Terpene resin based aqueous binder and application thereof to lithium ion battery cathode or super capacitor

一种锂离子电池、超级电容器的技术,应用在混合/双电层电容器制造、电池电极、电极集电体涂层等方向,能够解决影响电池长期循环性能电池高倍率性能、不利锂离子脱嵌、固态电解质膜阻抗大等问题,达到改善电池循环稳定性能、改善高倍率性能、降低界面阻抗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of test electrodes:

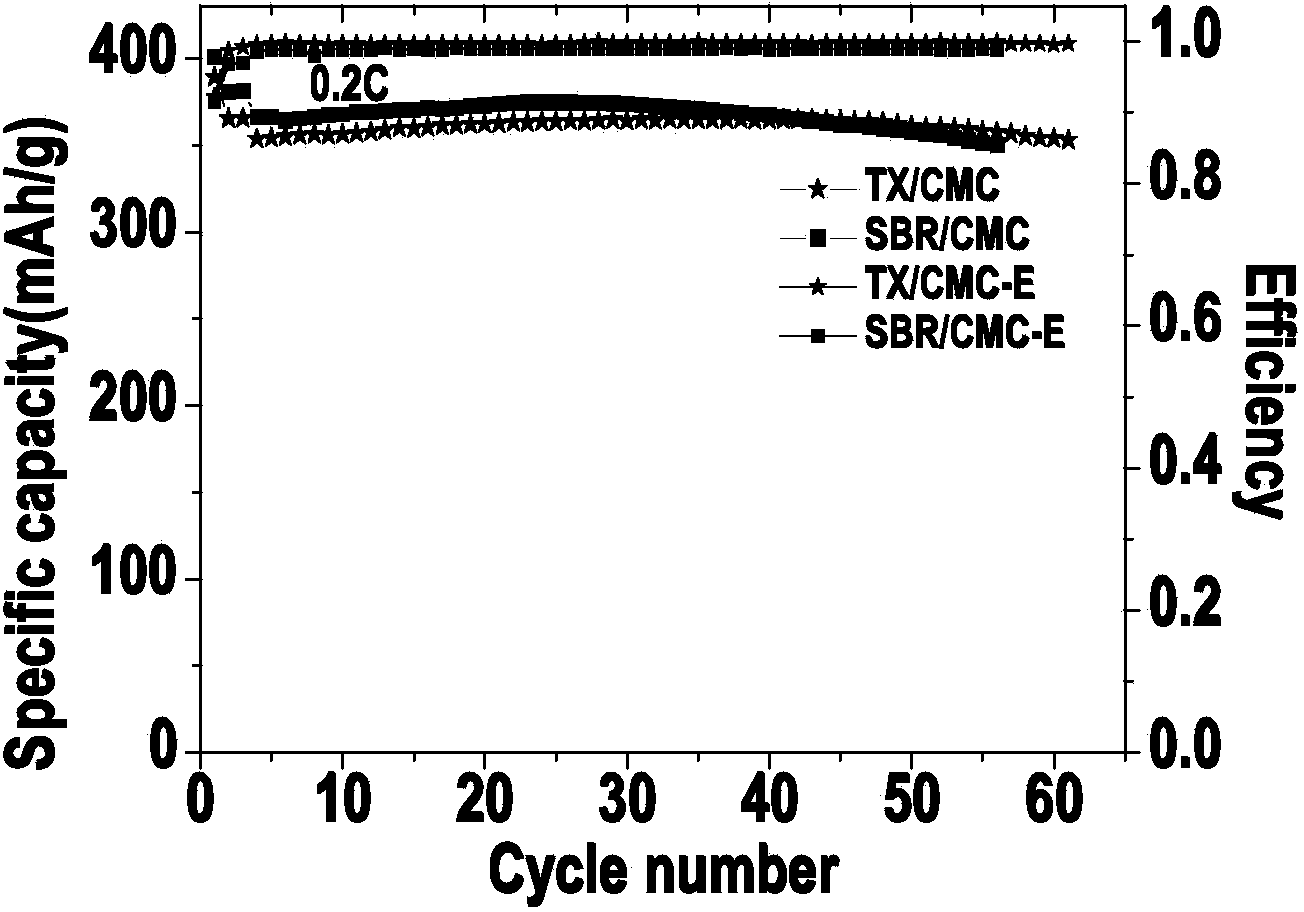

[0045]The mass ratio of the mass sum of the terpene resin and carboxymethyl cellulose in the graphite, the conductive agent and the terpene resin-based water-based binder is 95:1:4. Mix and stir the graphite and the conductive agent until uniformly dispersed; then add carboxymethyl cellulose to deionized water to make carboxymethyl cellulose aqueous solution, add the prepared carboxymethyl cellulose aqueous solution to the above system and stir evenly; then Add the terpene resin emulsion to the mixture obtained above (TX / CMC=3 / 2), add an appropriate amount of deionized water, and stir evenly to obtain a graphite electrode slurry (solid content is 45%); the prepared slurry Evenly coated on Cu foil, vacuum dried at 90°C to obtain graphite negative electrode sheet. After weighing the vacuum-dried electrode pieces, they were assembled in a 2025 battery case in a glove box, with a lithium sheet as the counter electrode, a polyethylene fi...

