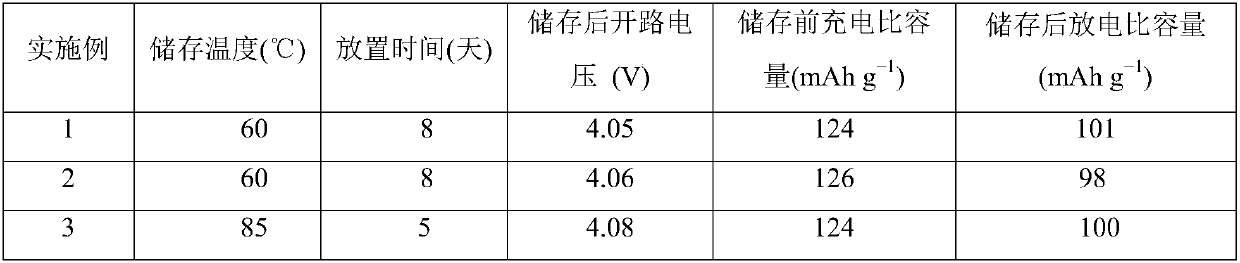

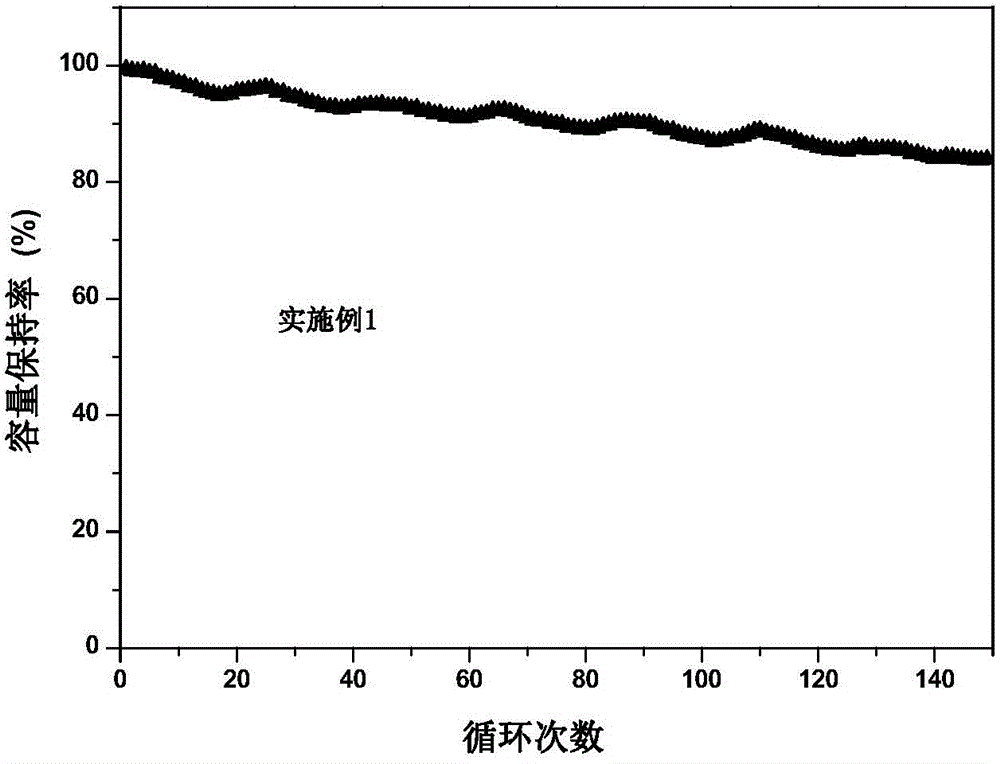

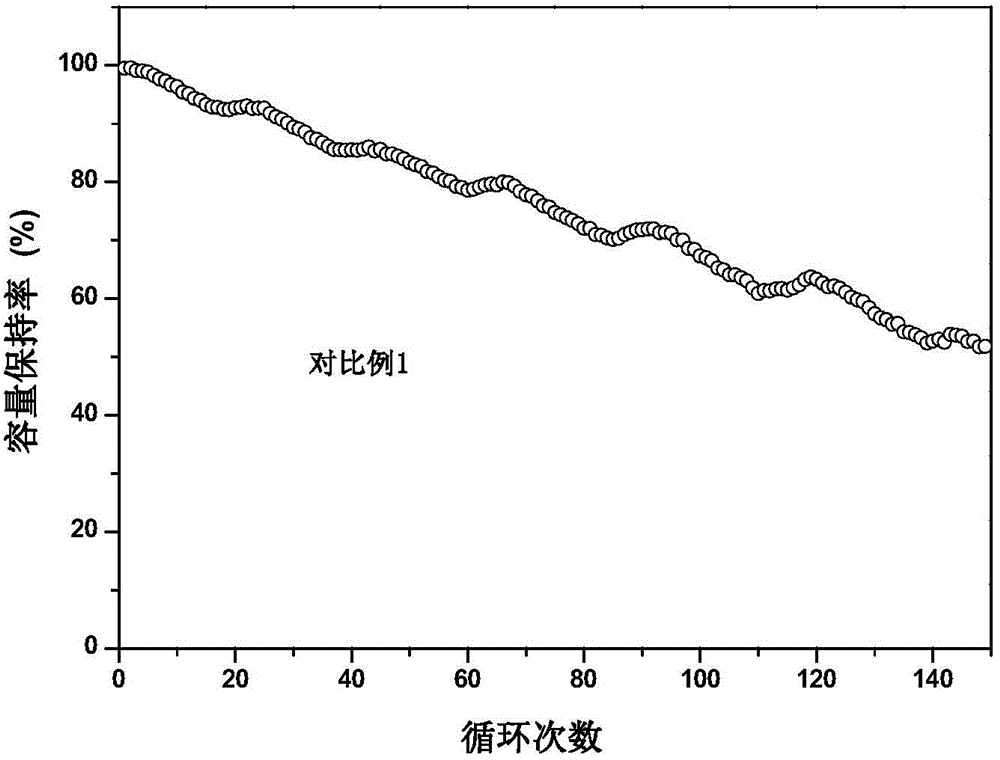

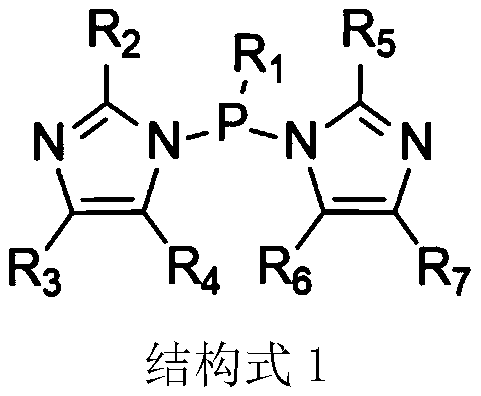

Lithium ion battery non-aqueous electrolyte and lithium ion battery comprising electrode

ActiveCN110416609AImprove cycle performanceEasy to storeFinal product manufactureSecondary cells servicing/maintenanceHigh temperature storageOrganic solvent

The invention discloses an electrolyte used for a lithium ion battery. The electrode comprises a non-aqueous organic solvent, an electrolyte lithium salt, a conventional additive and a functional additive, wherein the functional additive is a phosphorous diimidazole compound. After the additive is added into the electrolyte, interfacial films with excellent electrochemical stability and ionic conduction performance can be formed on positive and negative material interfaces in the formation stage of the battery, so that the cycle performance, high-temperature cycle performance and high-temperature storage performance of the lithium ion battery can be promoted effectively.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

