Multi-element functional modification polyvinyl alcohol-based lithium ion battery aqueous binder and application of the binder in electrochemical power storage device

A technology of polyvinyl alcohol-based lithium and lithium-ion batteries, applied in electrochemical generators, battery electrodes, electrical components, etc., can solve problems such as low impact strength, poor heat resistance, stress cracking, etc., to prolong service life and improve Uniformity, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) First dissolve 3 grams of polyvinyl alcohol in 50 ml of deionized water (DI-Water), and fully stir it under an argon atmosphere for 0.5-2.5 hours to obtain a uniform and well-dispersed solution;

[0040] (2) Weigh 0.1g NaOH catalyst in the reaction system in (1), fully stir to obtain a homogeneous system; add 2.5g acrylic acid monomer, the molar ratio of the hydroxyl-containing repeating polymerization unit of polyvinyl alcohol and acrylic acid monomer is 1 : 0.51, adjust the reaction temperature to 80°C, keep stirring, and react at constant temperature for 8 hours to obtain a transparent and uniform glue solution, and then neutralize it with LiOH to a pH of 6-7, which is a multi-functional modified polyvinyl alcohol-based lithium-ion battery water-based binder;

Embodiment 2

[0042] In this embodiment, the preparation method of the binder refers to Example 1, the difference is that the added monomer is a mixture: 2.5g of acrylic acid and 0.84g of acrylonitrile, polyvinyl alcohol containing hydroxyl repeating polymer units, acrylic acid monomer, and The molar ratio of acrylonitrile monomer is 1:0.51:0.23, and the reaction temperature is 80°C to obtain a white glue solution, which is then neutralized with LiOH to a pH of 6-7, which is a multi-functional modified polyvinyl alcohol-based lithium ion Water-based binder for batteries;

Embodiment 3

[0044] The preparation method of the binder in this example refers to Example 1, the difference is that the monomers added are a mixture: 2.5g of acrylic acid, 0.84g of acrylonitrile and 1g of acrylamide, polyvinyl alcohol containing repeating polymer units of hydroxyl groups, acrylic acid The molar ratio of monomer, acrylonitrile monomer, and acrylamide monomer is 1:0.51:0.23:0.21, and the reaction temperature is 80°C to obtain a white glue, which is then neutralized with LiOH to a pH of 6-7, which is Multifunctional modified polyvinyl alcohol-based lithium-ion battery water-based binder;

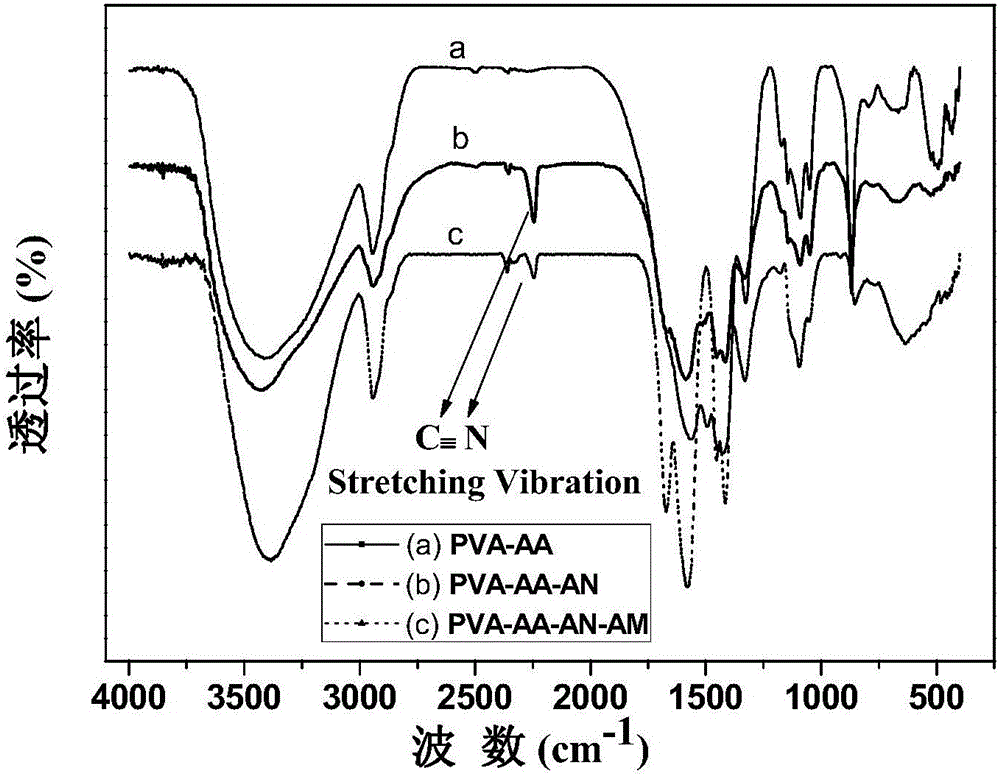

[0045] figure 1 It is the infrared contrast spectrum of the multifunctional modified polyvinyl alcohol lithium ion battery aqueous binder obtained in Examples 1-3 of the present invention. From figure 1 It can be seen from that, Example 1 is at 1668cm -1 There is an obvious stretching vibration signal of C=O in the carboxyl group at the wave number, and in addition to the stretching vib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com