Patents

Literature

167results about How to "Improved high-magnification performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

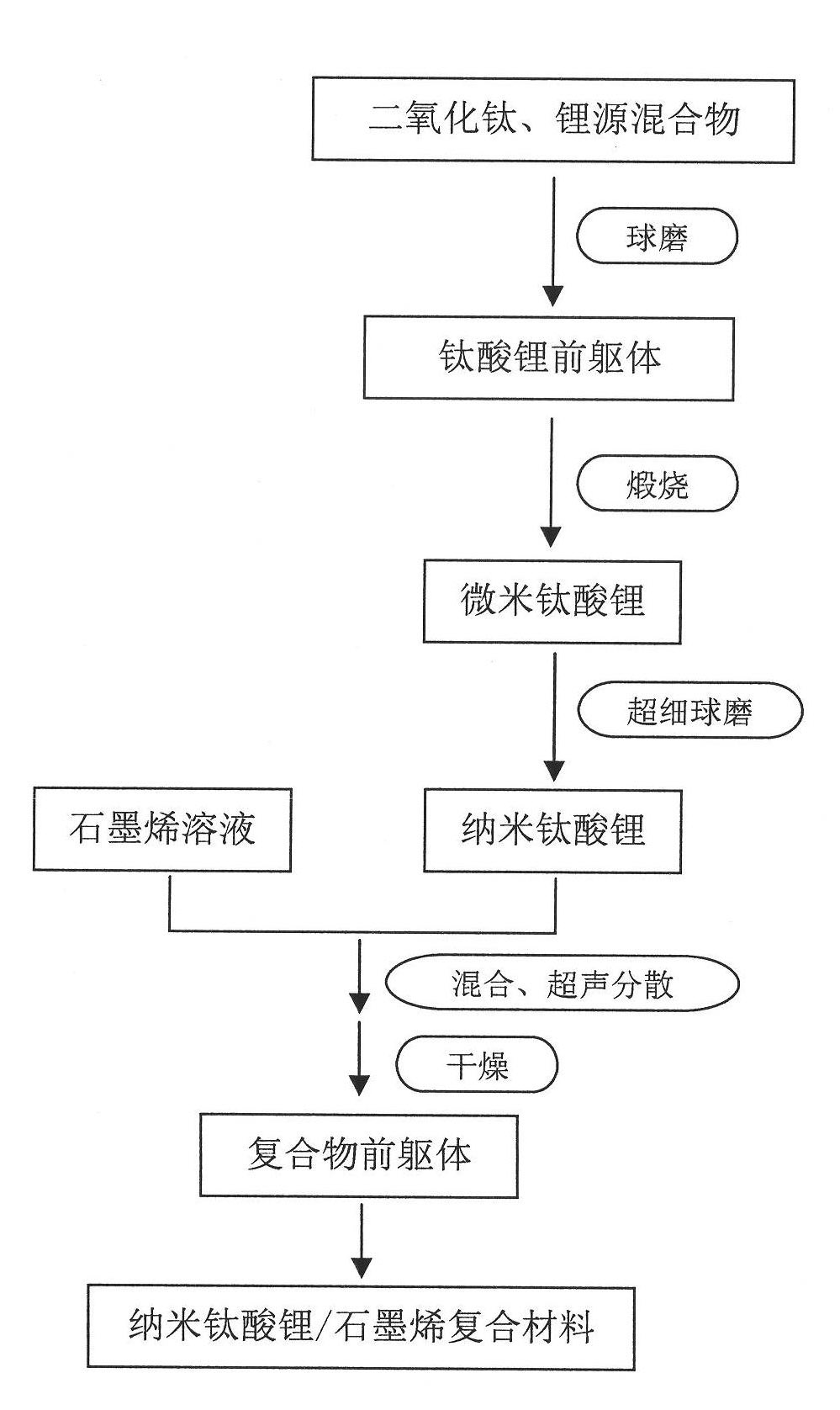

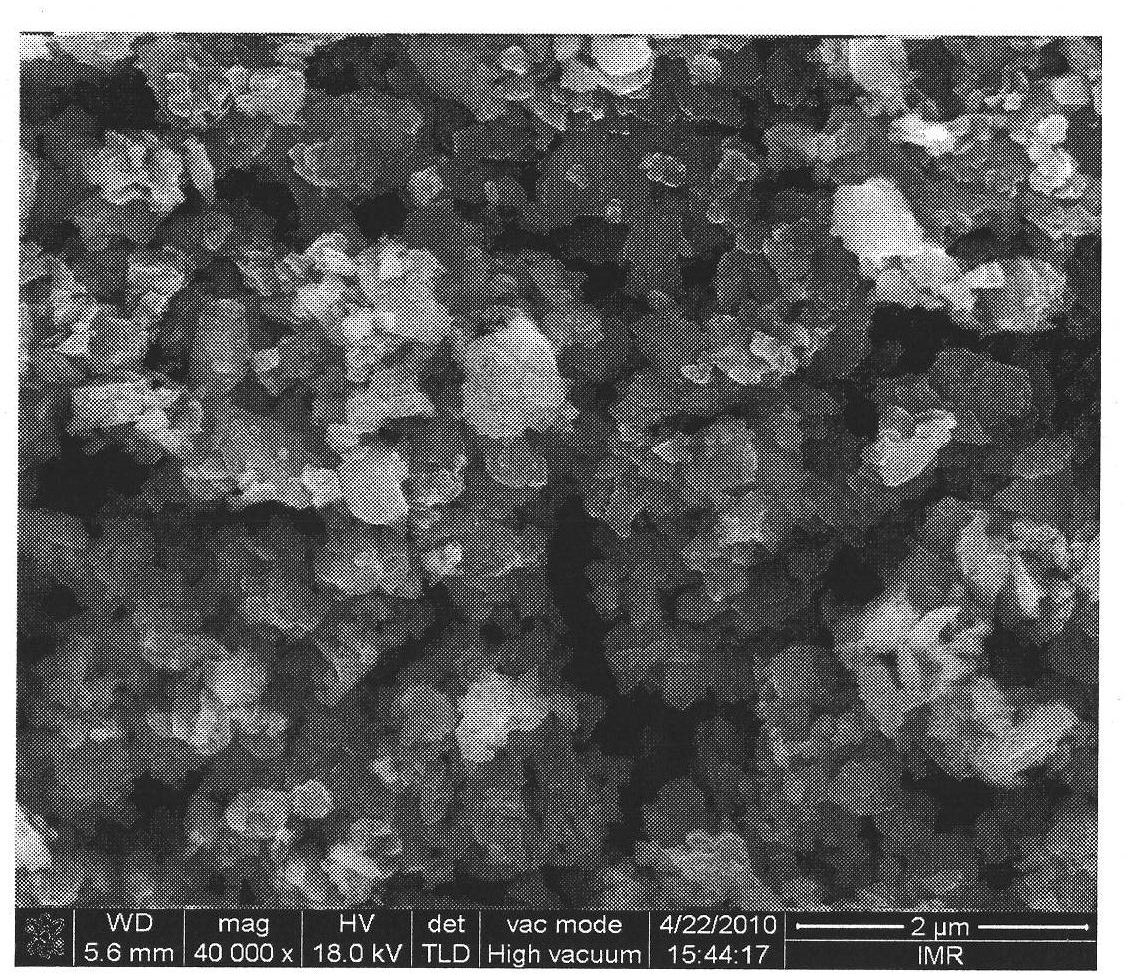

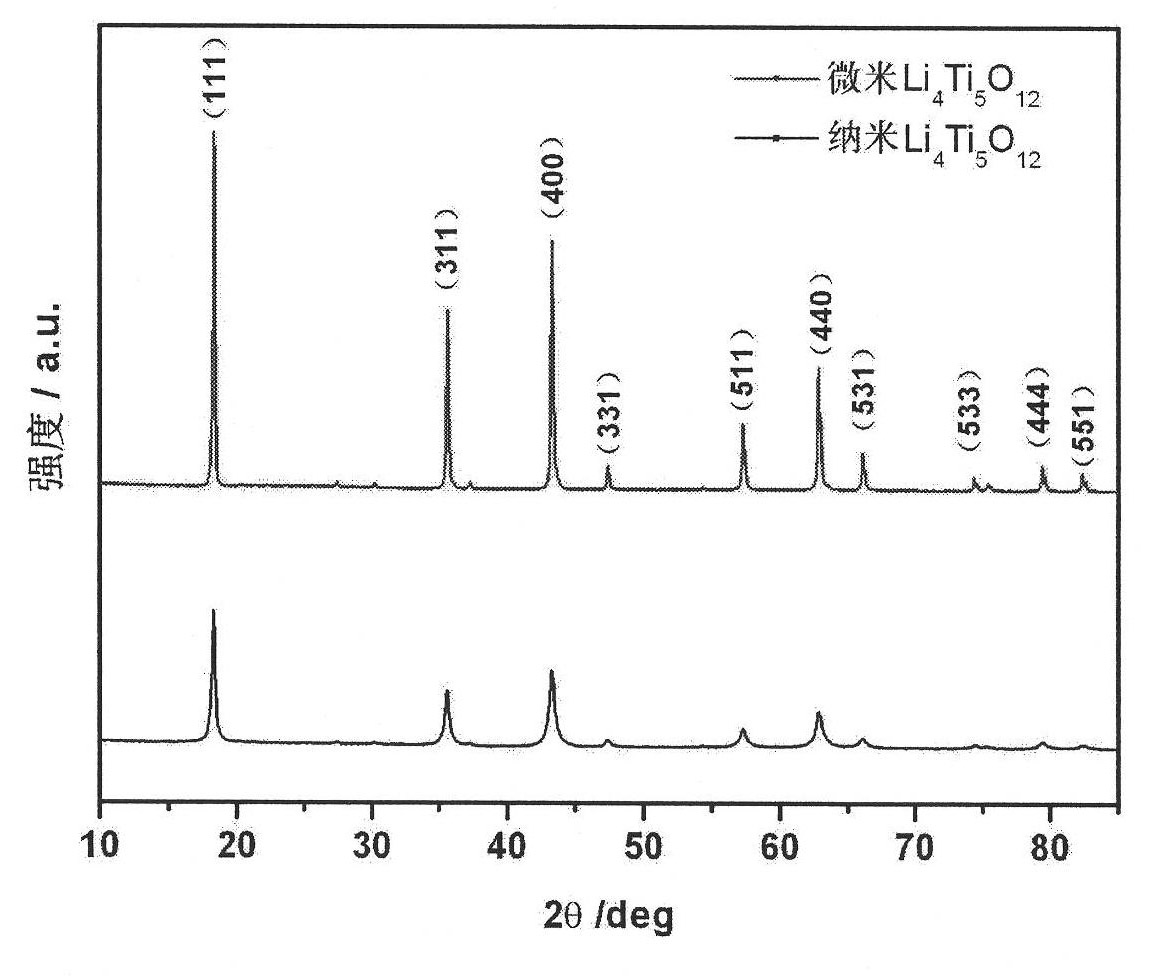

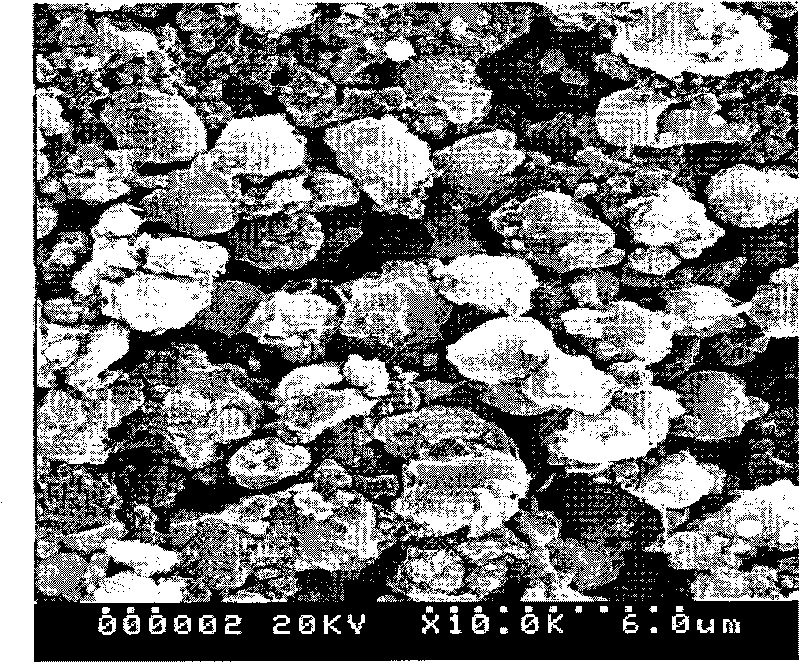

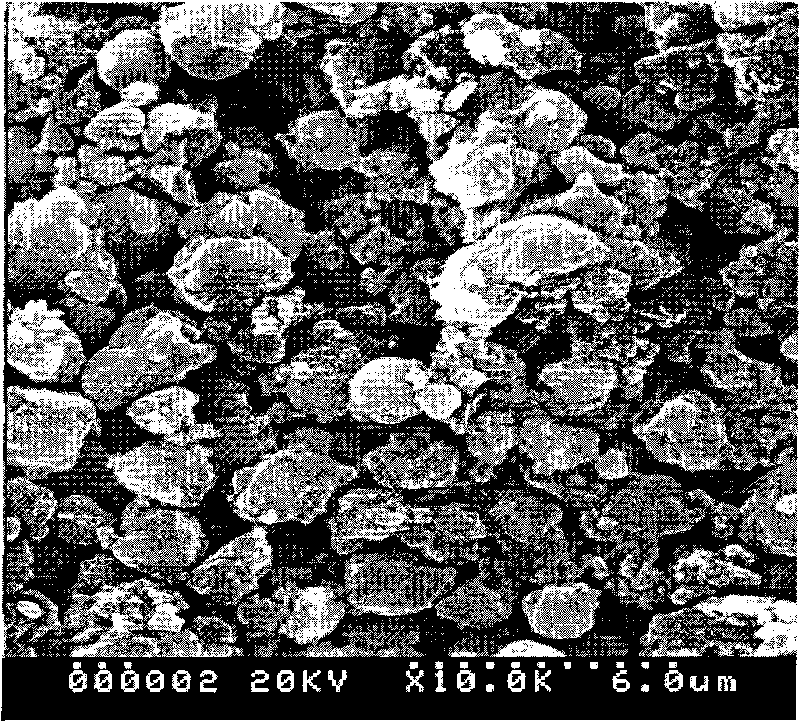

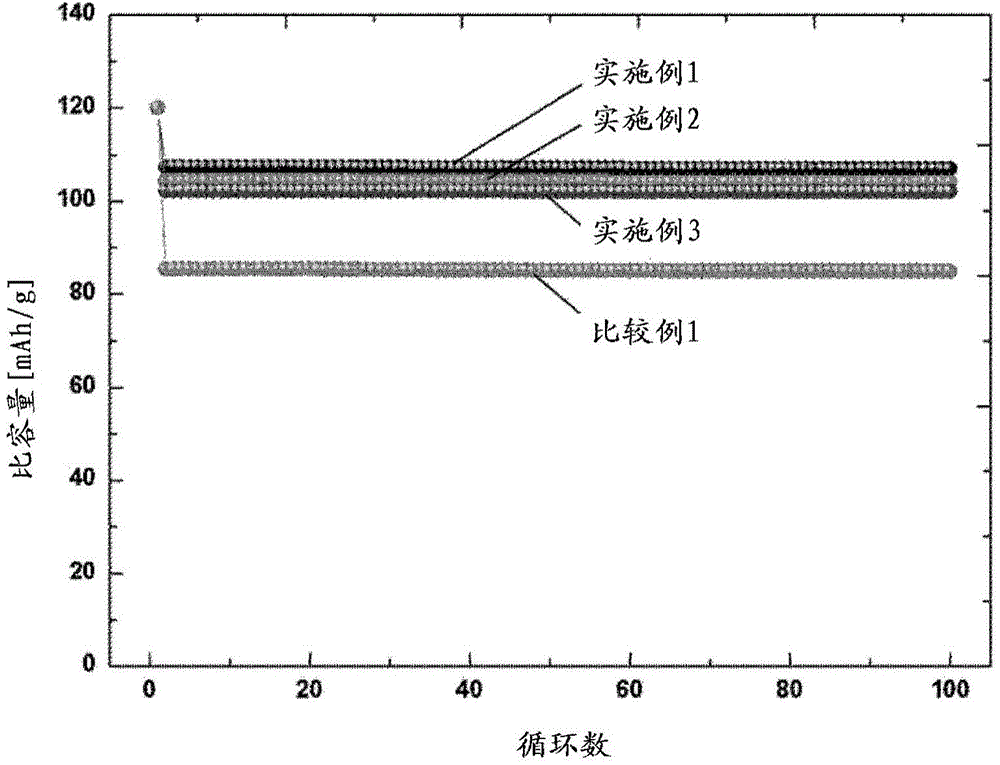

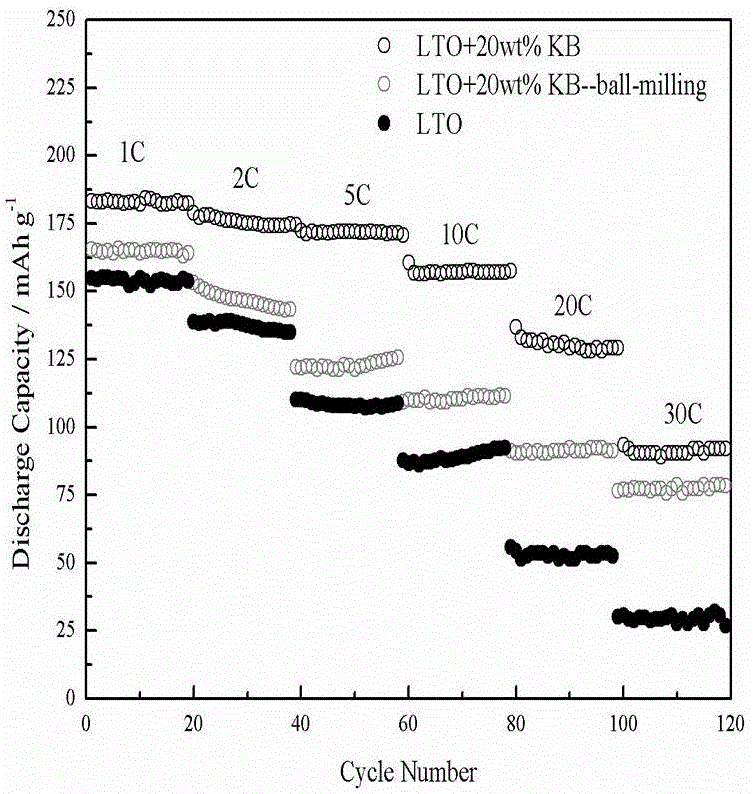

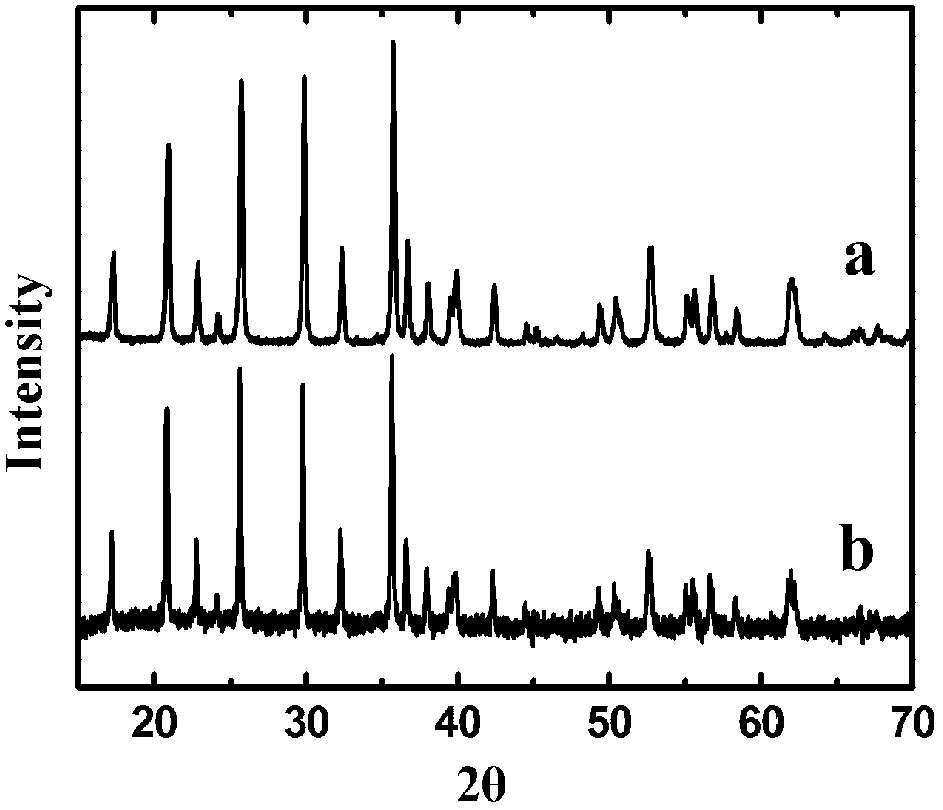

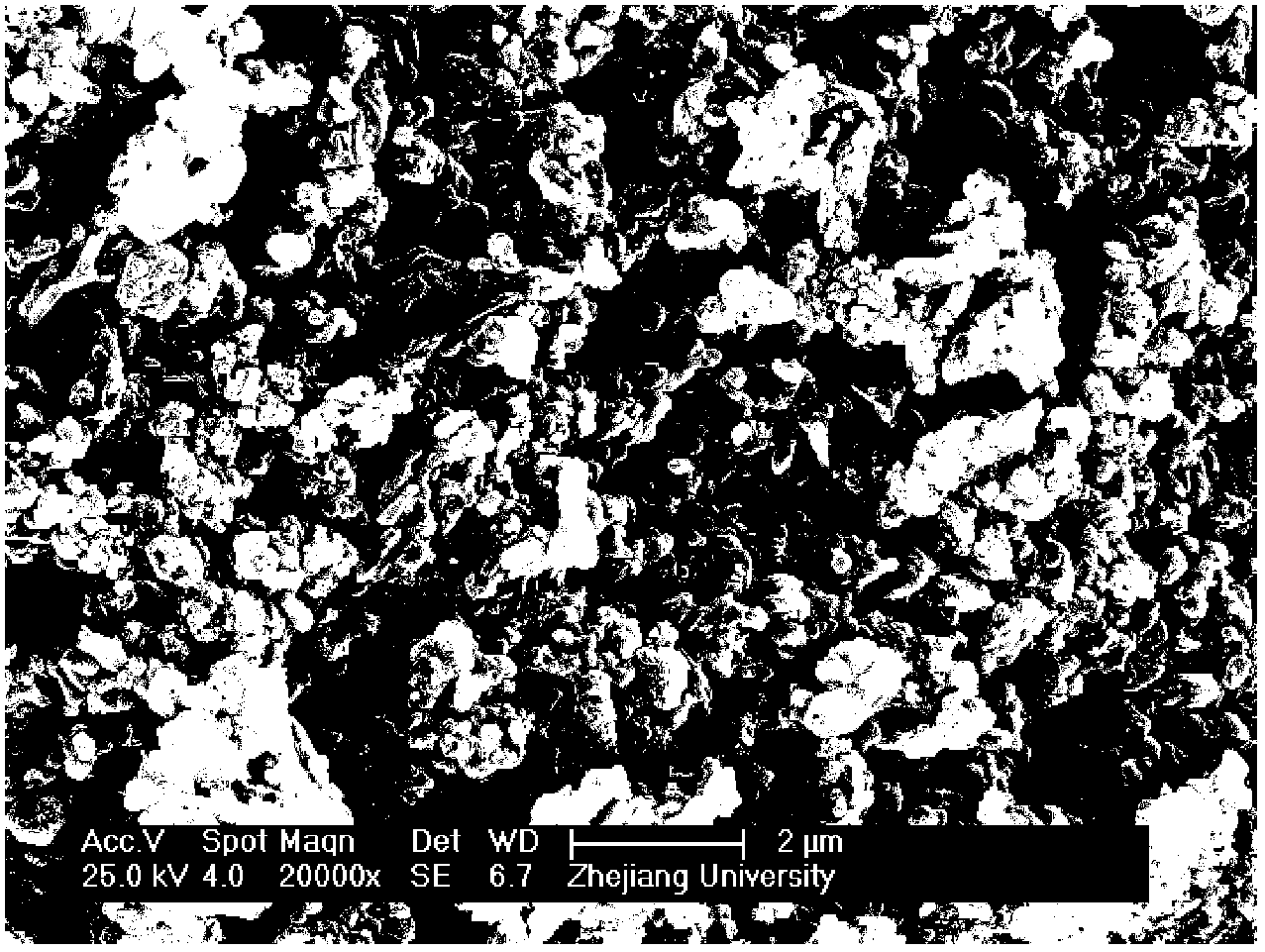

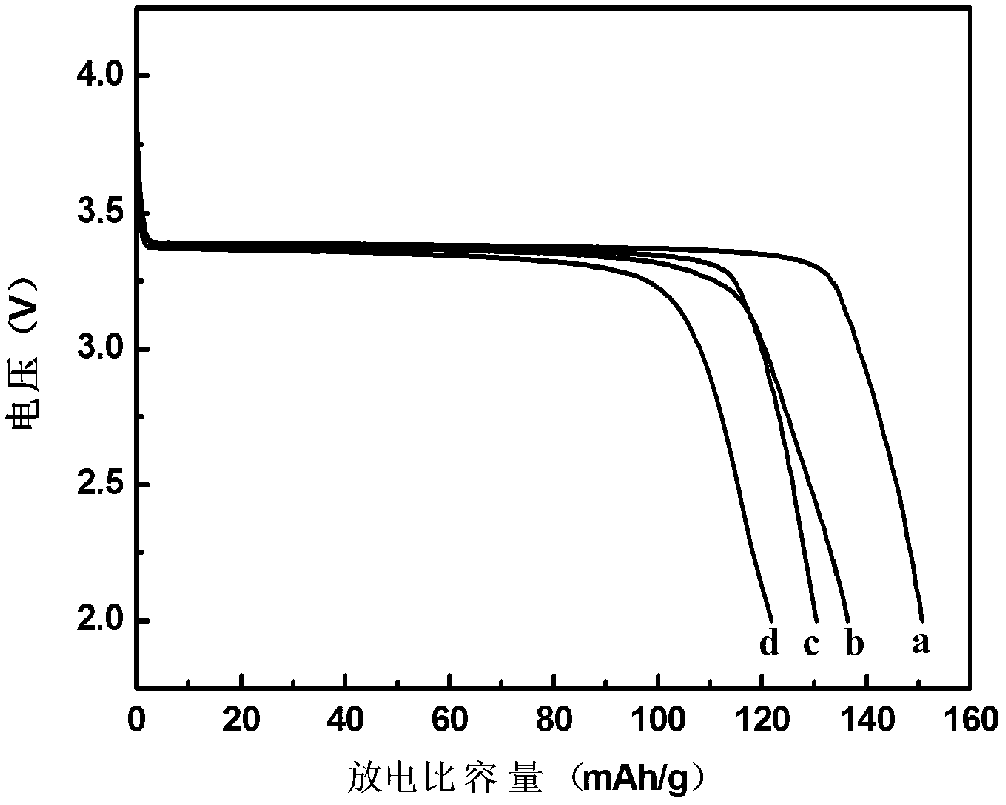

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

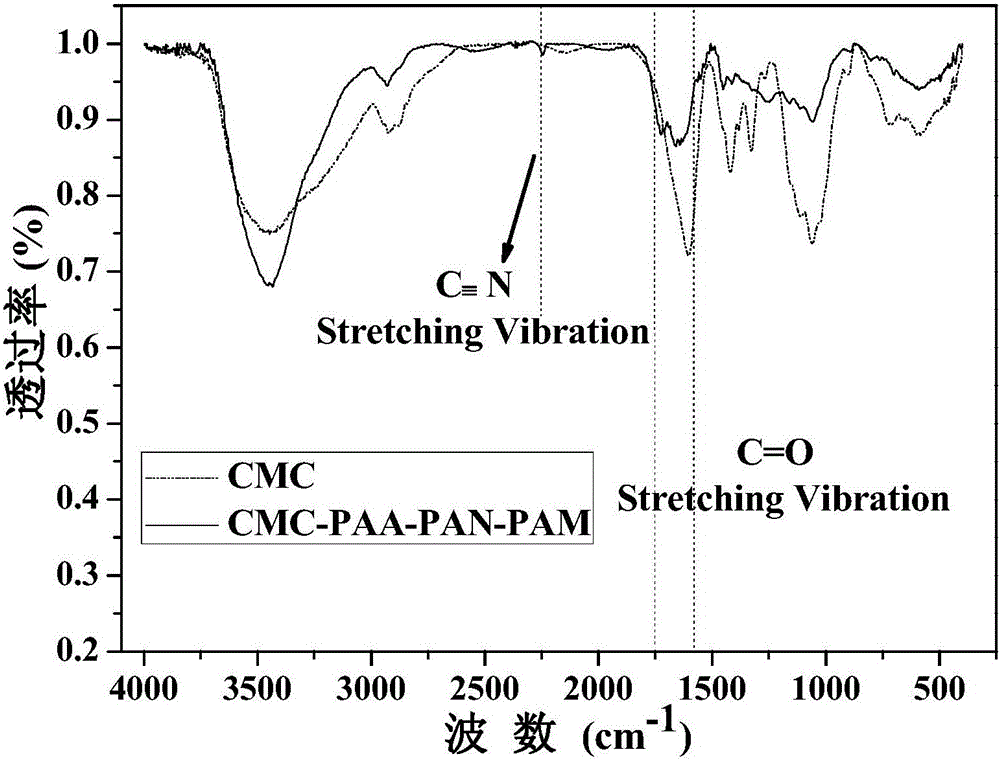

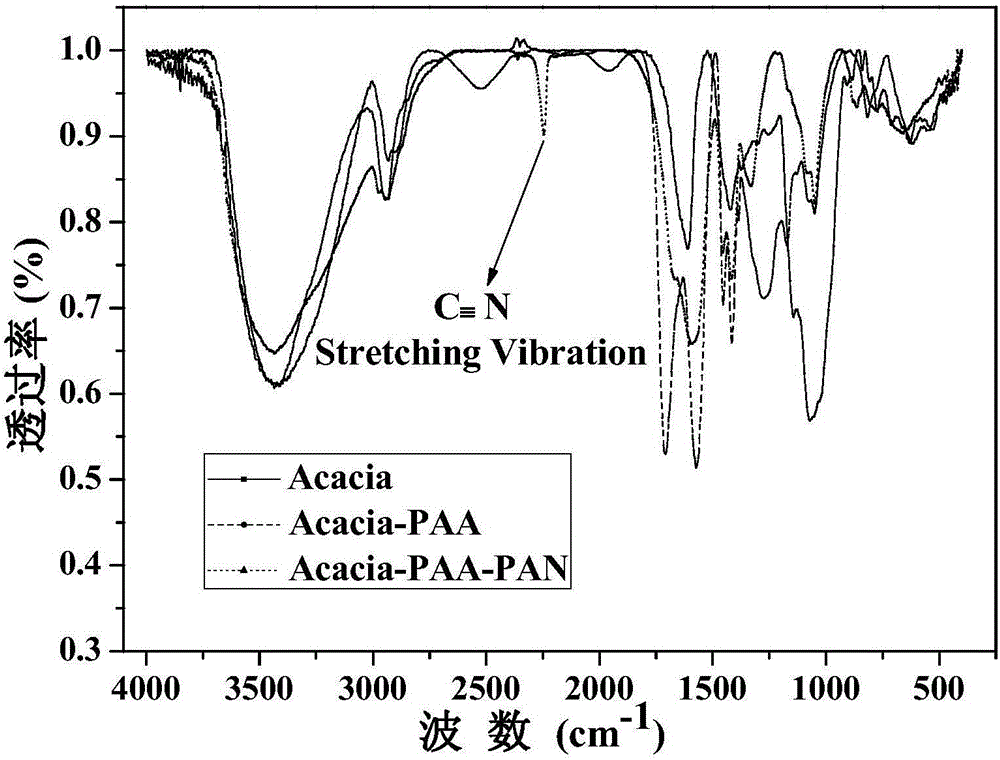

Multielement functional modified polymer binder for lithium ion battery and application of binder in electrochemical energy storage device

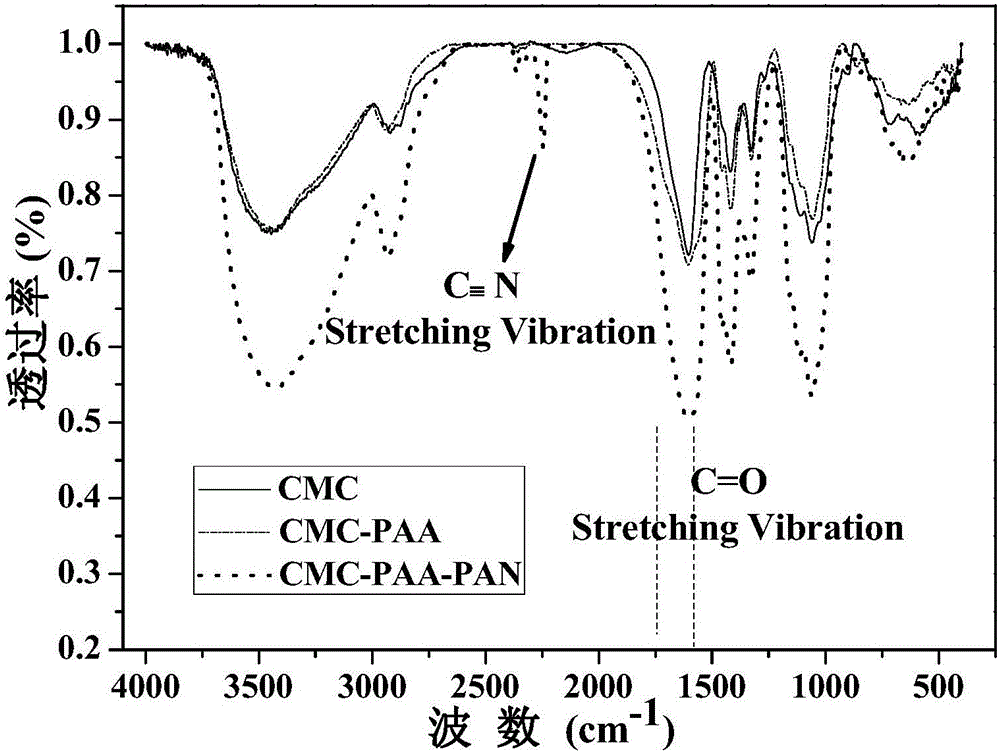

ActiveCN105914377AStable and uniform qualityGood overall performanceCyclodextrin adhesivesCellulose derivative adhesivesBiomassAddition reaction

The invention discloses a multielement functional modified binder for a polymer lithium ion battery. The binder takes a biomass polymer or a synthetic polymer as the substrate, takes a hydrophilic monomer and an oleophilic monomer as the functional modified monomer; and then the binder is prepared through a free radical graft copolymerization reaction or a Michael addition reaction in a modification manner. The binder has a multi-branch structured three-dimensional space network body, so that more active sites in contact with the electrode active material can be provided, and the uniformity and the smoothness of the electrode slurry in film-forming can be improved; the peeling strength of the active materials and the conductive agent on the metal substrate is reinforced; and meanwhile, the binder is excellent in elasticity and binding force, can be applied to water / organic solvent and can be applied to the positive electrode and negative electrode of the lithium ion battery; the conduction of electrons / ions in the charging-discharging process can be promoted; the electrochemical interface impedance of the pole piece is lowered; the high rate capacity and the cycling stability of the positive electrode material and the negative electrode material of the lithium battery are relatively improved; in addition, the synthetic raw material is wide in source, so that the cost can be obviously lowered; and therefore, the binder has a wide market prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

