Adhesive for lithium battery and preparation method thereof

A binder and lithium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cost, rate performance, cycle performance and other battery characteristics, and difficult binder modulation, etc., to achieve high rate performance , excellent plasticity, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of binder for lithium ion battery of the present invention is as follows:

[0027] The high molecular polymer A containing carboxyl functional group and the high molecular polymer B containing hydroxyl functional group are respectively stirred and dissolved in a container, and then according to the mass percentage, the high molecular polymer A containing carboxyl functional group accounts for 59-94%, and the high molecular polymer B containing hydroxyl functional group accounts for 59-94%. B accounts for 5-40% of the ratio and put it into the reactor, then add reaction initiator C with a mass percentage content of 0.5-1%, keep stirring, control the stirring speed at 100-150rpm, and stir at a constant temperature of 40-70°C Cool to room temperature after 10-12 hours to prepare a lithium-ion battery water-based binder.

[0028] The temperature is raised at a rate of 1-5° C. / hour until a constant temperature of 40-70° C. is reached.

[0029] The adh...

Embodiment 1

[0038] Put 10kg of anhydrous carboxyl-containing polymer A into a 50L reaction kettle, and stir and dissolve continuously.

[0039] Put 10kg of anhydrous hydroxyl-containing polymer B into a 50L reaction kettle, and continuously stir and dissolve.

[0040] Under stirring conditions, mix the 9.4kg anhydrous carboxyl-containing polymer A solution and 0.5kg anhydrous hydroxyl-containing polymer B solution after stirring and dissolving, and then add 0.1kg initiator C to oxidize dibenzoyl solution, the stirring speed is controlled at 100~110rpm.

[0041] After stirring for 3 hours, heat up at a heating rate of 5°C / hour, and finally control the temperature of the reactor at 45-50°C to react while stirring for about 12 hours, and finally cool to room temperature to obtain the binder product.

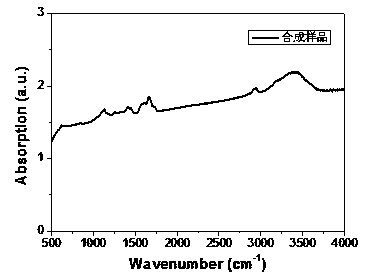

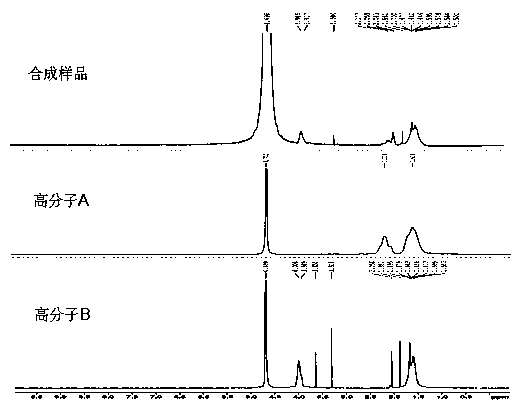

[0042] The properties of the material prepared in Example 1 were characterized. As detected by FTIR, a partial condensation reaction occurred between polymer A and polymer B. figure 2 with ...

Embodiment 2

[0045] With embodiment 1, A and B after stirring and dissolving, under stirring condition, the A solution containing 8kgA and the B solution of 1.9kgB are mixed, then add the initiator C solution containing 0.1kg peroxydicarbonate , the stirring speed is controlled at 140~150rpm.

[0046] After stirring for 2.5 hours, the temperature was raised at a heating rate of 5°C / hour, and finally the temperature of the reactor was controlled at 65-70°C to react while stirring for about 10 hours. Finally, cool to room temperature to obtain a binder product.

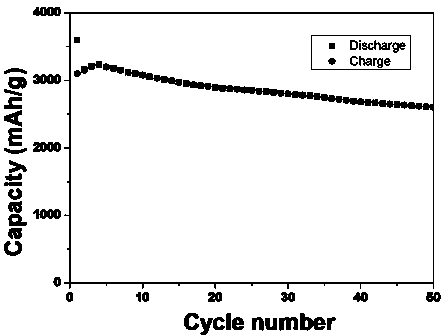

[0047] The binder of this embodiment has an initial discharge specific capacity of 3553 mAh / g at room temperature at a current of 4000 mA / g, and still maintains a high capacity of 2604 mAh / g after 50 weeks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com