High-temperature-resistant, high-voltage-resistant and high-load adhesive for lithium ion battery and battery positive pole piece applying same

A lithium-ion battery, high-temperature-resistant technology, applied to battery electrodes, positive electrodes, adhesives, etc., can solve the problems of battery thermal runaway, fire and explosion, etc., and achieve high temperature resistance, high load, and excellent bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

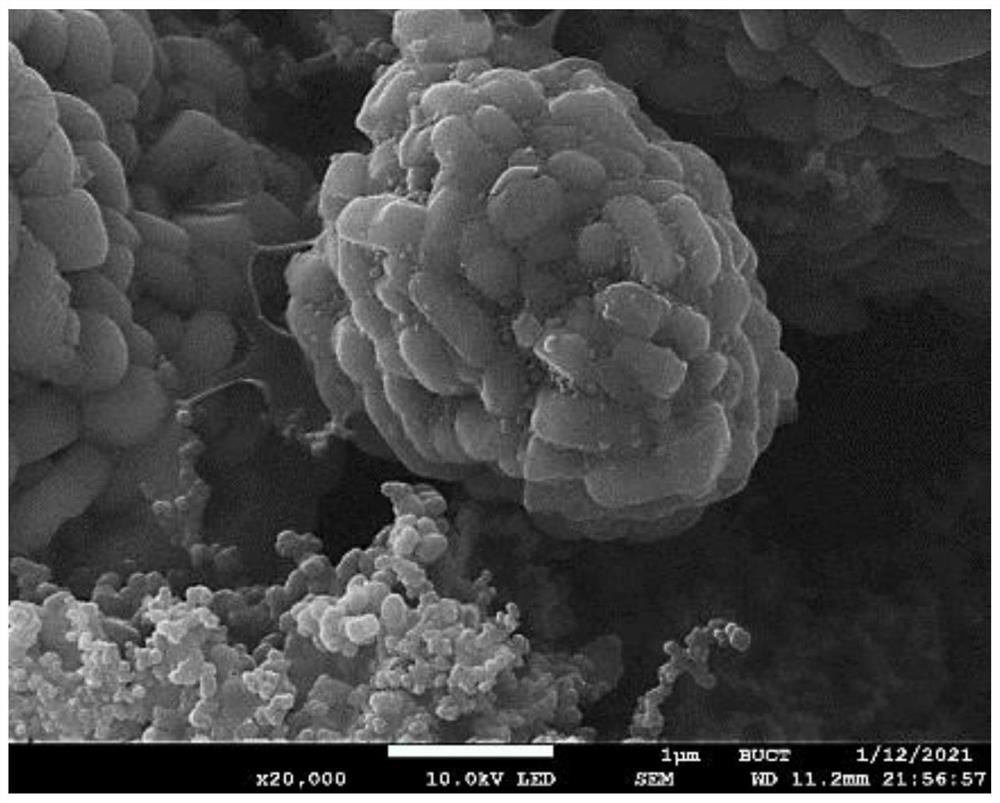

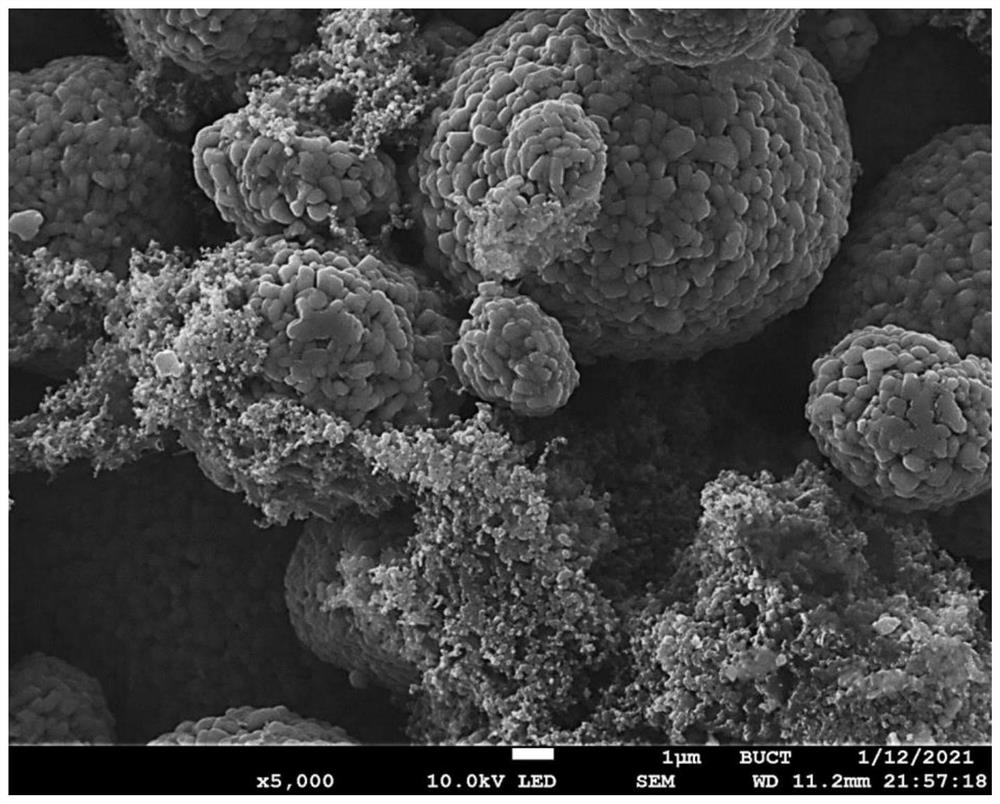

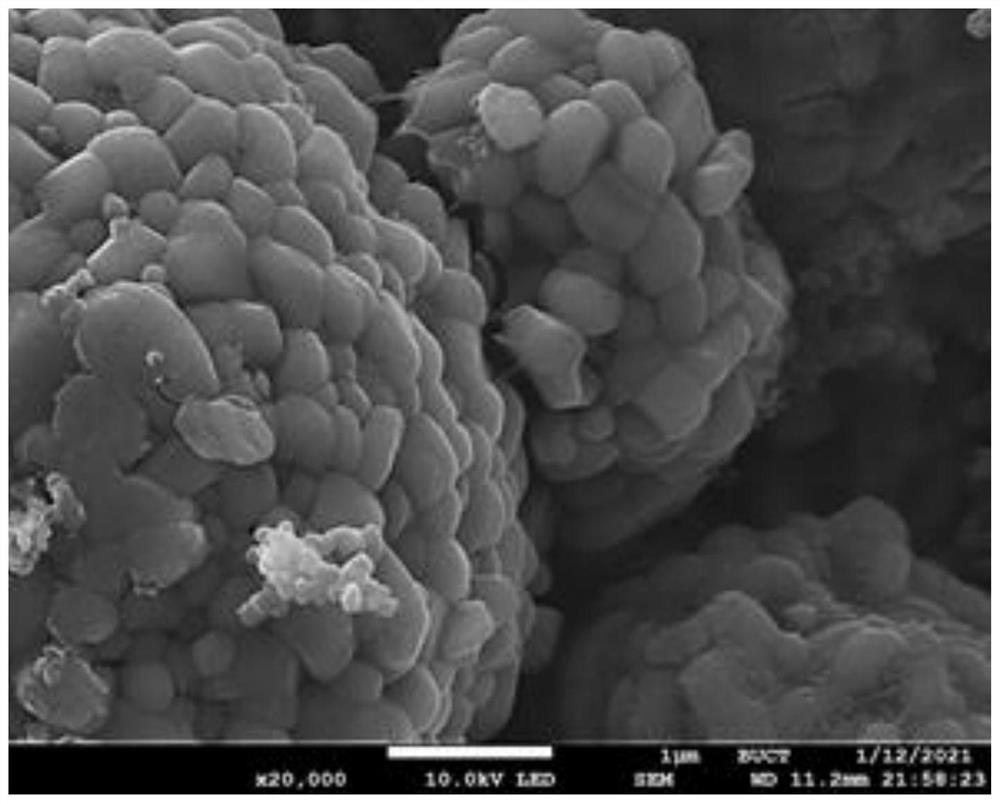

[0055] Weigh 1.96g of ODPA and 3.29g of BPADA with a molar ratio of 1:1, mix them evenly, place them in a feeding bottle and seal them for later use. Weigh 2.51g of ODA and dissolve it in 30mL of NMP solvent, stir it until it is completely dissolved, add the mixed ODPA and BPADA monomers in 6 batches under ice-water bath conditions, and obtain a polyamic acid gum with a solid content of 20wt%. solution, the polyamic acid glue solution was diluted to a solution with a solid content of 5 wt%. Mix positive electrode active material NCM811, conductive carbon black, and polyamic acid solution with a solid content of 5wt% (calculated according to its solute) according to a mass ratio of 94:3:3, add 1.01g of NMP solvent to adjust its viscosity, and stir for 2 hours. Obtain positive electrode slurry. Coat 10.68g of flexible polyimide slurry on an aluminum foil (10cm×12cm) and place it in an ultra-clean table to dry at room temperature for 12h, cut into a disc with a diameter of 14mm,...

Embodiment 2