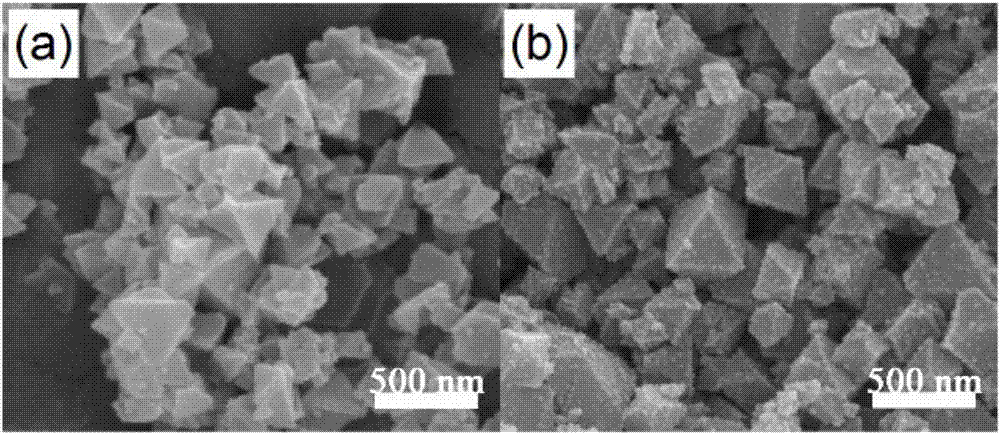

Surface modified lithium ion battery anode material and preparation method thereof

InactiveCN104600282AImprove the first charge and discharge efficiencyImprove cycle lifeCell electrodesOxide coatingSurface modification

The invention discloses a surface modified lithium ion battery anode material and a preparation method thereof. The preparation method comprises the following steps: (1) fully mixing a lithium ion battery anode material with one or more types of metal acetates; (2) heating the mixture obtained in the step (1) to a temperature 1 to ensure that the low-melting-point acetate in the mixture reaches a molten or co-molten state, and complete infiltration and complete coating are realized on the surface of the anode material; and (3) further heating to a temperature 2 to ensure that the metal acetate coating layer on the surface of the anode material is decomposed into a metal oxide coating layer and metal ions are diffused to the inside of the material to form a doped modified layer, thereby obtaining the surface modified lithium ion battery anode material. According to the preparation method disclosed by the invention, the melting and uniform coating of the metal acetates on the surface of the anode material are realized, the metal acetate coating layer is decomposed and converted into the oxide coating layer and is diffused to form the surface doped modified layer, the process is simple, the cost is relatively low, and the operation is convenient.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

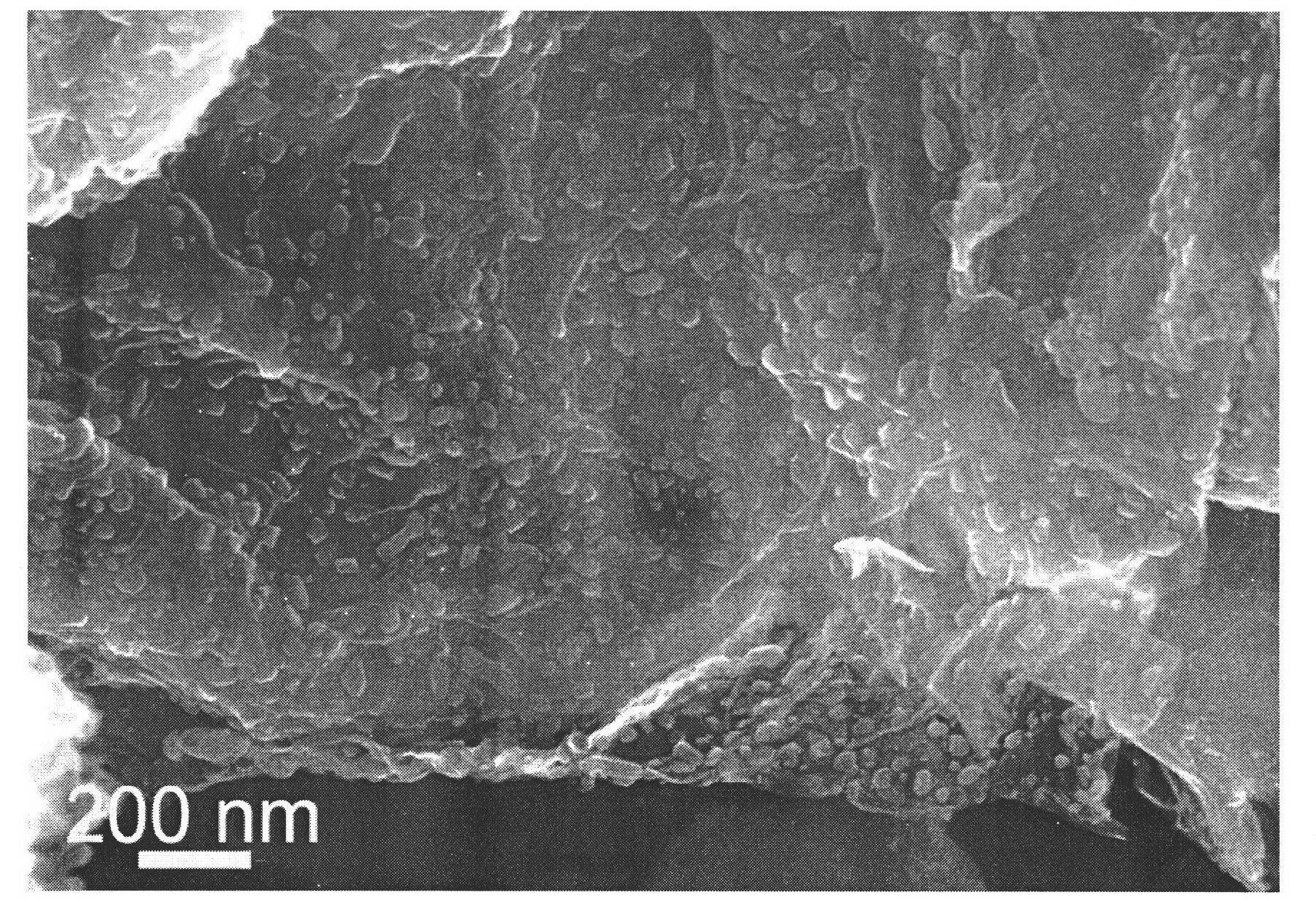

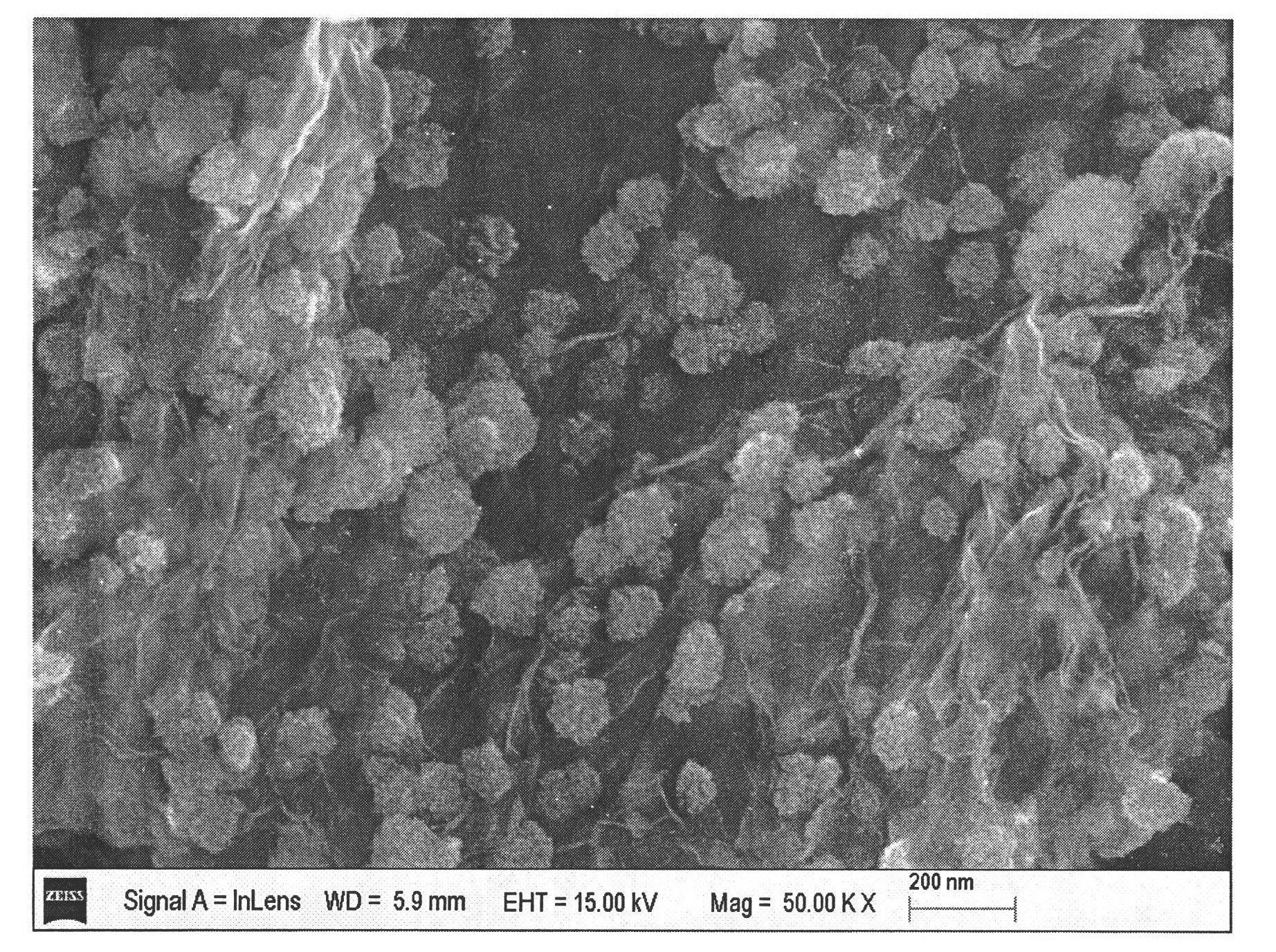

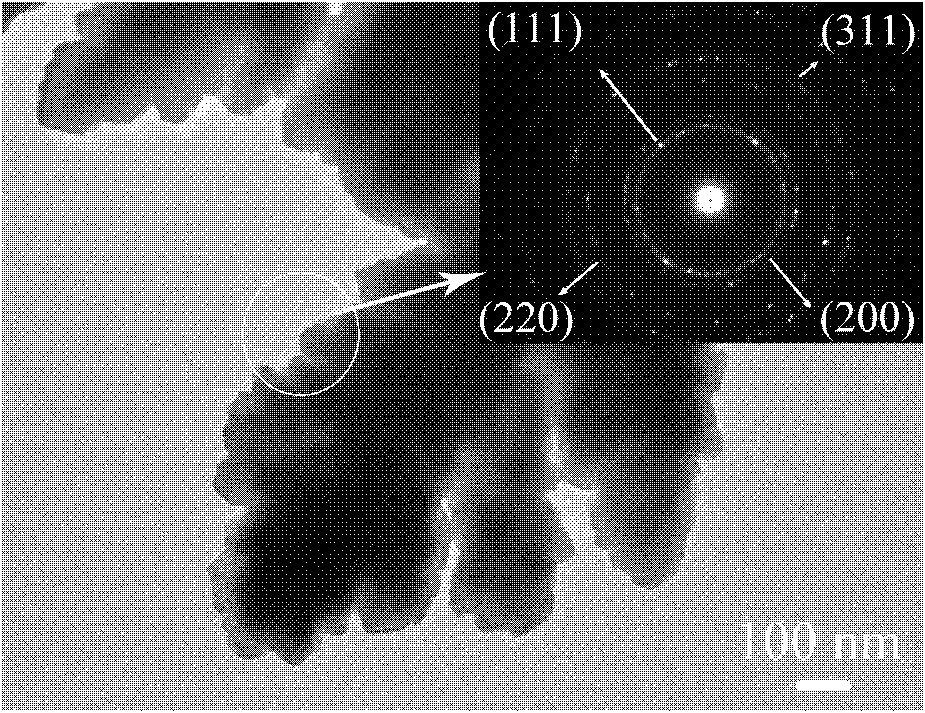

Graphene/transition metal oxide composite cathode material and preparation method thereof

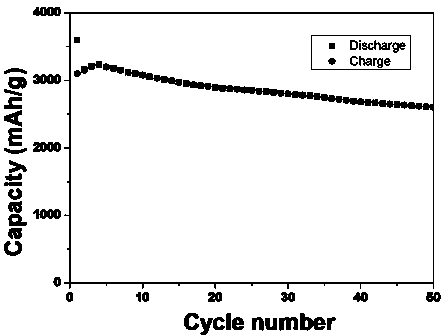

The invention provides a graphene / transition metal oxide composite electrode material applicable to a high-performance lithium ion battery. The diameter range of metal oxide nano particles is 10-100 nm, and the thickness of each graphene nano sheet is 1-20 layers. Metal oxides and the graphene nano sheets are connected by covalent bonds to form a strong interface reaction. The material has good high-rate performance and long-term circulation stability when being used as the cathode material of the lithium ion battery. Meanwhile, the invention also discloses a method for preparing the composite material.

