A continuous production method and device for preparing granular trans isoprene rubber

A technology of trans isoprene rubber and its production method, which is applied in the field of continuous production and equipment for the preparation of granular trans isoprene rubber, can solve problems such as unstable product quality, energy consumption, and small equipment scale, and achieve catalyst concentration and Uniform activity, precise intermediate control, and improved prepolymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

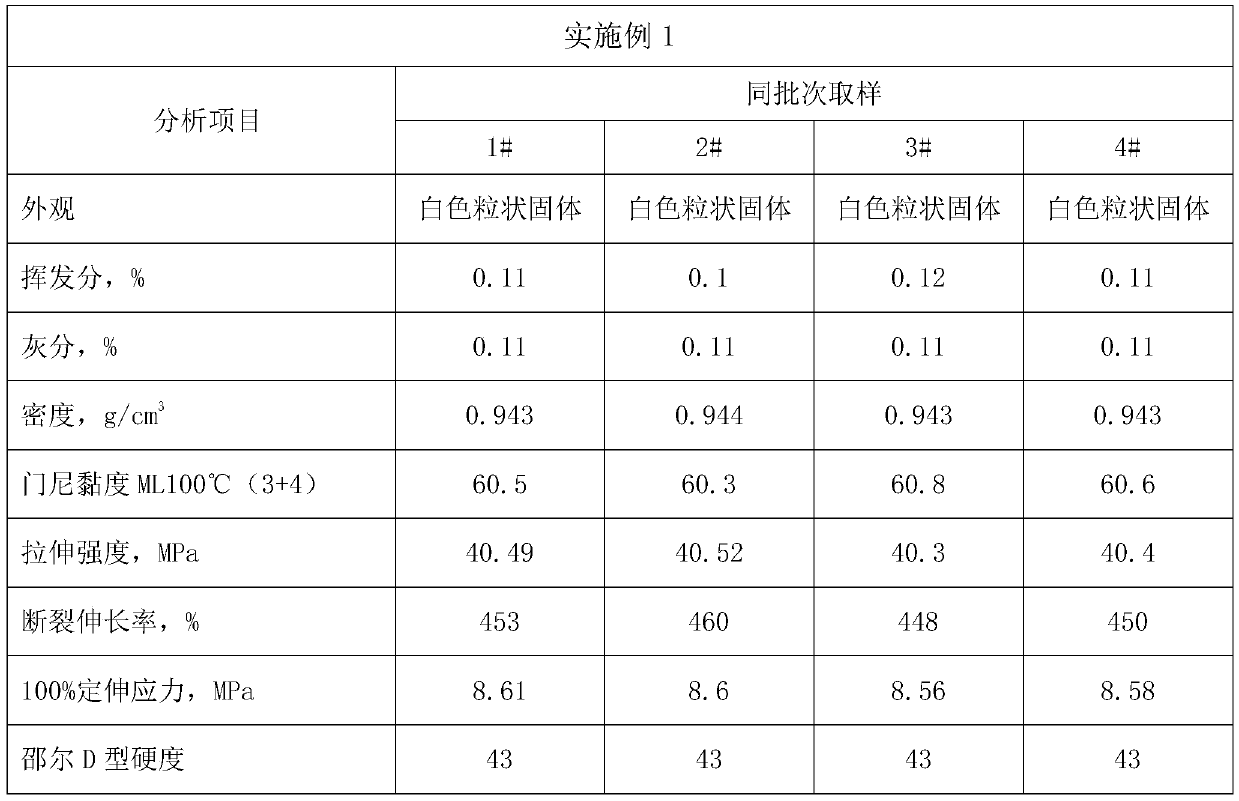

Embodiment 1

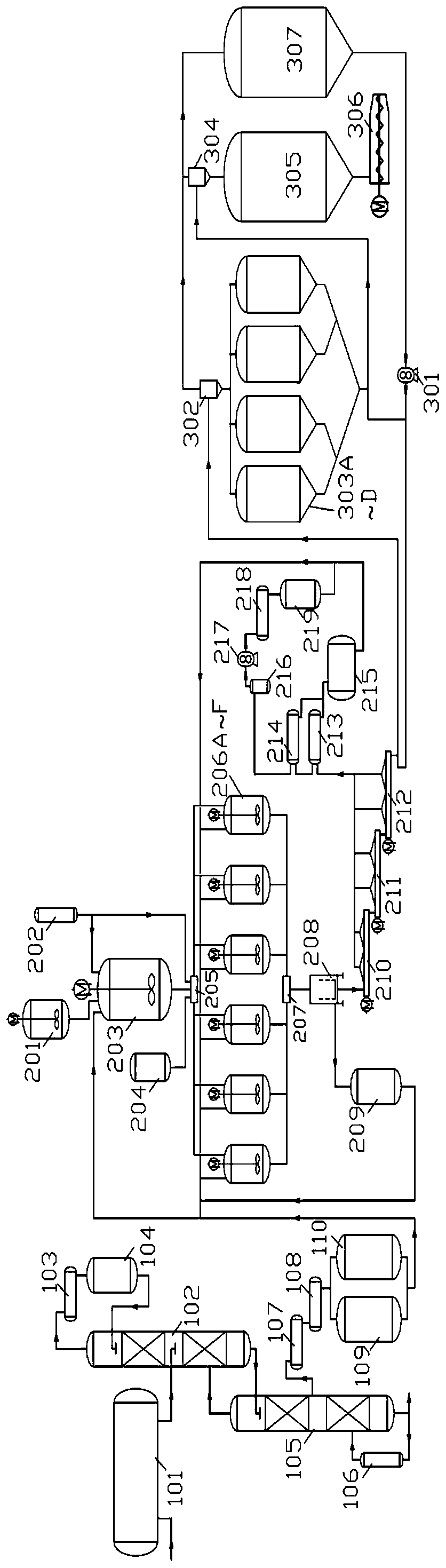

[0045] A continuous production method for preparing granular trans isoprene rubber, comprising the steps of monomer refining, pre-polymerization, polymerization, devolatilization, and granulation. The process flow chart is as follows figure 1 shown. figure 1 101 is the isoprene raw material tank, 102 is the first rectification tower, 103 is the tower top condenser, 104 is the tower top condensate collection tank, 105 is the second rectification tower, 106 is the second rectification tower Kettle reboiler, 107 is side extraction condenser, 108 is side extraction recooler, 109 is monomer metering tank, 110 is monomer metering tank, 201 is catalyst preparation tank, 202 is aluminum agent metering tank, 203 is pre- Polymerizer, 