A kind of polyolefin multilayer microporous film for lithium ion battery and preparation method thereof

A kind of technology of lithium ion battery and microporous membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

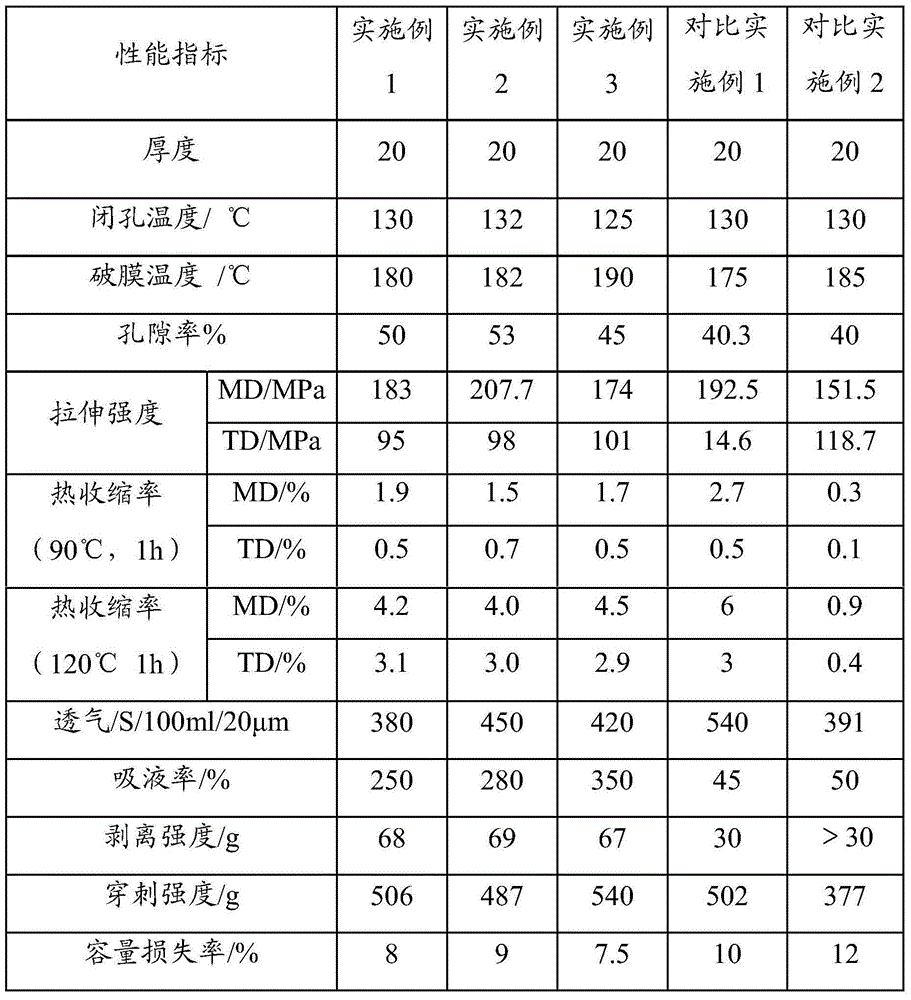

Examples

Embodiment 1

[0064] Preparation of polyethylene microporous layer: Get 20% high-density polyethylene and 80% liquid paraffin in a twin-screw extruder at 200 ° C by weight, form an oil film on a cooling roll at 25 ° C, and heat the above oil film at 120 ° C Two-way simultaneous stretching is carried out, the stretching ratio is 5×5, and the stretched oil film is subjected to heat setting treatment at 130°C for 20s. The high-boiling-point solvent in the solvent is eluted with dichloromethane extractant, and then dried to obtain a polyethylene microporous layer.

[0065] Preparation of the polypropylene microporous layer: the polypropylene was melt-extruded at 230° C. with an extrusion device, and then cooled to 90° C. for uniaxial stretching to obtain a polypropylene microporous layer.

[0066] Preparation of the ion acceleration layer: Add polyvinylidene fluoride to a mixture of acetone:glycerol=10:1, and prepare an ion acceleration layer solution at a mass ratio of polyvinylidene fluoride:...

Embodiment 2

[0069] Preparation of polyethylene microporous layer: Get 20% high-density polyethylene and 80% liquid paraffin in a twin-screw extruder at 200 ° C by weight, form an oil film on a cooling roll at 25 ° C, and heat the above oil film at 120 ° C Carry out two-way simultaneous stretching with a stretching ratio of 5×5, and heat-setting the stretched oil film at 130°C for 20s. The high-boiling-point solvent in the solvent is eluted with dichloromethane extractant, and then dried to obtain a polyethylene microporous membrane.

[0070] Preparation of the polypropylene microporous layer: the polypropylene was melt-extruded at 230° C. with an extrusion device, and then cooled to 90° C. for uniaxial stretching to obtain a polypropylene microporous layer.

[0071] Preparation of the ion acceleration layer: Add polyvinylidene fluoride and dioctyl phthalate to acetone, and prepare according to the mass ratio of polyvinylidene fluoride: dioctyl phthalate: acetone = 1:0.1:12 into ion accel...

Embodiment 3

[0074]Preparation of polyethylene microporous layer: Get 20% high-density polyethylene and 80% liquid paraffin in a twin-screw extruder at 200 ° C by weight, form an oil film on a cooling roll at 25 ° C, and heat the above oil film at 120 ° C Carry out two-way simultaneous stretching with a stretching ratio of 5×5, and heat-setting the stretched oil film at 130°C for 20s. The high-boiling-point solvent in the solvent is eluted with dichloromethane extractant, and then dried to obtain a polyethylene microporous membrane.

[0075] Preparation of the polypropylene microporous layer: the polypropylene was melt-extruded at 230° C. with an extrusion device, and then cooled to 90° C. for uniaxial stretching to obtain a polypropylene microporous layer.

[0076] Preparation of the ion acceleration layer: Add polyvinylidene fluoride to a mixture of acetone:glycerol=10:1, and prepare an ion acceleration layer solution at a mass ratio of polyvinylidene fluoride:mixture=1:15.

[0077] Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com