Large-capacity power lithium battery and preparation method thereof

A power lithium and large-capacity technology, which is applied in the field of large-capacity power lithium battery and its preparation, can solve problems such as power source application, and achieve good high-rate performance, no environmental pollution, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

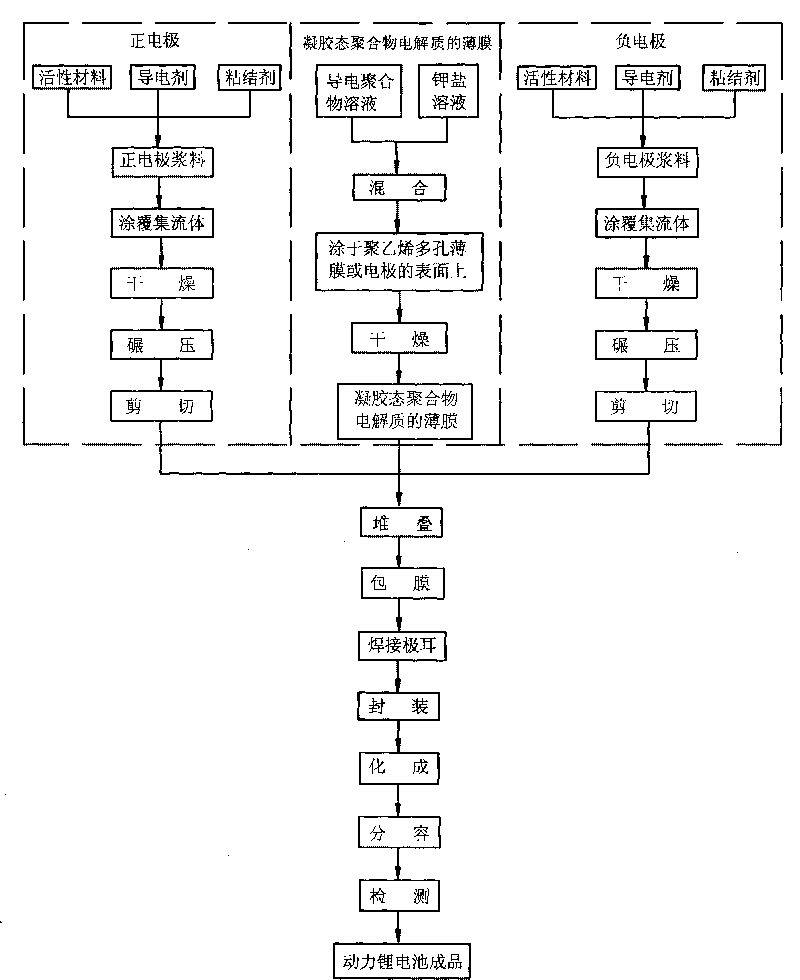

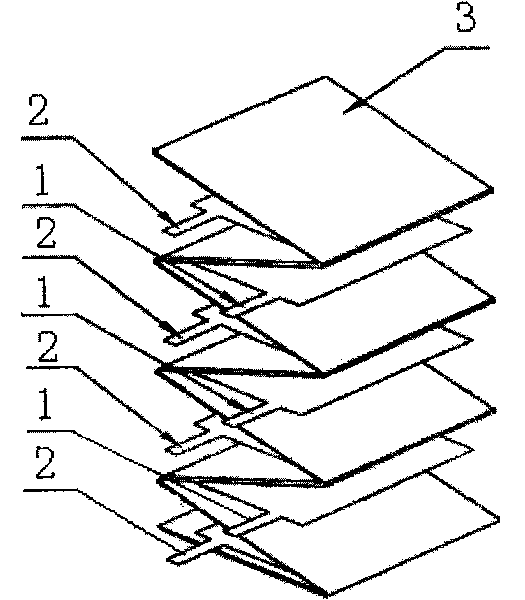

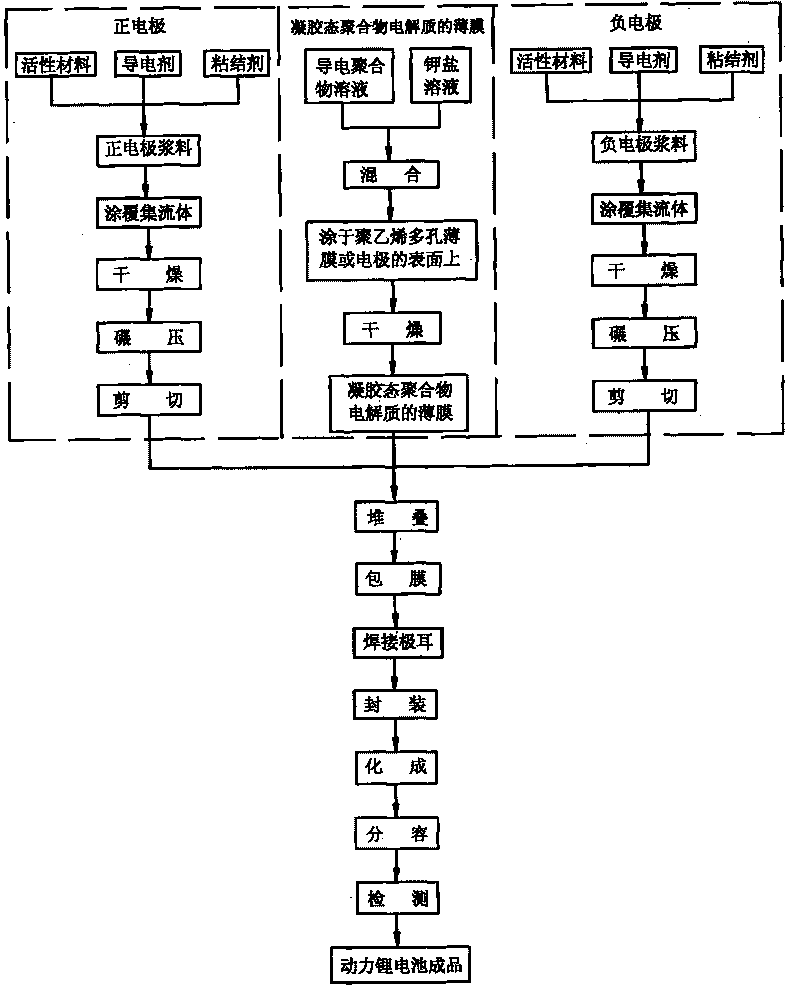

[0026] The high-capacity power lithium battery of this embodiment is designed according to the rated capacity of a single battery of 10Ah. It is formed by stacking and packaging a positive electrode, a film of a gel-state polymer electrolyte, and a negative electrode. The film isolation of the polymer electrolyte, the key is that the active material of the negative electrode has a particle size of 0.165μm and a specific surface area of 9.2m 2 / g of modified lithium titanate; the active material of the positive electrode is a ternary material; the film of the gel state polymer electrolyte is formed by mixing and drying a solution of a lithium salt and an organic solvent with a conductive polymer solution, Such as figure 1 Shown, its concrete preparation method is as follows:

[0027] A: 84% by weight of modified lithium titanate, 7% by weight of conductive carbon black and 9% by weight of polyvinylidene fluoride as a solute, and N-methylpyrrolidone as a solvent to adjust int...

Embodiment 2

[0034]The large-capacity power lithium battery of this embodiment is designed according to the rated capacity of a single battery of 40Ah. It is formed by stacking and packaging positive electrodes, films of gel-state polymer electrolytes, and negative electrodes. The film isolation of the polymer electrolyte, the key is that the active material of the negative electrode has a particle size of 0.165μm and a specific surface area of 9.2m 2 / g of modified lithium titanate; the active material of the positive electrode is a ternary material; the film of the gel state polymer electrolyte is formed by mixing and drying a solution of a lithium salt and an organic solvent with a conductive polymer solution, Such as figure 1 Shown, its concrete preparation method is as follows:

[0035] A: 84% by weight of modified lithium titanate, 7% by weight of conductive carbon black and 9% by weight of polyvinylidene fluoride as a solute, and N-methylpyrrolidone as a solvent to adjust into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com