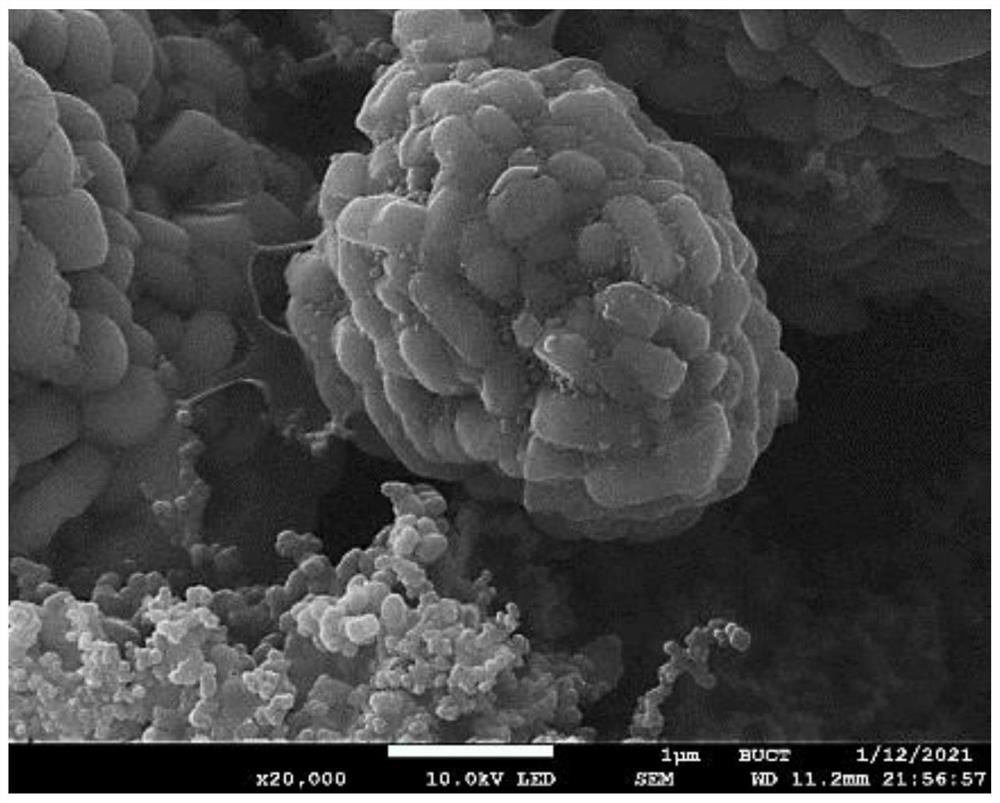

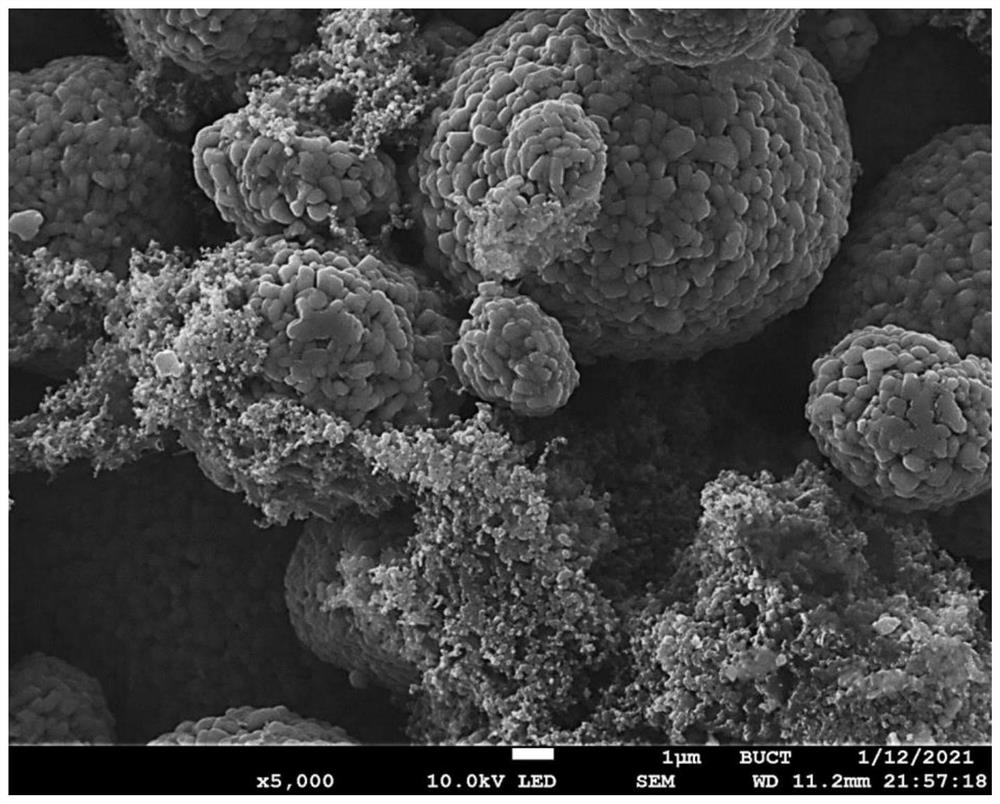

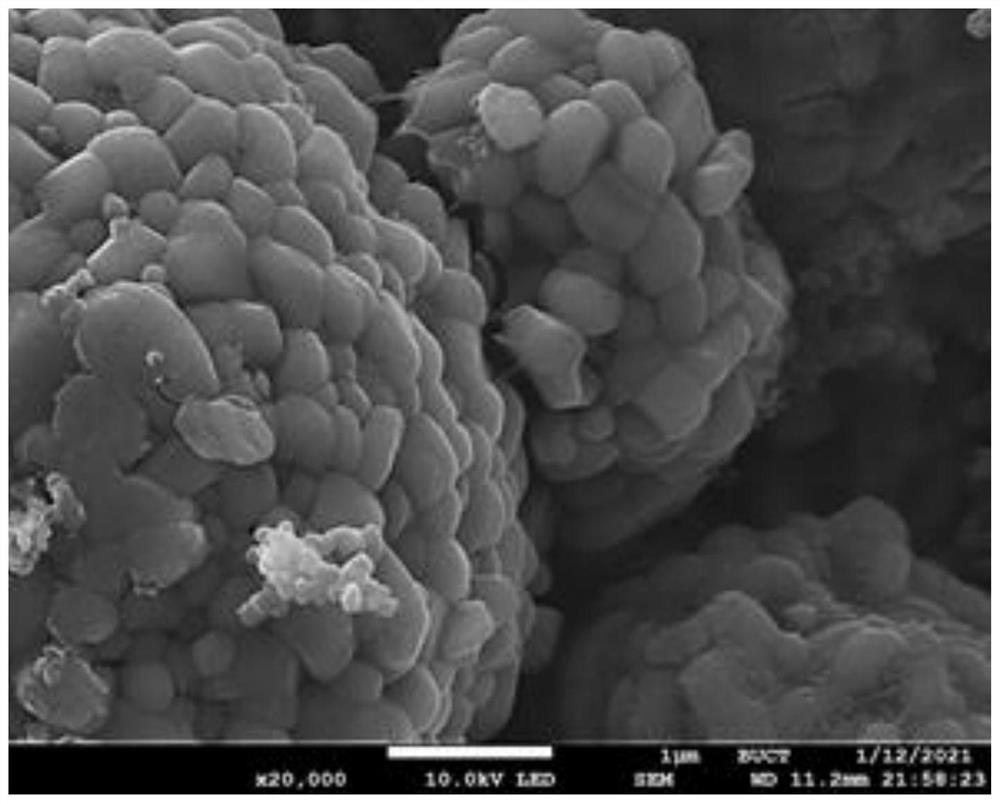

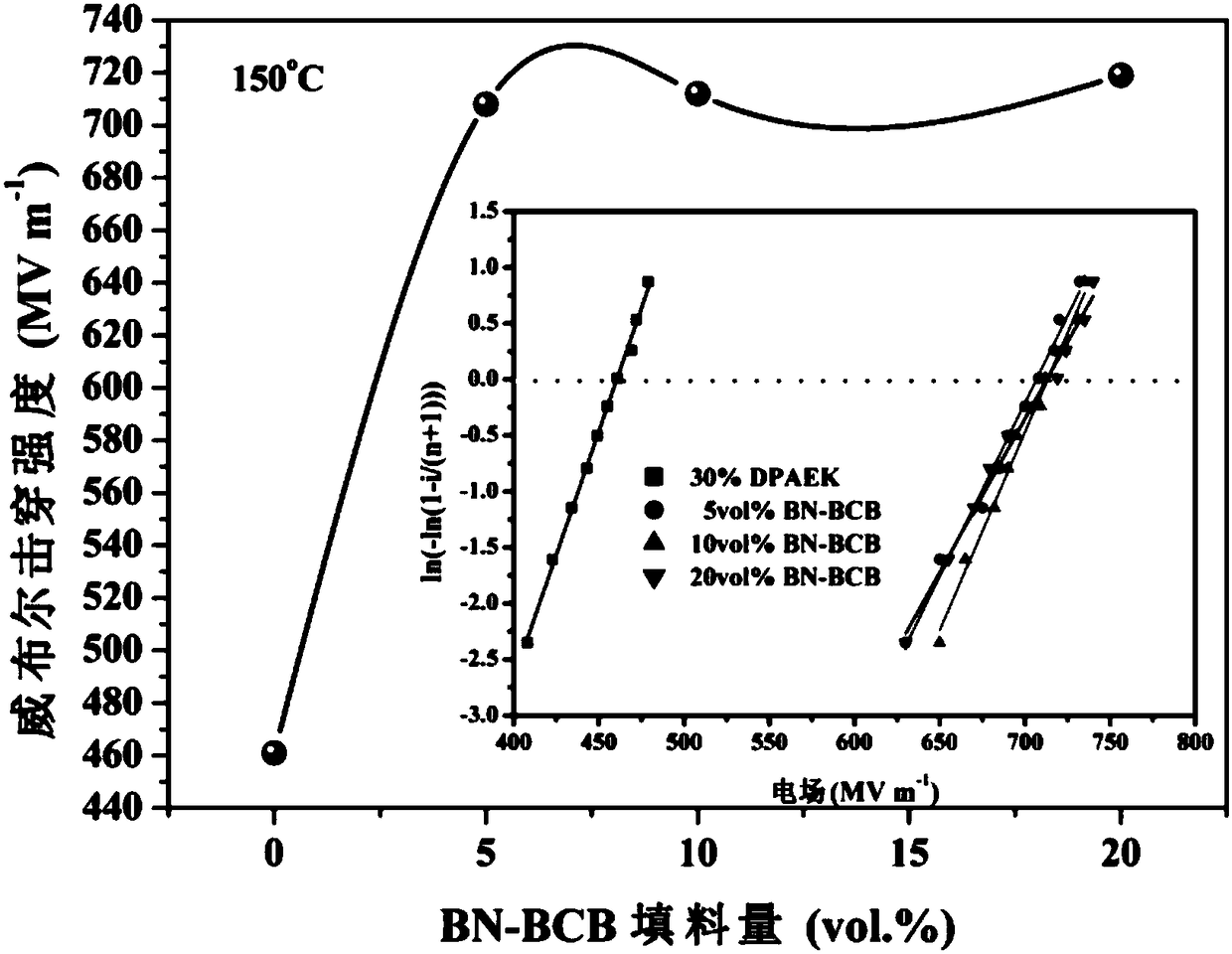

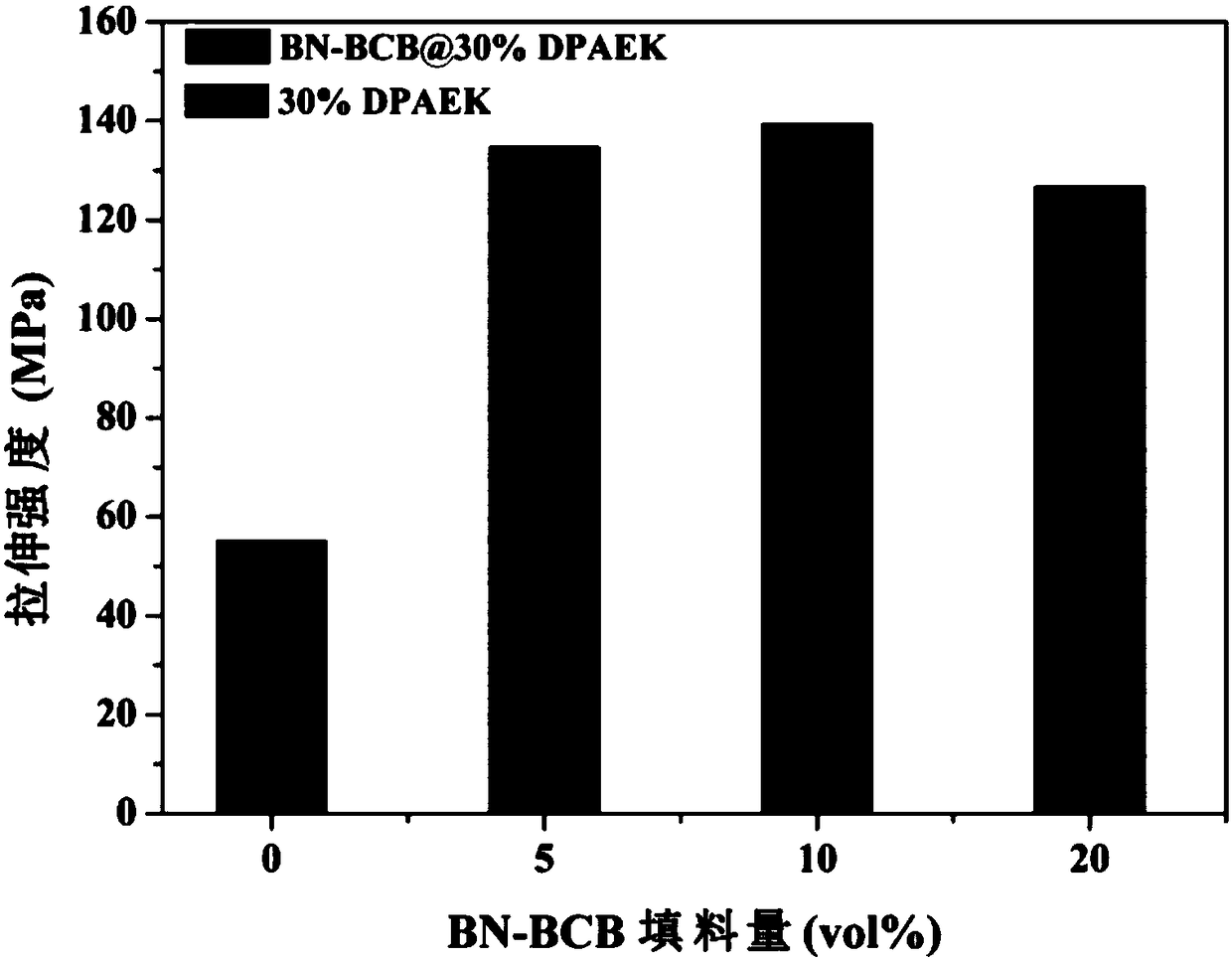

Crosslinking type polyaryletherketone based dielectric composite material as well as preparation method and application thereof

The invention discloses a crosslinking type polyaryletherketone based dielectric composite material as well as a preparation method and application thereof. The method comprises the steps: utilizing polyaryletherketone having good thermal and mechanical property and further containing an active functional group (allyl lateral group) as a polymer matrix material; meanwhile, utilizing an inorganic ceramic particle with high insulativity as inorganic filler, performing organic functional modification on the surface of the filler, guiding benzocyclobutene into to form an inorganic ceramic particlewith a reactable functional group and a core-shell structure, utilizing the inorganic ceramic particle as a crosslinking point, generating crosslinking reaction with the polyaryletherketone polymer matrix with the active functional group to form a three-dimensional network structure and preparing the crosslinking type polyaryletherketone based dielectric composite material with good thermal resistance, flexibility and high voltage resistance. The prepared polyaryletherketone based dielectric composite film has the advantages of lower dielectric loss and wider temperature application range; meanwhile, breakdown field strength of the prepared polyaryletherketone based dielectric composite film is obviously improved; thus, higher high voltage resistance under the high temperature can be obtained.