Embodiment 2

[0055] 1. Preparation of test electrodes:

[0056] The difference between this embodiment and embodiment 1 is that the test electrode uses TX / CMC as a binder, where TX / CMC=4:1.

[0057] Second, the preparation of the contrast electrode:

[0058] With embodiment 1.

[0059] 3. Electrochemical test:

[0060] Electrochemical tests were carried out on the charge-discharge cycle stability and rate performance of the test electrode and the reference electrode.

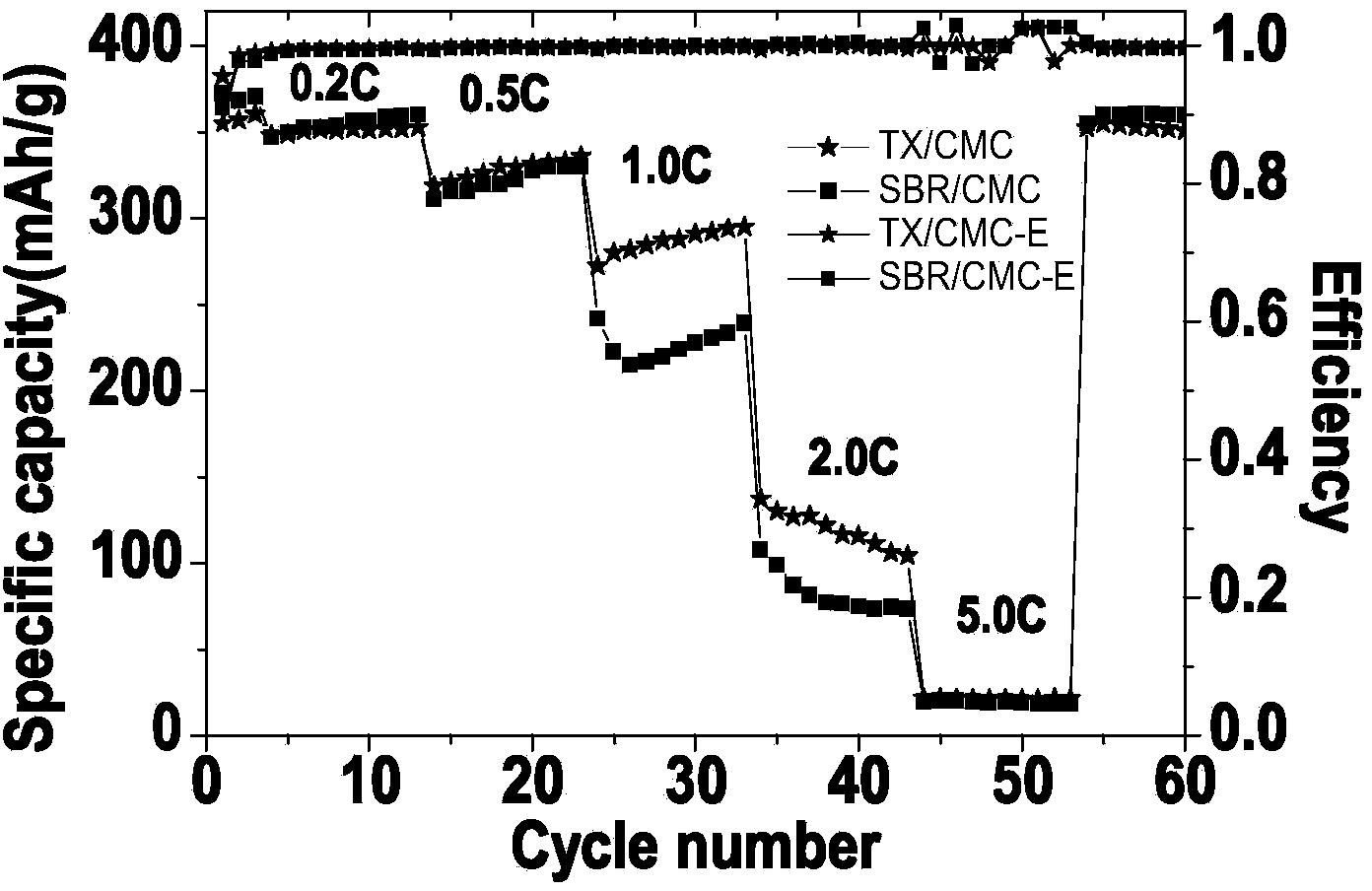

[0061] 4. Results analysis:

[0062] figure 2 It is the cycle performance test curve of the test electrode and the comparison electrode in this embodiment under different charge and discharge current densities. It can be seen from the figure that using TX / CMC as the binder of graphite shows good high-rate characteristics. When the magnification is higher than 0.5C, the graphite using TX / CMC as the binder is much higher than that of SBR / CMC. When the rate is 1C, the specific capacity of graphite prepared by using TX / C...

