Power polymer lithium ion battery and fabricating process thereof

A lithium-ion battery and polymer technology, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as low bulk density and tap density, difficulty in coating positive electrode slurry, and slow diffusion of lithium ions. , to achieve the effect of high rate charge and discharge performance improvement, high rate performance improvement, uniform and full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

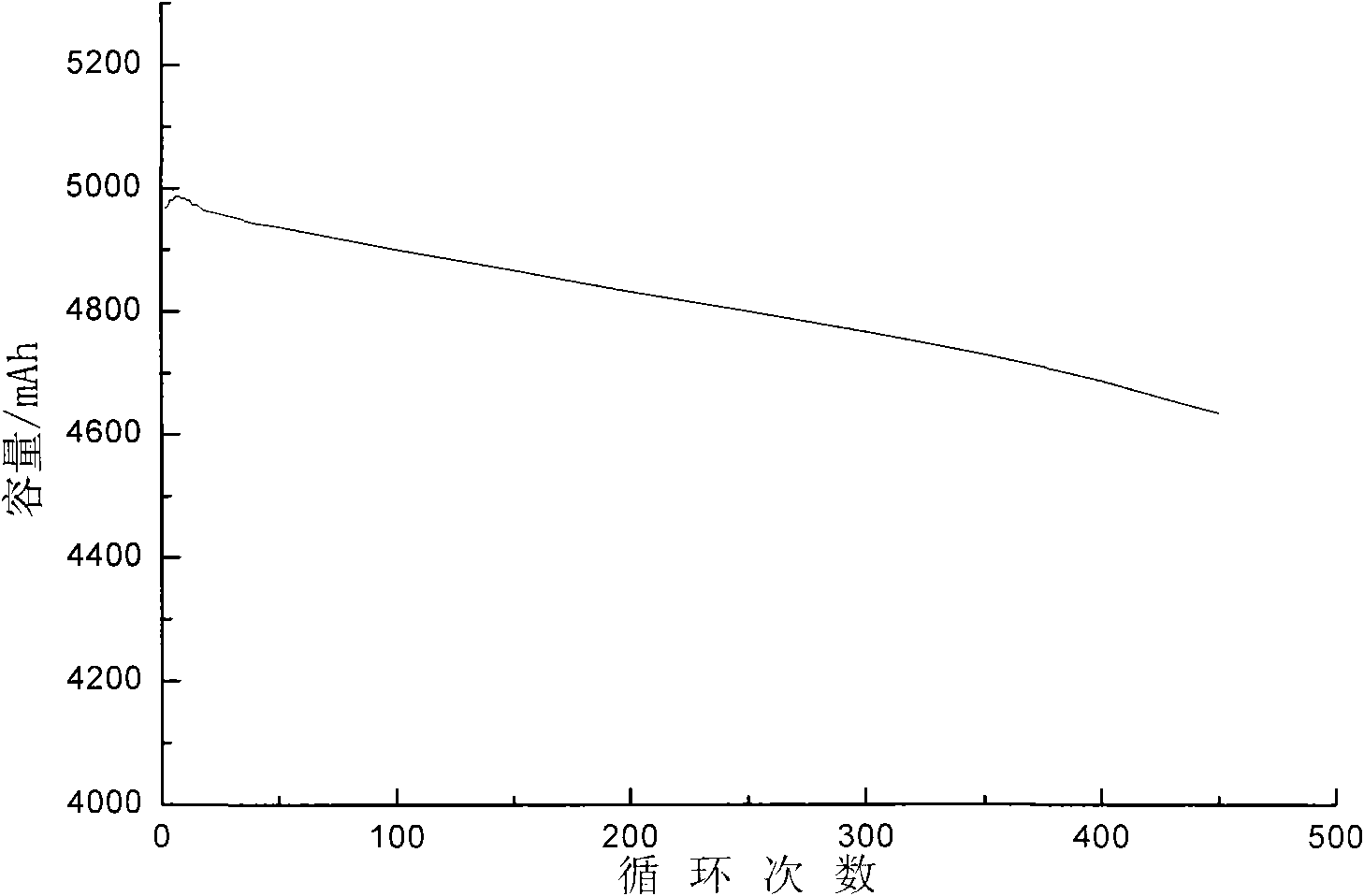

[0034] The manufacturing steps of Example 1 are roughly the same as the above-mentioned embodiment, the difference is that the weight percentage of each component is determined. In the first step, 86.5% of modified lithium iron phosphate, 4% of KS-6 conductive agent, and 4% of Super-p conductive agent 4%, Hypermer KD-1 dispersant 0.5%, mixed grinding, drying, then add PVDFHSV900 positive electrode binder 5%, then add Hypermer KD-1 dispersant 0.5% and stir to make positive electrode slurry. The viscosity is 10000-15000mPa·s, and the slurry is coated on both sides of the aluminum foil. After drying at 110°C, roll pressing to form a pole piece with a thickness of 135 μm and a compacted density of 2.3 g / cm 3 , to obtain the positive electrode sheet. In the step 2, add 95% of artificial graphite into the deionized aqueous solution containing 8% of LA132 negative electrode binder to make negative electrode slurry. The viscosity of the slurry should be 2000-3000mPa·s. Both sides of...

