Coil disk structures for wind power generation systems under extreme conditions

A technology for wind power generation systems and extreme conditions, applied in the shape/style/structure of winding conductors, etc., can solve the problems of low resistance to high voltage, increased heating temperature of coil discs, and low insulation of coils, so as to improve high resistance to high voltage. Voltage performance, insulation enhancement, eddy current prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

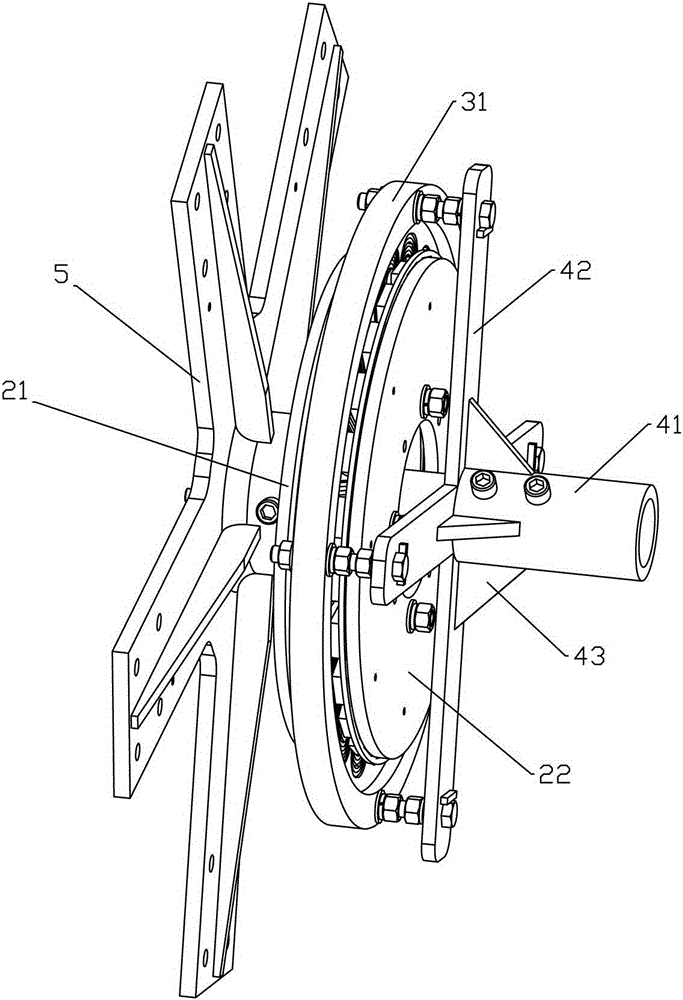

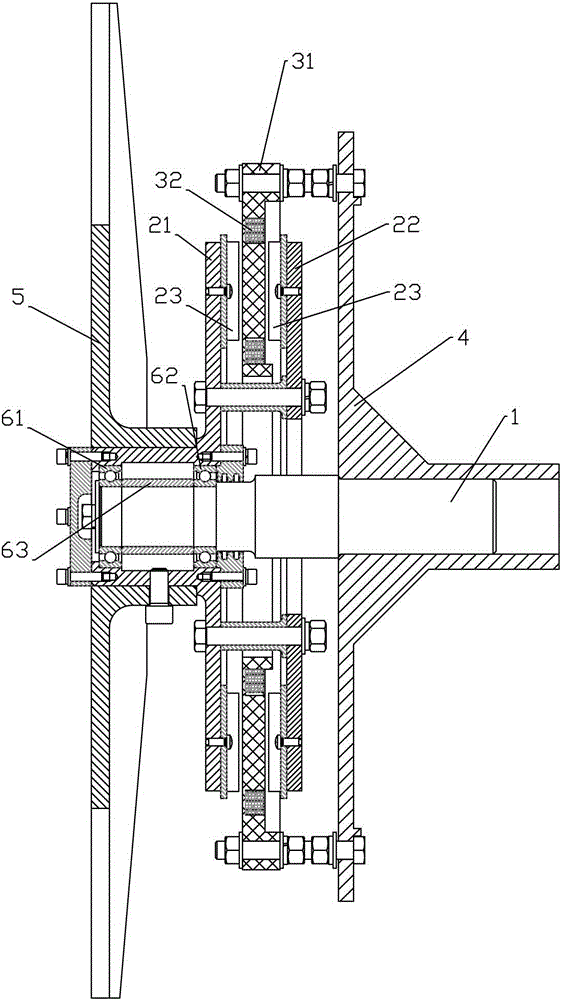

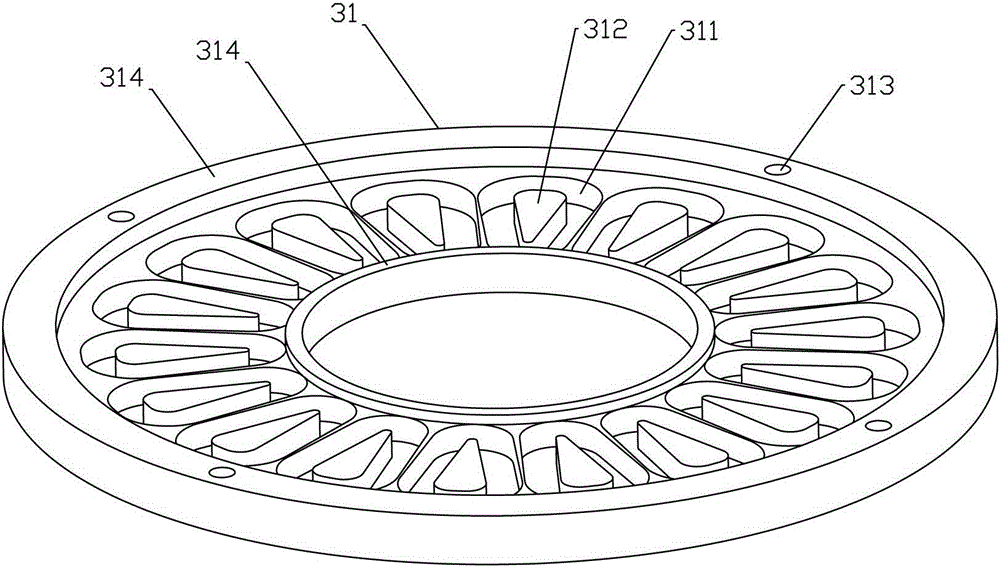

[0023] refer to Figure 1 to Figure 7 , the coil disk structure of the wind power generation system under extreme conditions of the present invention includes a coil disk 31 formed by epoxy resin and glass fiber cloth under high pressure, because epoxy resin has excellent bonding strength to the surface of metal materials and non-metal materials , good dielectric properties, good insulation, small set shrinkage, high hardness, good flexibility; and glass fiber cloth has good covering function, can ensure uniform surface structure, strong tensile properties, insulation Well, therefore, the coil disk 31 made by high-pressure molding of epoxy resin and glass fiber cloth has the characteristics of high hardness, non-conductivity, magnetic conductivity, and high temperature resistance, so as to avoid the gap between the coil disk and the magnetic steel disk due to the magnetic conduction of the coil disk. A magnetic attraction force is generated between them to hinder the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com