High-temperature resistant oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid, high temperature resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as the inability to meet the needs of ultra-high temperature shale gas wells, and achieve good application effects, stable system performance, and filterability. small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

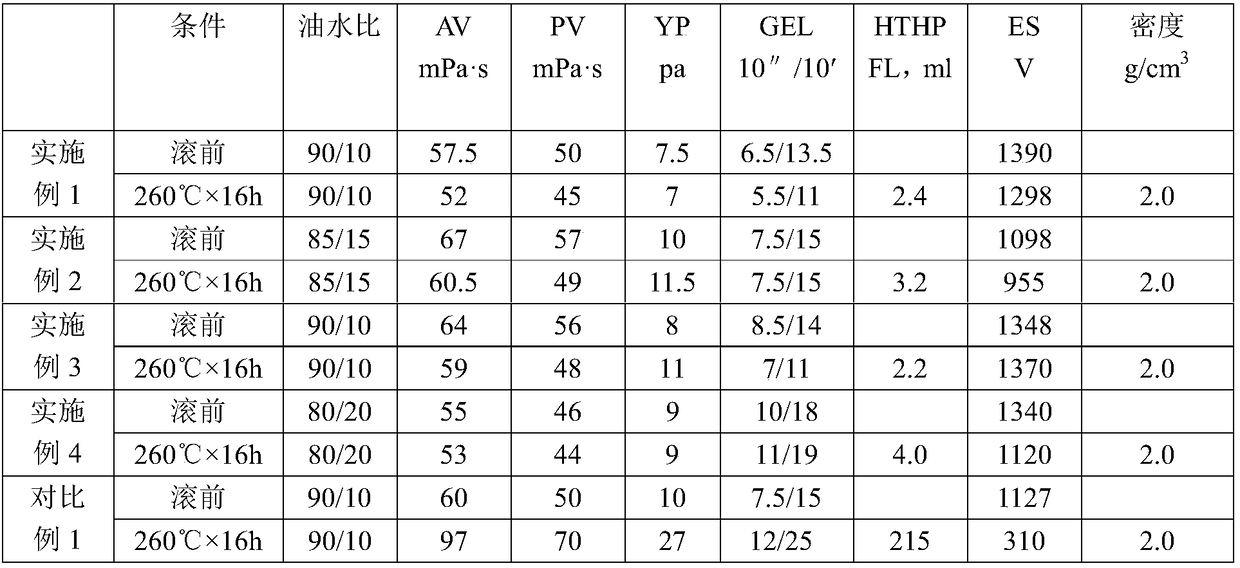

Embodiment 1

[0035] A high temperature resistant oil-based drilling fluid, the drilling fluid is composed of water-in-oil base fluid, primary emulsifier, secondary emulsifier, fluid loss reducer, alkalinity regulator, organic soil, wetting agent and weighting agent powder; The water-in-oil base liquid is composed of No. 3 white oil with a volume ratio of 90:10 and a calcium chloride aqueous solution with a concentration of 25%; calculated per 100mL of water-in-oil base liquid, the addition amount of the remaining components is: organic Bentonite 0.5g, PF-MOMUL 1g, PF-MOCOAT 1.4g, PF-MOWET-260 1g, calcium oxide 2g, sulfonated pitch 6g, barite 220g.

[0036] A preparation method for high-temperature resistant oil-based drilling fluid, comprising the following steps:

[0037] A. Measure 270ml No. 3 white oil with a measuring cylinder, pour it into a high-speed mixing cup, add 3g PF-MOMUL, 4.2gPF-MOCOAT, 3g PF-MOWET-260 respectively, and stir for 5 minutes;

[0038] B. adding 30ml concentrati...

Embodiment 2

[0040] A high temperature resistant oil-based drilling fluid, the drilling fluid is composed of water-in-oil base fluid, primary emulsifier, secondary emulsifier, fluid loss reducer, alkalinity regulator, organic soil, wetting agent and weighting agent powder; The water-in-oil base liquid is composed of No. 3 white oil with a volume ratio of 85:15 and a calcium chloride aqueous solution with a concentration of 25%. In terms of per 100mL of water-in-oil base liquid, the addition amount of the remaining components is: organic Bentonite 1g, PF-MOMUL 1.5g, PF-MOCOAT 1.5g, PF-MOWET-260 1.5g, calcium oxide 1.5g, modified asphalt 5g, barite 210g.

[0041] A preparation method for high-temperature resistant oil-based drilling fluid, comprising the following steps:

[0042] A. Measure 255ml No. 3 white oil with a measuring cylinder, pour it into a high-speed mixing cup, add 4.5gPF-MOMUL, 4.5gPF-MOCOAT, 4.5gPF-MOWET-260 respectively, and stir for 4min;

[0043] B. adding 45ml concentra...

Embodiment 3

[0045] A high temperature resistant oil-based drilling fluid, the drilling fluid is composed of water-in-oil base fluid, primary emulsifier, secondary emulsifier, fluid loss reducer, alkalinity regulator, organic soil, wetting agent and weighting agent powder; The water-in-oil base liquid is composed of No. 0 diesel oil with a volume ratio of 90:10 and a calcium chloride aqueous solution with a concentration of 20%; calculated per 100 mL of water-in-oil base liquid, the addition amount of the remaining components is: organic Mongolia Destone 2.5g, PF-MOMUL 2g, PF-MOCOAT 2g, PF-MOWET-260 2g, calcium oxide 3g, natural asphalt 7g, iron ore powder 210g.

[0046] A preparation method for high-temperature resistant oil-based drilling fluid, comprising the following steps:

[0047]A. Measure 270ml No. 0 diesel oil with a measuring cylinder, pour it into a high-speed mixing cup, add 6g PF-MOMUL, 6g PF-MOCOAT, 6g PF-MOWET-260 respectively, and stir for 6 minutes;

[0048] B. Add 30ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com