Beneficiation method for recycling extremely-low-grade iron and fluorite resources in iron-containing surrounding rock

A beneficiation method and resource recovery technology, which are applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problem of inability to recover extremely low-grade iron and fluorite resources, and achieve significant energy saving, consumption reduction, and effect. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

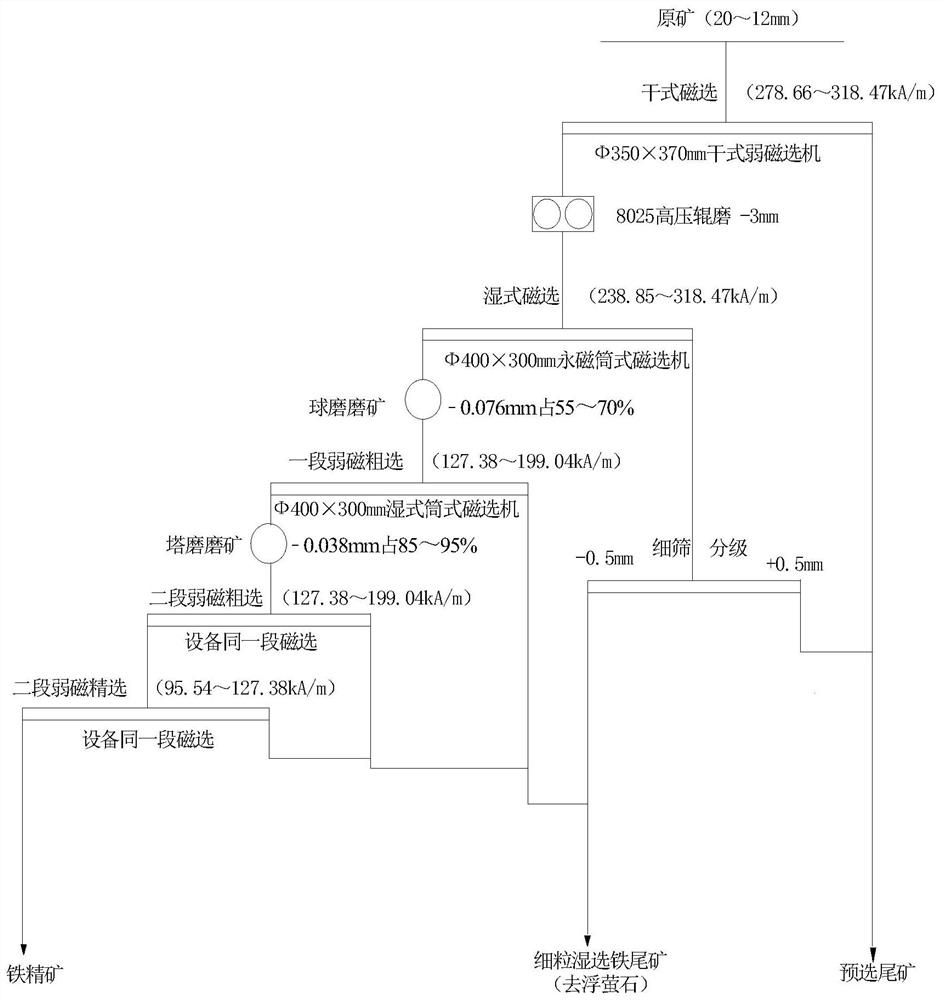

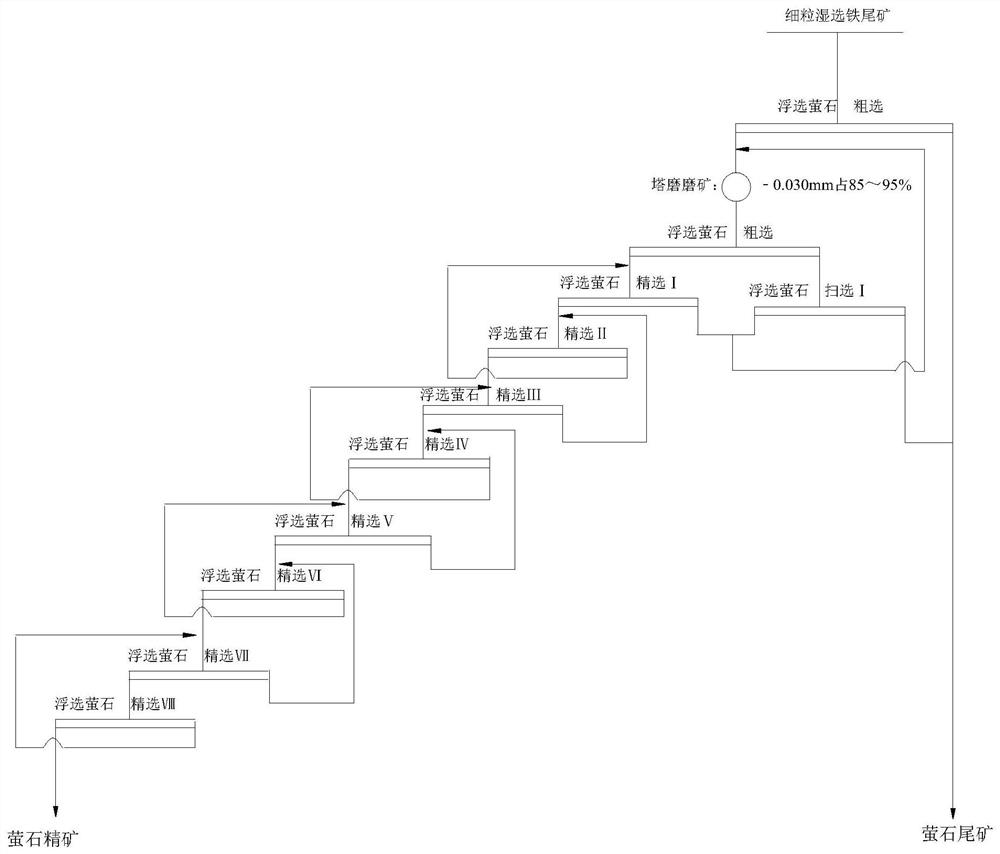

[0030] In order to describe the present invention, the beneficiation method for recovery of extremely low-grade iron and fluorite resources in iron-bearing surrounding rocks