Embodiment 3

[0064] 1. Preparation of test electrodes:

[0065] The difference between this embodiment and embodiment 1 is that the test electrode uses TX / CMC as a binder, where TX / CMC=100:1.

[0066] Second, the preparation of the contrast electrode:

[0067] With embodiment 1.

[0068] 3. Electrochemical test:

[0069] Impedance test after 3 cycles of the test electrode and the reference electrode.

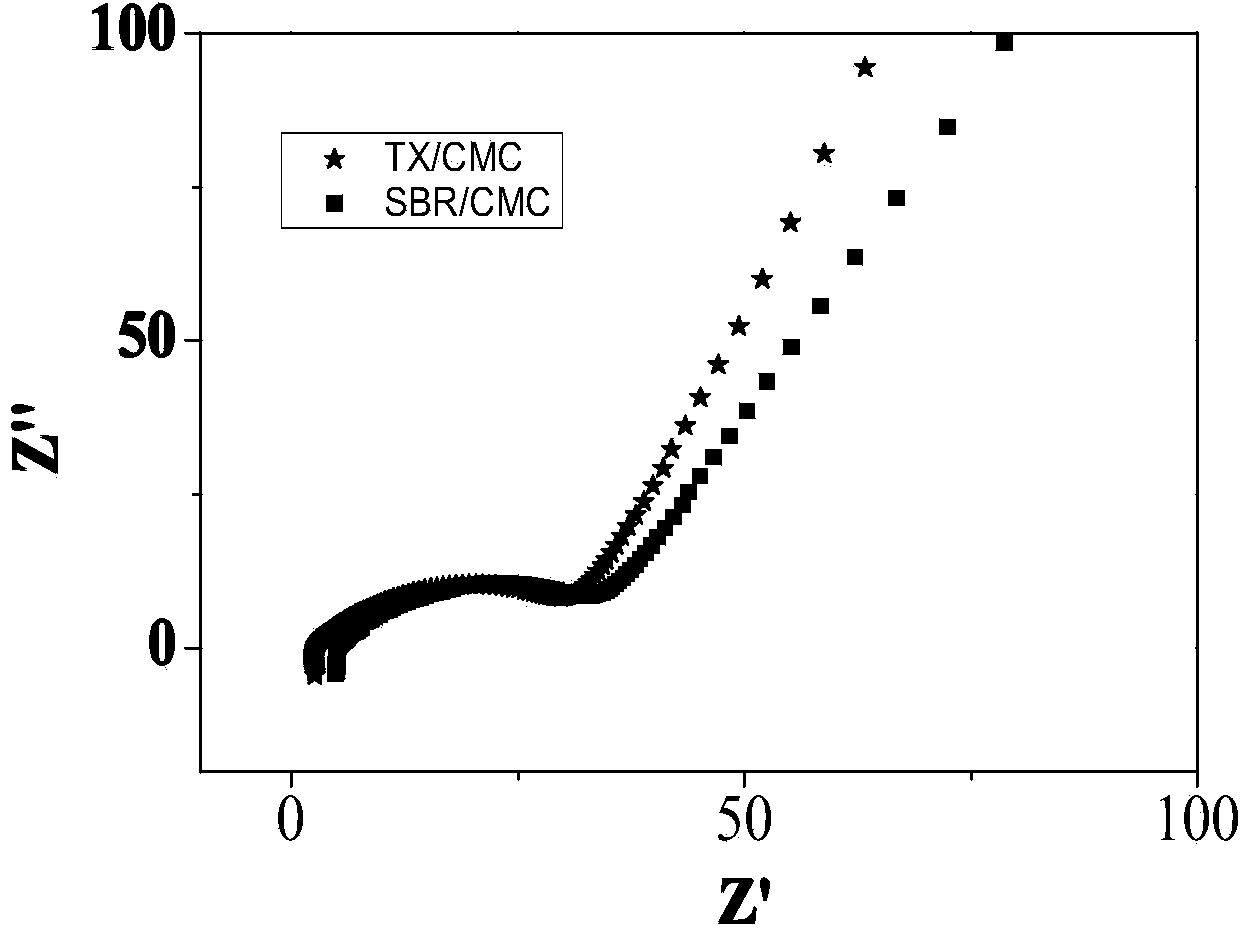

[0070] 4. Results analysis:

[0071] image 3 For this example, the impedance test results of the test electrode and the reference electrode in the 0.2C magnification, using TX / CMC and SBR / CMC as the binder, and the graphite electrode after 3 cycles. It can be seen from the figure that when TX / CMC is used as the binder, the impedance value of the graphite electrode is relatively smaller than that of SBR / CMC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com