Ternary lithium battery electrolyte and high-temperature resistant, high-capacity and high-safety lithium battery core

A ternary lithium battery and electrolyte technology, which is applied in the direction of battery electrodes, secondary batteries, organic electrolytes, etc., can solve the problem that the safety performance and high temperature performance of the ternary system cannot meet the needs of the whole vehicle, the phenomenon of oxidation and decomposition of the electrolyte is intensified, and the cathode Problems such as intensified dissolution of metal ions, to achieve the effect of high rate charge and discharge, capacity and safety performance improvement, safety performance and high temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 2. Preparation of batteries:

[0031] When using the present invention to prepare lithium-ion batteries, the positive electrode material used is made of nano-titanium dioxide and ternary materials (LiNi 0.8 co 0.1 mn 0.1 o 2 ) mixture (2:98), milled for 12 hours, and calcined at 800-1000°C for 10 hours to make titanium dioxide in the ternary material (LiNi 0.8 co 0.1 mn 0.1 o 2 ) form a complete coating on the surface. The new ternary material after coating (LiNi 0.8 co 0.1 mn 0.1 o 2 ) positive electrode material, reduce the reaction between the electrode and the interface, and improve the cycle of lithium battery materials during charge and discharge. The gram specific capacity of this high-nickel ternary material can be 187mAh / g, compacted to 3.5g / cm3, improving the mass and volumetric energy density of the battery. In the following examples, the positive electrode active material ternary material (LiNi 0.8 co 0.1 mn 0.1 o 2 ) is mixed with supercondu...

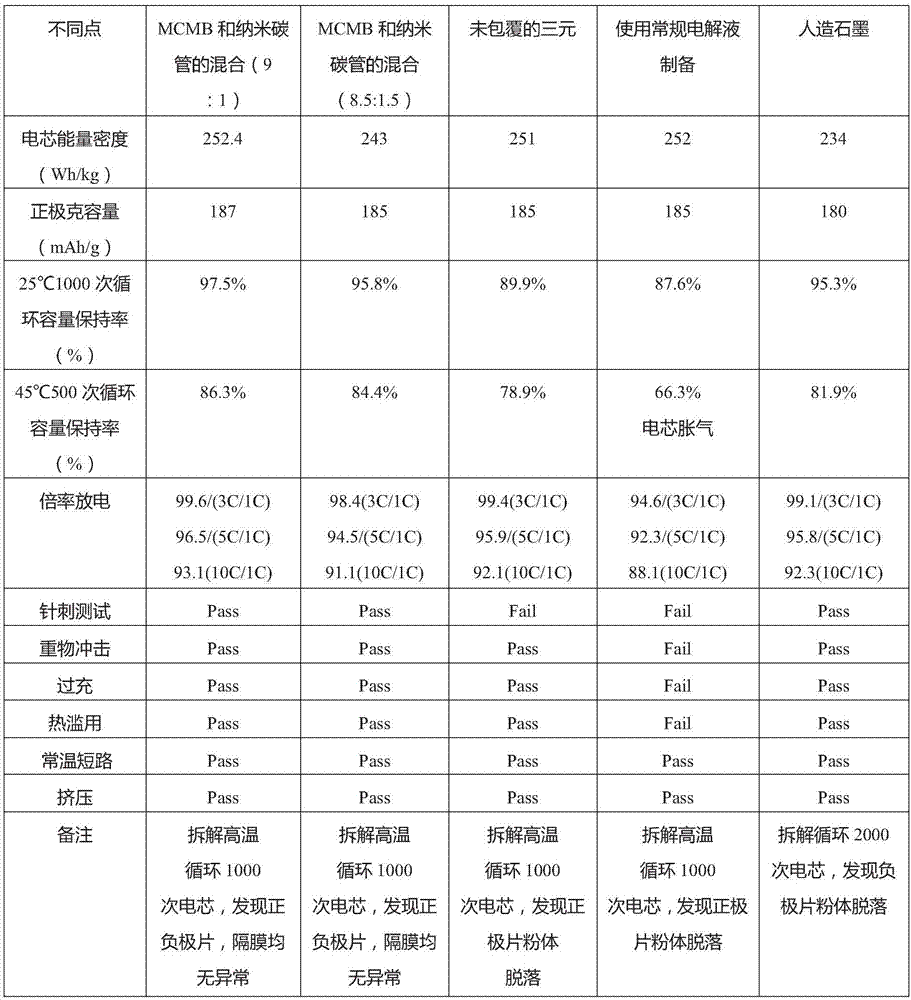

Embodiment 1

[0041] The positive electrode is made of coated ternary material (LiNi 0.8 co 0.1 mn 0.1 o 2 ), mixed with superconducting carbon black SP, using PVDF as a binder to prepare positive electrode slurry; mixing (9:1) of negative electrode active material MCMB and carbon nanotubes, CMC as a thickener, and SBR as a binder Prepared as negative electrode slurry. Use high-temperature resistant high-safety electrolyte (1.3mol / l LiBOB and LiFSI / EC (ethylene carbonate): EMC (ethyl methyl carbonate): DEC (diethyl carbonate) (3:4:3), FEC (fluorinated Ethylene carbonate) + MMDS (methylene disulfonate) + TMP (trimethyl phosphate) additives, polymer lithium-ion batteries.

Embodiment 2

[0043] The positive electrode is made of coated ternary material (LiNi 0.8 co 0.1 mn 0.1 o 2 ), mixed with superconducting carbon black SP, using PVDF as a binder to prepare positive electrode slurry; mixing (8.5:1.5) of negative electrode active material MCMB and carbon nanotubes, CMC as a thickener, and SBR as a binder Prepared as negative electrode slurry. Use high-temperature resistant high-safety electrolyte (1.0mol / 1 LiBOB and LiFSI / EC (ethylene carbonate): EMC (ethyl methyl carbonate): DEC (diethyl carbonate) (2:5:3), FEC (fluorinated Ethylene carbonate) + MMDS (methylene disulfonate) + TMP (trimethyl phosphate) additives, polymer lithium-ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com