of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0031] The research object is the iron-bearing surrounding rock of an iron mine dump in China, which is used as the raw ore. The results of ore chemical multi-element analysis are shown in Table 1, and the results of iron phase analysis are shown in Table 2.

[0032] Table 1 raw ore chemical multi-element analysis results (%)

[0033] element TF mFe CaO MgO SiO 2

al 2 o 3

MnO K Na 2 o

content 13.31 5.75 18.06 8.09 17.86 5.14 2.35 1.84 1.06 element S P CuO TiO 2

ZnO CaF 2

BaO content 0.86 0.48 0.01 0.59 0.16 7.83 1.31

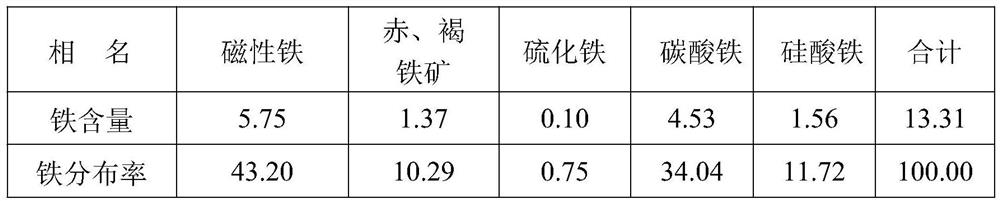

[0034] Table 2 Raw ore iron phase analysis results (%)

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com