Owner:BEIJING UNIV OF CHEM TECH

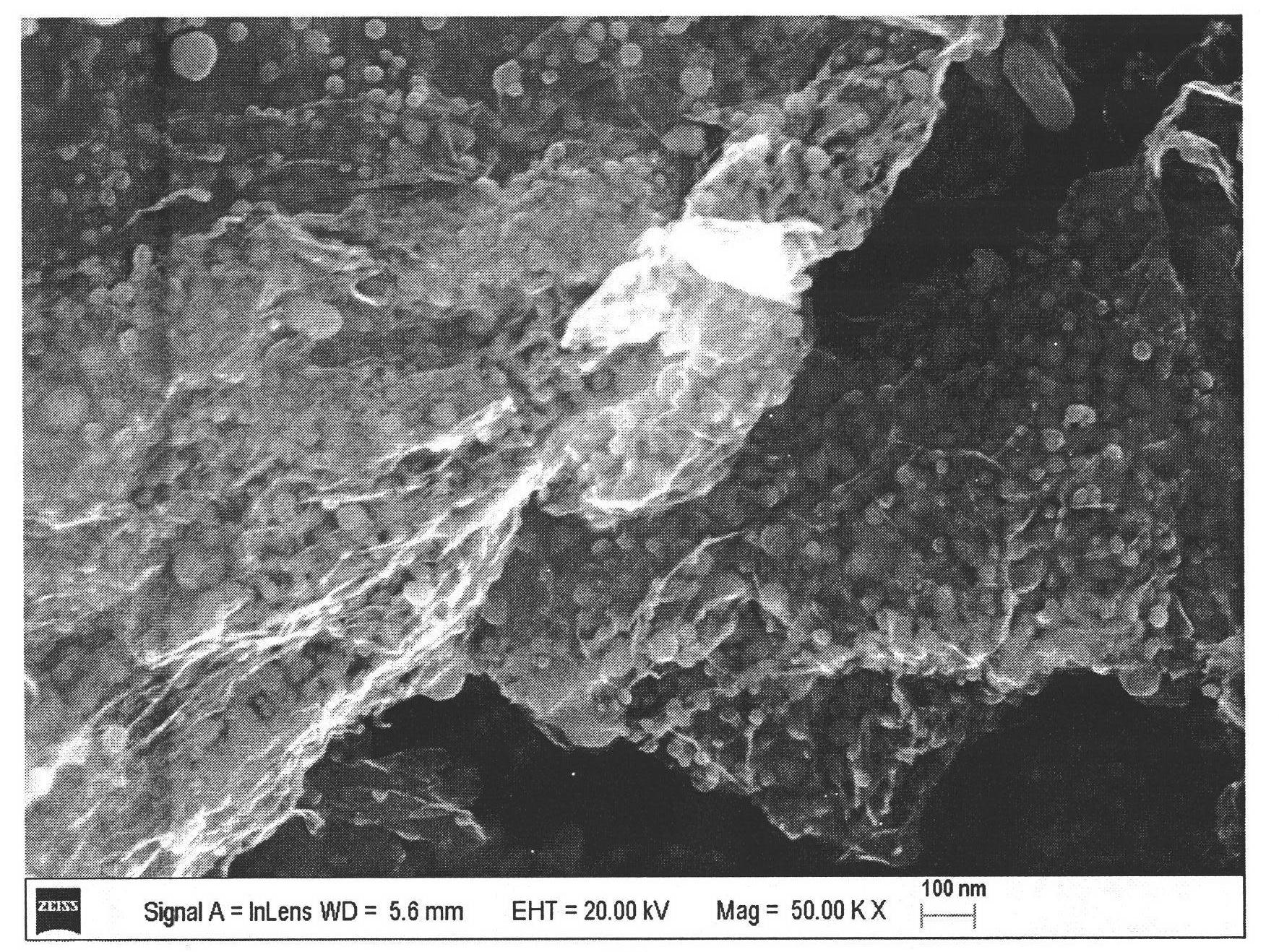

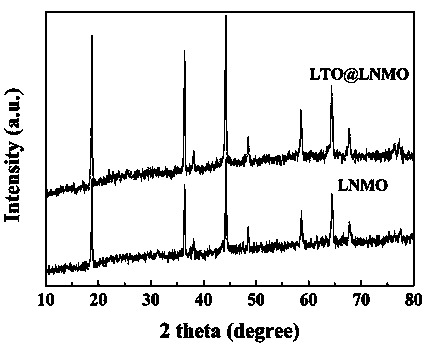

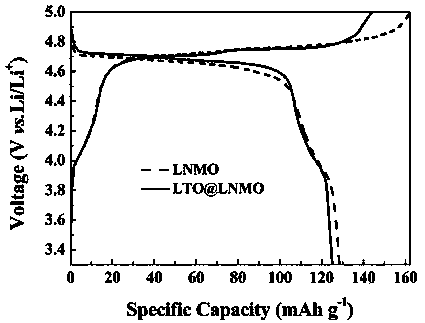

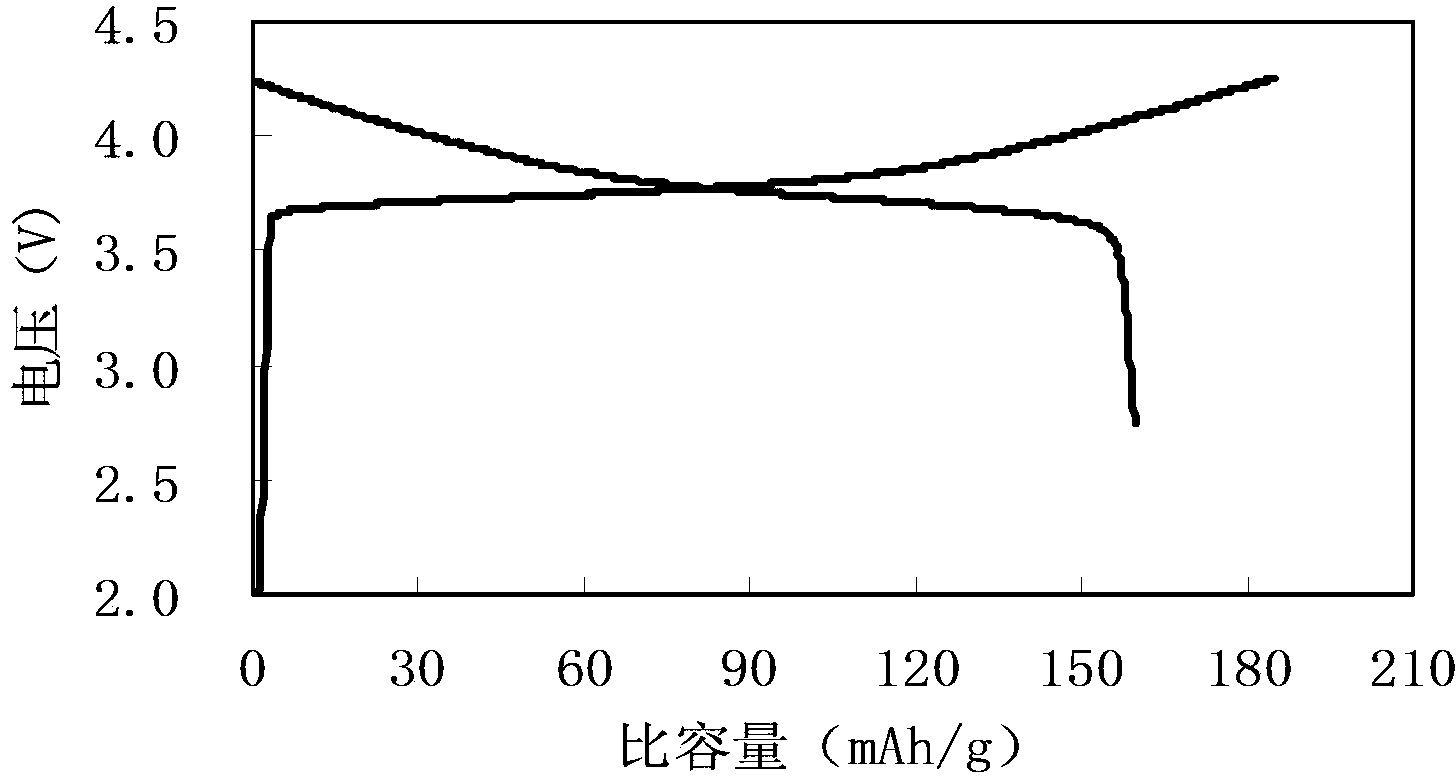

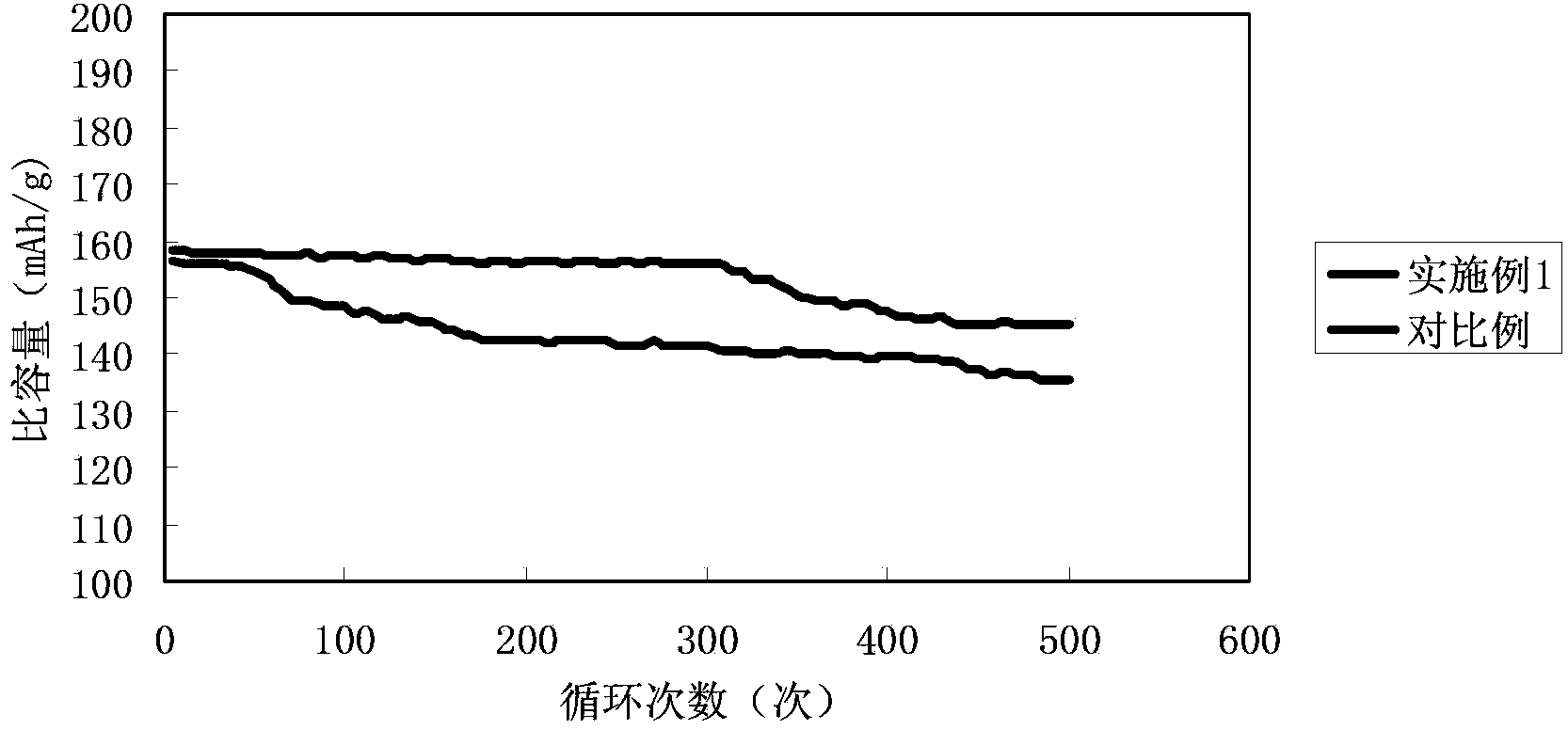

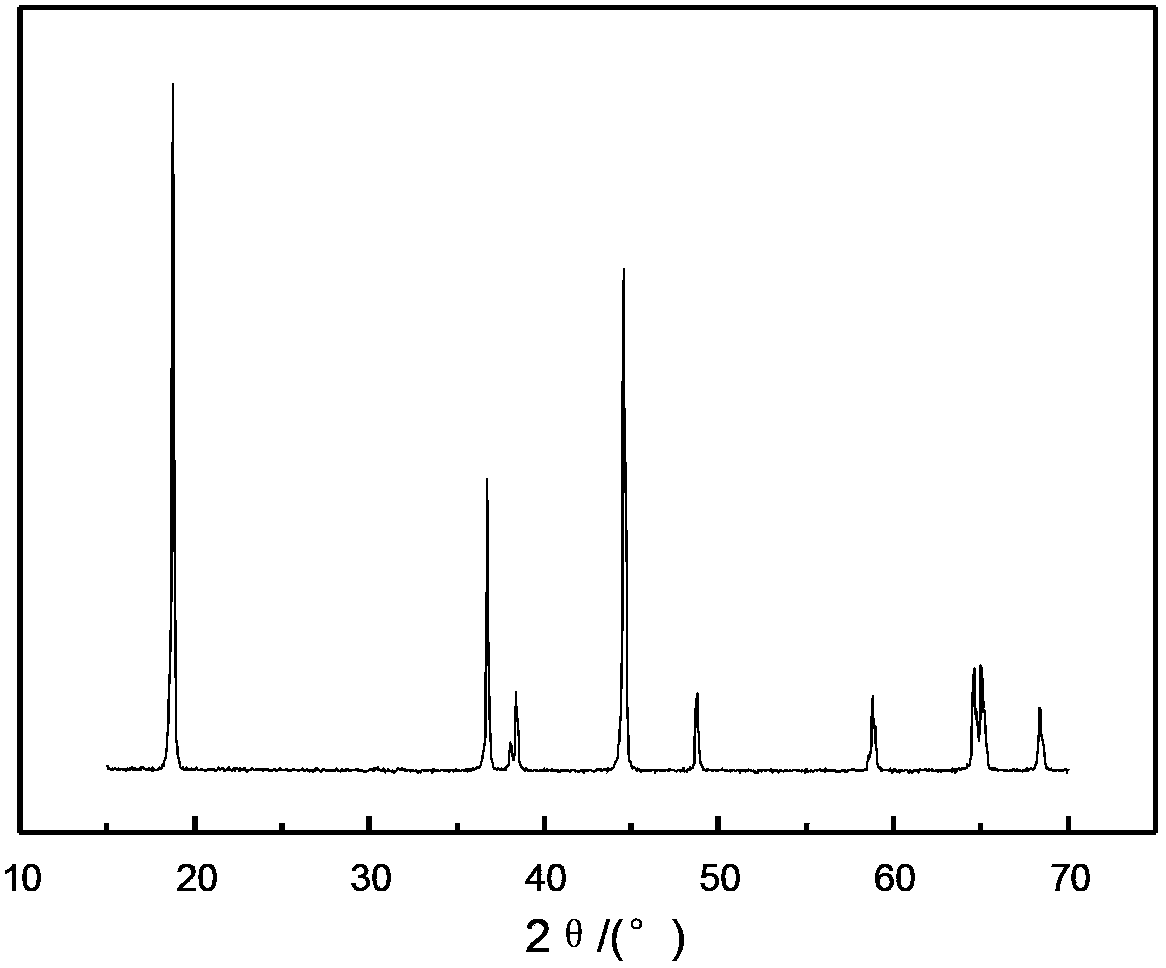

Modified LiNi1/2Mn3/2O4 cathode material prepared by coating with lithium ion conductor Li2MO3 (M=Ti, Si or Zr) and preparation method thereof

ActiveCN103413930ACoated evenlyImproved high temperature cycle stabilityCell electrodesElectrical conductorLithium-ion battery

A modified LiNi1 / 2Mn3 / 2O4 cathode material prepared by coating with lithium ion conductor Li2MO3 (M=Ti, Si or Zr) and a preparation method thereof belong to the technical field of lithium ion battery cathode materials. The coated cathode material in the method is LiNi0.5Mn1.5O4; the chemical constitution of the lithium ion conductor is Li2MO3, wherein M is Ti or Si or Zr; Li2MO3 accounts for 1%-3% of the mass of the coated cathode material. According to the invention, the lithium ion conductor replaces a coating layer, so that the modified cathode material has excellent high-temperature cycling stability and rate capability and can adapt to large-scale production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Polyvinylpyrrolidone modified graphene coated sulfur/porous carbon composite anode material and preparation method thereof

ActiveCN104078685AIncrease contentImprove the utilization rate of active substancesCell electrodesLi-accumulatorsCvd grapheneHigh rate

The invention relates to a polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite anode material and a preparation method thereof, which relates to a sulfur / carbon composite material applied to a lithium-sulfur secondary battery anode material and a preparation method of the composite material, and solves the technical problem of the existing lithium-sulfur battery anode material graphene-coated sulfur-containing composite material that the electrochemical property is low. The polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite material is characterized in that the outer surface of a sulfur / porous carbon composite material particle is uniformly coated with a polyvinylpyrrolidone modified graphene slab layer, a graphene conductive network is formed between every two adjacent particles, and a grading core-shell structure is formed. The preparation method comprises the steps of adding the sulfur / porous carbon composite material into graphene slurry modified by the polyvinylpyrrolidone, and mixing the sulfur / porous carbon composite material with the graphene slurry, and coating the sulfur / porous carbon composite material with the graphene slurry modified by the polyvinylpyrrolidone. The anode material is high in specific capacity, long in cycle life and good in high-rate performance.

