Succinonitrile-based electrolyte coupled with organic lithium salt and fluoroethylene carbonate as well as preparation method and application of electrolyte

A fluoroethylene carbonate and organolithium technology, applied in the field of lithium ion batteries, can solve problems such as metal lithium incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

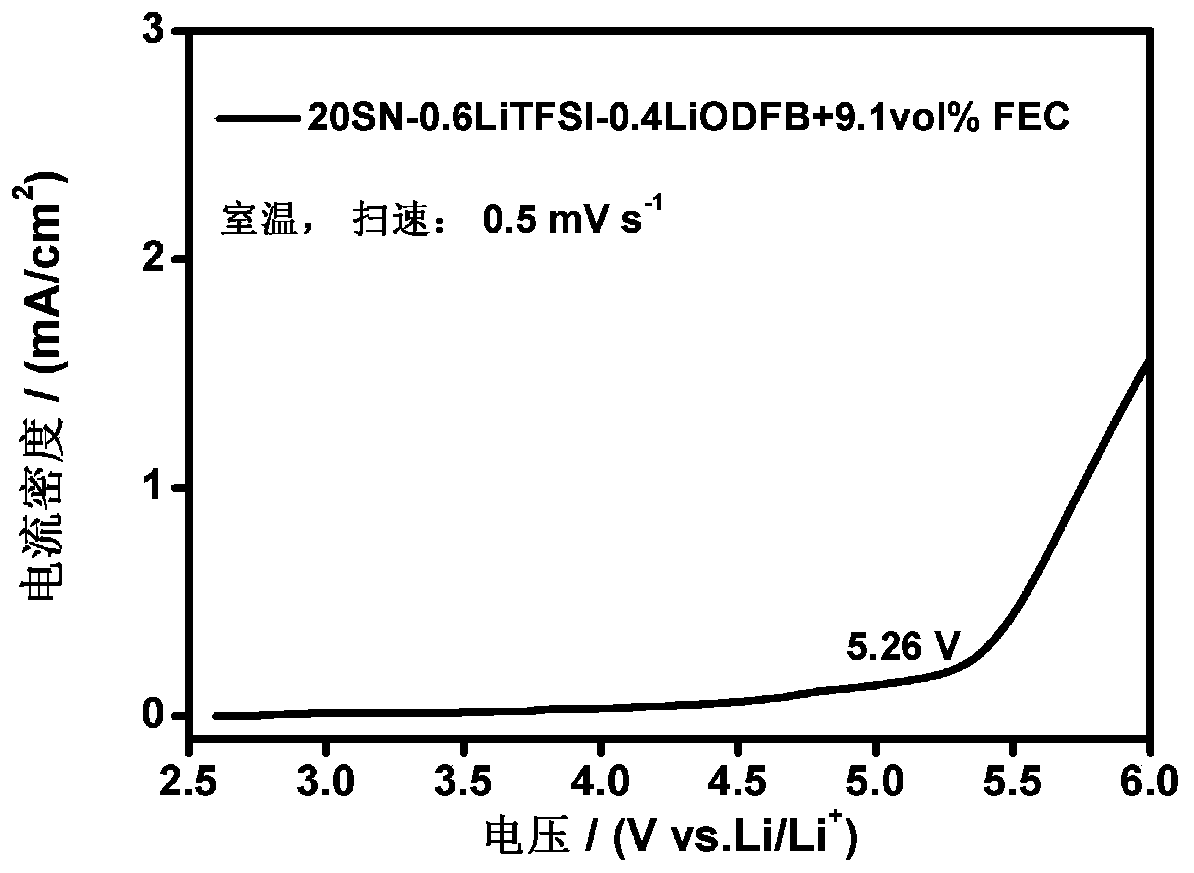

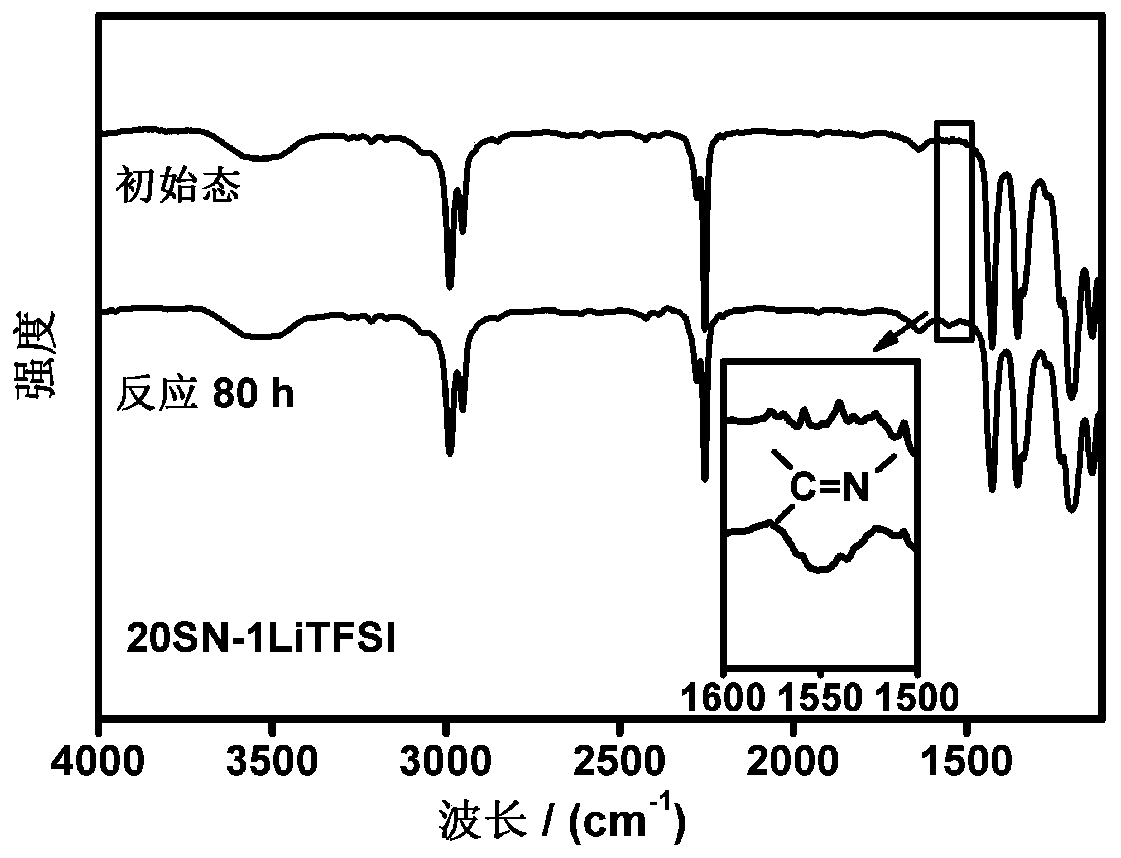

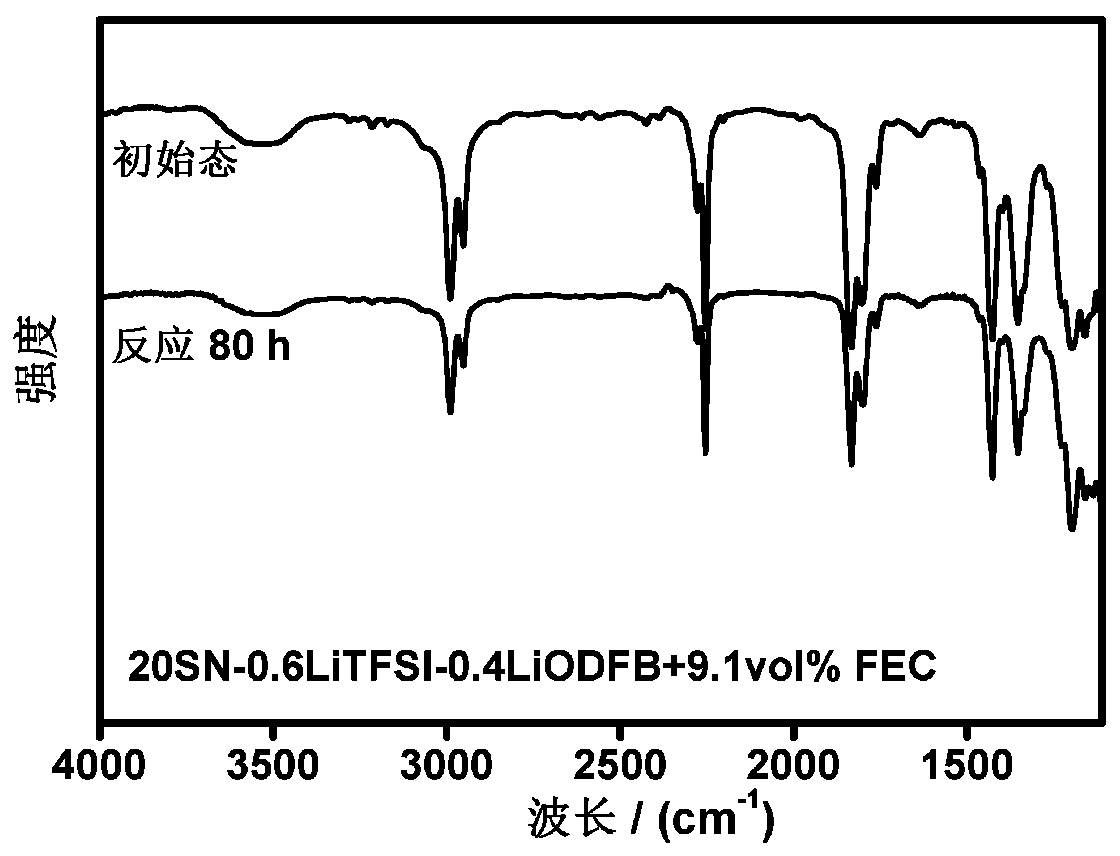

[0027] A succinonitrile-based electrolyte coupling organic lithium salt and fluoroethylene carbonate, comprising succinonitrile, organic lithium salt and fluoroethylene carbonate, wherein the molar ratio of succinonitrile to organic lithium salt is 100:1 ~1:1, organolithium salt is a