Method for preparing magnetic graphene oxide by using NH3.H2O-NH4NO3 solution

A technology of stone oxide and graphene is applied in the field of preparing magnetic graphene oxide by using NH3·H2O-NH4NO3 solution, and it can solve the problems of corrosion damage, unstable product performance, unsuitable for open system, etc. To achieve the effect of reducing corrosion, expanding layer spacing, and good dissociation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

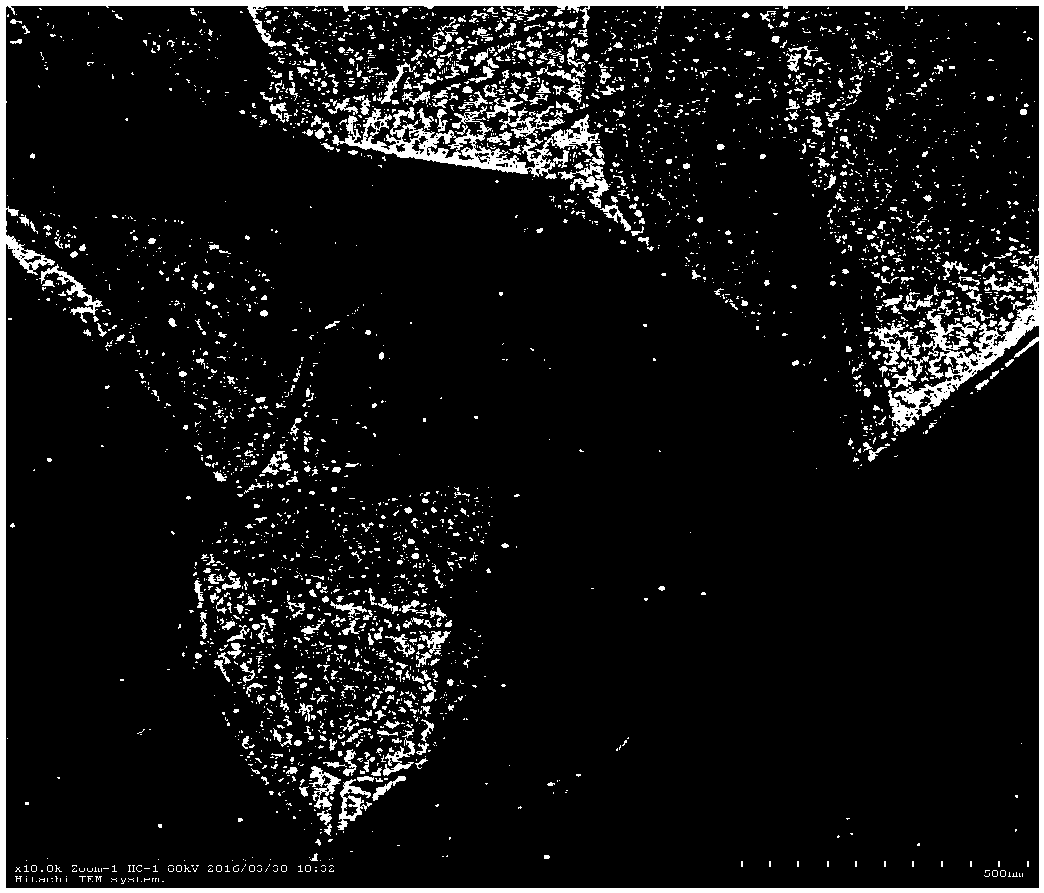

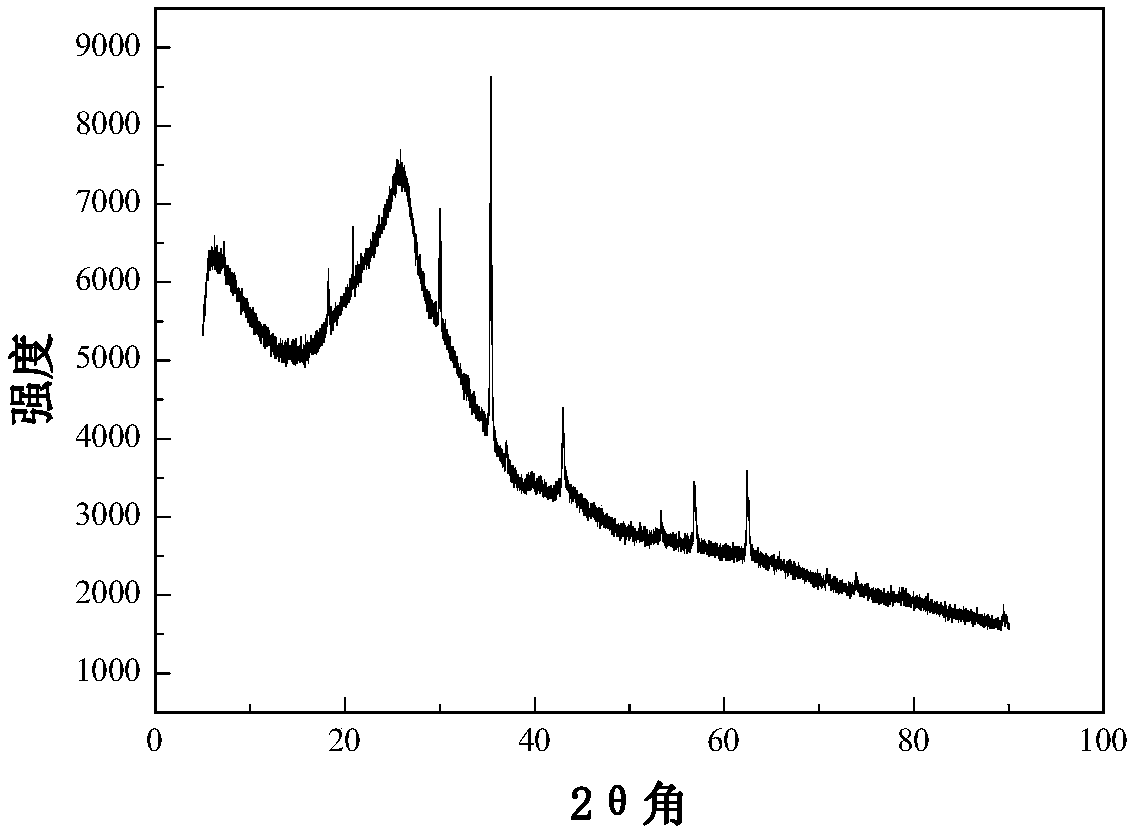

Image

Examples

Embodiment 1

[0022] (1) Preparation of graphene oxide suspension: mix 6g of graphite and 3g of sodium nitrate and place in an ice-water bath, under stirring, slowly drop in 100mL of 98% concentrated sulfuric acid for 1 hour; add 18g of potassium permanganate and react for 6 hours Then add 18g of potassium permanganate, and continue to react for 12h; cool, wash, sonicate, take the upper layer suspension, and concentrate to 1 / 4 volume;

[0023] (2) Preparation of magnetic graphene oxide: graphene oxide suspension, FeCl-containing 2 and FeCl 3 mixed solution and NH 3 ·H 2 O-NH 4 NO 3 The solution was mixed, heated to 50°C, then placed in an ultrasonic cell pulverizer, (repeated by ultrasonication for 5s / interval of 10s), heated to 70°C, and the total reaction was 40min (including ultrasonic time and interval time), cooled, washed, and freeze-dried ; Among them, FeCl 2 and FeCl 3 The molar ratio is 1:2, NH 3·H 2 O-NH 4 NO 3 The molar ratio of the two is 3:1.

Embodiment 2