Owner:HARBIN INST OF TECH

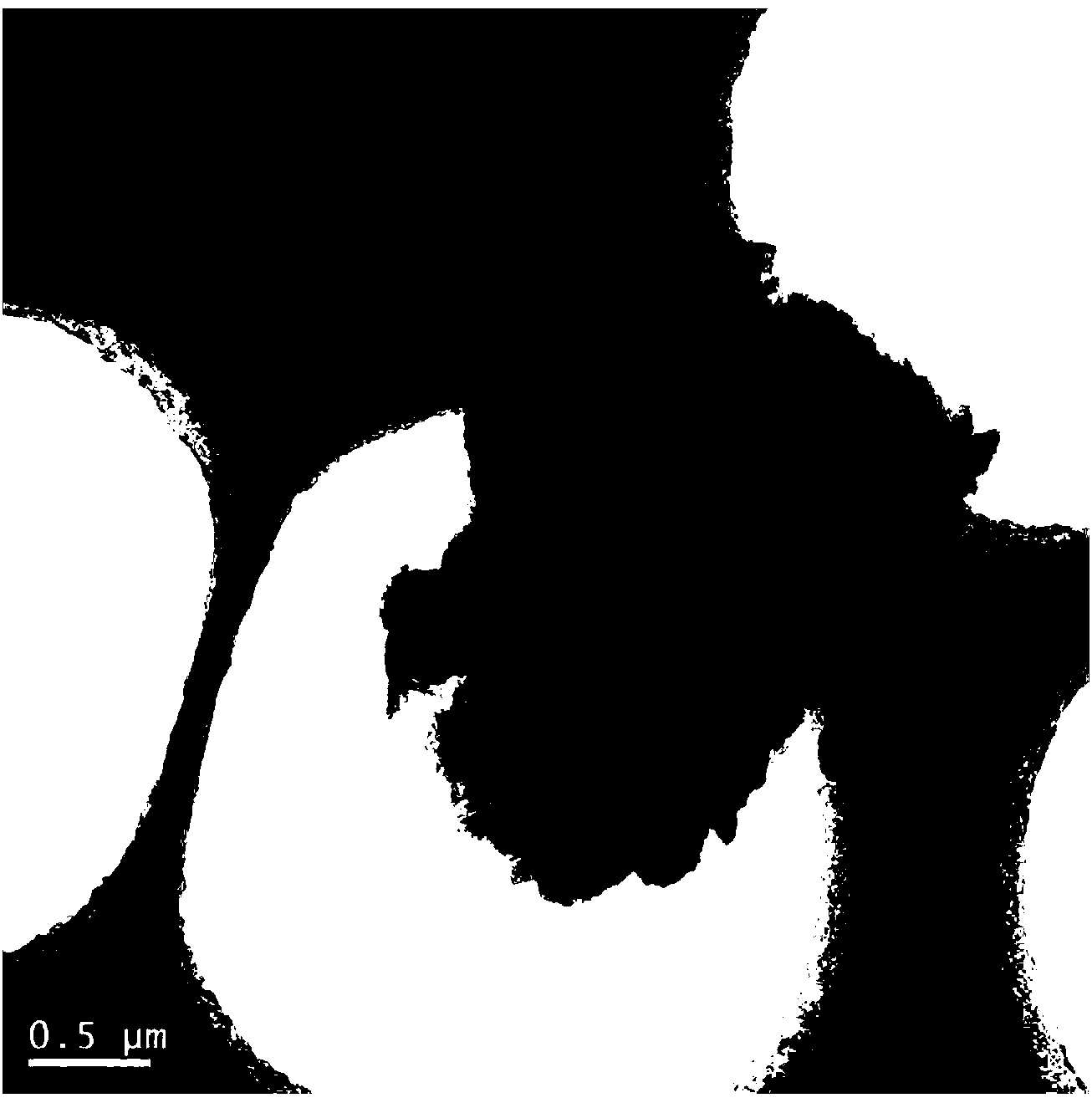

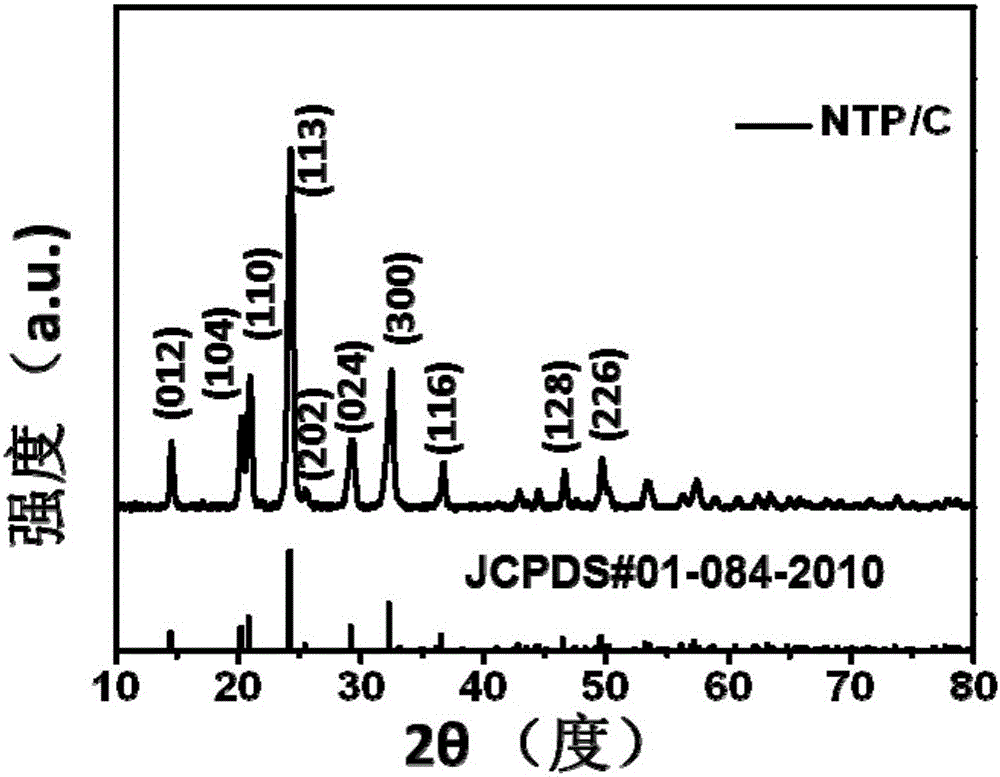

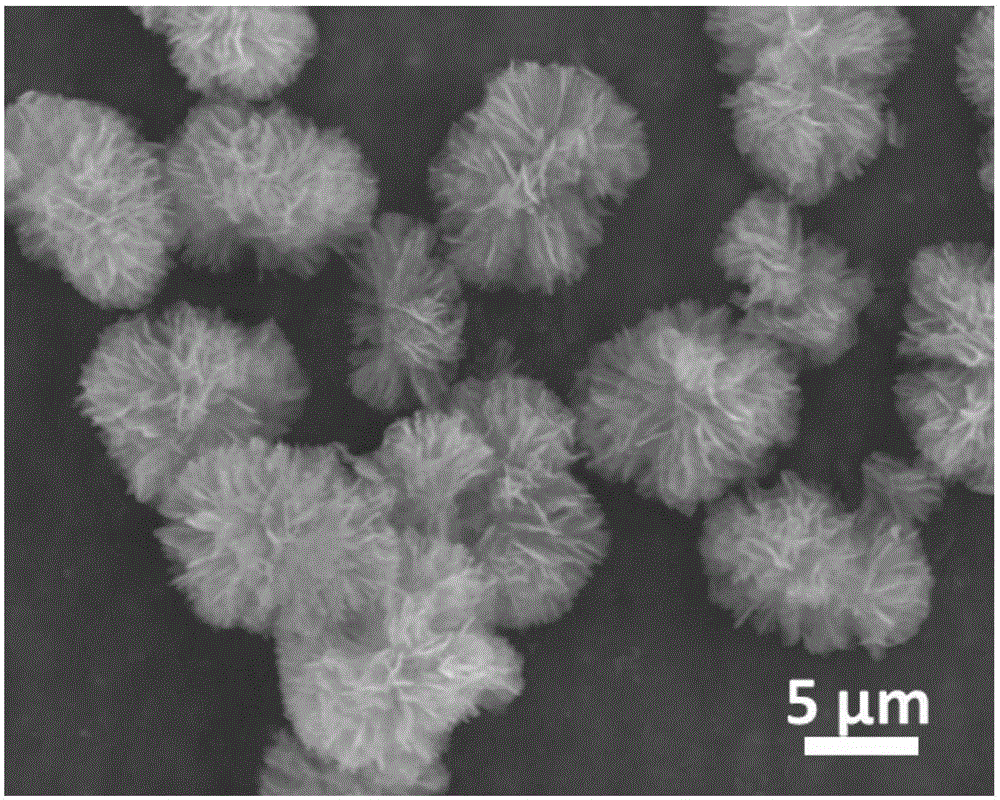

Three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3>/C micrometer flower electrode material and preparation method and application thereof

The invention relates to a three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower electrode material and a preparation method and application thereof. The diameter of the three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower electrode material is 5-10 micrometers, the thickness of a carbon-clad NaTi<2>(PO<4>)<3> / C nanosheet subunit is only 1-5 nanometers, mesopores with pore diameters of 2-30 nanometers are formed in the carbon-clad NaTi<2>(PO<4>)<3> / C nanosheet subunit, the thickness of a surface carbon layer is 2-5 nanometers, and the nanosheet subunits are in over joint to form a three-dimensional conductive network. The three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower electrode material has the advantages that the three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower is prepared by a simple and practical solovothermal method combined with a high-temperature calcination method, and is endowed with excellent high rate performance and stable long-circulation capability when taken as a positive electrode active material of a sodium ion battery. The process is simple, the three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3> / C micrometer flower electrode material is high in practicable and is high in safety coefficient, the requirement on a device is low due to the adoption of the solovothermal method and the calcination processing, production can be expanded, and market promotion is promoted.

Owner:WUHAN UNIV OF TECH

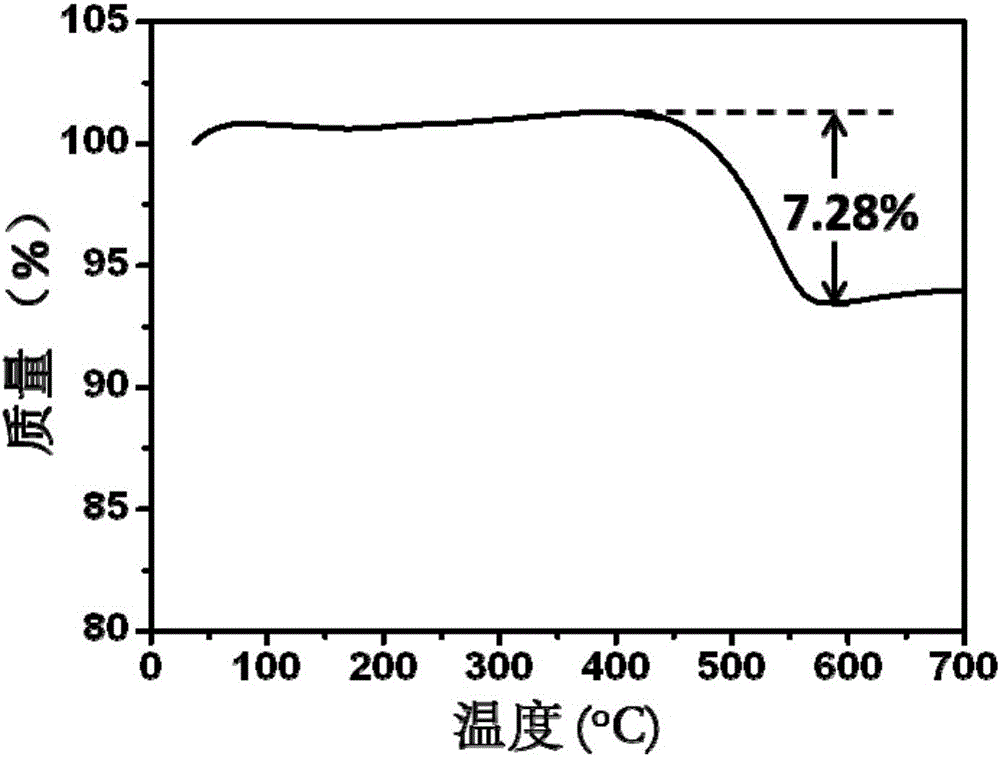

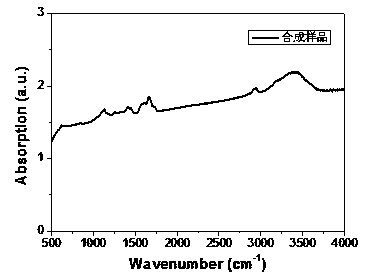

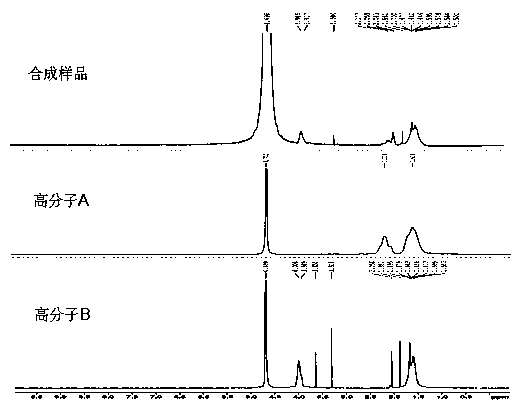

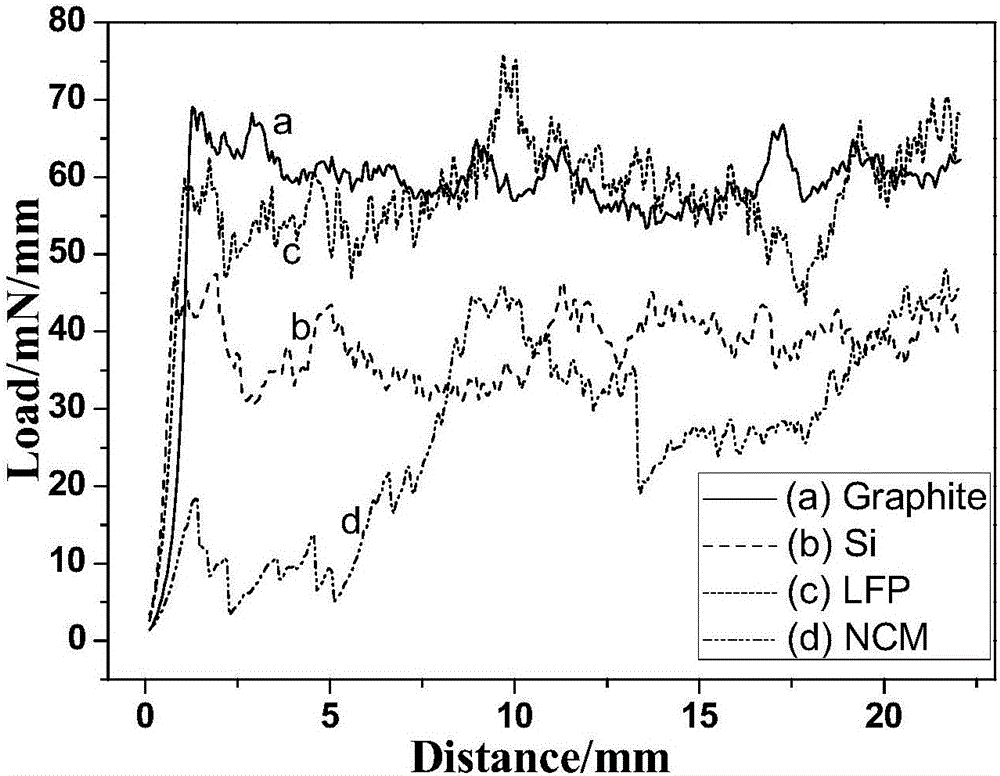

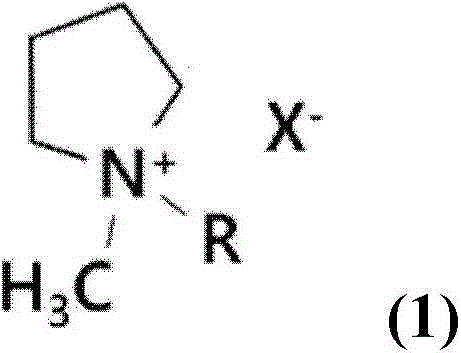

Adhesive for lithium battery and preparation method thereof

ActiveCN103427083APromote circulationImproved high-magnification performanceCell electrodesPolymer scienceAdhesive

The invention relates to adhesive for a lithium battery and a preparation method thereof. The adhesive is aqueous and is prepared through polymer A containing carboxyl functional groups and polymer B containing hydroxyl functional groups. The preparation method includes dissolving and placing the polymer A containing the carboxyl functional groups and the polymer B containing the hydroxyl functional groups in a reactor in proportion, then adding reaction initiator C to stir without a break for 10 to 12 hours at the constant temperature ranging from 40 to 70 DEG C, and cooling to the room temperature to obtain the adhesive. The adhesive has high-strength adhesion and excellent plasticity, prepared slurry can be preserved for long time without phase separation and can be mass produced, so that a battery producing process is easier and more facilitated, and consistence of battery quality can be guaranteed.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

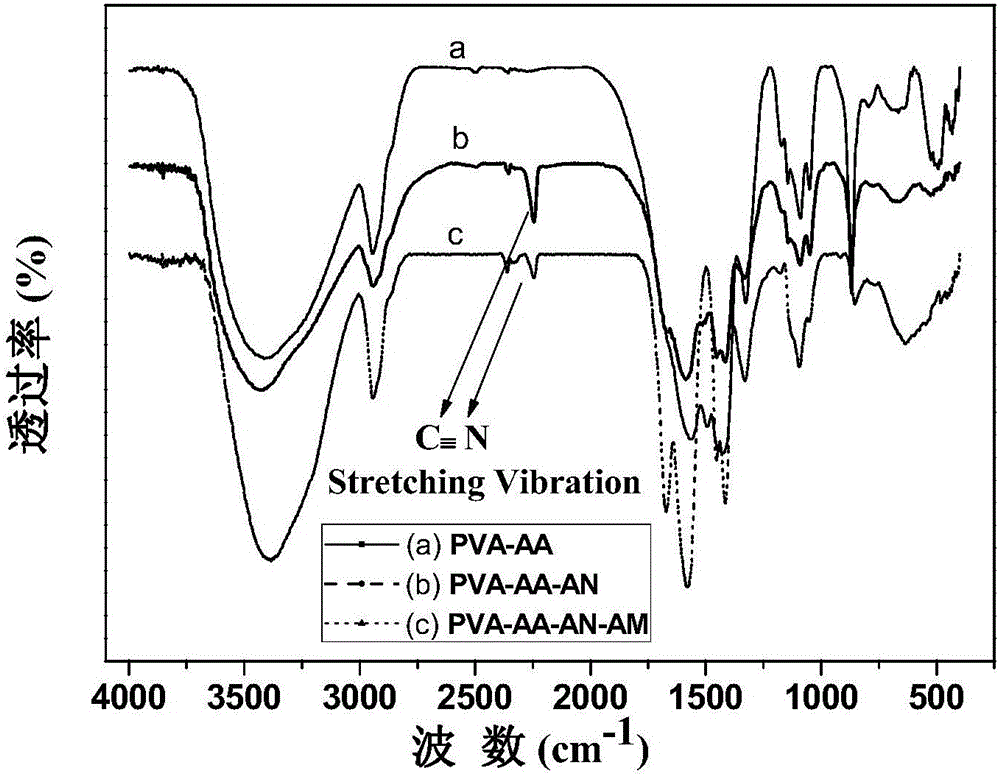

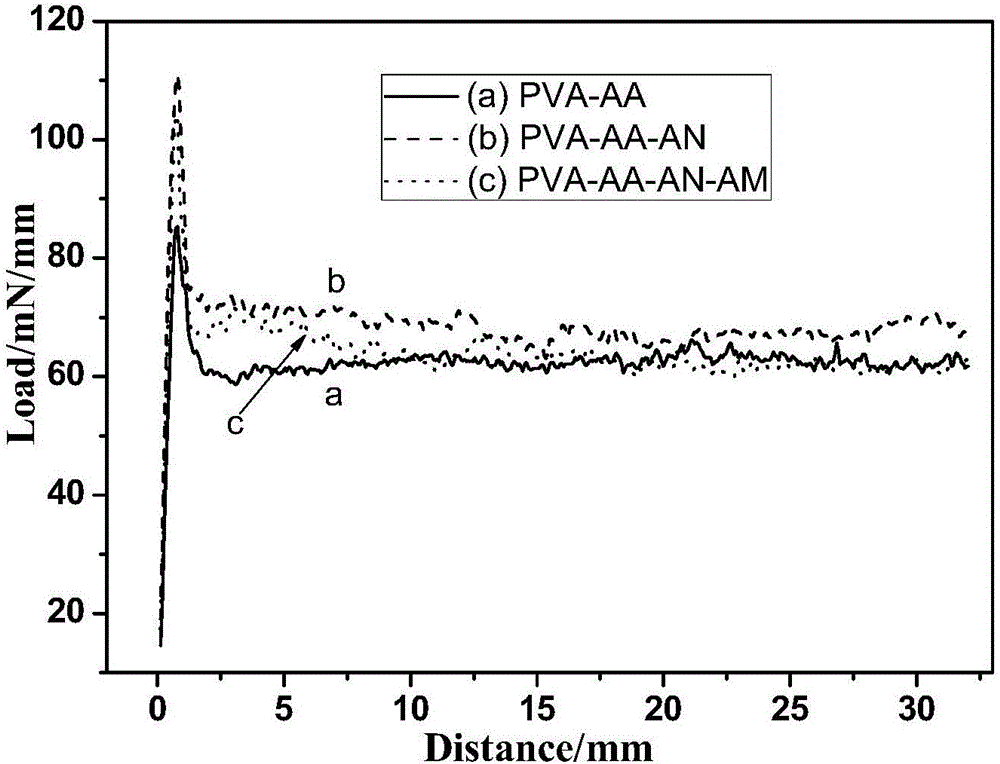

Multi-element functional modification polyvinyl alcohol-based lithium ion battery aqueous binder and application of the binder in electrochemical power storage device

ActiveCN105958075AStable and uniform product qualityImprove performanceCell electrodesSecondary cellsSolubilityHydrophilic monomer

The invention discloses a multi-element functional modification polyvinyl alcohol-based lithium ion battery aqueous binder and application of the binder in an electrochemical energy storage device. According to the binder, polyvinyl alcohol is taken as substrate, and hydrophilic monomers and oleophylic monomers are taken as functional modification monomers. Through adoption of Michael addition reaction modification preparation, the binder has good water solubility, elasticity and bonding performance. Through application of the binder in the preparation process of the lithium ion battery electrode plate, the homogeneity of electrode slurry can be improved. Therefore, the electrode slurry can form film on a current collector evenly and flatly, the material of the electrode plate will not fall off, the capacity will not be reduced, the high rate capability and circulation stability of the lithium ion battery cathode and anode materials can be greatly improved, and the service life of the battery can be effectively extended.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

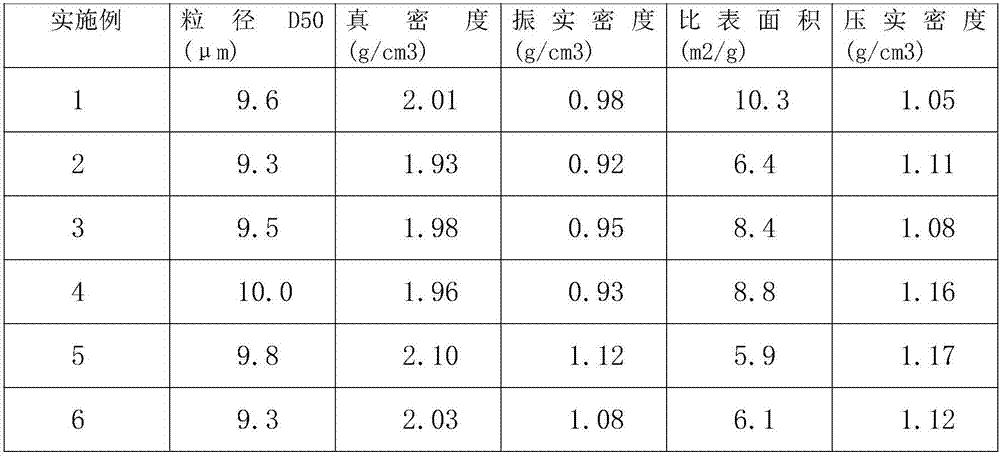

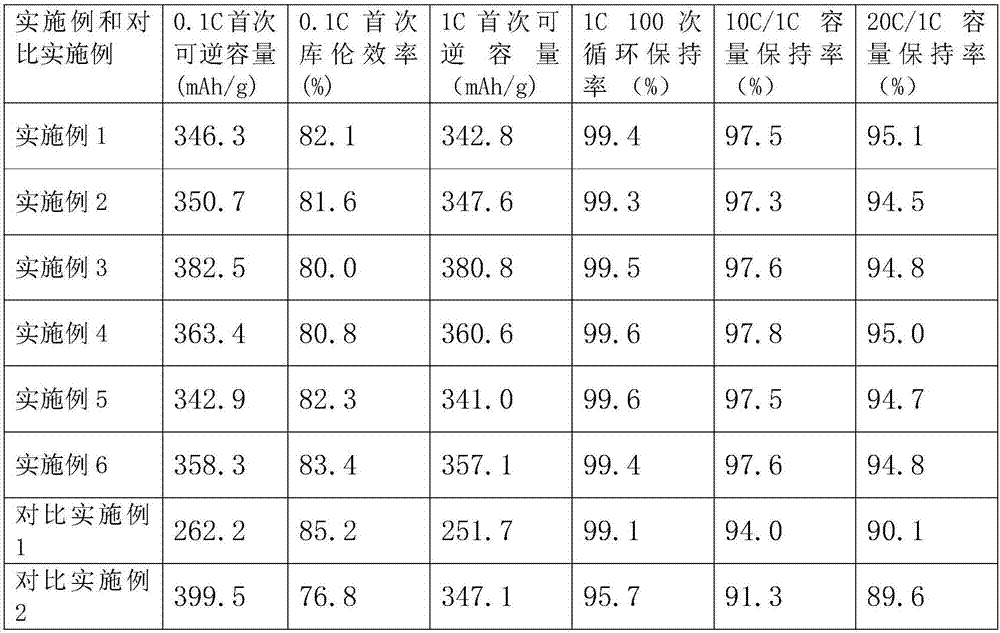

Preparation method of spherical hard carbon negative electrode material of high-capacity lithium ion battery

PendingCN106995210AOvercoming complexityOvercome costsCell electrodesSecondary cellsHigh rateCarbonization

The invention relates to the technical field of a lithium ion battery, in particular to a preparation method of a spherical hard carbon negative electrode material of a high-capacity lithium ion battery. The preparation method is characterized by comprising the following steps of (1) material mixing; (2) precrosslinked polymerization reaction; (3) crushing and grading; (4) polymer powder pelletizing treatment; (5) oxidation stability treatment; (6) pre-carbonization treatment; (7) carbonization treatment. Compared with the prior art, the preparation method has the advantages that the raw material sources are wide; the preparation process is simple; the structure and the processing performance of a precursor organic carbon source can be effectively improved through the precrosslinked polymerization reaction; the prepared spherical hard carbon has unique appearance and good pore diameter distribution, and also has the advantages of particle granularity distribution uniformity, high stacking density and the like; high capacity, high first coulombic efficiency, excellent high-rate performance and excellent circulation performance are also realized.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Carbon compound cathode material for ultracapacitor battery

InactiveCN101740230AGood lithium ion intercalation/extraction cycle performanceExcellent Capacitive Energy Storage PerformanceElectrolytic capacitorsFiberCapacitance

The invention discloses a carbon compound cathode material for an ultracapacitor battery, comprising a nuclear layer and a shell layer, wherein the shell layer accounts for the total weight of 10-40 percent; the nuclear layer is made of graphite materials subjected to surface nanometer treatment; and the shell layer is made of a porous carbon material. The surface nanometer treatment of the nuclear layer is to form a nano carbon fiber, a cabon nanotube or a nano hole on the surface of natural graphite, artificial graphite or an in intermediate phase carbon microsphere material in situ; and the porous carbon material comprises a three-dimensional structure that millipores are distributed on a carbon organism. Metal elements are doped in the shell layer. The component formula is reasonable; the prepared material has the nuclear and shell structures in which the metal elements are doped; meanwhile, the invention has favorable characteristics of energy accumulation by using double electric layers and lithium ion stripping / embedding, can effectively improve the high multiplying power and the power density of a lithium ion battery, meets the double requirements of the ultracapacitor battery on energy accumulation by using the lithium ion and double electric layers of the cathode material, can be used as a cathode of a high-performance lithium ion battery, and has favorable high multiplying power charge-discharge performances and industrial prospect.

