Thermal-knock resisting diamond spar-spinele refractory materials and its production

A technology of refractory materials and spinel, which is applied in the field of refractory materials, can solve problems such as pollution, and achieve the effects of reducing production costs, suitable load softening temperature, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Ingredients composition

[0030] Aggregate: spinel particles 1-3mm 36%

[0031] Spinel particles below 1mm 10%

[0032] Fused corundum particles 1-3mm 8%

[0033] Fused corundum particles below 1mm 12%

[0034] Mixed powder: corundum powder≤180 mesh 13%

[0035] Alumina powder≤320 mesh 12%

[0036] Fused magnesium powder≤320 mesh 5%

[0037] Titanium dioxide≤320 mesh 4%

[0038] Additional binder: 3% yellow dextrin solution with a concentration of 20%

[0039] (2) Process

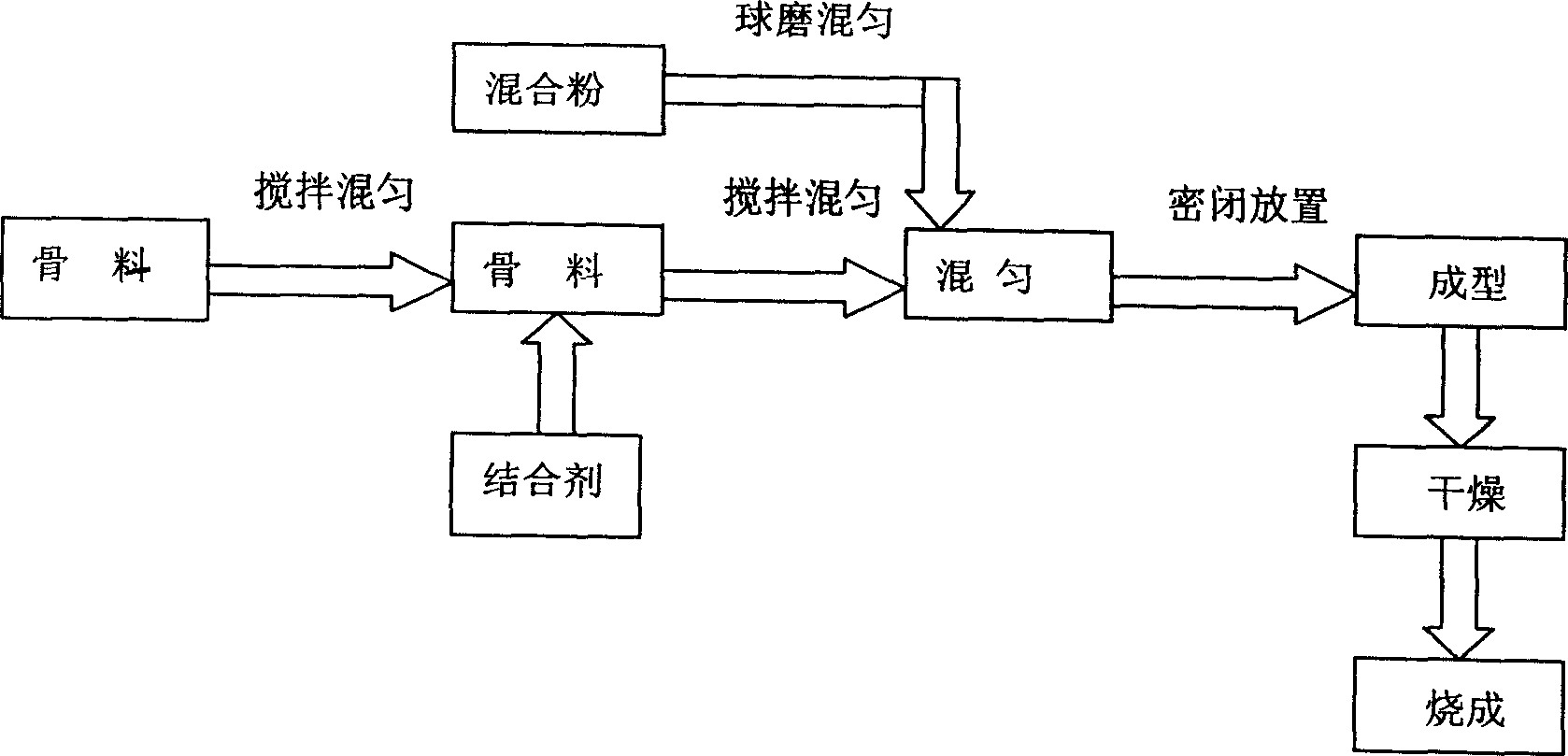

[0040] As shown in the attached picture, the mixed powder mixing process is carried out in a ball mill. The aggregate mixing process uses a 750-type planetary sand mixer. After the aggregate is mixed evenly, the binder is added for wet mixing, and then the mixed powder is added and stirred evenly. Sealed Place for 4 to 24 hours. Forming with a 400-ton friction brick press, drying with a tunnel kiln dryer at 60-80°C, with a residual moisture of les...

Embodiment 2

[0042] (1) Ingredients composition

[0043] Aggregate: Spinel particles 1-3mm 36%

[0044] Spinel particles below 1mm 4%

[0045] Fused corundum particles 1-3mm 8%

[0046] Fused corundum particles below 1mm 22%

[0047] Mixed powder: corundum powder≤180 mesh 10%

[0048] Alumina powder≤320 mesh 11%

[0049] Fused magnesium powder≤320 mesh 7%

[0050] Titanium dioxide≤320 mesh 2%

[0051] Additional binder: 5% yellow dextrin solution with a concentration of 20%

[0052] (2) Process

[0053] The highest firing temperature is 1680°C, other processes are as in Example 1

Embodiment 3

[0055] (1) Ingredients composition

[0056] Aggregate: Spinel particles 1-3mm 40%

[0057] Spinel particles below 1mm 10%

[0058] Fused corundum particles 1-3mm 6%

[0059] Fused corundum particles below 1mm 9%

[0060] Mixed powder: corundum powder≤180 mesh 10%

[0061] Alumina powder≤320 mesh 12%

[0062] Fused magnesium powder≤320 mesh 3%

[0063] Titanium dioxide≤320 mesh 10%

[0064] Additional binder: 4% yellow dextrin solution with a concentration of 20%

[0065] (2) Process

[0066] Technological process is as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

| Load softening temperature | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com