Chemical imidization preparation method of nano rectorite/polyimide film

A technology of polyimide film and chemical imidization, which is applied in the field of preparation of nano-laminated stone/polyimide film, can solve the problems of poor dispersion of nano-clay and unstable film-forming performance of thermal imidization, etc. Achieve low dimensional stability, improve isotropy, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

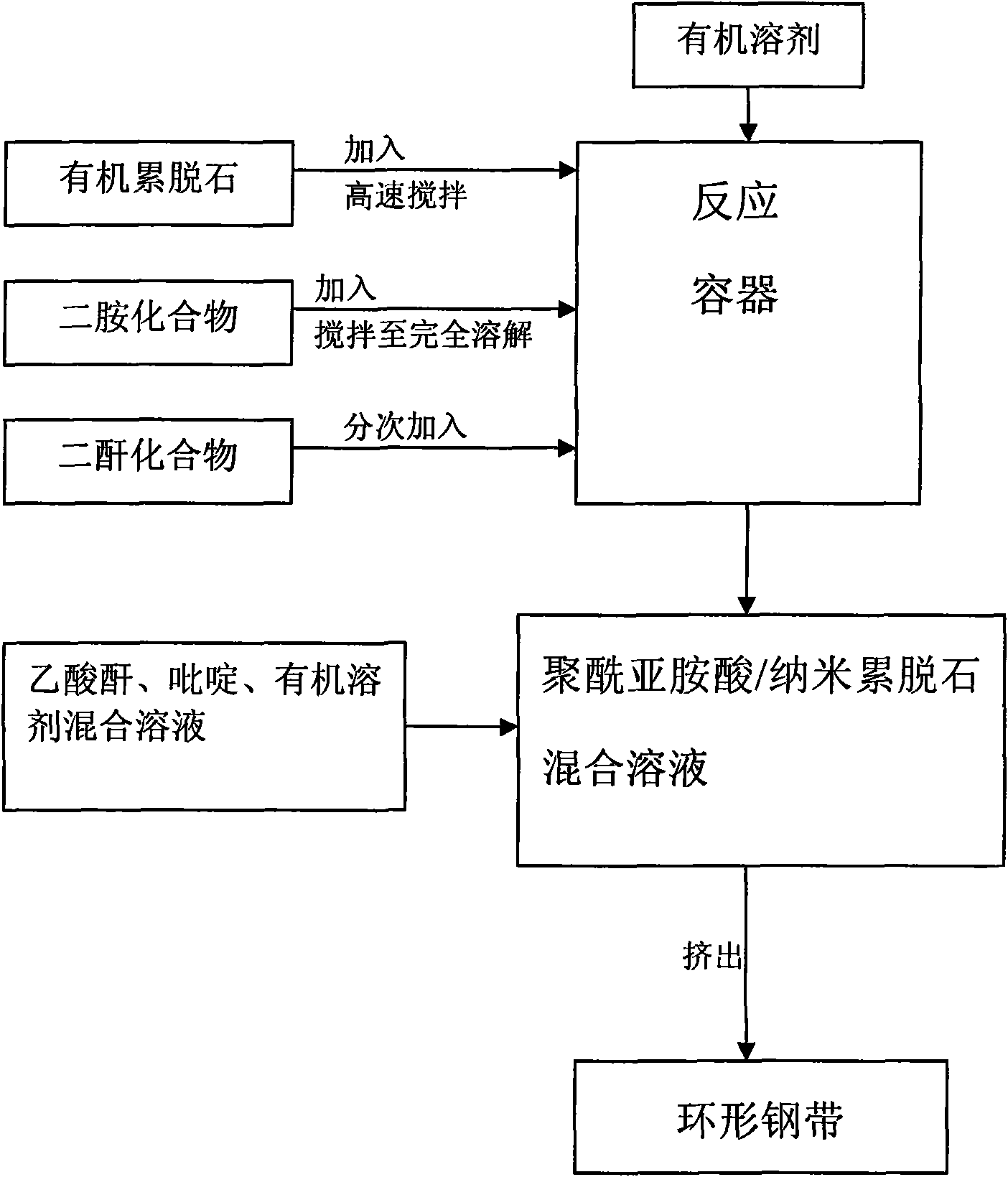

Method used

Image

Examples

Embodiment 1

[0034] (1) The formulation of the components used in the preparation of nanometer calcite / polyimide film in this embodiment is as follows:

[0035] Nano Latex 2 parts

[0036] 4,4'-diaminodiphenyl ether 6 parts

[0037] 3 parts p-phenylenediamine

[0038] 5 parts pyromellitic dianhydride

[0039] 11 parts of acetic anhydride

[0040] 6 parts of pyridine

[0041] 67 parts of N,N-dimethylformamide.

[0042] (2) Preparation of nanometerite: soak 20 parts of stone in 1000 parts of deionized water to obtain the slurry of stone, add 10 parts of organic modifier, organic modifier is GS14-3-14, in Stirring and reacting at 90° C. for 9 hours, suction filtration and drying to obtain organically modified nano-pearlite.

[0043](3) The manufacture method of the nanometer calcite / polyimide film is: weigh each component according to the formula amount, and divide the solvent N,N-dimethylformamide into two parts. Add a portion of solvent N,N-dimethylformamide into the reaction vessel,...

Embodiment 2

[0045] (1) The formulation of the components used in the preparation of nanometer calcite / polyimide film in this embodiment is as follows:

[0046] 5 parts of organic Latex

[0047] 15 parts of diamino-p-phenylene ether

[0048] Dibenzoic acid ketone dianhydride 10 parts

[0049] 10 parts of acetic anhydride

[0050] Propionic anhydride 5 parts

[0051] 2 parts pyridine

[0052] 53 parts of N,N-dimethylformamide.

[0053] Preparation of nano-randolith: Soak 15 parts of rentonite in 1000 parts of deionized water to obtain rentonite slurry, add 10 parts of organic modifier, the organic modifier is GS12-4-12, at 60 ° C , stirred and reacted for 10 hours, and dried with suction to obtain organically modified nano-plastite.

[0054] (3) The manufacture method of the nanometer calcite / polyimide film is: weigh each component according to the formula amount, and divide the solvent N,N-dimethylformamide into two parts. Add a portion of solvent N,N-dimethylformamide into the reac...

Embodiment 3

[0057] (1) The formulation of the components used in the preparation of nanometer calcite / polyimide film in this embodiment is as follows:

[0058] 3 servings of organic Latex

[0059] Diaminodiphenyl ether 5 parts

[0060] 15 parts of pyromellitic dianhydride

[0061] Butyric anhydride 10 parts

[0062] Pyridine 8 parts

[0063] 59 parts of N,N-dimethylformamide.

[0064] The preparation of nanometerite: Soak 20 parts of mentionite in 1000 parts of deionized water to obtain mentionite slurry, add 10 parts of organic modifier, the organic modifier is GS16-4-16, at 80 ℃ , stirred and reacted for 9 hours, and was dried by suction filtration to obtain organically modified nano-plastite.

[0065] (3) The manufacture method of the nanometer calcite / polyimide film is: weigh each component according to the formula amount, and divide the solvent N,N-dimethylformamide into two parts. Add a portion of solvent N,N-dimethylformamide into the reaction vessel, then add nanometer calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com