Owner:CENT SOUTH UNIV +1

Supercapacitor three-dimensional porous composite film and preparation method thereof

The invention discloses a three-dimensional porous compound film of a super-capacitor and a preparation method thereof. The preparation method comprises the following steps of: reacting for 60-180 seconds by the cathodic electro-deposition method to generate a three-dimensional porous nano nickel film; reacting for 100-400 seconds to deposit by using the three-dimensional porous nano nickel film as the carrier and the cathodic electro-deposition method, compounding a cobalt hydroxide nano sheet layer on the three-dimensional porous nano nickel film and preparing the three-dimensional porous nano nickel / cobalt hydroxide nano sheet compounded film for the super-capacitor, wherein the aperture of the three-dimensional porous nano nickel layer is 5-10 microns; the distance between the sheets of the cobalt hydroxide nano sheet layers is 10-300 nm; the thickness of the compound film is 30-200 microns; and the weight ratio of the cobalt hydroxide nano sheet to the three-dimensional porous nono nickel film is 5:100 to 20:100. The compound film disclosed by the invention has high capacitance, high power, high energy density and high cycle life and has wide application prospect in the fields such as electric automobiles, communication and signal control and the like.

Owner:ZHEJIANG UNIV

Method for preparing positive electrode material of anion-cation multi-component compound lithium battery

The invention discloses a method for preparing a positive electrode material of an anion-cation multi-component compound lithium battery, which comprises the following steps of: performing ball-milling mixing on a substitute and a substrate raw material, adding at least one of water, ethanol and acetone serving as a ball-milling solvent into the mixture; performing spray drying to obtain a precursor; and sintering the spray-drying precursor under the protection of an inert atmosphere to finally obtain LiFe1-m(NixCoyMnz)mP1-nDnO4 positive electrode material of the lithium battery. The molecular formula of the material is LiFe1-m(NixCoyMnz)mP1-n-DnO4, wherein the Fe position is partially substituted by a ternary precursor (NixCoyMnz)(OH)2, and simultaneously the D at the P position uses a compound or a simple substance of boron, sulfur, silicon, chlorine, selenium, tellurium and tungsten and adopts a multi-component composite radical as a substitute to achieve the synergistic action of anions and cations or ion radicals so as to synchronously improve the ion diffusion and the electron conductivity of the material. The material prepared by the method has high charge and discharge capacities, good multiplying factor performance and good circle performance.

Owner:重庆特瑞新能源材料有限公司

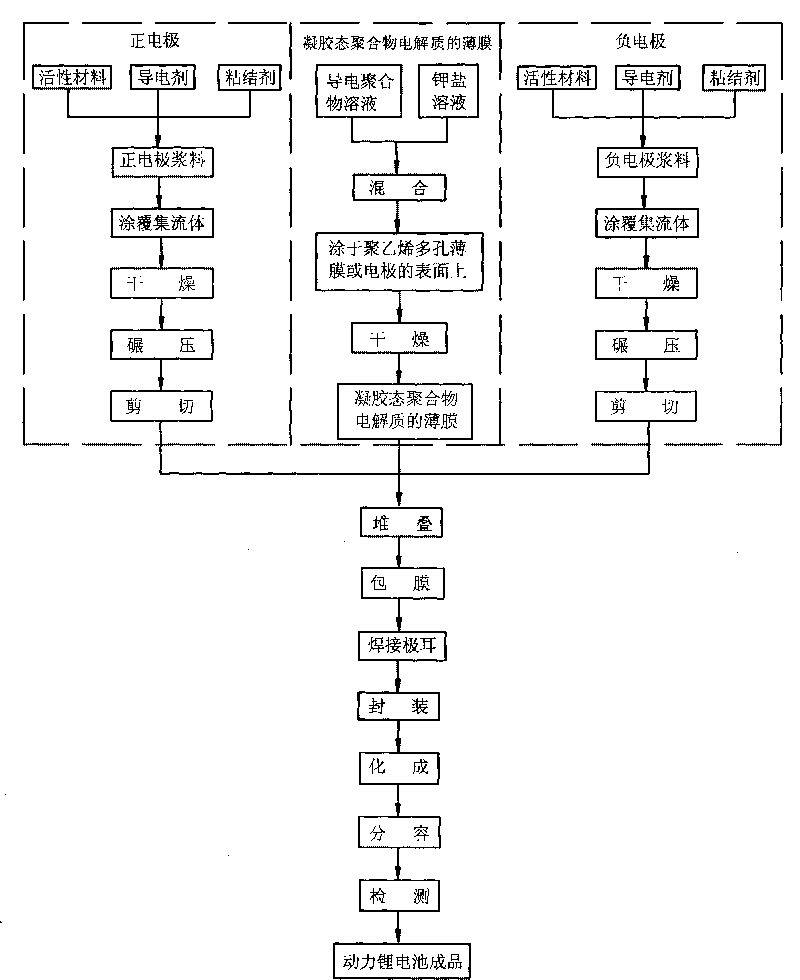

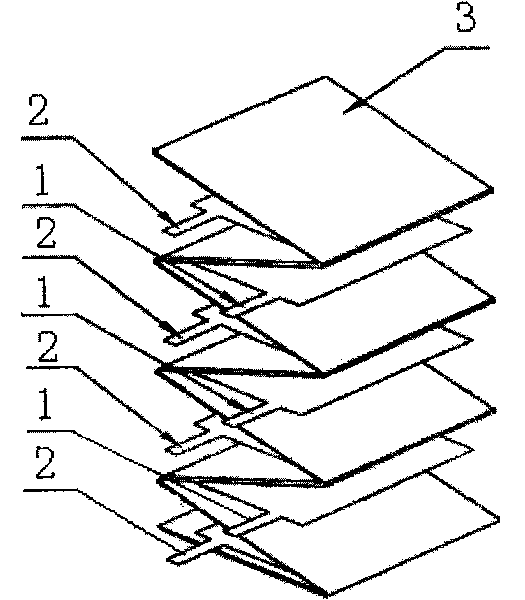

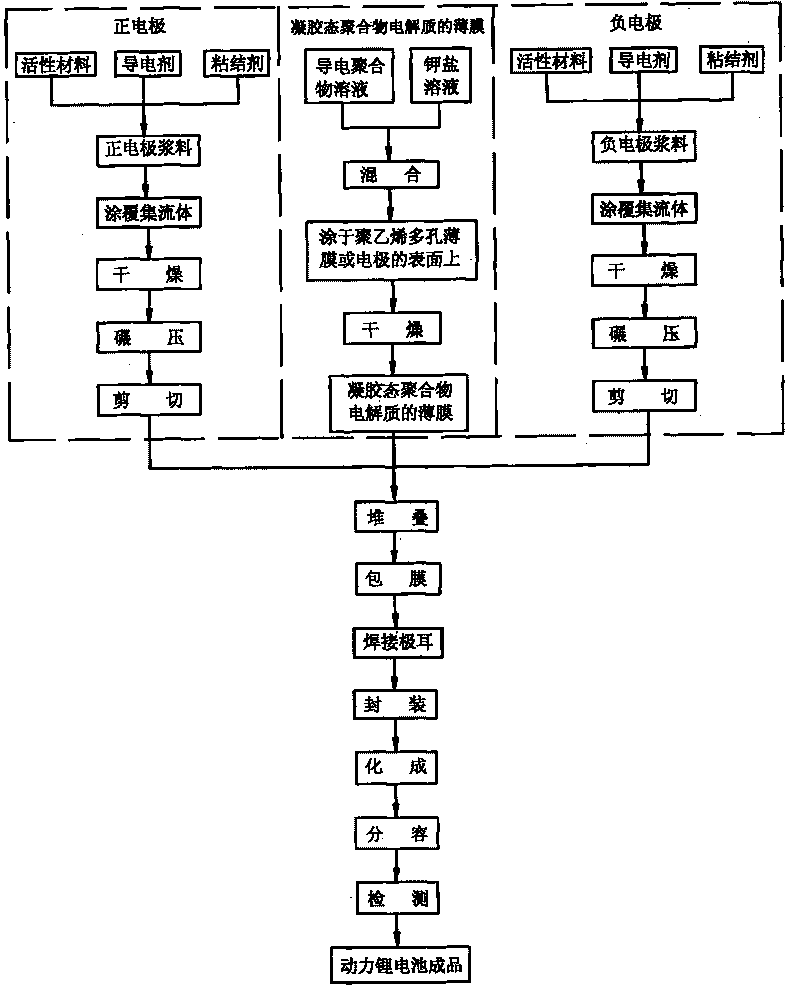

Large-capacity power lithium battery and preparation method thereof

InactiveCN101740809AGood thermal stabilityGood structural stabilityFinal product manufactureCell electrodesLarge capacityPolymer electrolytes

The invention provides a large-capacity power lithium battery which can be used in the field of vehicles as a power source and a preparation method thereof. The large-capacity power lithium battery of the invention is prepared by stacking and packaging a positive electrode, the thin film of a gel-state polymer electrolyte and a negative electrode, wherein the active material of the negative electrode is modified lithium titanate, the active material of the positive electrode is one or more of a ternary material, lithium manganate and ferric lithium manganate, and the thin film of the gel-state polymer electrolyte is prepared by mixing and drying a lithium salt, the solution of an organic solvent and a conductive polymer solution. The power lithium battery has the characteristics of environmental friendliness, excellent high magnification performance, excellent heat dispersion and the like. The preparation is simple, environmental pollution and leakage do not exist, the storage service life is long, enlargement is easy and the temperature range for use is wide. The large-capacity power lithium battery can be used as the power source and applied to the fields such as hybrid electric vehicle, electric vehicle and the like.

Owner:CHERY AUTOMOBILE CO LTD

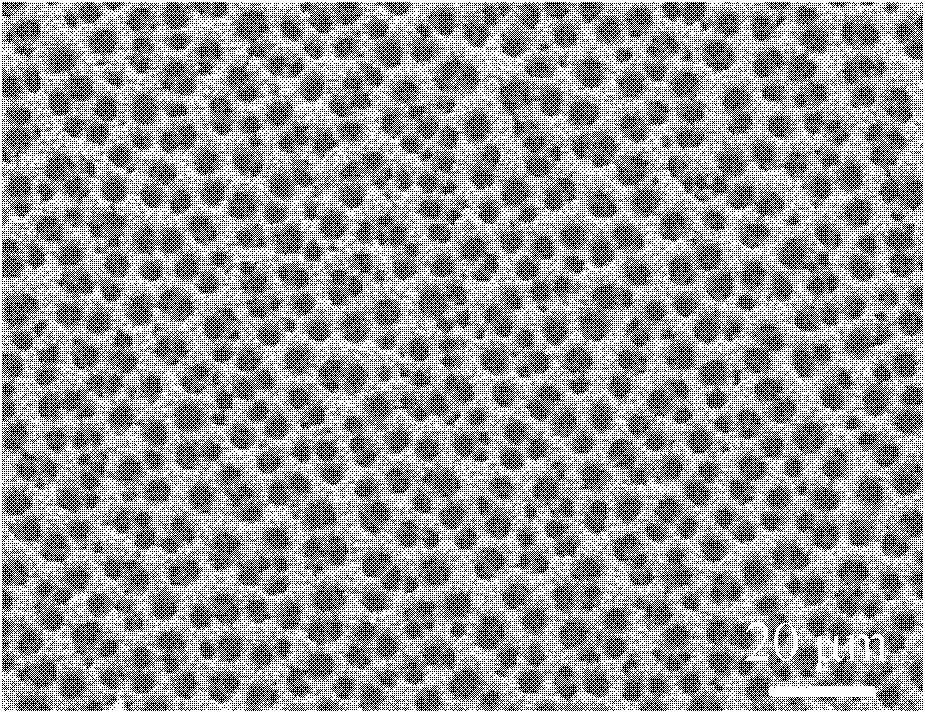

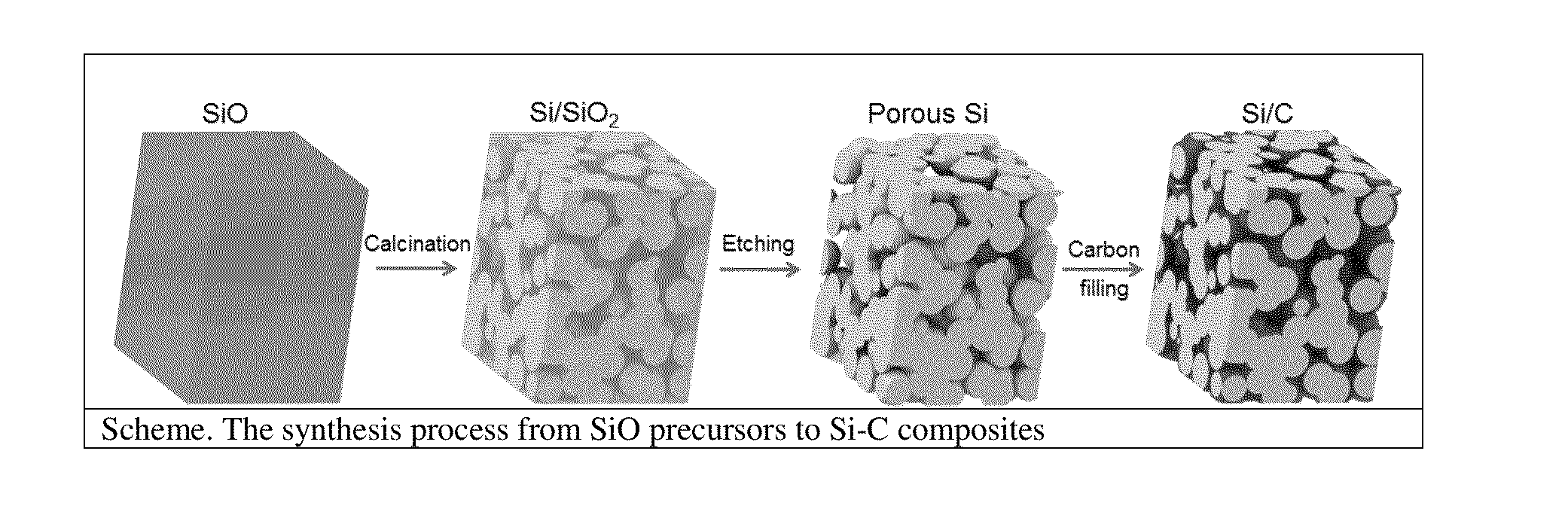

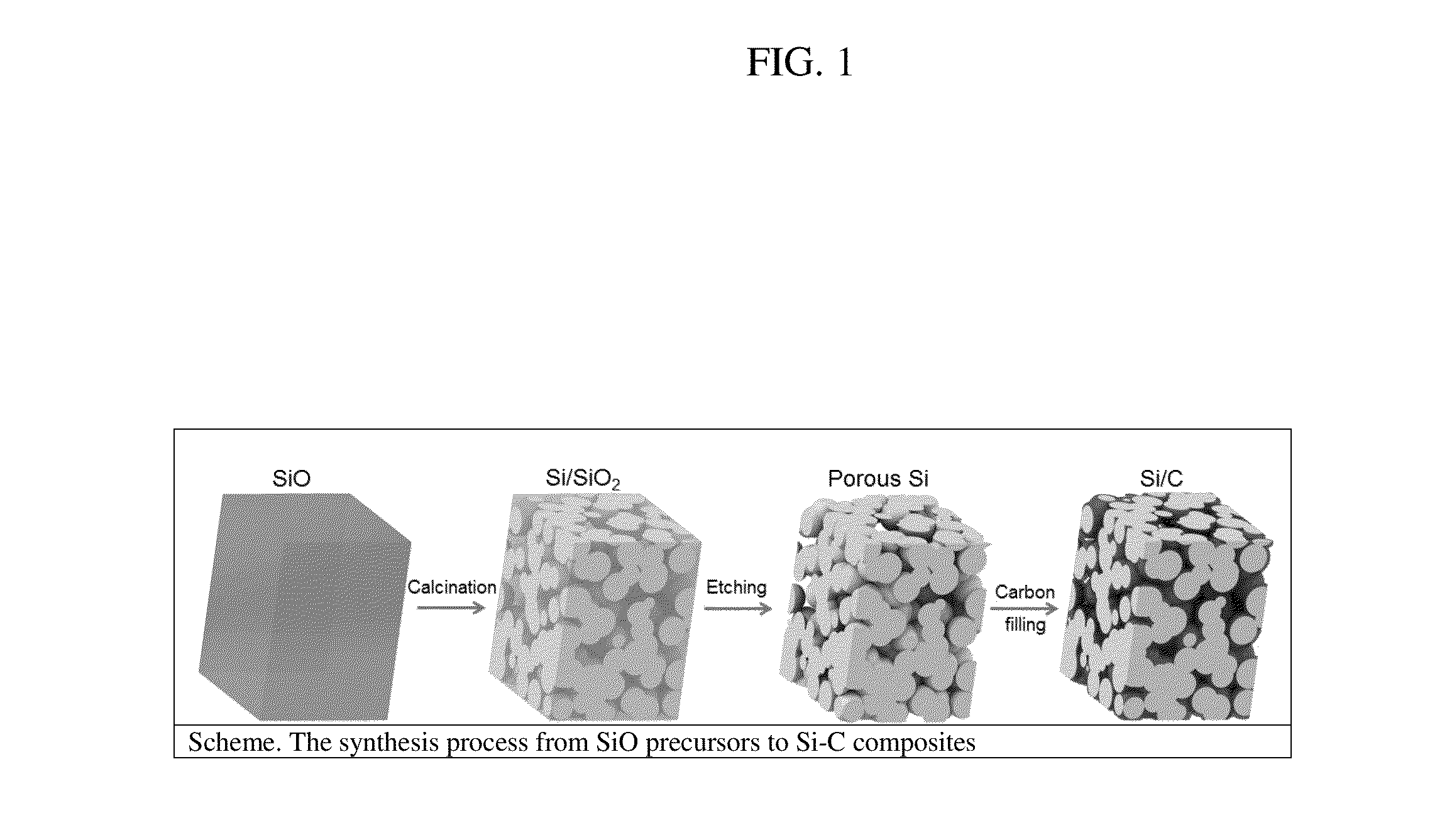

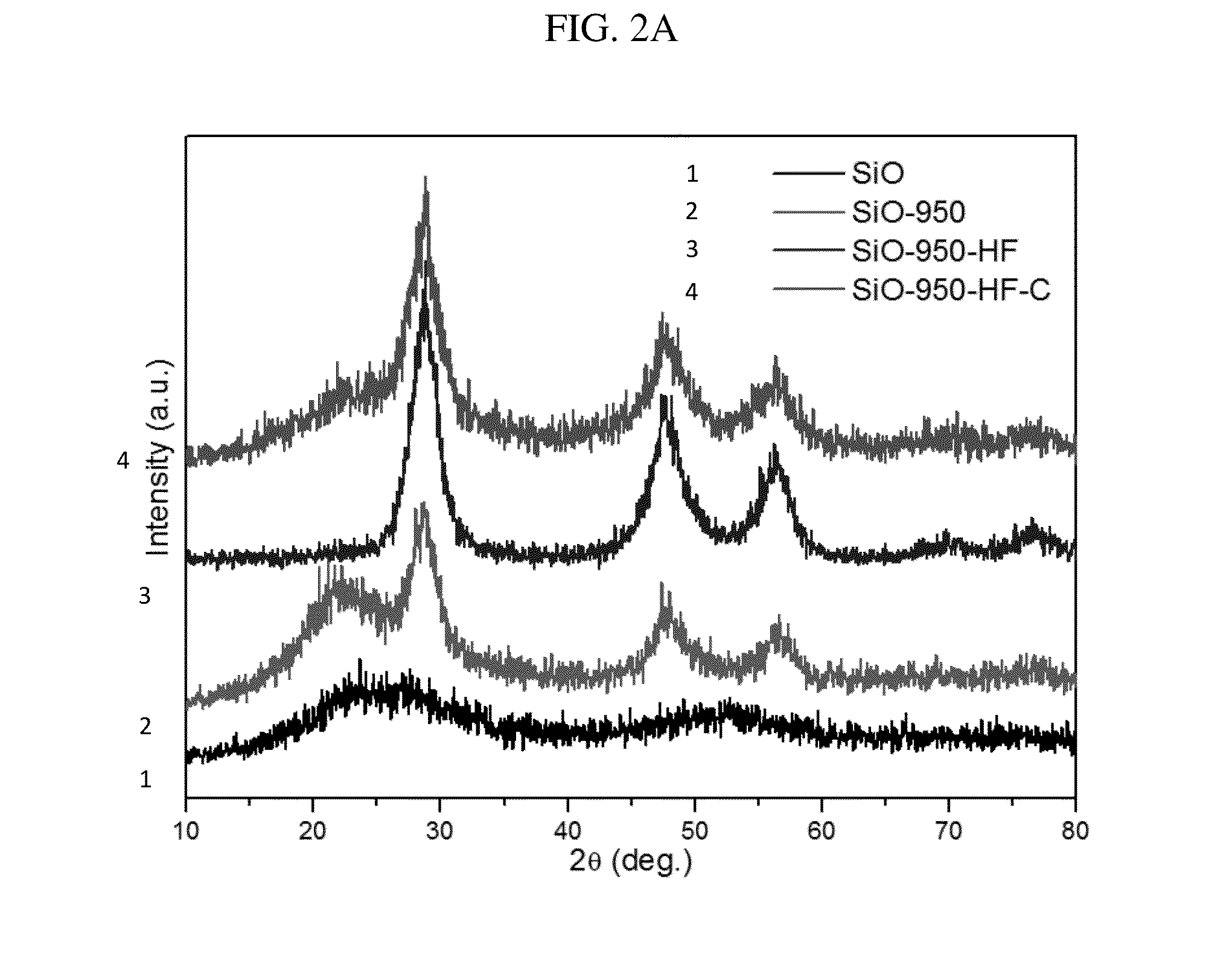

Synthesis of Micro-Sized Interconnected Si-C Composites

ActiveUS20140106219A1Improve electrochemical performanceImproved high-magnification performanceElectrode thermal treatmentPaper/cardboard articlesThermal depositionAlloy

Embodiments provide a method of producing micro-sized Si—C composites or doped Si—C and Si alloy-C with interconnected nanoscle Si and C building blocks through converting commercially available SiOx (0<x<2) to a silicon framework by calcination, followed by etching and then by carbon filling by thermal deposition of gas containing organic molecules that have carbon atoms.

Owner:PENN STATE RES FOUND

Power polymer lithium ion battery and fabricating process thereof

InactiveCN101567469AImprove electronic conductivityImprove high-magnification performanceElectrode manufacturing processesElectrode carriers/collectorsHigh ratePositive current

The invention discloses a power polymer lithium ion battery and a fabricating process thereof. A positive plate comprises modified lithium iron phosphate, conductive agent, positive adhering agent, dispersant and positive current collector. A negative plate comprises graphite, conductive agent, negative adhering agent and negative current collector. The fabricating process comprises the following steps: firstly, dispersing the conductive agent; secondly, dispersing the modified lithium iron phosphate; thirdly, adding the efficient organic adhering agent so as to increase the adhering property among grains of the conductive agent, between the conductive agent and the positive material, and between the conductive agent and the positive material and the current collector, and to increase the electrode contact conductivity and electron conductivity, thereby greatly improving the battery high-rate charge and discharge property. The invention has the advantages of simple process, easy control, good product safety and long circulation service life.

Owner:ZHEJIANG ZHENLONG BATTERY

Electrolyte for magnesium rechargeable battery and preparation method thereof

ActiveCN105322229AImprove discharge capacityImproved high-magnification performanceSecondary cellsOrganic electrolytesMetal chloridePhysical chemistry

Disclosed is an electrolyte solution for a magnesium rechargeable battery with a high ionic conductivity and a wide electrochemical window compared to the conventional electrolyte solution. The electrolyte solution is prepared by dissolving magnesium metal into the ethereal solution using combinations of metal chloride catalysts. The electrolyte solution can be applied to fabricate magnesium rechargeable batteries and magnesium hybrid batteries with a markedly increased reversible capacity, rate capability, and cycle life compared to those batteries employing the conventional electrolyte solution. Also disclosed is a method for preparing the electrolyte.