204 is a hydrogen buffer tank, 205 is a pre-polymerization distributor, 206A~F is a polymerizer A~F, 207 is a polymerizer distributor, 208 is a centrifugal kettle, 209 is a liquid phase transfer storage tank, 210 is Three-stage rake dryer-I, 211 is three-s...

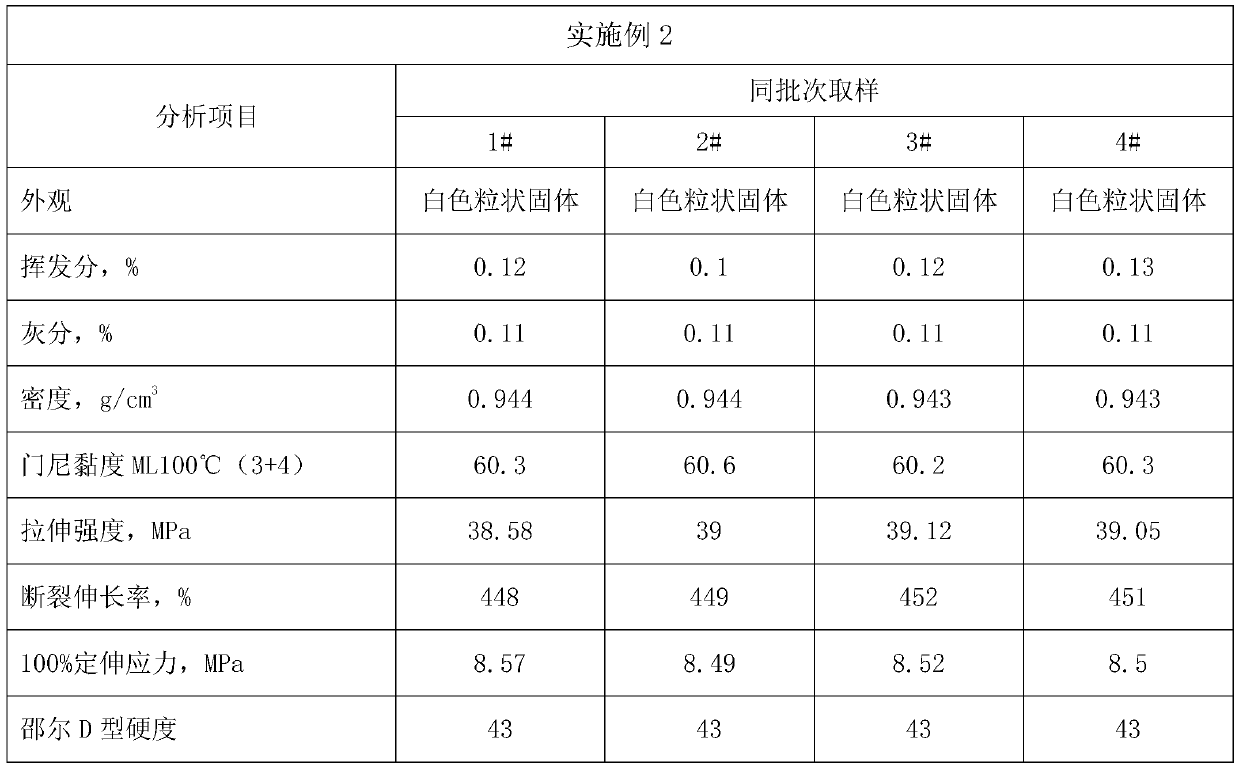

Embodiment 2

[0056] A continuous production method for preparing granular trans isoprene rubber, comprising the steps of monomer refining, prepolymerization, polymerization, devolatilization and granulation. Pump the refined isoprene stored in 109 monomer metering tanks and 110 monomer metering tanks at a rate of 16m per kettle 3 Send it to 203 prepolymerization kettle, pass -7°C chilled water in the jacket to cool the material to 10°C, then add 2Kg triisobutylaluminum and 6.5L liquid catalyst for every 680Kg of isoprene, and fully stir it. Pre-polymerized at 12°C for 0.5 hour to form polymeric particles with the catalyst as the core. Then it is evenly distributed to the polymerization tanks 206A-F.

[0057]The polymerization step is carried out by putting the prepolymerized material into a jacketed reactor with ribbon stirring. Before the pre-polymerized polymer material is put in, add 20m3 of fresh isoprene, and polymerize under sufficient stirring. Cooling water at 7°C is passed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com