Owner:JILIN UNIV

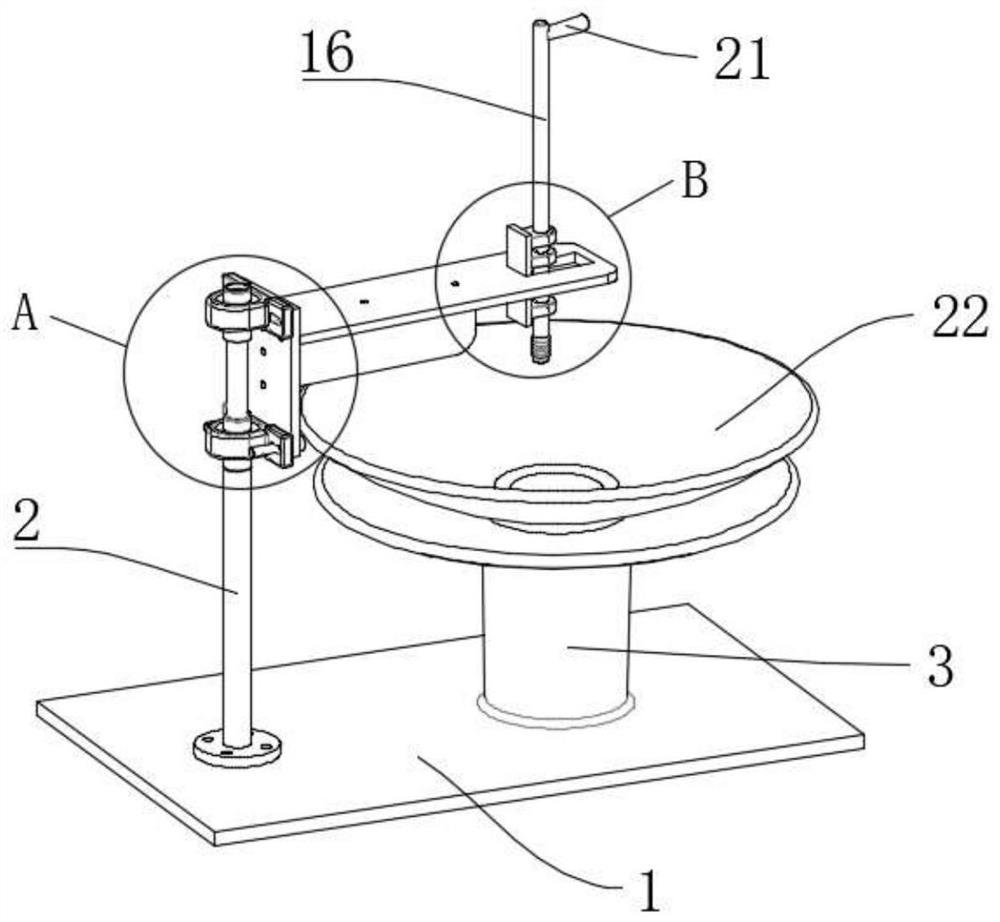

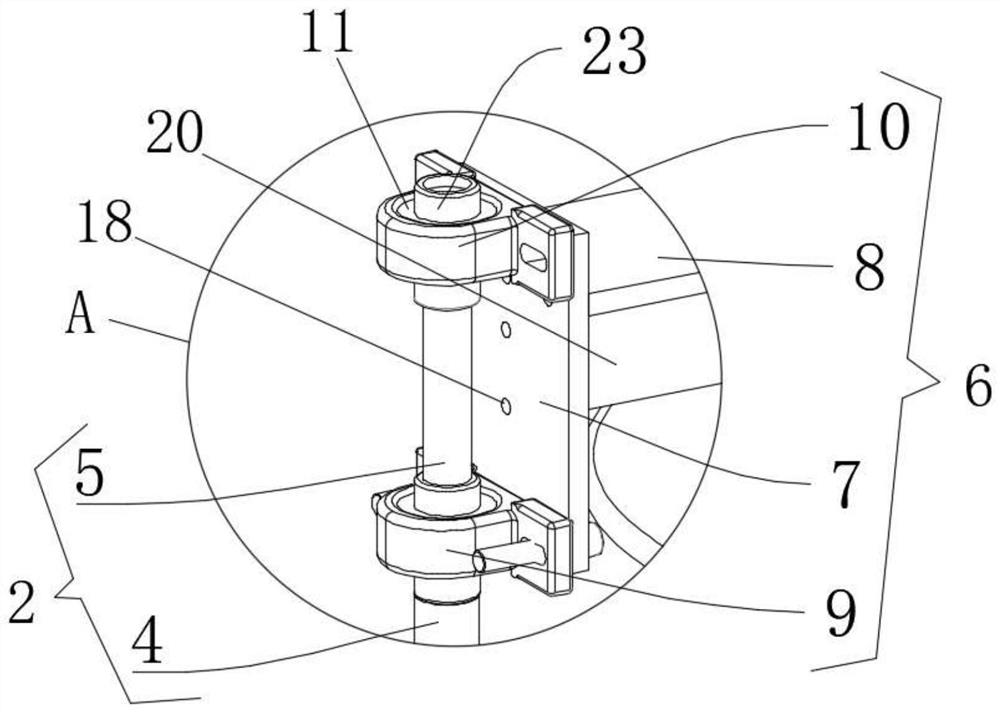

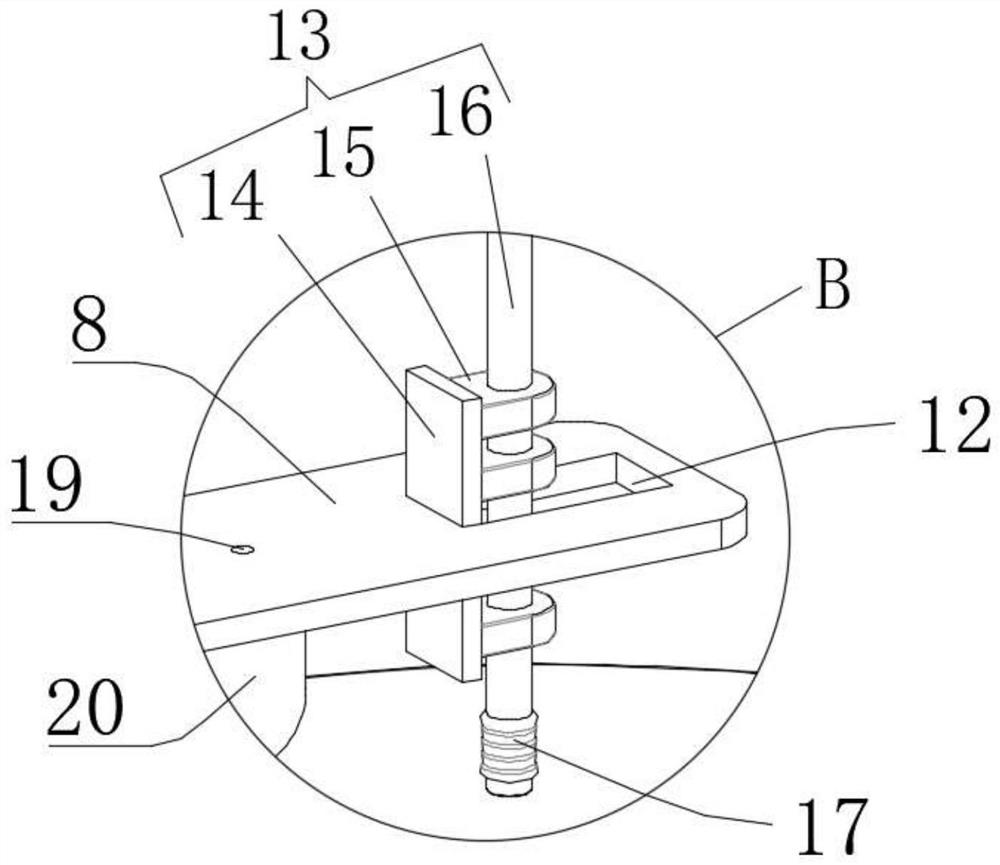

Cylindrical insulator inner hole groove rolling machine

PendingCN113580330AImprove high voltage resistance performanceImprove product qualityPress rollersAuxillary shaping apparatusEngineeringMachine

The invention relates to the related technical field of insulator production equipment, and particularly discloses a cylindrical insulator inner hole groove rolling machine. The cylindrical insulator inner hole groove rolling machine comprises a base, a vertical rod, a porcelain piece containing seat, a rotating support and a groove rolling assembly, the base is a rectangular platform, the vertical rod is formed by combining a mounting pipe and a rotating rod, the lower end of the mounting pipe is fixedly welded to the base, the rotating rod is mounted in an inner cavity of the mounting pipe, and the rotating support is formed by combining a mounting plate, a cross beam plate, a lower bearing seat and an upper bearing seat. The cylindrical insulator inner hole groove rolling machine formed by combining the base, the vertical rod, the porcelain piece containing seat, the rotating support and the groove rolling assembly is arranged, so that the inner side wall of a cylindrical head of an insulator is rolled into a porcelain wire with a certain angle, the performance of a porcelain material is brought into full play, and enough and stable mechanical performance is provided for a product; and meanwhile, the smooth surface is beneficial to improving the high voltage resistance of the porcelain piece, excellent voltage resistance is provided for the product, and the product quality of the porcelain insulator is effectively improved.