Owner:KOREA INST OF SCI & TECH

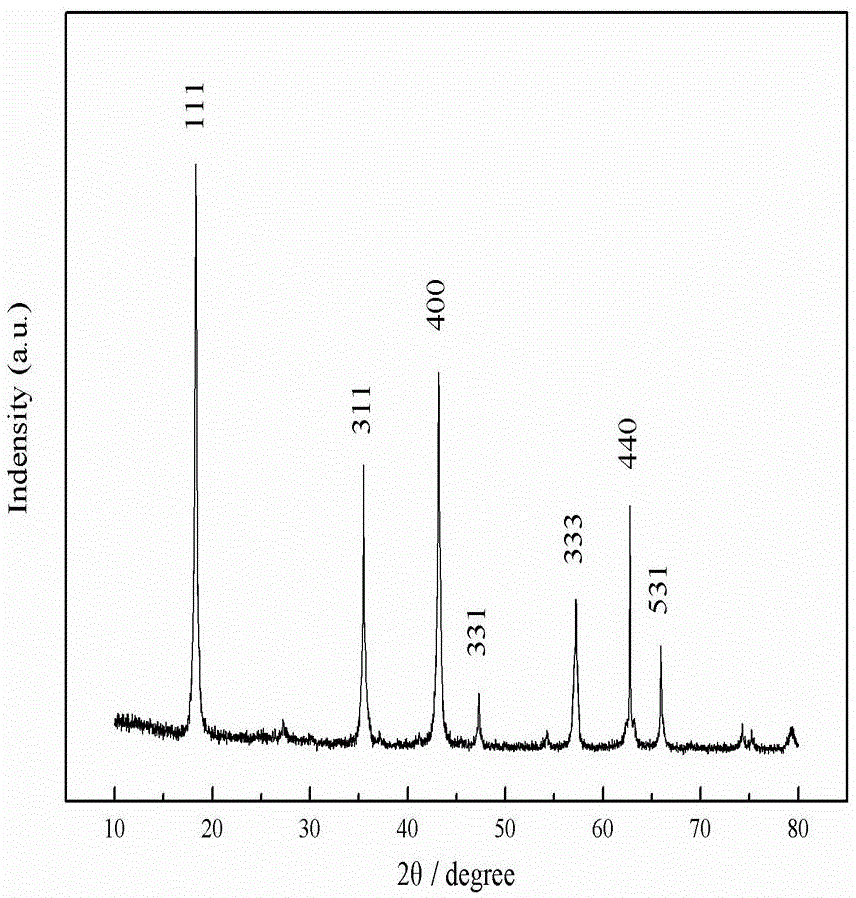

Modified lithium titanate material and preparation method thereof

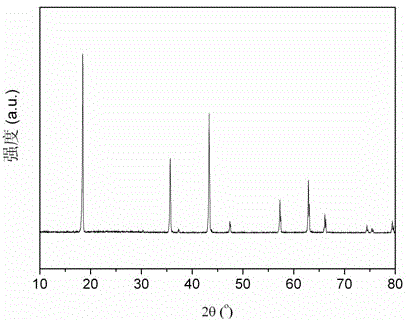

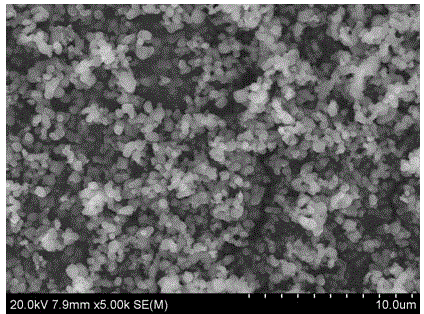

InactiveCN102983319ALow reaction temperatureShort reaction timeCell electrodesTitanium compoundsIonHigh rate

The invention provides a modified lithium titanate material and a preparation method thereof. The modified lithium titanate material is characterized in that a molecular formula of the lithium titanate material is LiaMpNqTixO12, wherein M and N in the molecular formula are doped and modified metal ions; a is equal to 4; p is more than 0 and less than 0.1; q is more than 0 and less than 0.1; p+q is more than 0 and less than or equal to 0.1; p+q+x is equal to 5; and the metal elements M and N respectively are one of La, Ce, Pr, Nd, Sm, Gd, Dy, Zr, Mn, Ta, Hf and V. The invention further provides a preparation method of the modified lithium titanate material. Compared with the conventional lithium titanate preparation method, the preparation method provided by the invention has the advantages that the reaction temperature is reduced, and the reaction time is reduced. Furthermore, the preparation process is simple; the preparation period is short; and the preparation method is applicable to industrial mass production. Moreover, the modified lithium titanate prepared by the method has the properties of good charging and discharging properties, good circulation property and high-rate property.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method of lithium vanadium phosphate-coated ternary material of lithium ion battery

InactiveCN107204428AIncrease energy densityHas a core-shell structureElectrode thermal treatmentLithium vanadium phosphate batteryPhysical chemistry

The invention relates to a method of a lithium vanadium phosphate-coated ternary material of a lithium ion battery. The active electrode material of lithium vanadium phosphate is used as a coating material, and can form a uniform coating layer at the surface of the ternary material. A preparation method comprises the following steps of (1) preparing the ternary material; (2) mixing the ternary material and the lithium vanadium phosphate; (3) calcining a mixed sample under the reduction atmosphere. The method has the advantages that the transmission rate of lithium ions of the surface-coated lithium vanadium phosphate material is quick, and the large rate property of the material is improved; the lithium vanadium phosphate material has good stability, the erosion of electrolyte to the ternary material of an inner core is effectively inhibited, the coated ternary material integrates the advantages of the ternary material and the lithium vanadium phosphate, and the good rate property and cyclic property are realized.

Owner:CENT SOUTH UNIV

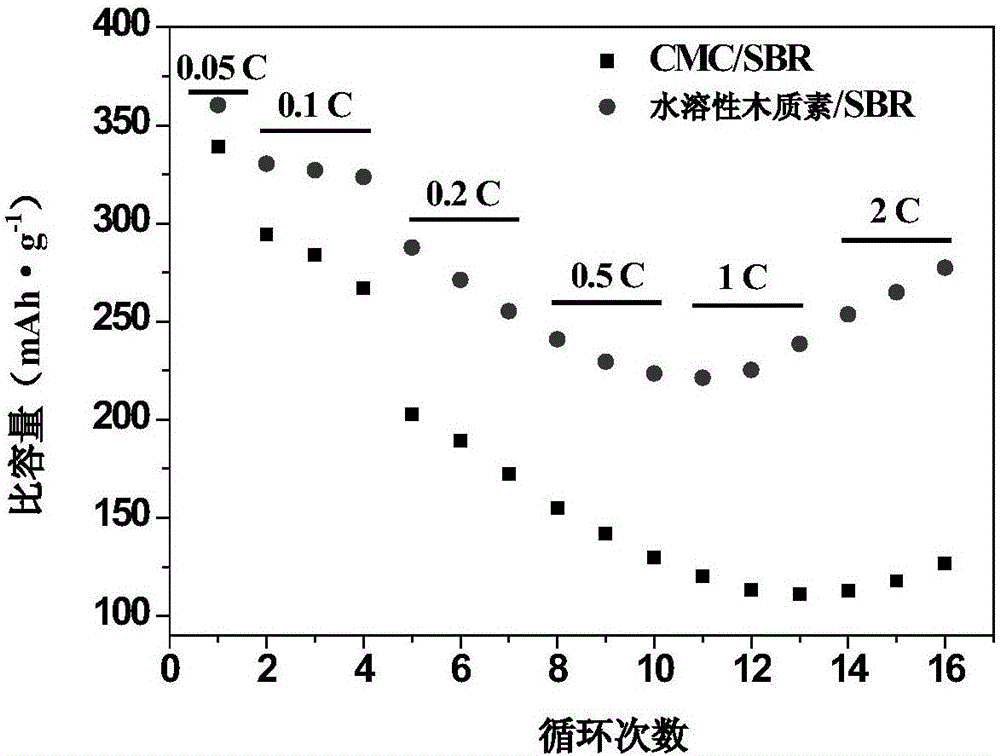

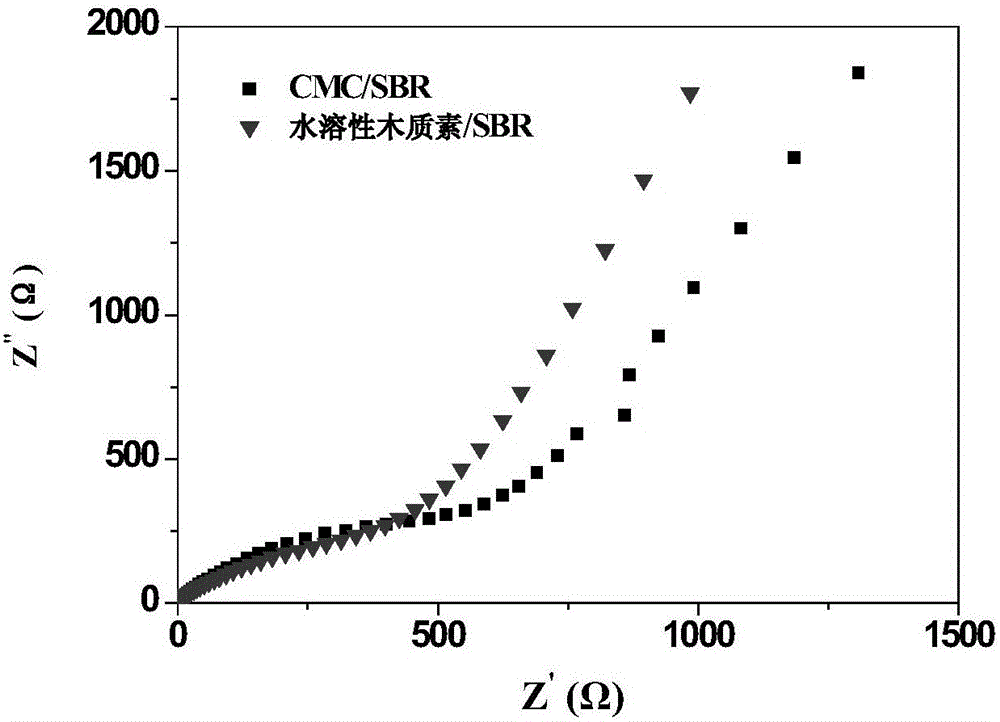

Lignin-based aqueous adhesive applied to negative electrode of lithium ion battery, electrode plate based on adhesive and lithium ion battery

ActiveCN106025283ALow costGood dispersionCell electrodesSecondary cellsElectrical batteryInterface impedance

The invention belongs to the technical field of lithium ion batteries, and discloses a lignin-based aqueous adhesive applied to a negative electrode of a lithium ion battery, an electrode plate based on the adhesive and a lithium ion battery. The lignin-based aqueous adhesive comprises the following components in parts by weight: 100 parts of water-soluble lignin, and 20-1,000 parts of butadiene styrene rubber. The invention further provides an electrode plate of the negative electrode of the lithium ion battery based on the adhesive and the lithium ion battery thereof. The lignin-based aqueous adhesive is applied to the negative electrode of the lithium ion battery, so that the dispersity and the binding power of an electrode material is improved, agglomeration of active materials is effectively overcome, the uniformity of coating electrode slurry on a Cu foil is improved, the toughness of the electrode material is good, interface impedance can be reduced, the resistance of the negative electrode plate is reduced, and the high rate performance of the material is greatly improved; in the other aspect, the lignin provided by the invention is widely from natural plants, and therefore, is green and environment-friendly, and when the lignin is applied to the aqueous adhesive, the costs of batteries can be remarkably reduced.

Owner:SOUTH CHINA UNIV OF TECH

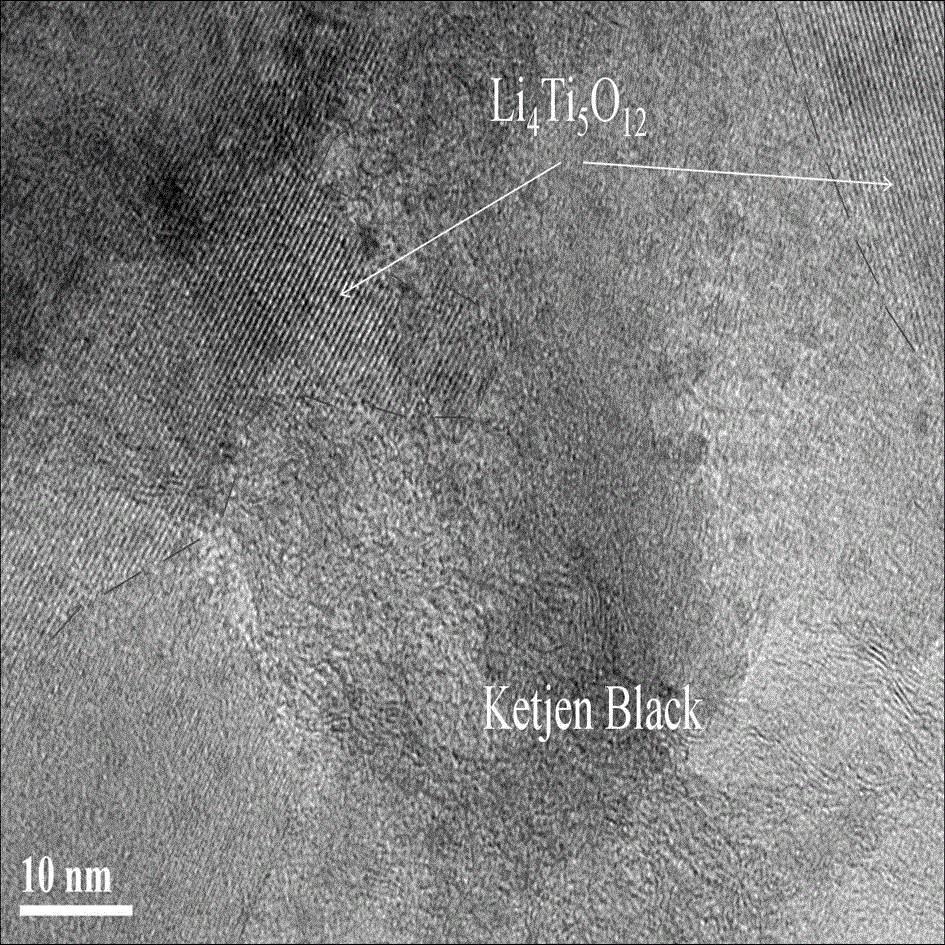

Lithium titanate/porous carbon composite material and preparation method of lithium titanate/porous carbon composite material

InactiveCN105789582AImprove electronic conductivityIncrease the diffusion coefficientCell electrodesSecondary cellsCarbon compositesHydration reaction

The invention discloses a lithium titanate / porous carbon composite material. The invention further discloses a preparation method of the lithium titanate / porous carbon composite material. The prepapration method comprises the following steps: weighing lithium hydroxide monohydrate, tetrabutyl titanate and porous carbon according to a certain stoichiometric ratio; adding ethanol and de-ionized water and uniformly mixing; transferring a stirred suspension solution into a hydrothermal reaction kettle and reacting at 180 DEG C for 24h to 48h to obtain precursor slurry; drying and crushing the precursor slurry to obtain precursor powder; treating the precursor powder in an inert atmosphere at the temperature of 500 DEG C to 700 DEG C for 5 to 10 hours to obtain the lithium titanate / porous carbon composite material. The composite material prepared by the technical scheme provided by the invention has excellent rate performance and low-temperature property.

Owner:EAST CHINA UNIV OF SCI & TECH

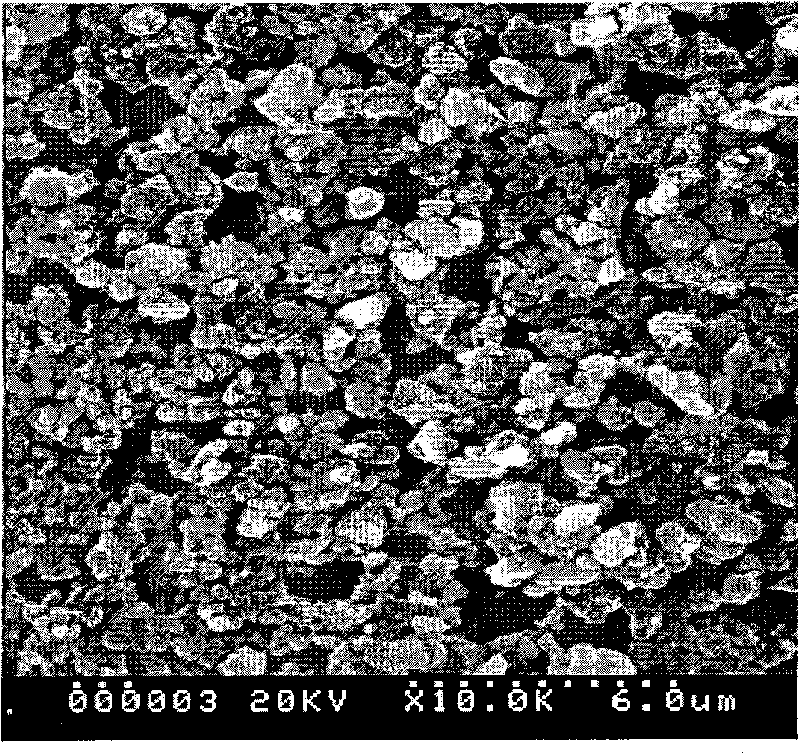

Vanadium-titanium ion-codoped lithium iron phosphate material and preparation method thereof

InactiveCN103078113AHigh discharge specific capacityImprove rate discharge performanceCell electrodesArgon atmosphereControllability

The invention provides a vanadium-titanium ion-codoped lithium iron phosphate (LiFePO4) material and a preparation method thereof. The preparation method comprises the following steps: weighing a lithium source, an iron source, a phosphorus source and a dopant according to the ionic molar ratio of Li<+>, iron ion, Ti<4+>, V<5+> and PO4<3-> as 1: (1-x-y): x: y: 1, adding a carbon source and a mixing medium, mixing uniformly by liquid-phase ball milling, placing in a nitrogen or argon atmosphere, heating up to 350-450 DEG C for pre-sintering, performing heat preservation for 4-6 hours, heating up to 650-750 DEG C for calcination, and performing heat preservation for 8-12 hours; and cooling to room temperature, and grinding to obtain the vanadium-titanium ion-codoped LiFePO4 material that has a general formula of LiFe1-x-yTixVy(PO4) / C, wherein x is smaller than or equal to 0.01 and larger than or equal to 0.005; y is smaller than or equal to 0.02 and larger than or equal to 0.005; and x+y is smaller than or equal to 0.03 and larger than or equal to 0.01. According to the invention, the vanadium-titanium ion-codoped LiFePO4 material has higher discharge specific capacity as well as preferable rate discharge performance and cycle stability, and is perfect in crystallization and smaller in particle size. The preparation method is simple in process and low in energy consumption; and the obtained material is superior in electrochemical performance, strong in controllability, and convenient for industrial mass production.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

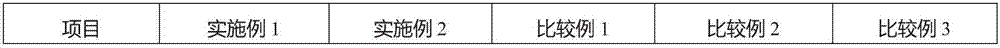

Ternary lithium battery electrolyte and high-temperature resistant, high-capacity and high-safety lithium battery core

InactiveCN107978794AImprove securityImprove high temperature resistanceMaterial nanotechnologyCell electrodesCarbon nanotubeCarbonate

The invention discloses a ternary lithium battery electrolyte and a high-temperature resistant, high-capacity and high-safety lithium battery core. According to the lithium battery core, a high-temperature resistant high-safety electrolyte is prepared by adopting a novel lithium salt of a conductive lithium salt LiBOB (lithium bis(oxalate)borate) and a lithium salt LiFSI (lithium bis(fluorosulfonyl)imide) and adding a proper amount of additive of FEC (fluoroethylene carbonate), MMDS (methylene methanedisulfonate) and TMP (trimethyl phosphate). A novel ternary positive electrode material coatedwith a mixture of nano titanium dioxide and a ternary material (LiNi0.8Co0.1Mn0.1O2) is adopted by a positive electrode, and a mixture of mesocarbon microbeads MCMB and carbon nanotubes is adopted bya negative electrode, thereby preparing the novel high-temperature resistant high-capacity lithium-ion power battery core for an automobile. According to the prepared battery core, the cycle performance is improved, and meanwhile, the problem of high-temperature air expansion is well solved.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

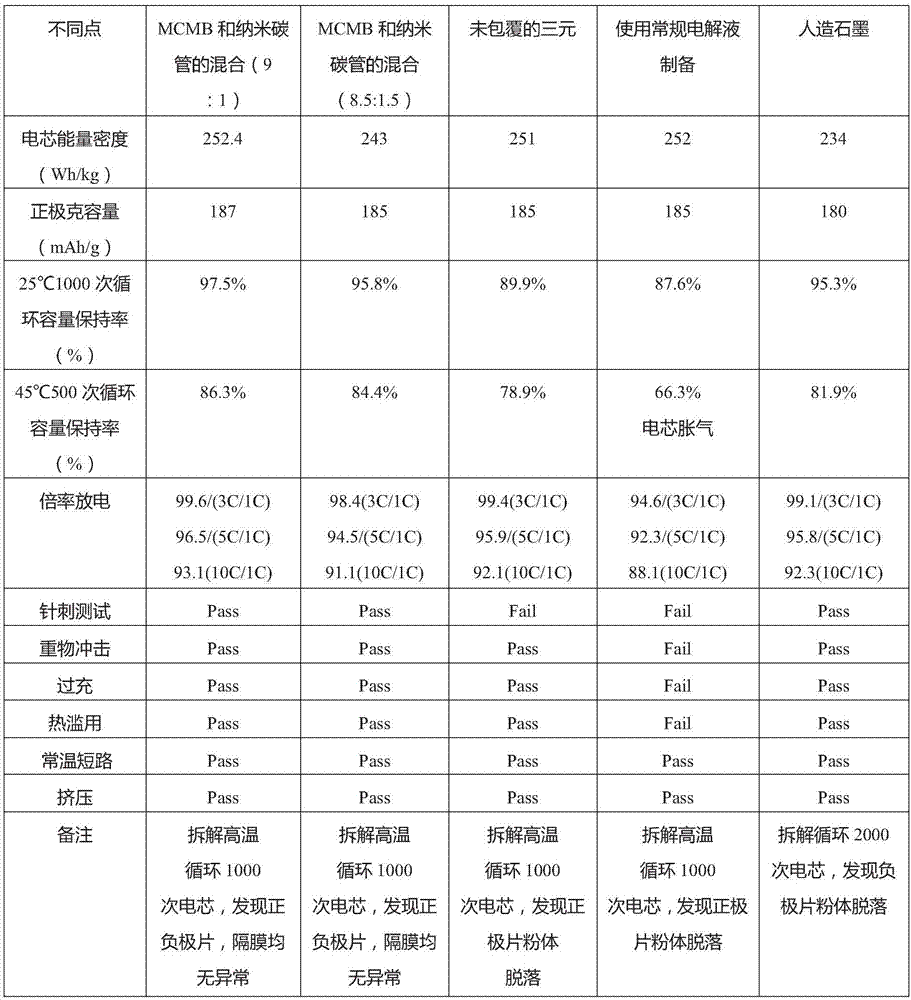

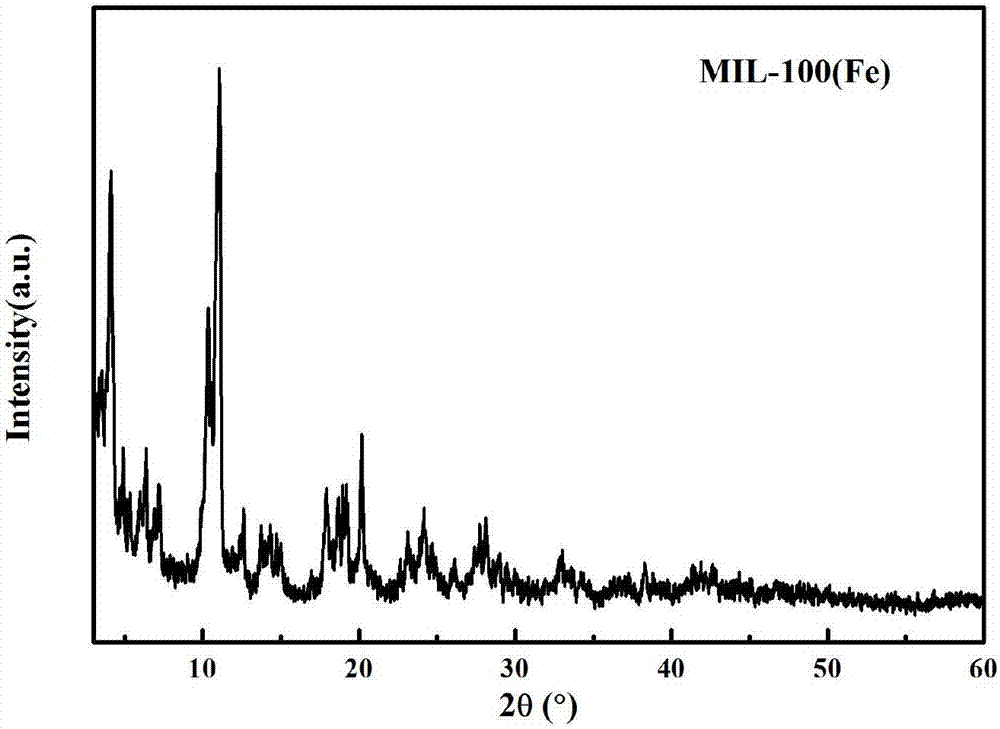

Carbon/carbon composite material for sodium-ion battery and preparation method thereof

ActiveCN106953076AEasy to embedPromote prolapseMaterial nanotechnologyCell electrodesCarbon compositesPorous carbon

The invention discloses a carbon / carbon composite material for a sodium-ion battery and a preparation method thereof. The carbon / carbon composite material is formed by coating graphitized porous carbon particles with an amorphous porous carbon layer. The preparation method of the carbon / carbon composite material comprises the steps of: carrying out synthesis on water system solution containing metal salt and an organic ligand by a hydrothermal method to form a metal organic frame material; dispersing the metal organic frame material in aqueous carbon solution, and preparing a carbon-coated metal organic frame composite material by a hydrothermal reaction; and carrying out carbonization and acid pickling on the carbon-coated metal organic frame composite material to obtain the carbon / carbon composite material. The prepared carbon / carbon composite material, as a negative electrode of the sodium-ion battery, has excellent long-circulation stability, excellent rate capability and the like, is simple in preparation method and low in cost, and has a wide industrial application prospect.

