a non-aqueous electrolyte

A non-aqueous electrolyte, structural technology, applied in the field of new materials and electrochemistry, can solve the problems of accelerated side reactions between electrolyte and electrodes, electrolyte leakage of battery flammability, battery expansion and deformation, etc., to achieve redox resistance. Strong, improve high voltage resistance performance, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

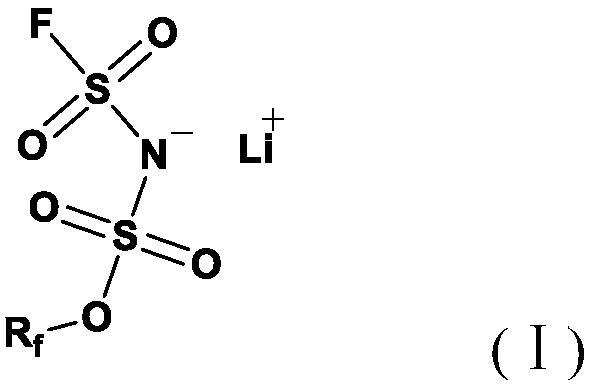

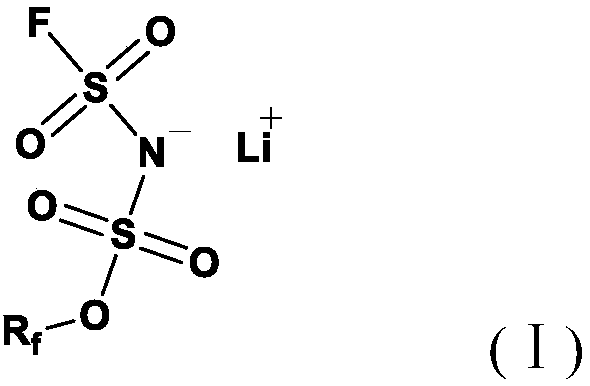

Image

Examples

Embodiment 1

[0015] 1) Fabrication of positive electrode: LiCoO 2 Powder, carbon black (particle size 1000nm), polyvinylidene fluoride (PVDF) and N,N-dimethylpyrrolidone (NMP) are mixed to make a uniform slurry, and the slurry is evenly coated on an aluminum foil (15 μm) current collector on, then dried and rolled to obtain LiCoO 2 Cathode material. Bake at 120°C for 12 hours, in the dried pole piece, LiCoO 2 Accounting for 94% of the total coating, the binder accounted for 4%, and carbon black accounted for 2%. Then the obtained pole piece was cut into a disc with a diameter of 12 mm as the positive pole.

[0016] 2) Preparation of negative electrode: Mix artificial graphite, polyvinylidene fluoride (PVDF) and N,N-dimethylpyrrolidone (NMP) to make a uniform slurry, and evenly coat the slurry on a copper foil (15 μm) set fluid, then dried and rolled to obtain a carbon negative electrode material. Bake at 120°C for 12 hours. In the dried pole piece, graphite accounts for 96.4% of the t...

Embodiment 3

[0026] 12 parts, 7 parts of lithium oxalate phosphate, LiN(SO 2 R F ) 2 5 parts, 4 parts of 1,4-butanediol sulfate, 11 parts of adiponitrile, 20 parts of pimelonitrile, 13 parts of suberonitrile, 16 parts of sebaconitrile, 4-fluoro-1,3-dioxolane 51 parts of cyclo-2-ketone, 8 parts of ethylene carbonate (EC), 5 parts of propylene carbonate (PC), 5 parts of dihydroxystyrene carbonate, 7 parts of monohydroxystyrene carbonate, 4 parts of anti-overshoot additive , 1.3 parts of tributyl phosphate, 2 parts of hexamethyldisilazane or triphenyl phosphite;

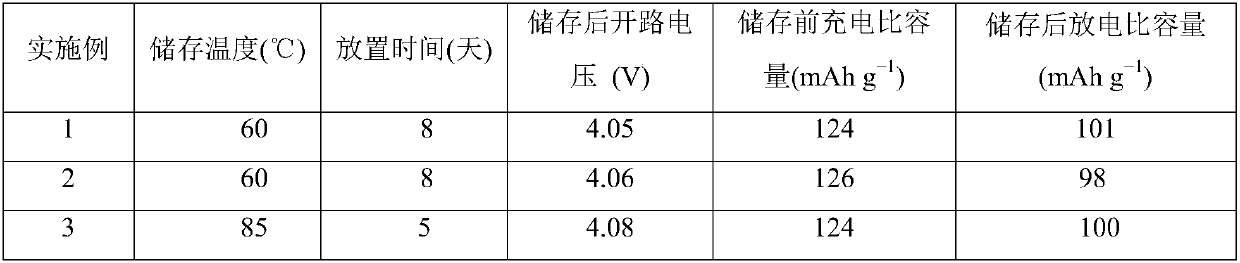

[0027] Assembled into the same battery as in Example 1, the high-temperature cycle performance test was carried out. Test conditions: The assembled battery is directly subjected to a high-temperature cycle test in a constant temperature test box at 60°C, and the cut-off voltage is 4.2–2.75V. The charge rate is 0.5C, and the discharge rate is 0.2C. The test data of this embodiment is shown in Table 1.

[0028] The electrolyte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com