High-temperature-resisting type UV-LED (Ultraviolet-Light Emitting Diode) inkjet printing solder-resisting ink as well as preparation method and application thereof

A UV-LED, inkjet printing technology, used in applications, inks, household appliances, etc., to achieve high hardness, good high temperature resistance, good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~3

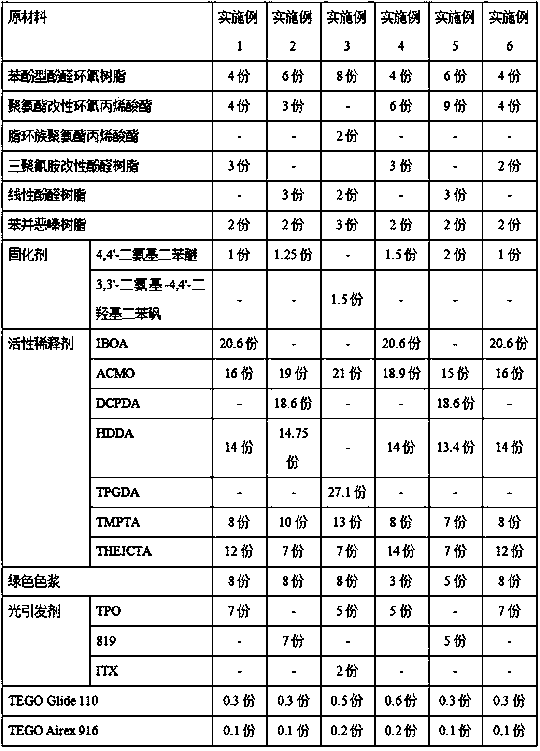

[0070] The consumption of the raw material of embodiment 1~6 is as shown in table 1 by mass parts;

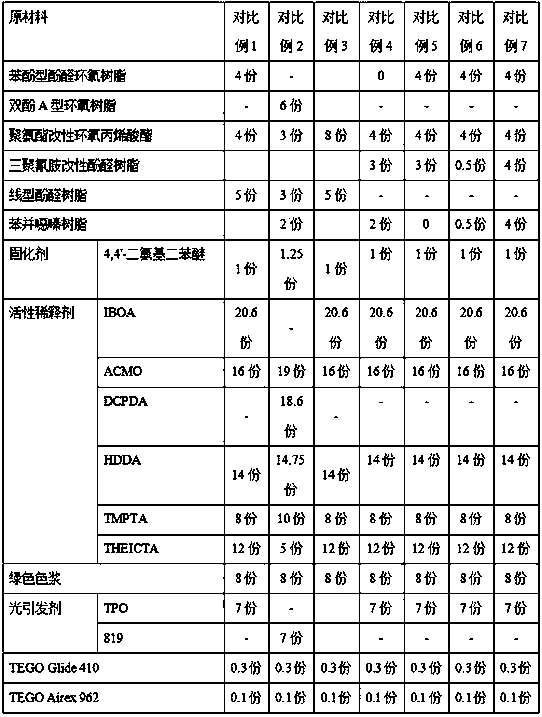

[0071] The usage amounts of the raw materials in Comparative Examples 1-7 are shown in Table 2 in terms of parts by mass.

[0072] The preparation method of the above-mentioned high-temperature-resistant UV-LED inkjet printing solder resist ink is as follows:

[0073] S1. Stir novolac epoxy resin, photocurable acrylic resin, phenolic resin, benzoxazine resin, and nano-color paste at 1000r / min for 1 hour to mix evenly, and set aside;

[0074] S2. Dissolve the photoinitiator in the reactive diluent, mix well, and set aside;

[0075] S3. Mix the mixture of resin and color paste, curing agent, monomer dissolved in photoinitiator, and additives, stir at 1000r / min for 1 hour, and then filter through a 1-micron filter membrane to obtain a green high-temperature-resistant UV - LED inkjet printing solder resist ink.

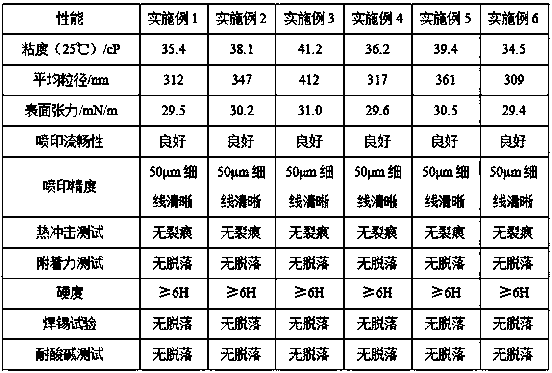

[0076] Various tests were performed on the high temperature resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com