Owner:CENT SOUTH UNIV

Lithium ion positive electrode material cladded by nanometer alumina membrane and preparation method thereof

ActiveCN103515611AImprove cycle performanceImprove thermal stabilityCell electrodesSodium bicarbonateLithium

The invention provides a lithium ion positive electrode material cladded by a nanometer alumina membrane and a preparation method thereof. The preparation method comprises the following steps: evenly mixing a positive electrode material with a deionized water solution of sodium bicarbonate; slowly adding an aluminum salt solution with a certain concentration into a mixed solution of the positive electrode material; continuously stirring at the temperature within 50 DEG C to 55 DEG C and regulating the pH value of the solution to reach 8-12 by adding a proper amount of ammonium hydroxide at the same time; stirring for 20-120 minutes; then standing for 60-100 minutes; filtering, washing and drying the solution; calcining for 2-10 hours at the temperature within 100 DEG C to 700 DEG C under the oxygen atmosphere after the drying of the solution, thereby obtaining the positive electrode material cladded by the nanometer alumina membrane, wherein the nanometer alumina membrane is within 10nm to 40nm in thickness. The method is simple in synthetic process, uniform in membrane cladding and easy in industrial production, and is used for optimizing the high-rate performance and high-temperature cycling performance of the material. Thus, the requirement of the market on the positive electrode material is satisfied well.

Owner:HENAN KELONG NEW ENERGY CO LTD

High-density ordered graphene with ion spacer layers and preparation method and application of high-density ordered graphene

ActiveCN104240960AHigh specific capacitanceLarge pseudocapacitive currentElectrolytic capacitorsCapacitanceHigh rate

The invention relates to a high-density graphene material and a preparation method thereof and application of the high-density ordered graphene into supercapacitors, in particular to a high-density ordered graphene with ion spacer layers and a preparation method and application of the high-density ordered graphene and aims to solve the technical problem of low volumetric specific capacitance and low density of existing graphene. The high-density ordered graphene with the ion spacer layers has graphene lamination layers in ordered parallel arrangement, alkali metal ions are embedded among the graphene lamination layers to form the spacer layers, and the high-density ordered graphene is porous high-density graphene. The preparation method of the high-density graphene material includes: subjecting oxidized graphene aqueous dispersion to reduction in an alkaline reduction medium, and directly coating graphene aqueous dispersion onto a current collector after lavation to make a film or grind into powder after drying. The high-density ordered graphene has the advantages of high density, high volumetric specific capacitance, high rate capability and long cycle life and is applicable to electrode active materials of supercapacitors.

Owner:哈尔滨工业大学高新技术开发总公司

Lithium ion battery composite cathode material and preparation method thereof

InactiveCN101640263AHigh reversible capacityImproved high-magnification performanceElectrode manufacturing processesSecondary cellsArgon atmosphereLithium-ion battery

The invention relates to a lithium ion battery composite cathode material which is characterized by being prepared from powder which is formed by uniformly coating amorphous carbon on the surfaces ofin situ composite Li3V2(PO4)3 and LiFePO4, wherein the powder contains the components in percentage by weight: 75.0-74.0 percent of LiFePO4, 21.8-21.8 percent of Li3V2(PO4)3 and 2.3-4.8 percent of amorphous carbon. A preparation process of the composite cathode material adopts a carbothermic reduction solid phase sintering method which comprises the following steps: mixing raw materials of FePO4,Li2CO3, NH4H2PO4 and NH4VO3 according to a stoichiometric ratio; adding petroleum coke accounting for 15-25 percent of the total weight of the raw materials; and after adding acetone to ball mill andmix the raw materials on a ball milling machine, and calcining the raw materials in argon atmosphere at 600-700 DEG C for 8-12 hours. When used as a cathode of a lithium ion battery, the composite cathode material has the advantages of simple preparation method, high charge and discharge capacity, good performance of high multiplying power charge and discharge, good cyclical stability, and the like.