[0059] Weigh 2.22g of BPDA and 3.93g of BPADA with a molar ratio of 1:1, mix them evenly, place them in a feeding bottle and seal them for later use. Weigh 1.62g of PDA and dissolve it in 30mL of NMP solvent, stir it until it is completely dissolved, add the mixed BPDA and BPADA monomers in 6 batches under ice-water bath conditions, and obtain a polyamic acid gum with a solid content of 20wt%. solution, the polyamic acid glue solution was diluted to a solution with a solid content of 5 wt%. Mix positive electrode active material NCM811, conductive carbon black, and polyamic acid solution with a solid content of 5wt% (calculated according to its solute) according to a mass ratio of 94:3:3, add 1.01g of NMP solvent to adjust its viscosity, and stir for 2 hours. Obtain positive electrode slurry. Coat 10.68g of rigid polyimide slurry on an aluminum foil (10cm×12cm) and place it in an ultra-clean table to dry at room temperature for 12h, cut into a disc with a diameter of 14mm, ro...

Embodiment 3

[0063] Weigh 0.35g of ODPA and 5.21g of BPADA with a molar ratio of 1:9, mix them evenly, place them in a feeding bottle and seal them for later use. Weigh 2.21g of ODA and dissolve it in 30mL of NMP solvent, stir it until it is completely dissolved, add the mixed ODPA and BPADA monomers in 6 batches under ice-water bath conditions, and obtain a polyamic acid gum with a solid content of 20wt%. solution, the polyamic acid glue solution was diluted to a solution with a solid content of 5 wt%. Mix positive electrode active material NCM811, conductive carbon black, and polyamic acid solution with a solid content of 5wt% (calculated according to its solute) according to a mass ratio of 94:3:3, add 1.01g of NMP solvent to adjust its viscosity, and stir for 2 hours. Obtain positive electrode slurry. Coat 10.68g of flexible polyimide slurry on an aluminum foil (10cm×12cm) and place it in an ultra-clean table to dry at room temperature for 12h, cut into a disc with a diameter of 14mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com