Polyolefin multilayer micro porous diaphragm for lithium ion battery and preparation method of polyolefin multilayer micro porous diaphragm

A technology of lithium-ion batteries and microporous membranes, which is applied in the field of diaphragm materials for lithium-ion batteries and its preparation, can solve the problems of reducing the porosity of diaphragms, poor cycle life and safety performance, and poor battery safety performance. Effects of discharge power and cycle life, good liquid absorption and retention, excellent lyophilicity and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

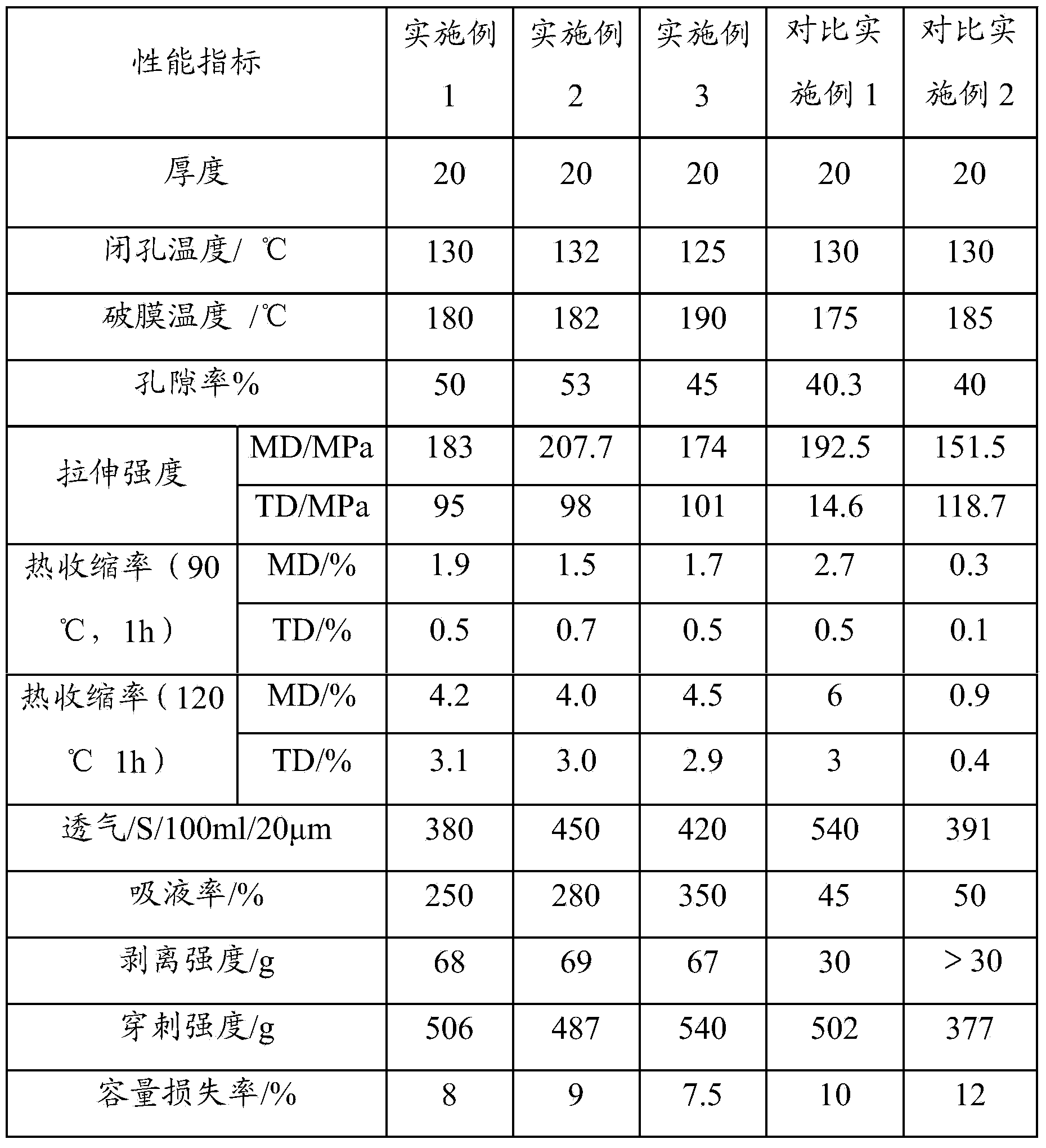

Embodiment 1

[0064] Preparation of polyethylene microporous layer: Take 20% by weight high-density polyethylene and 80% liquid paraffin and extrude in a twin-screw extruder at 200 ° C, form an oil film on a cooling roll at 25 ° C, and heat the above oil film at 120 ° C Two-way simultaneous stretching is carried out, the stretching ratio is 5×5, and the stretched oil film is subjected to heat setting treatment at 130°C for 20s. The high-boiling-point solvent in the solvent is eluted with dichloromethane extractant, and then dried to obtain a polyethylene microporous layer.

[0065] Preparation of the polypropylene microporous layer: the polypropylene was melt-extruded at 230° C. with an extrusion device, and then cooled to 90° C. for uniaxial stretching to obtain a polypropylene microporous layer.

[0066] Preparation of ion acceleration layer: Add polyvinylidene fluoride to acetone: glycerol = 10: 1 mixed solution, and prepare ion acceleration layer solution according to the mass ratio pol...

Embodiment 2

[0069] Preparation of polyethylene microporous layer: Take 20% by weight high-density polyethylene and 80% liquid paraffin and extrude in a twin-screw extruder at 200 ° C, form an oil film on a cooling roll at 25 ° C, and heat the above oil film at 120 ° C Carry out two-way simultaneous stretching with a stretching ratio of 5×5, and heat-setting the stretched oil film at 130°C for 20s. The high-boiling-point solvent in the solvent is eluted with dichloromethane extractant, and then dried to obtain a polyethylene microporous membrane.

[0070] Preparation of the polypropylene microporous layer: the polypropylene was melt-extruded at 230° C. with an extrusion device, and then cooled to 90° C. for uniaxial stretching to obtain a polypropylene microporous layer.

[0071] Preparation of the ion acceleration layer: Add polyvinylidene fluoride and dioctyl phthalate to acetone, and prepare according to the mass ratio of polyvinylidene fluoride: dioctyl phthalate: acetone = 1:0.1:12 i...

Embodiment 3

[0074] Preparation of polyethylene microporous layer: Take 20% by weight high-density polyethylene and 80% liquid paraffin and extrude in a twin-screw extruder at 200 ° C, form an oil film on a cooling roll at 25 ° C, and heat the above oil film at 120 ° C Carry out two-way simultaneous stretching with a stretching ratio of 5×5, and heat-setting the stretched oil film at 130°C for 20s. The high-boiling-point solvent in the solvent is eluted with dichloromethane extractant, and then dried to obtain a polyethylene microporous membrane.

[0075] Preparation of the polypropylene microporous layer: the polypropylene was melt-extruded at 230° C. with an extrusion device, and then cooled to 90° C. for uniaxial stretching to obtain a polypropylene microporous layer.

[0076] Preparation of ion acceleration layer: Add polyvinylidene fluoride to acetone: glycerol = 10: 1 mixed solution, and prepare ion acceleration layer solution according to the mass ratio polyvinylidene fluoride: mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com