Owner:山东高亚绝缘子有限公司

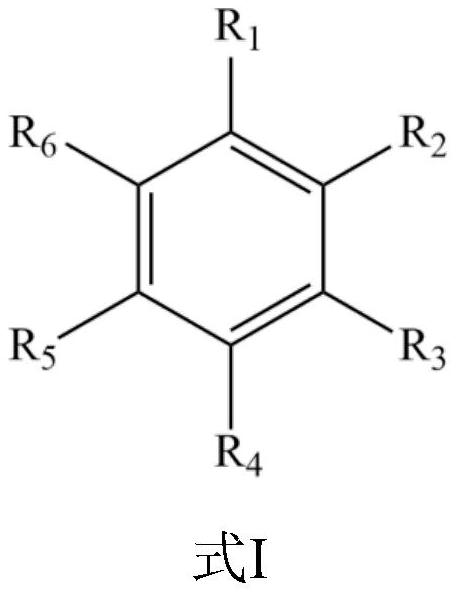

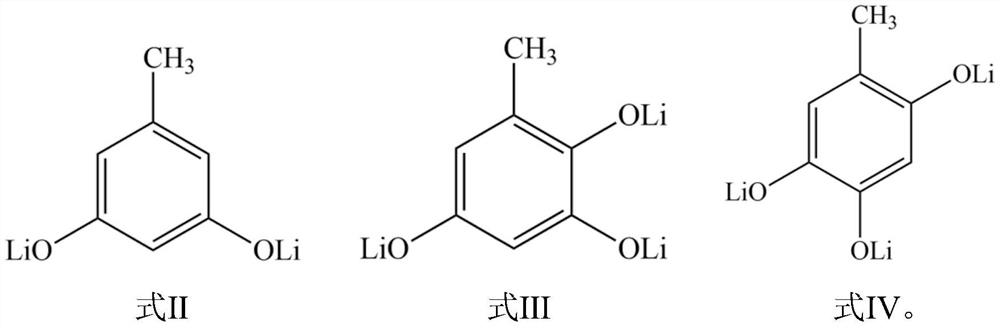

Positive lithium supplement additive, positive pole piece, preparation method of positive pole piece and lithium ion battery

PendingCN114790131AThe production will notImprove high voltage resistance performanceOrganic chemistrySecondary cells servicing/maintenanceCapacity lossPole piece

The invention provides a positive pole lithium supplement additive, the structure of the additive is shown in the following formula, the invention provides a positive pole piece and a preparation method thereof, and the positive pole piece contains the positive pole lithium supplement additive. The invention also provides a lithium ion secondary battery. The lithium ion secondary battery comprises the positive pole piece, a negative pole piece, an organic electrolyte, a diaphragm and a packaging film. The positive electrode lithium supplement additive provided by the invention can supplement lithium ions consumed in the formation process of an SEI film of a lithium ion battery, can effectively reduce the capacity loss problem of the lithium ion battery in the first charging and discharging process, improves the first charging and discharging efficiency, and improves the energy density of the lithium ion battery;

Owner:FARASIS TECH (GANZHOU) CO LTD

A post-mounted magnetic mirror field-strength current ion acceleration system

ActiveCN108271310BSuppression of strong space charge effectsReduced divergence lossAcceleratorsIon beamIon acceleration

The invention discloses a rear-mounted magnetic-mirror field high-current ion acceleration tube. The rear-mounted magnetic-mirror field high-current ion acceleration tube comprises an external insulating magnetic ring, a grading ring and an internal inlet flange, an inlet beam-limiting conical cylinder, an ultra-thin heat tube, an acceleration electrode, shielding electrodes, weak correcting magnets, an outlet conical cylinder, a magnetic mirror apparatus and an outlet flange; the outer surface of the insulating magnetic ring is waveform and plated with glaze; the ultra-thin heat tube is arranged on the periphery of the inlet beam-limiting conical cylinder; the two shielding electrodes in the middle are provided with the weak correcting magnets respectively; and the magnetic mirror apparatus is mounted on the outlet flange. By virtue of the rear-mounted magnetic-mirror field high-current ion acceleration tube provided by the invention, the high-voltage ignition risk of the accelerationtube is lowered, and high-current ion beam acceleration stability is improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