Embodiment 2

[0037]The manufacturing steps of the second embodiment are roughly the same as those of the first embodiment, except that the weight percentages of the components of the positive electrode slurry are 80% of the modified lithium iron phosphate, 8% of the KS-6 conductive agent, and 8% of the Super-p Conductive agent 2%, mixed grinding, drying, adding 761PVDF positive electrode binder 10% and colloid mixed with NMP, stirring to make positive electrode slurry.

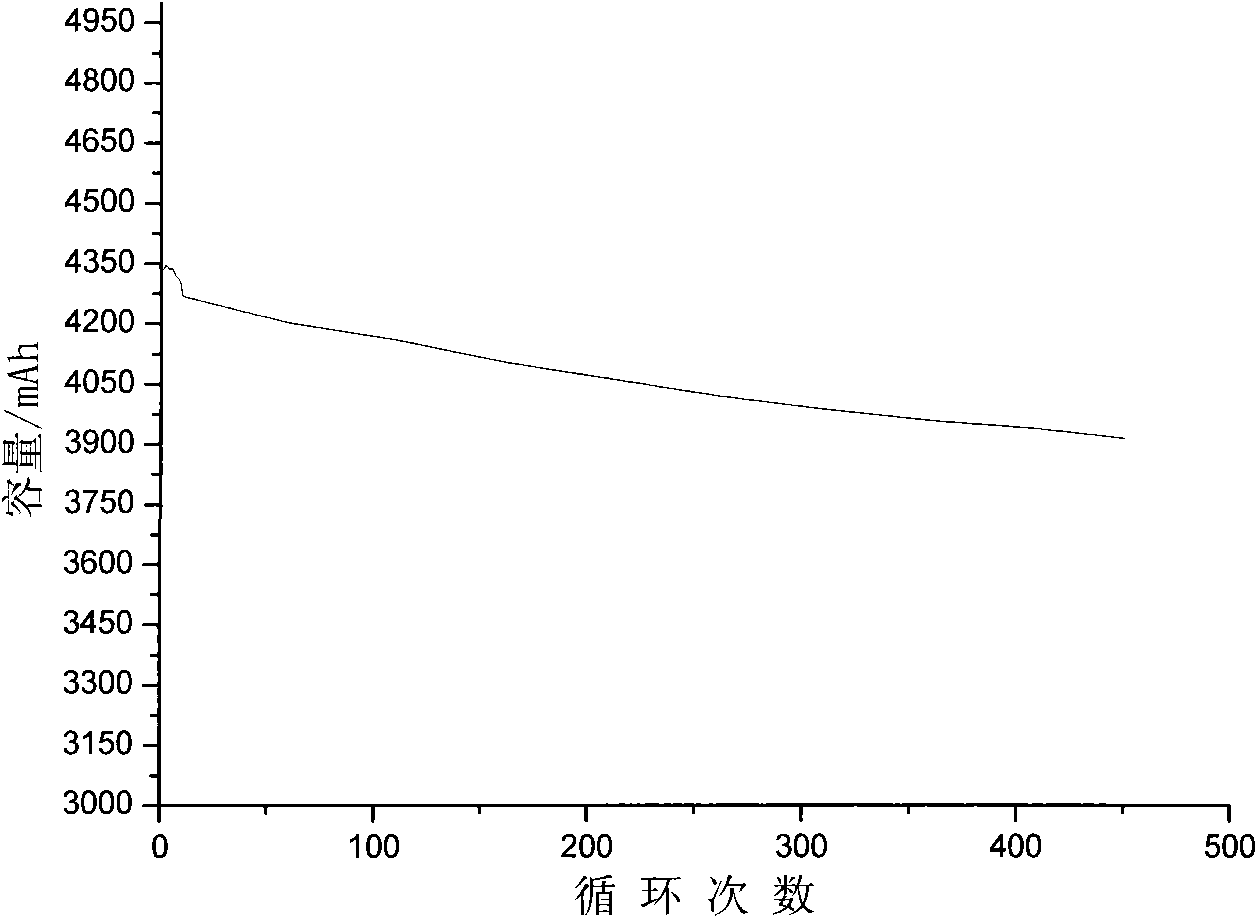

[0038] Such as image 3 Shown is the 1C charging and discharging cycle life of the power polymer lithium-ion battery of the second embodiment of the present invention. After testing, the charging and discharging voltage is 2.2-3.8V, and the discharge platform is 3.2V at 1C. The battery capacity is about 4300mAh, and the cycle is 450 The weekly volume retention rate was 91.3%.

[0039] Through the comparison of Example 1 and Example 2, it can be found that the percentage by weight of the conductive agent and the binder com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com