Owner:杭州海孚新能源科技有限公司 +1

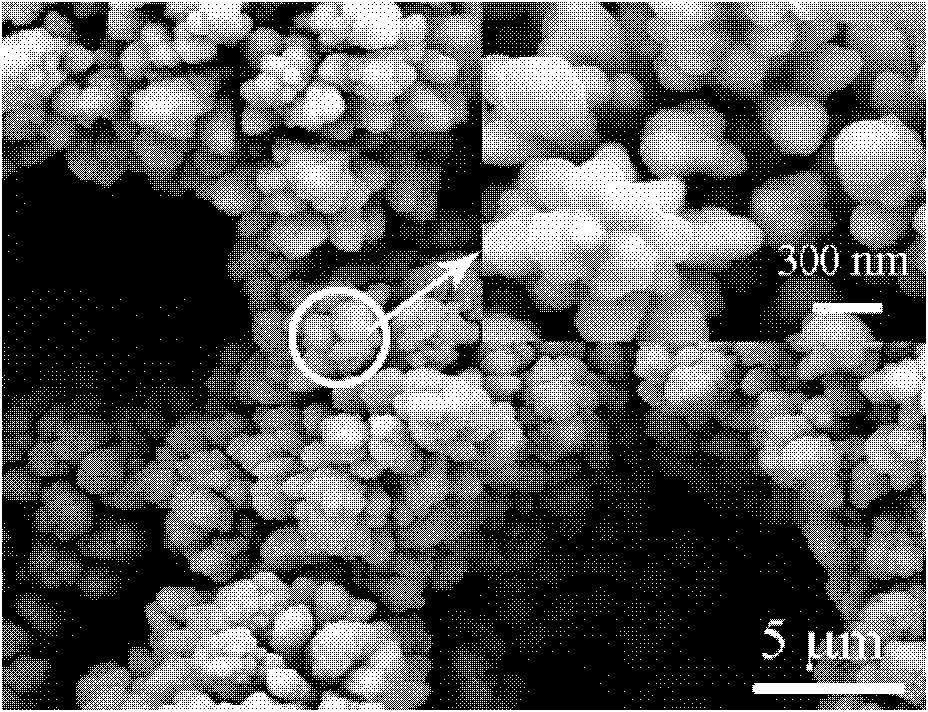

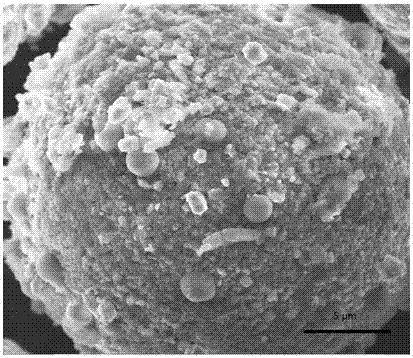

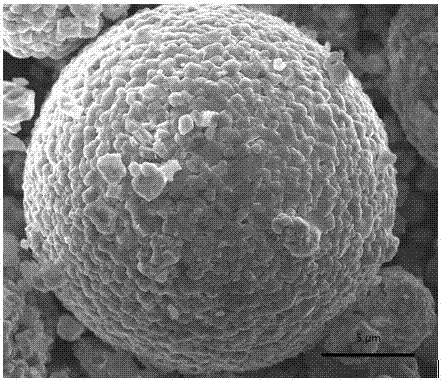

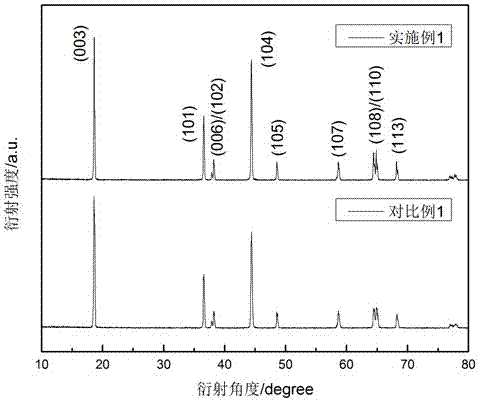

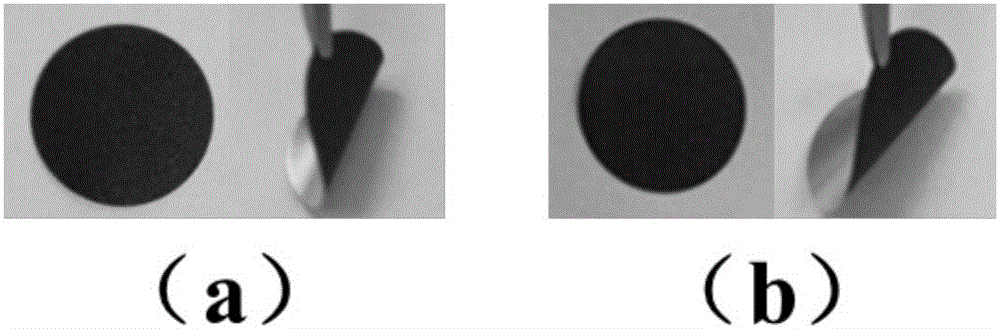

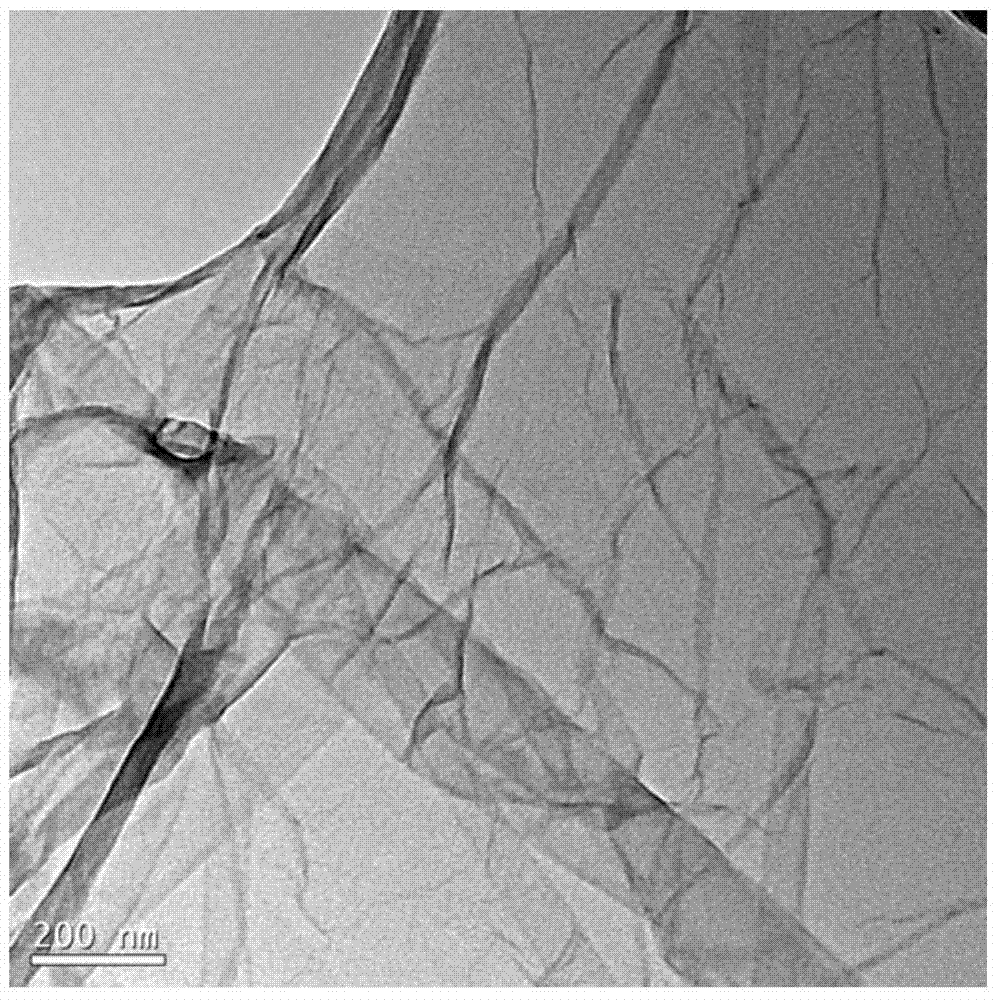

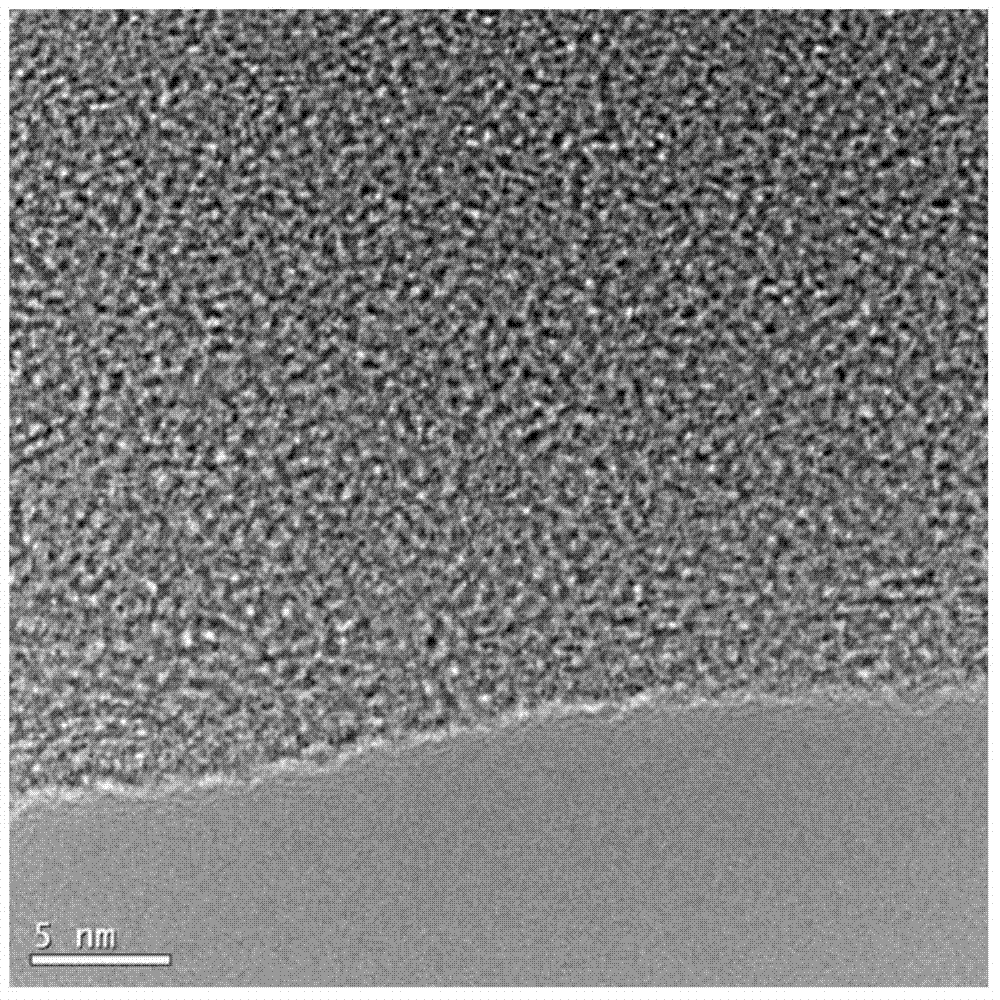

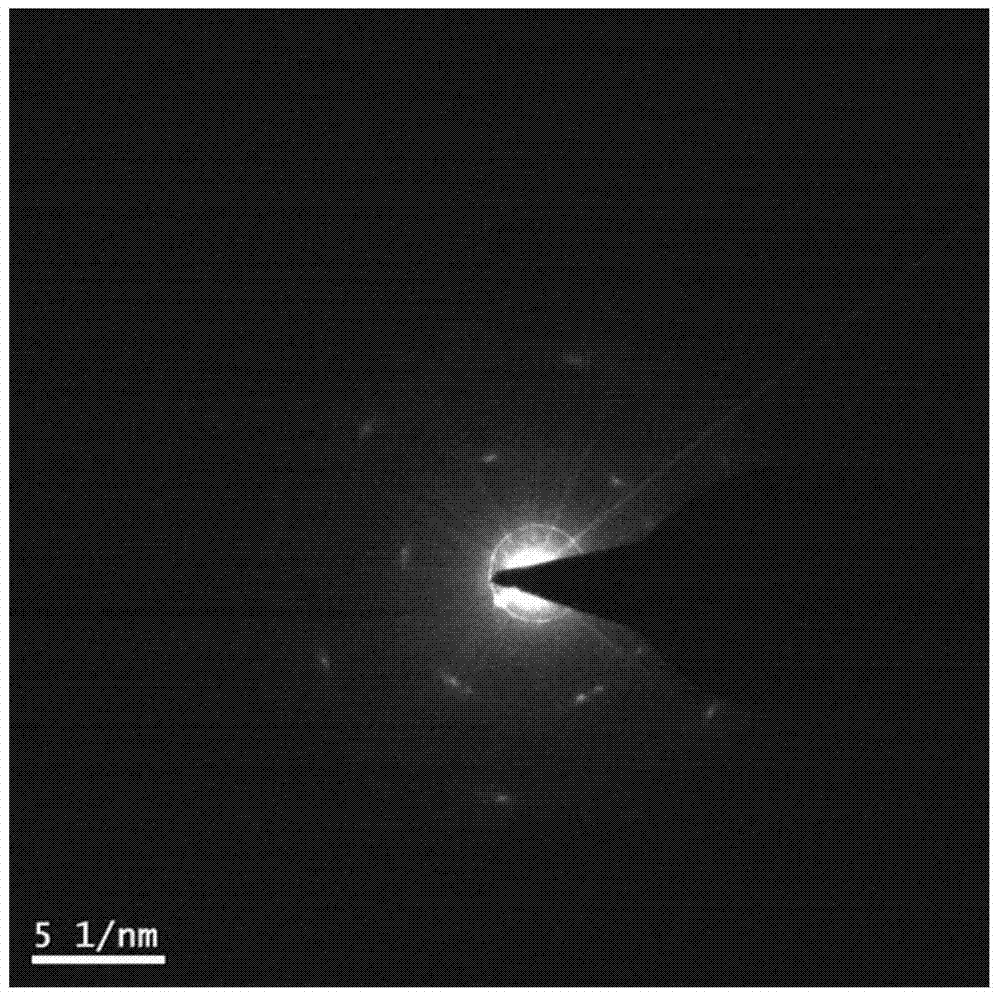

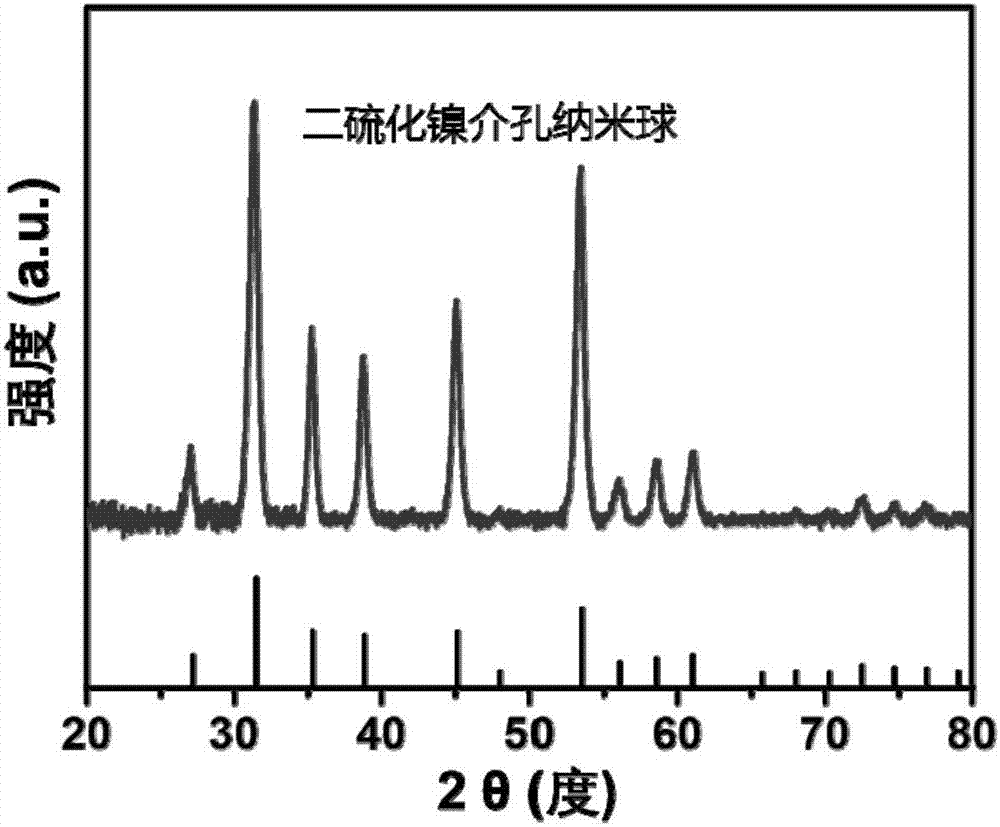

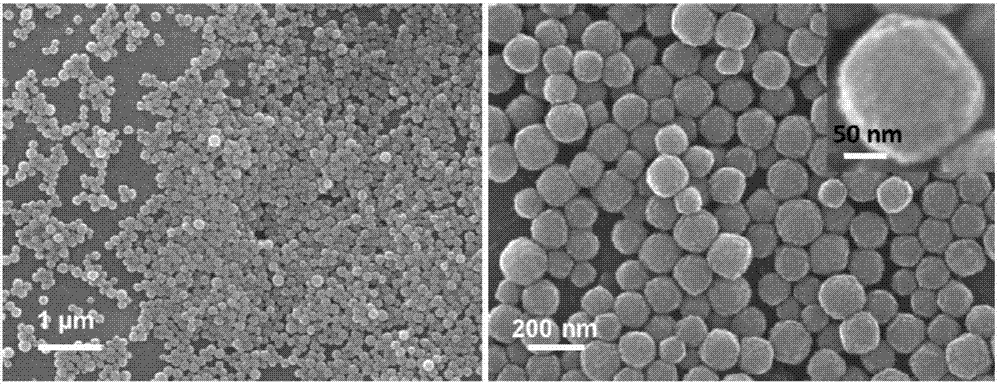

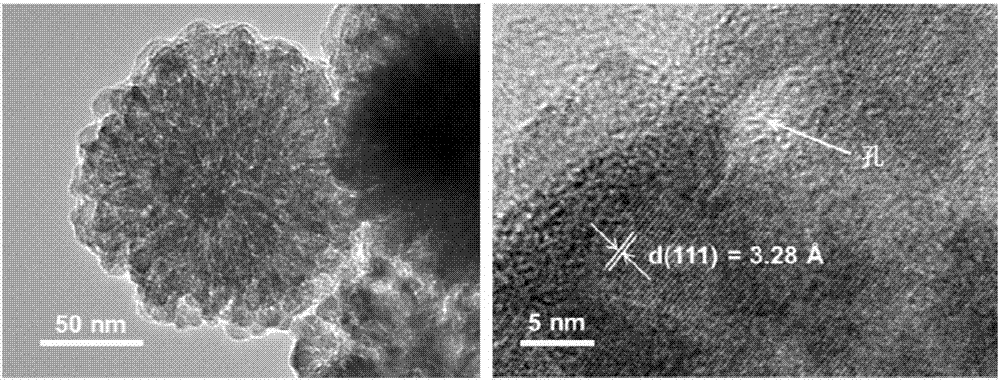

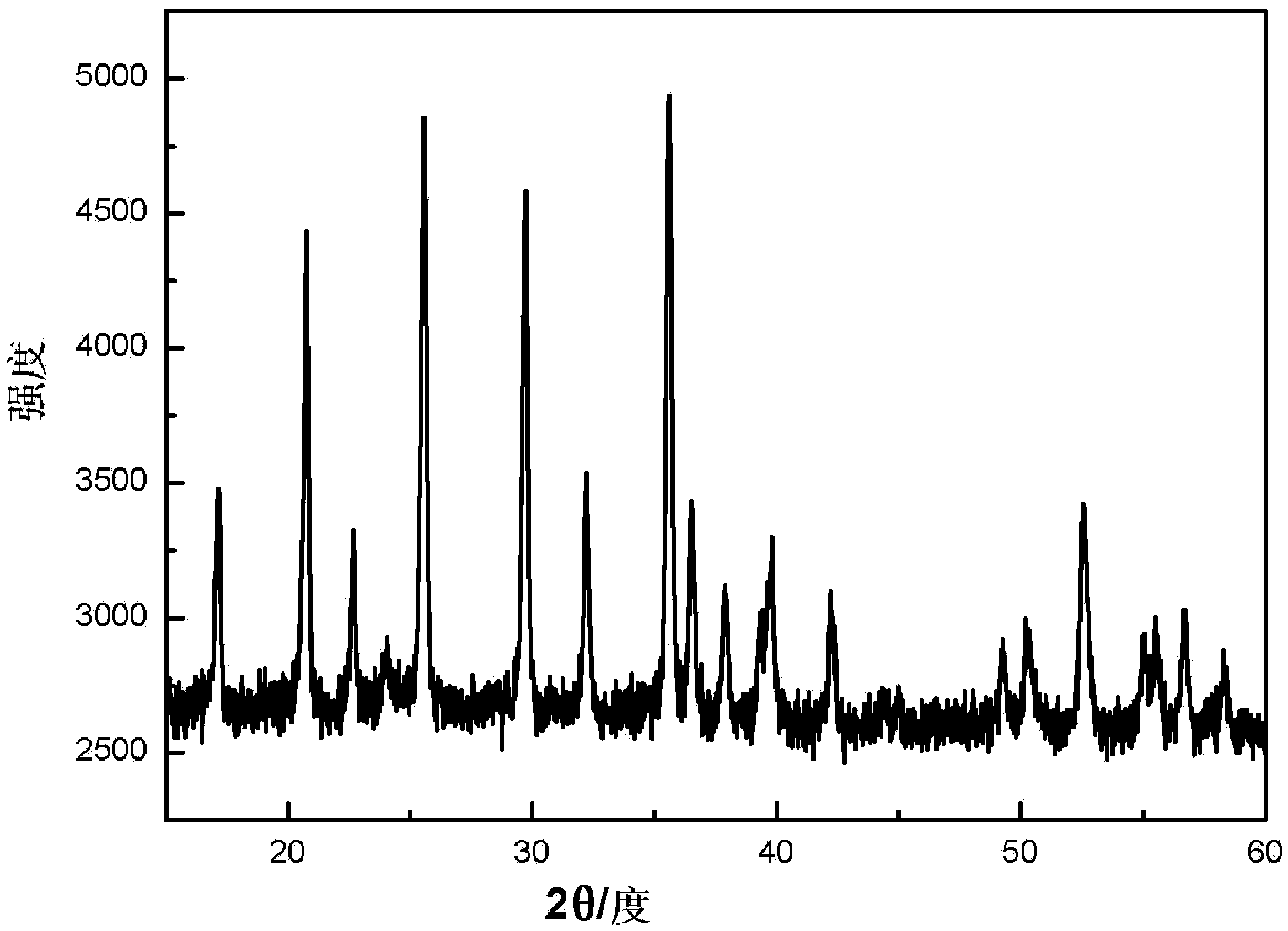

NiS2 mesoporous nanosphere material, preparation method thereof and application

ActiveCN107140699AImprove structural stabilityIncrease contact areaMaterial nanotechnologySecondary cellsIonHigh rate

The invention relates to a NiS2 mesoporous nanosphere material and a preparation method thereof. The material can serve as a long-life and high-rate sodium-ion battery negative electrode active material, a plurality of NiS2 subunit nano-particles are regularly stacked to form mesoporous nanosphere structures with uniform shapes, mesopores are formed among the NiS2 subunit nano-particles, the sizes of the mesopores are mainly distributed within the range of 3-4 nanometers, mesoporous nanospheres are free from agglomeration and good in dispersity, the diameters of the NiS2 subunit nano-particles are 150-200 nanometers, and the specific surface area of each mesoporous nanosphere is 49.1m<2>g<1>. The material has the advantages that the NiS2 mesoporous nanosphere material is successfully synthesized and shows excellent high-rate performance, cycling stability and long service life when serving as the sodium-ion battery negative electrode active material, and the material is a potential applied material for a high-power and long-life sodium-ion battery.

Owner:WUHAN UNIV OF TECH

Carbon-coated lithium ion battery positive electrode material lithium iron phosphate and preparation method thereof

InactiveCN103441268ALow costLow process temperatureCell electrodesPhosphorus compoundsElectrical batteryLithium-ion battery

The invention relates to a preparation method for a carbon-coated lithium ion battery positive electrode material. The preparation method comprises the following steps: successively adding a carbon source dispersion liquid, a phosphorus source dispersion liquid, a lithium source dispersion liquid and a ferric iron source dispersion liquid into a solution of a dispersant or deionized water; fully mixing an obtained mixed liquid so as to obtain a uniformly dispersed solution or turbid liquid; drying the mixed liquid to obtain a precursor and then pre-decomposing and sintering the precursor so as to obtain the single-phase carbon-coated lithium ion battery positive electrode material lithium iron phosphate. According to the method, usage of the ferric iron source enables cost for raw materials to be substantially reduced; process temperature of the synthesized material is low, high-temperature processing time is short, a preparation period for the material is substantially shortened, and production cost is effectively reduced; there is no requirement for raw materials, so the source of the raw materials is broadened. The synthesized lithium iron phosphate has the advantages of a particle size of 60 to 550 nm, good particle dispersion, high conductivity, great specific capacity, a long cycle life, etc. and can meet needs of practical application of a lithium ion battery.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

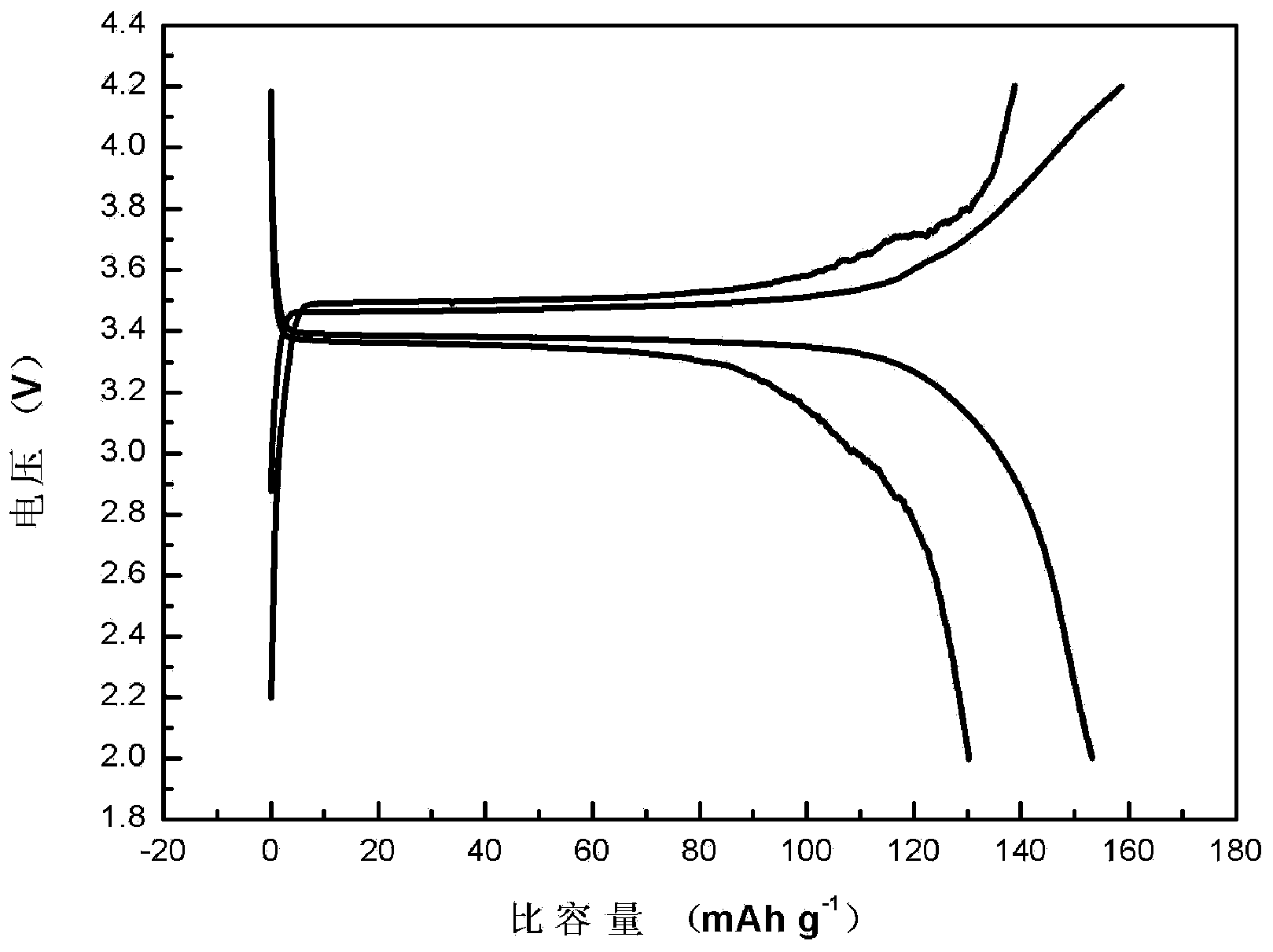

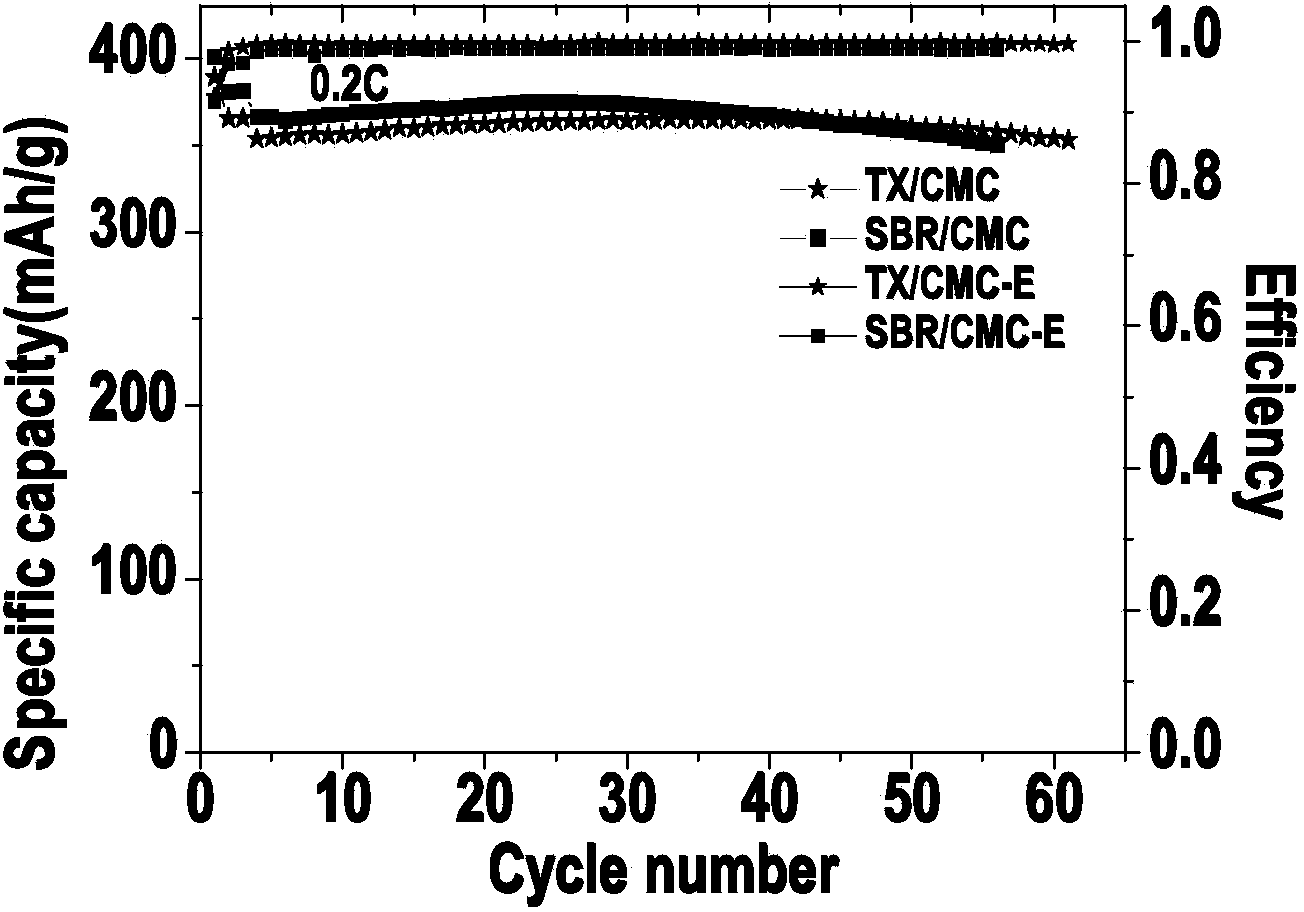

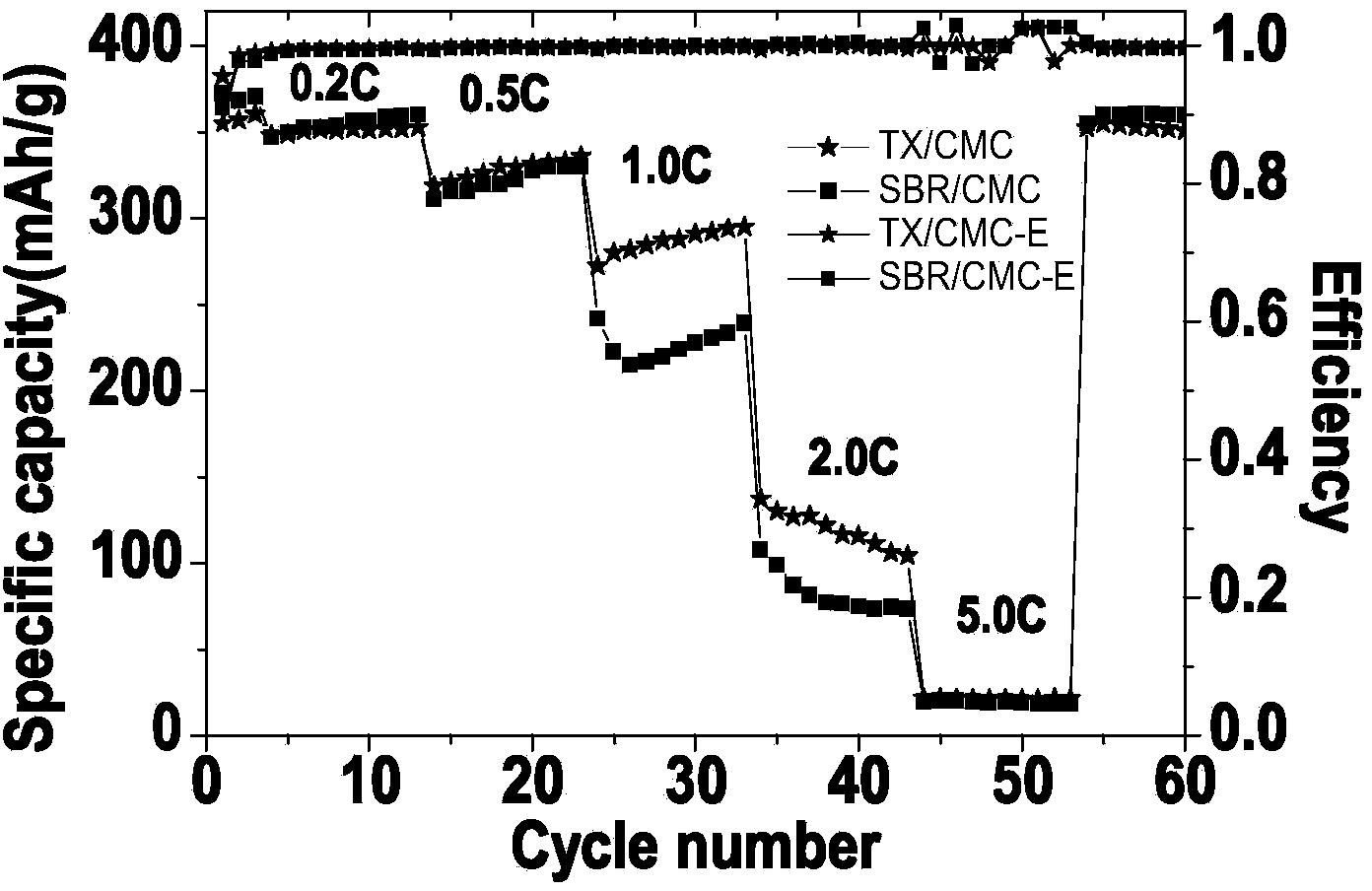

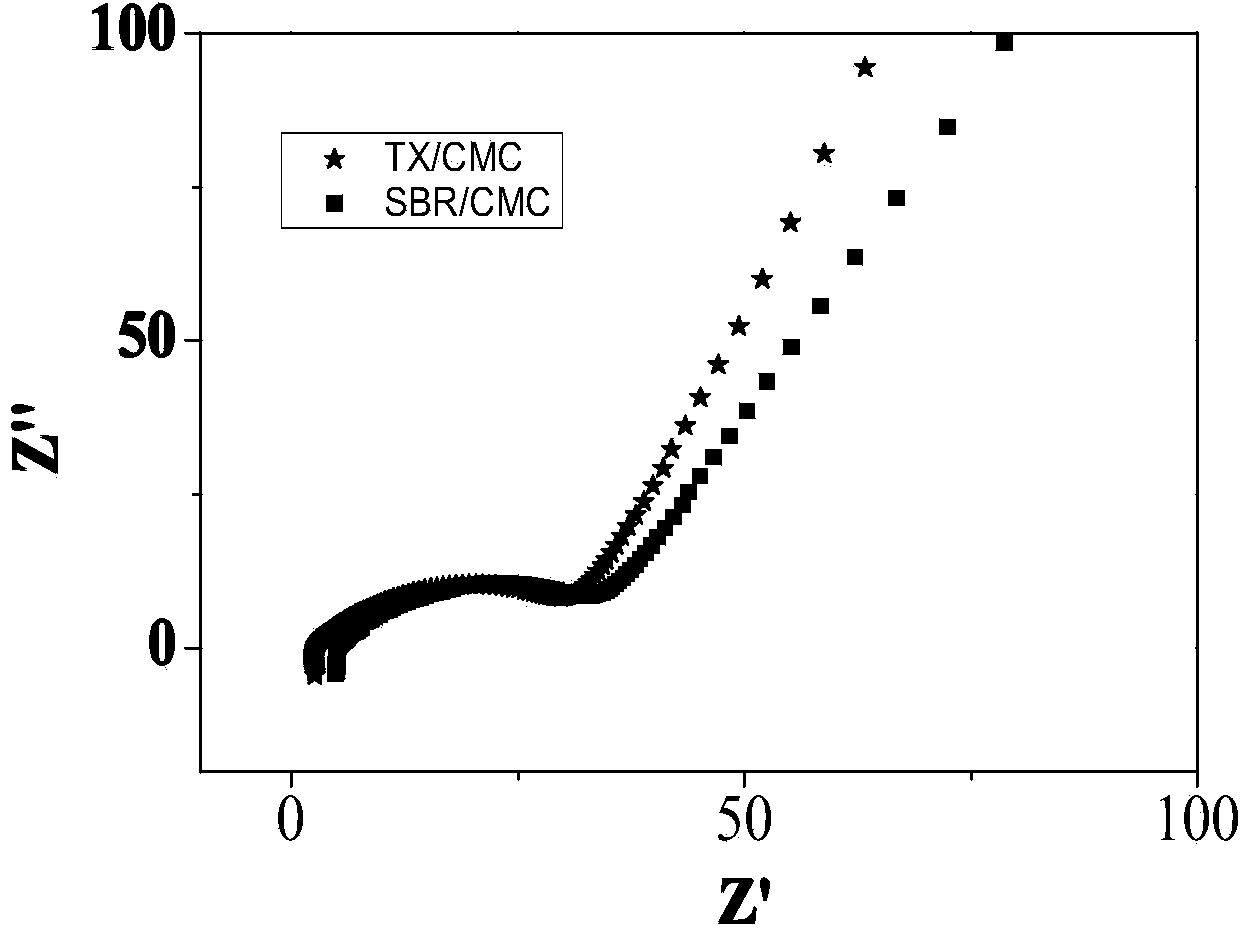

Terpene resin based aqueous binder and application thereof to lithium ion battery cathode or super capacitor

ActiveCN104017520AReduce interface impedanceImprove cycle stabilityProtein waste adhesivesHybrid capacitor electrodesCarboxymethyl celluloseElectrical battery

The invention provides the application of a terpene resin based aqueous binder to a lithium ion battery cathode or a super capacitor. The terpene resin based aqueous binder is composed of a terpene resin emulsion and carboxymethyl cellulose in a certain proportion, wherein the weight ratio of terpene resin to carboxymethyl cellulose is 100: 1-1:100. The lithium ion battery cathode and super capacitor containing the terpene resin based aqueous binder satisfies the composition proportion of: an active material: a conductive agent: (terpene resin+carboxymethyl cellulose)=70: 95:1:20:4-10. The invention adopts natural environment-friendly terpene resin the aqueous binder of the lithium ion battery or super capacitor, can greatly improve the overall cycling stability and rate capability of the battery, and can significantly reduce the cost of the battery.

Owner:SHENZHEN XIN CHANG LONG NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com