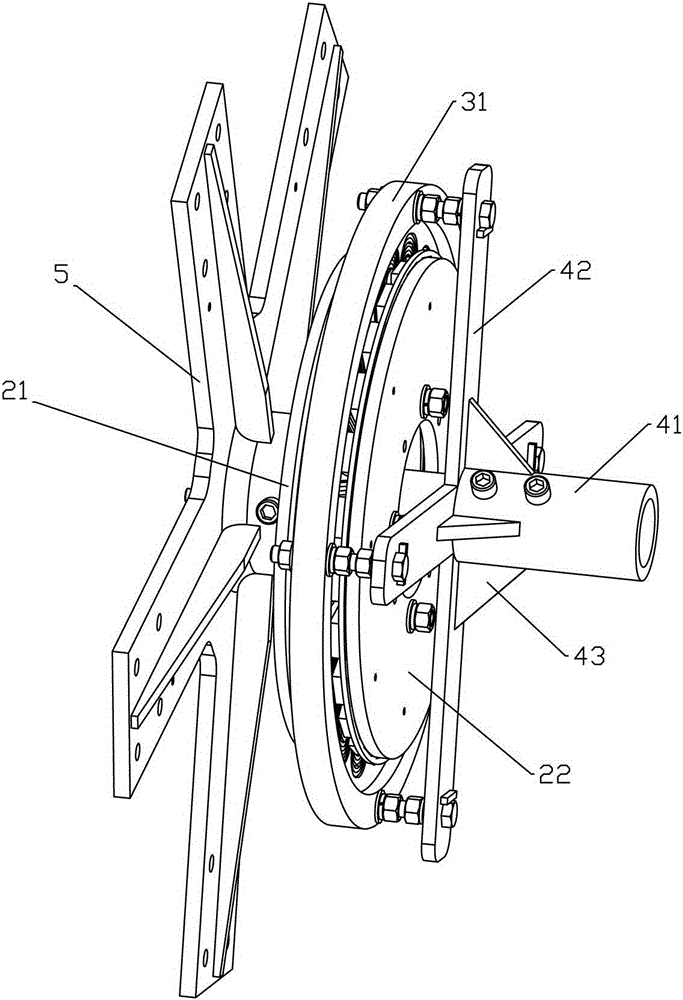

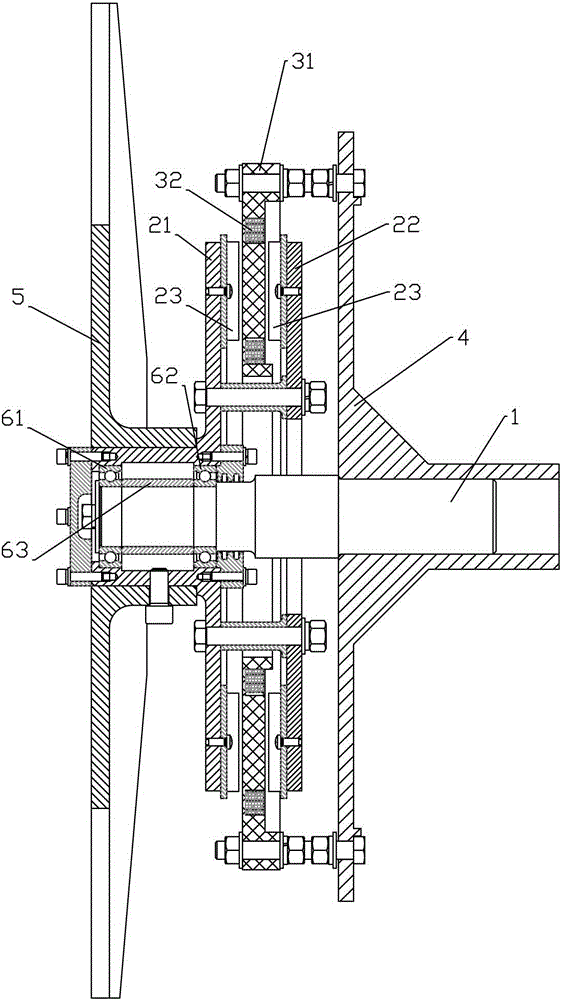

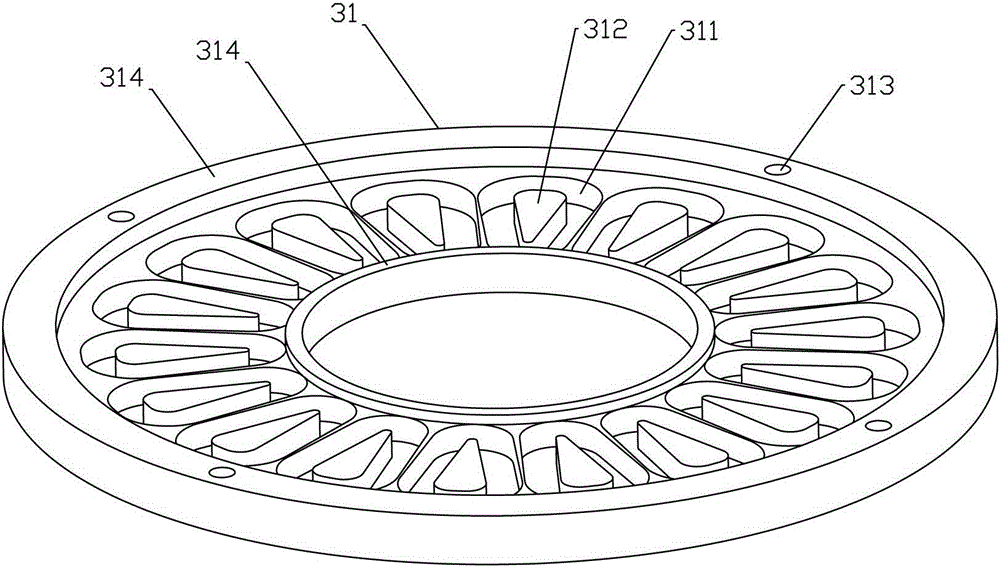

Coil disk structures for wind power generation systems under extreme conditions

InactiveCN103730970BHigh hardnessHigh temperature resistanceWindings conductor shape/form/constructionElectricityEngineering

Owner:WINDPOWER ENERGY CO LTD SHUNDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com