[0025] (1) Preparation of graphene oxide suspension: mix 4g of graphite and 2g of potassium nitrate and place in an ice-water bath, under stirring, slowly drop in 90mL of 98% concentrated sulfuric acid for 1h; add 30g of hydrogen peroxide, react for 6h before adding 30g hydrogen peroxide, continue to react for 12h; cool, wash, sonicate, take the upper suspension, concentrate to 1 / 4 volume;

[0026] (2) Preparation of magnetic graphene oxide: graphene oxide suspension, FeCl-containing 2 and FeCl 3 mixed solution and NH 3 ·H 2 O-NH 4 NO 3 The solutions were mixed, heated to 60°C, then placed in an ultrasonic cell pulverizer, (repeated by ultrasonication for 6s / interval of 12s), heated to 80°C, and the total reaction was 60min (including ultrasonic time and interval time), cooled, washed, and freeze-dried ; Among them, FeCl 2 and FeCl 3 The molar ratio is 1:2, NH 3 ·H 2 O-NH 4 NO 3 The molar ratio is 2:1.

Embodiment 3

[0028] (1) Preparation of graphene oxide suspension: mix 9g of graphite with 4g of sodium nitrate and place in an ice-water bath, under stirring, slowly drop in 120mL of 98% concentrated sulfuric acid for 1 hour; add 24g of potassium permanganate and react for 6 hours Then add 24g of potassium permanganate, and continue to react for 12h; cool, wash, sonicate, take the upper layer suspension, and concentrate to 1 / 4 volume;

[0029] (2) Preparation of magnetic graphene oxide: graphene oxide suspension, FeCl-containing 2 and FeCl 3 mixed solution and NH 3 ·H 2 O-NH 4 NO 3 The solution was mixed, heated to 70°C, then placed in an ultrasonic cell pulverizer, (repeated by ultrasonication for 8s / interval of 15s), heated to 90°C, and the total reaction was 80min (including ultrasonic time and interval time), cooled, washed, and freeze-dried ; Among them, FeCl 2 and FeCl 3 The molar ratio is 1:2, NH 3 ·H 2 O-NH 4 NO 3 The molar ratio is 4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com