combination of lithium sulfonylimide salt and lithium difluorooxalate borate, wherein the molar ratio of lithium sulfonylimide salt to lithium difluorooxalate borate is 100:1~1:1 The fluoroethylene carbonate accounts for 5%-50% of the total volume percentage of the succinonitrile-based electrolyte.

[0028] Preferably, the molar ratio of succinonitrile to organic lithium salt is 20:1˜5:1.

[0029] Preferably, the molar ratio of the lithium sulfonylimide salt to lithium difluorooxalate borate is 50:1˜1:1.

[0030] Preferably, the lithium sulfonylimide salt is at least one of lithium bistrifluoromethylsulfonimide LiTFSI and lithium bisfluorosulfonimide LiFSI.

specific Embodiment approach 2

[0032] The preparation method of the succinonitrile-based electrolyte of coupling organic lithium salt and fluoroethylene carbonate described in the specific embodiment one, comprises the following steps:

[0033] Step 1. Mix succinonitrile and organic lithium salt according to the molar ratio, and stir at 60-80°C until the lithium salt is fully dissolved to obtain mixture A;

[0034] Step 2: Add fluoroethylene carbonate to the mixture A according to volume percentage, stir and mix evenly at 60-80° C. to obtain a succinonitrile-based electrolyte coupling organic lithium salt and fluoroethylene carbonate.

specific Embodiment approach 3

[0036] A lithium metal battery, comprising the succinonitrile-based electrolyte coupling organic lithium salt and fluoroethylene carbonate described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com